Functional ionic liquid and preparation method thereof as well as method for ultrasonic intensified leaching of Cd in soil and recycling method

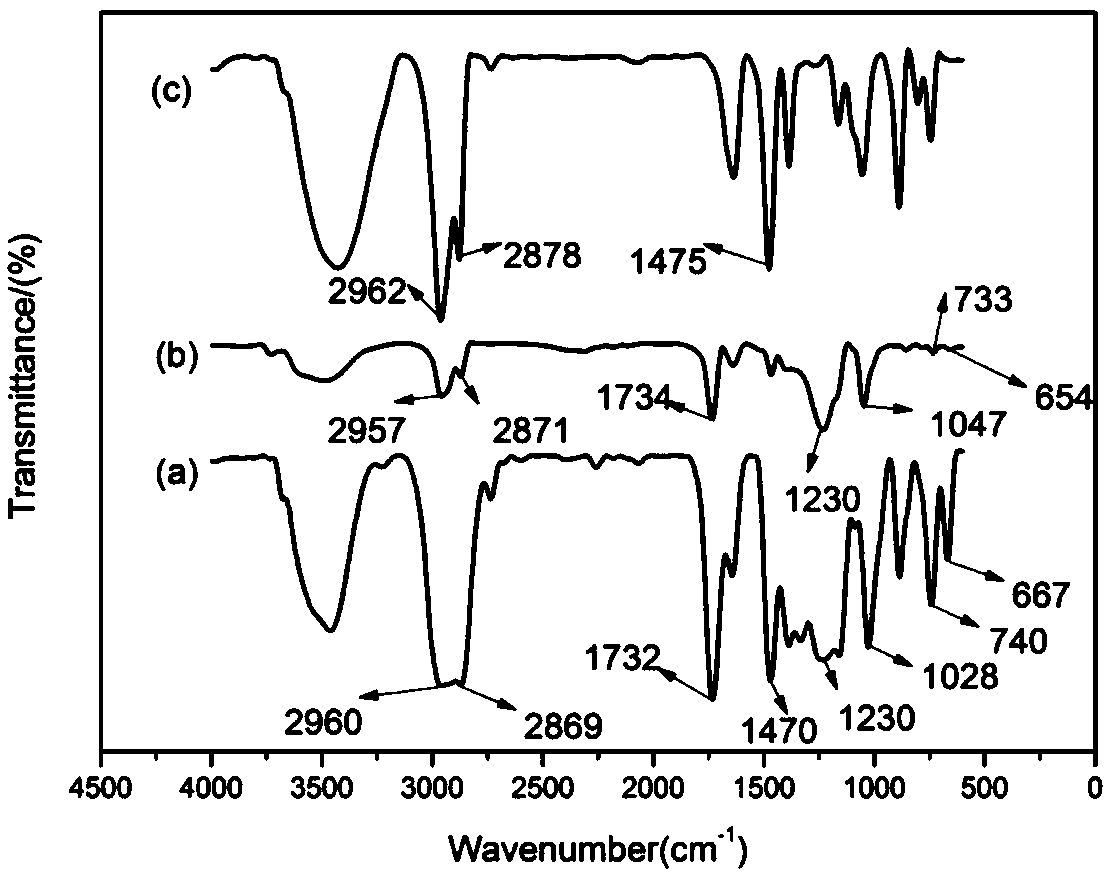

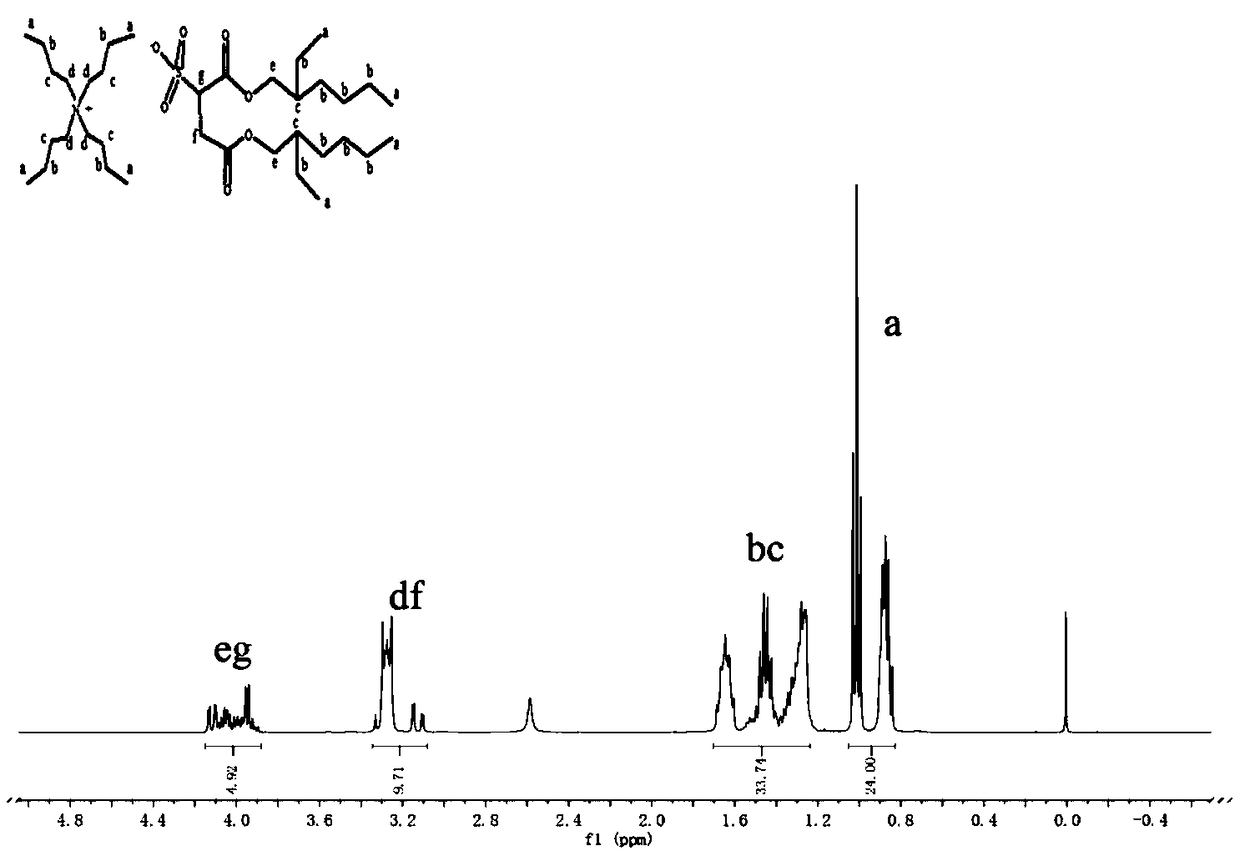

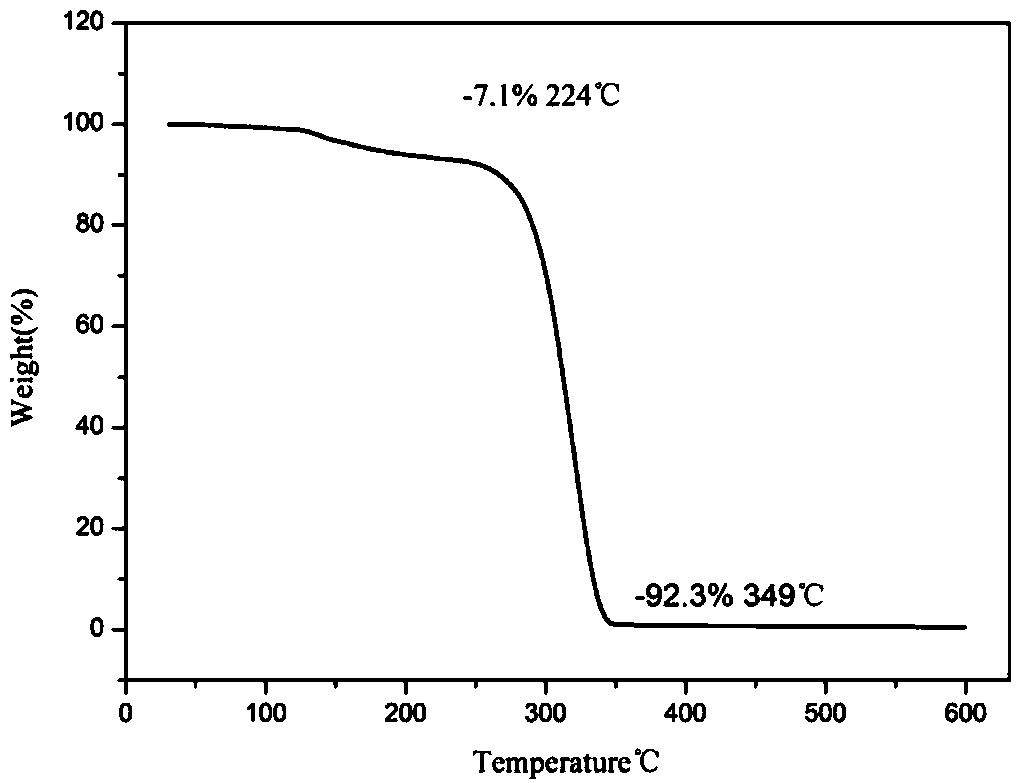

An ionic liquid and functional technology, which is applied in the field of soil heavy metal pollution restoration, can solve the problems of difficult reuse, poor biodegradability, and secondary pollution of soil, etc., and achieve the effect of high reuse rate, easy recycling, and high thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of described functional ionic liquid, comprises the steps:

[0036] Step 1: Two (2-ethylhexyl) sodium sulfosuccinate (NaAOT) and tetrabutylammonium chloride are raw materials, weigh 20mmol NaAOT and tetrabutylammonium chloride respectively and put in two beakers, respectively Add 50mL of chloroform into two beakers, and stir to dissolve. After about 15 minutes, it will be completely dissolved. After dissolving, transfer it to a 100mL round-bottom flask for mixing. Stir magnetically at 45°C-55°C for 20-30h, during which time it will be condensed and refluxed to obtain Crude product; Wherein, the mol ratio of two (2-ethylhexyl) sodium sulfosuccinate and tetrabutyl ammonium chloride is 1:1;

