Ion exchange method for extracting gallium from seed separation mother liquid

A technology of ion exchange method and separation of mother liquor, which is applied in the field of ion exchange method, can solve the problems affecting the production of alumina, increase the consumption of alumina steam, increase the amount of resin used, etc., to improve the leaching method and reduce the filling amount , the effect of reducing the amount of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

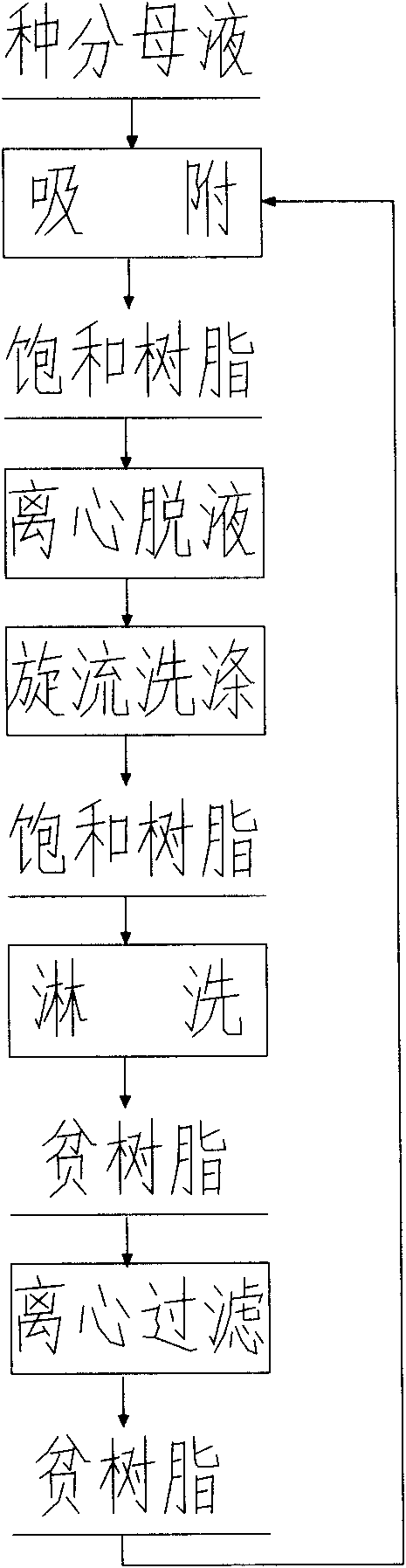

[0023] The method described in this embodiment includes the following steps:

[0024] a. Adsorption process: The resin is sent to the adsorption tower after being centrifuged to separate the eluent. After the 1# tower is filled, the adsorption mother liquor goes up countercurrently, with low entry and high exit, entering the adsorption tower from the bottom of the adsorption tower, The overflow comes out, and the adsorption adopts multiple fixed beds to adsorb in parallel. 1#, 2#, and 3# can be adsorbed at the same time. The adsorption time of each tower is 1 hour, and the adsorption flow rate is 50m 3 / h, the tail liquid concentration reaches 95mg / L;

[0025] b. Centrifugal removal of mother liquor and swirling washing process: After the resin in the 1# tower is saturated, it is placed in a centrifuge for full washing and centrifuged to remove the mother liquor. Swirl washing to wash away the impurities entrained by the resin, after washing clean, put it into the correspondi...

example 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] Adsorption process: After 2# is filled with resin, start to adsorb. The saturated resin in the 2# adsorption tower is centrifuged to separate the mother liquor and to be washed by cyclone separation.

[0031] For rinsing, 4 leaching towers of No. 1-2-3-4 tower are used for rinsing in series, and the eluent is used to enter the liquid from the upper part of the leaching tower and the lower part to discharge the liquid, and the resin in the leaching tower is leached. The line speed is controlled at 9.5m / h, and the time is 1 hour; the No. 4 tower enters the eluent, and the No. 1 tower exits the qualified liquid.

example 3

[0033] The difference between this embodiment and embodiment 1 is:

[0034] Adsorption process: After 3# is filled with resin, start to adsorb. The saturated resin of the 3# adsorption tower is centrifuged to separate the mother liquor and to be washed by cyclone separation.

[0035] For rinsing, 4 elution towers of tower No. 1-2-3-6 are used for rinsing in series, and the eluent is used to enter the liquid from the upper part of the leaching tower and the lower part to discharge the liquid, and the resin in the leaching tower is leached. The line speed is controlled at 9.5m / h, and the time is 1 hour; the eluent enters the No. 3 tower, and the qualified liquid comes out of the No. 6 tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com