Printing circuit board and method for testing anisotropic conducting membrance

A technology of anisotropic conductive film and printed circuit board, which is applied in the direction of printed circuit, measuring device, optical test defect/defect, etc. connected with non-printed electrical components, which can solve the problem that the detection of anisotropic conductive adhesive cannot be correctly judged, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

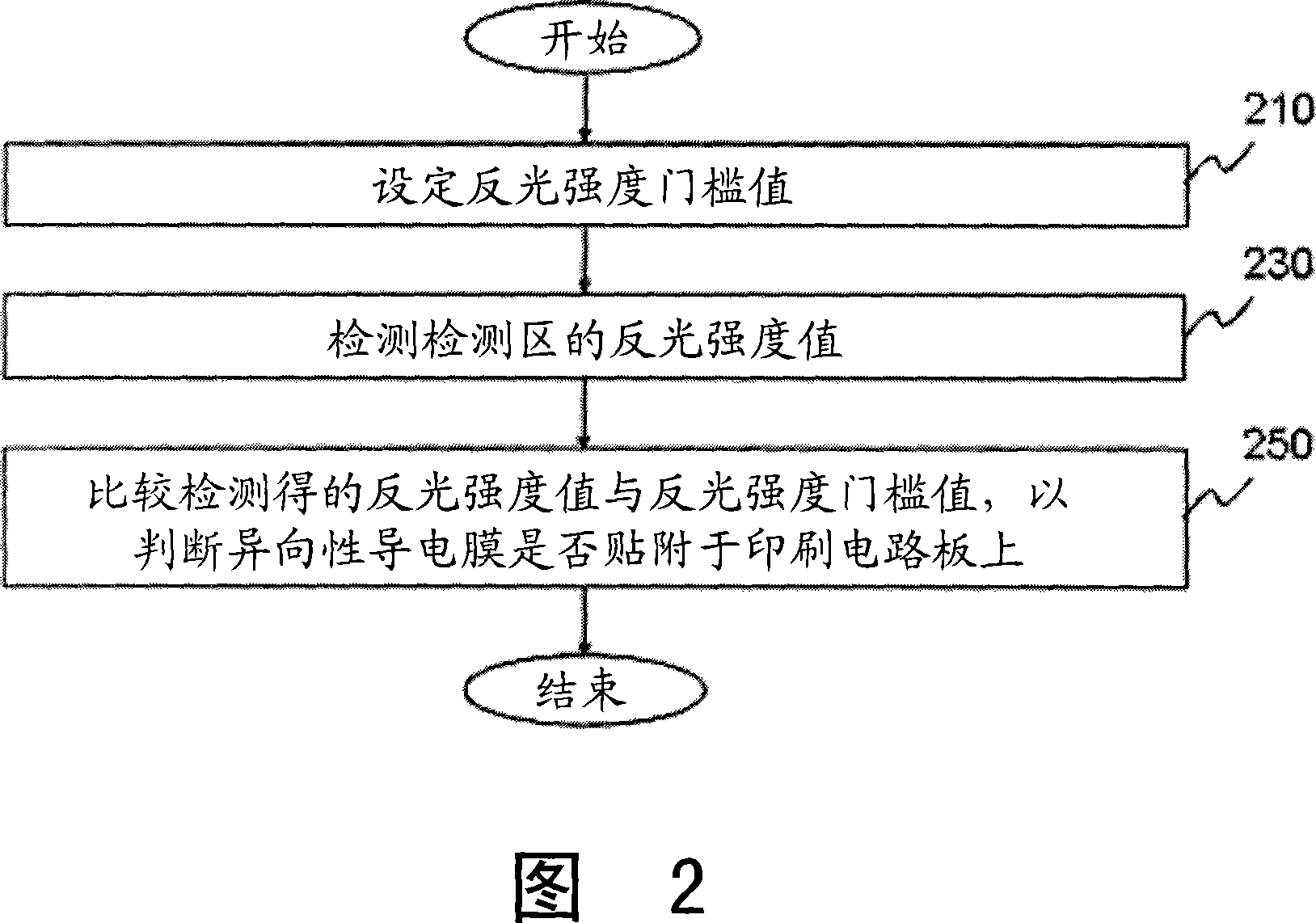

[0017] Specific embodiments are given below to describe the content of the present invention in detail, and the accompanying drawings are used as auxiliary descriptions.