[0037] Step 2: washing the crude product with water several times until no chlorine ions are detected in the aqueous phase;

[0038] Step 3: Evaporate the product obtained in Step 2 to remove chloroform, and then vacuum-dry it at 60-90° C. for 30-50 h to obtain...

Embodiment 1

[0046] The preparation method of described functional ionic liquid, comprises the steps:

[0047] Step 1: Two (2-ethylhexyl) sodium sulfosuccinate (NaAOT) and tetrabutylammonium chloride are raw materials, weigh 20mmol NaAOT and tetrabutylammonium chloride respectively and put in two beakers, respectively Add 50mL of chloroform to the two beakers, and stir to dissolve. After about 15 minutes, it will be completely dissolved. After dissolving, transfer to a 100mL round-bottomed flask for mixing, and stir magnetically at 50°C for 24h, during which time it will be condensed and refluxed to obtain the crude product; among them, The mol ratio of two (2-ethylhexyl) sodium sulfosuccinate and tetrabutylammonium chloride is 1:1;

[0048] Step 2: washing the crude product with water until no chloride ions are detected in the aqueous phase;

[0049] Step 3: The product obtained in Step 2 was evaporated to remove chloroform, and then vacuum-dried at 80° C. for 48 hours to obtain a functi...

Embodiment 2

[0051] The preparation method of described functional ionic liquid, comprises the steps:

[0052]Step 1: Two (2-ethylhexyl) sodium sulfosuccinate (NaAOT) and tetrabutylammonium chloride are raw materials, weigh 20mmol NaAOT and tetrabutylammonium chloride respectively and put in two beakers, respectively Add 50mL of chloroform into the two beakers, and stir to dissolve. After about 15 minutes, all of them are dissolved. After dissolving, transfer to a 100mL round bottom flask for mixing, and stir magnetically at 45°C for 20h. The mol ratio of two (2-ethylhexyl) sodium sulfosuccinate and tetrabutylammonium chloride is 1:1;

[0053] Step 2: washing the crude product with water until no chloride ions are detected in the aqueous phase;

[0054] Step 3: The product obtained in Step 2 was evaporated to remove chloroform, and then vacuum-dried at 70° C. for 50 h to obtain a functional ionic liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com