Method and device for detecting textile structure and dying defect using infrared laser

A technology of infrared laser and textiles, applied in the field of physics, can solve problems such as inaccurate results of manual identification of textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

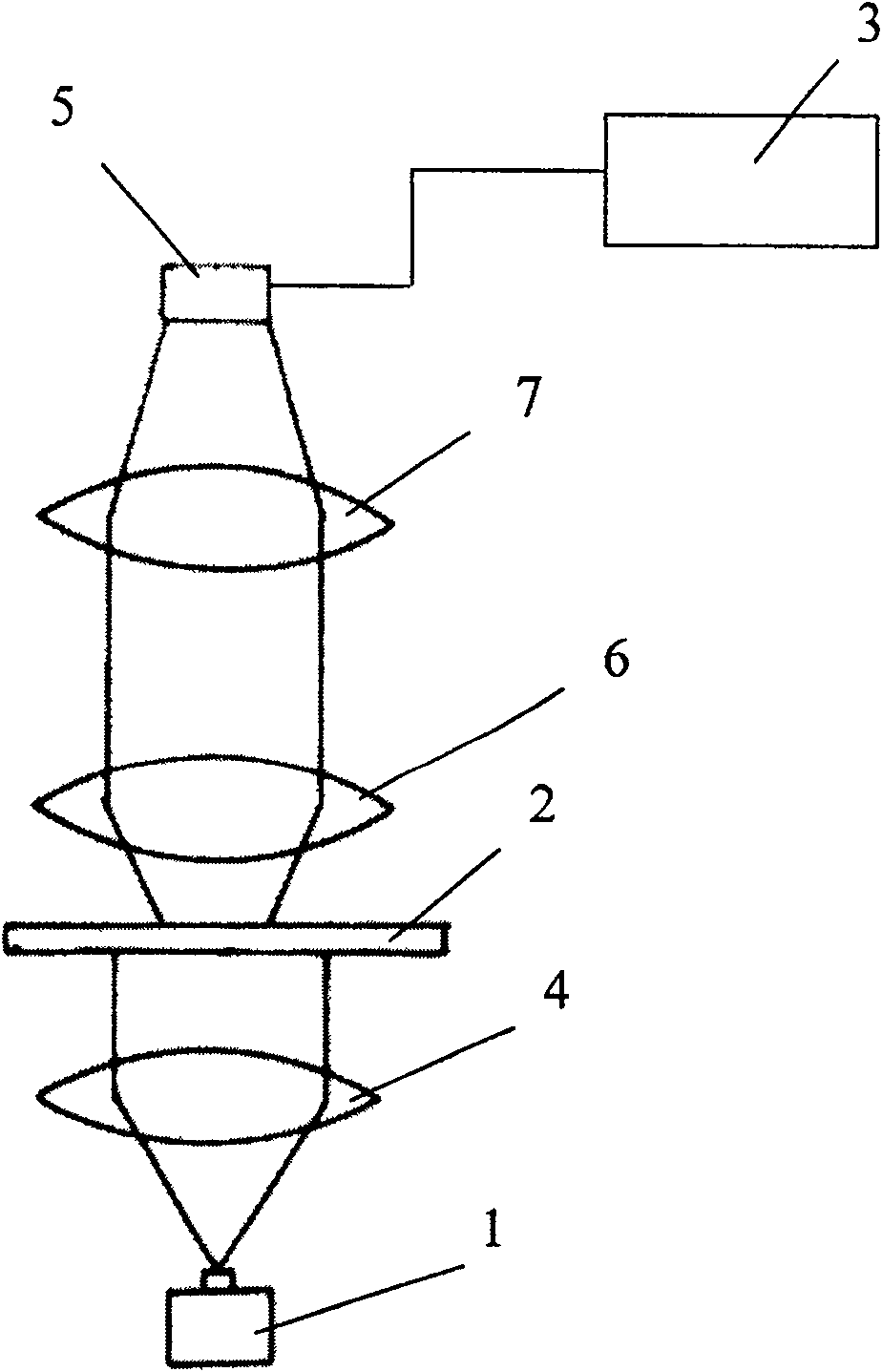

[0031] like figure 1 As shown, the method for detecting textile structure and dyeing defects using infrared laser of the present invention includes a process of collecting the image of the fabric sample 2, wherein the process of collecting the image of the fabric sample 2 includes a process of projecting an infrared laser to the fabric sample 2 Steps, a step of collecting the infrared laser transmission image of the fabric sample 2 and a step of displaying the infrared laser transmission image of the fabric sample 2 on the display device 3 .

[0032] Further, in the step of projecting the infrared laser to the fabric sample 2, the semiconductor laser 1 is used to project the infrared laser to the back or front of the fabric sample 2, and the semiconductor laser 1 and the back or front of the fabric sample 2 A condenser lens 4 is arranged in the light path, and the infrared laser is converged by the condenser lens 4. In the step of collecting the infrared laser transmission ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com