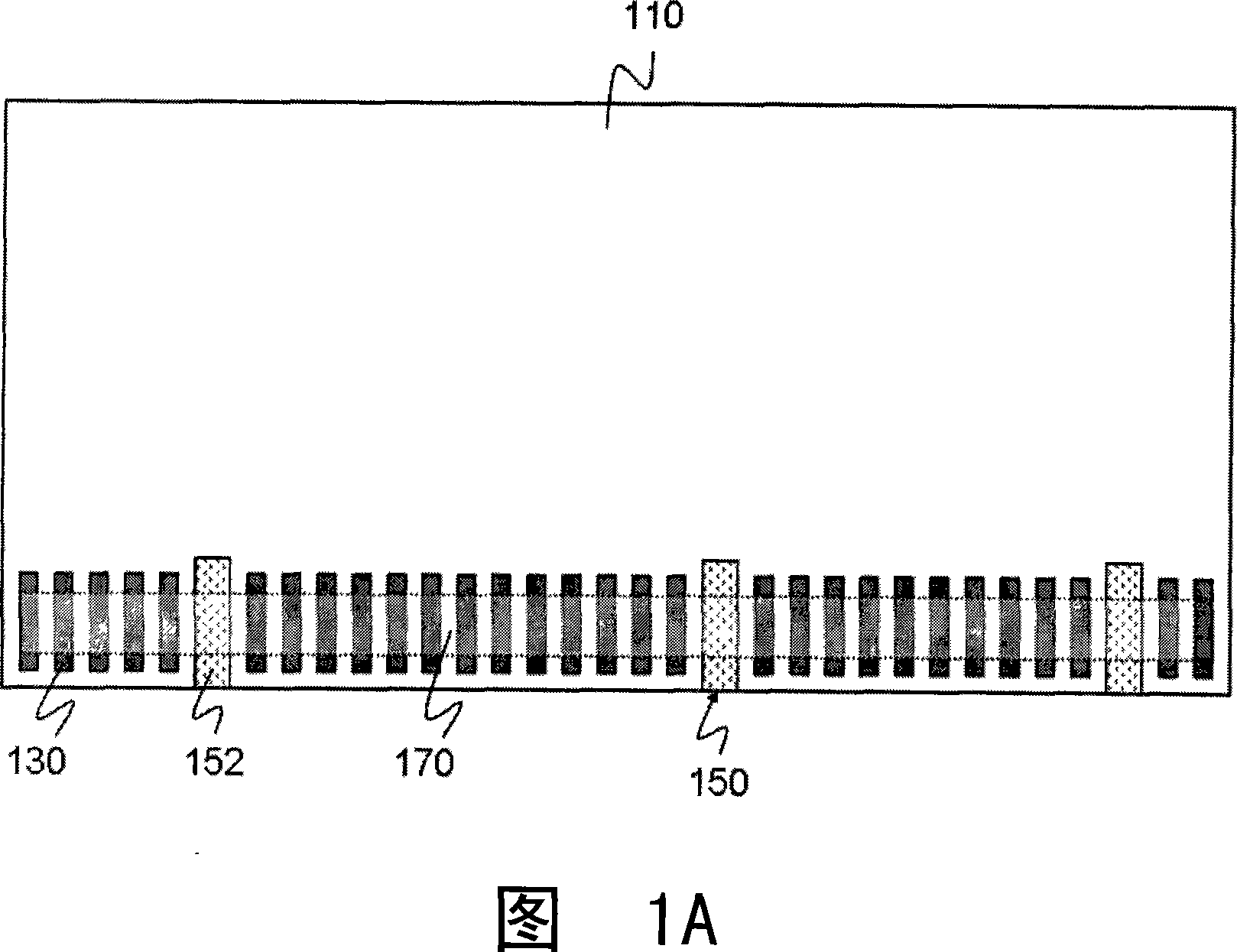

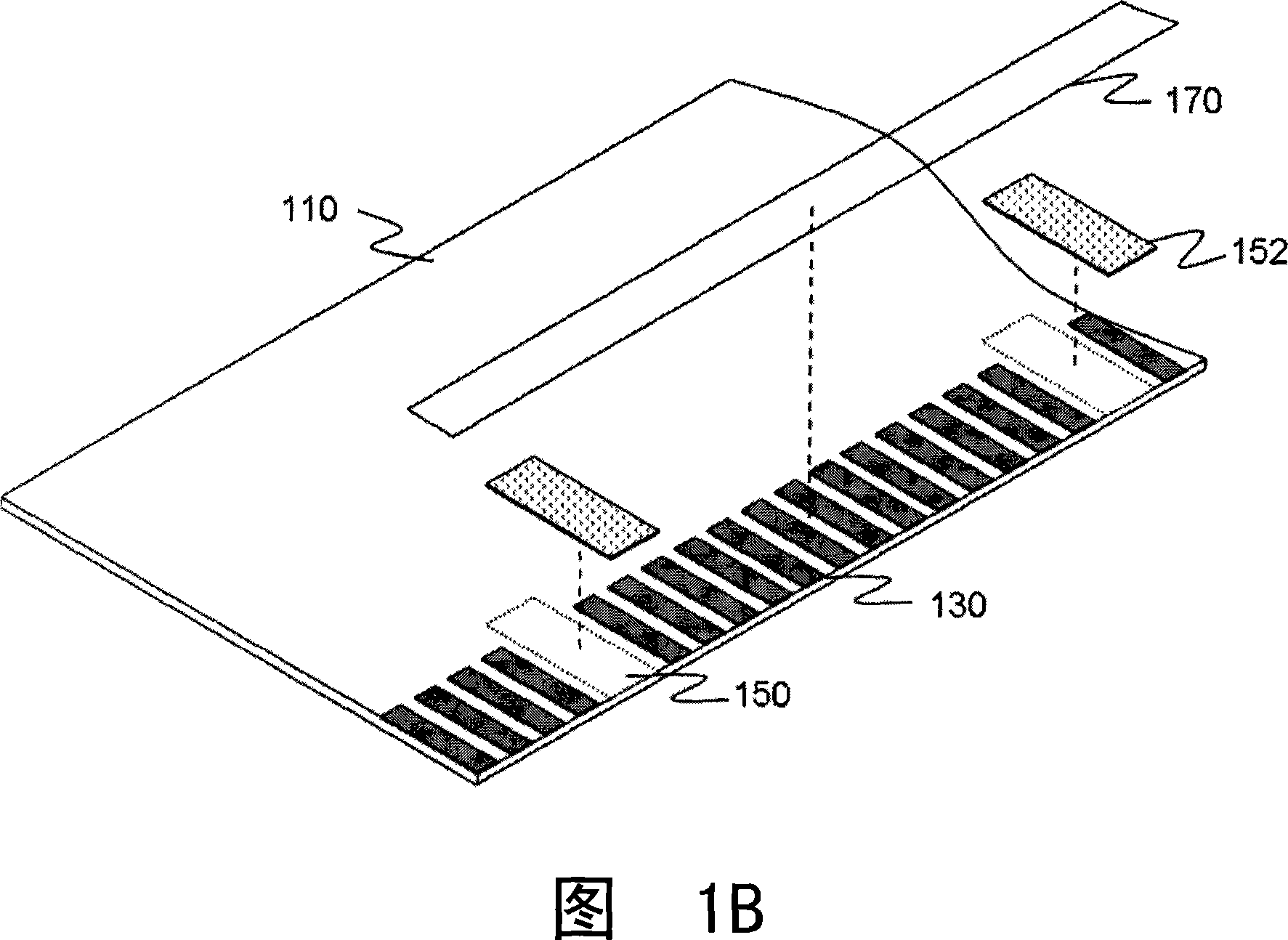

[0018] FIGS. 1A and 1B are schematic diagrams of a printed circuit board of the present invention. The printed circuit board includes: a substrate 110 , a conductive lead 130 , a detection area 150 and a pigment coating 152 .

[0019] The conductive terminals 130 are arranged in a row on the substrate 110 , and one or more detection regions 150 are disposed between the conductive terminals 130 , and the detection regions 150 are covered with a pigment coating 152 .

[0020] Among them, the pigment coating 152 is preferably a paint with stable color; more precisely, the pigment coating 152 is not easily affected by environmental conditions (eg, temperature, humidity, etc.). In a preferred embodiment, the pigment coating 152 is resistant to chemical solvents, especially commonly used chemical solvents (eg alco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap