Metallic tantalum, special-purpose grinding fluid for alloy of the same and preparation method thereof

A technology of grinding fluid and alloy, applied in the field of soft metals, can solve the problem that ordinary grinding fluid can not meet the processing well, and achieve the effect of good surface quality and high grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: when the ambient temperature is 25°C.

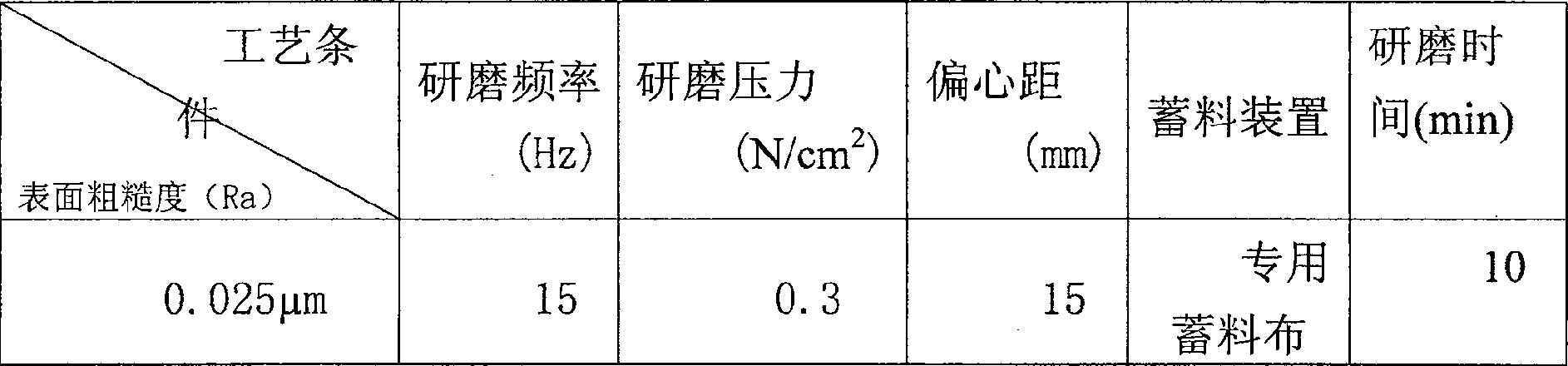

[0020] (1) Implementation conditions

[0021] BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, 2205 surface roughness measuring instrument, special grinding liquid, tantalum, tungsten and hafnium workpiece, special storage cloth for storing abrasive materials, grinding parameters are: frequency 15Hz, pressure 0.3N / cm 2 , eccentric distance 15cm, grinding time 10min.

[0022] (2) Preparation method of special grinding liquid

[0023] The preparation ratio of the grinding liquid is: the uniform mixture of abrasive and mixed fat, 25% of vegetable oil and 50% of kerosene in volume ratio.

[0024] (3) Preparation method:

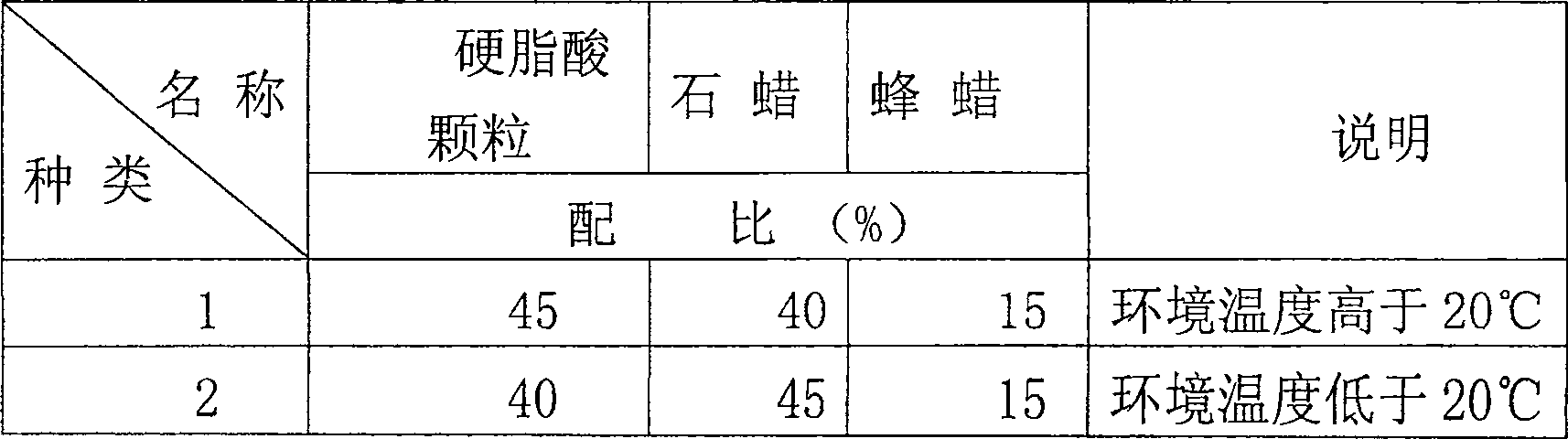

[0025] 1. the mass ratio is 45% stearic acid granules (C 17 h 35 COOH), 40% paraffin (cypress oil) and 15% beeswax are heated until melting and mixed, then filtered for subsequent use;

[0026] ② Pour the green SiC abrasive with a particle size of W...

Embodiment 2

[0030] Embodiment 2: when the ambient temperature is 18°C.

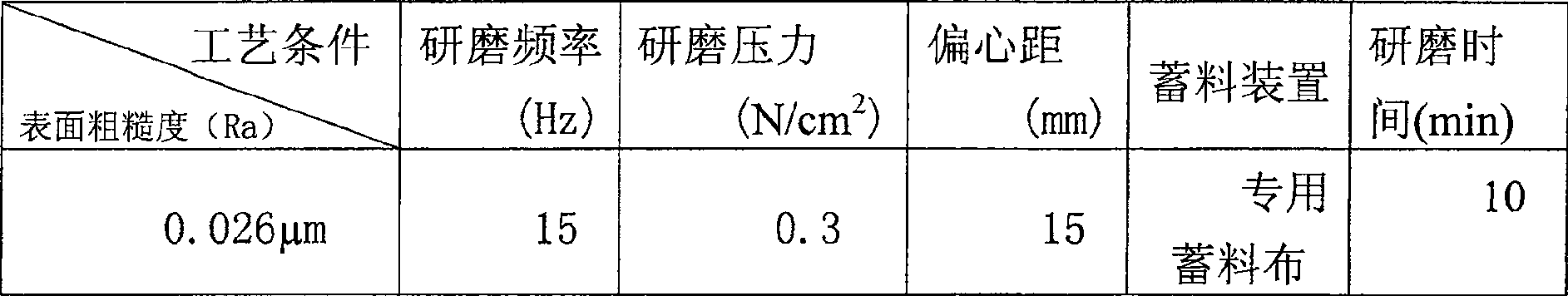

[0031] (1) Implementation conditions

[0032] BDE-1B frequency conversion and speed regulation optical two-axis grinding and polishing machine, 2205 surface roughness measuring instrument, special grinding liquid, tantalum, tungsten and hafnium workpiece, special storage cloth for storing abrasive materials, grinding parameters are: frequency 15Hz, pressure 0.3N / cm 2 , eccentric distance 15cm, grinding time 10min.

[0033] (2) Preparation method of special grinding liquid

[0034] The preparation ratio of the grinding liquid is: the uniform mixture of abrasive and mixed fat, 25% of vegetable oil and 50% of kerosene in volume ratio.

[0035] (3) Preparation method:

[0036] 1. the mass ratio is 40% stearic acid granules (C 17 h 35 COOH), 45% paraffin (cypress oil) and 15% beeswax are heated until melting and mixed, then filtered for subsequent use.

[0037] ② Pour the green SiC abrasive with a particle size of W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com