Process of making synthetic leather with metal surface

A metal surface, synthetic leather technology, applied in textile decoration, textiles and papermaking, etc., can solve the problems of lack of 3D stereoscopic effect of synthetic leather, chromatic aberration of metal surface, easy to wear, etc., to achieve rich patterns and variability, increase design sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are listed below and the structure, features and effects of the present invention will be described in detail with reference to the accompanying drawings.

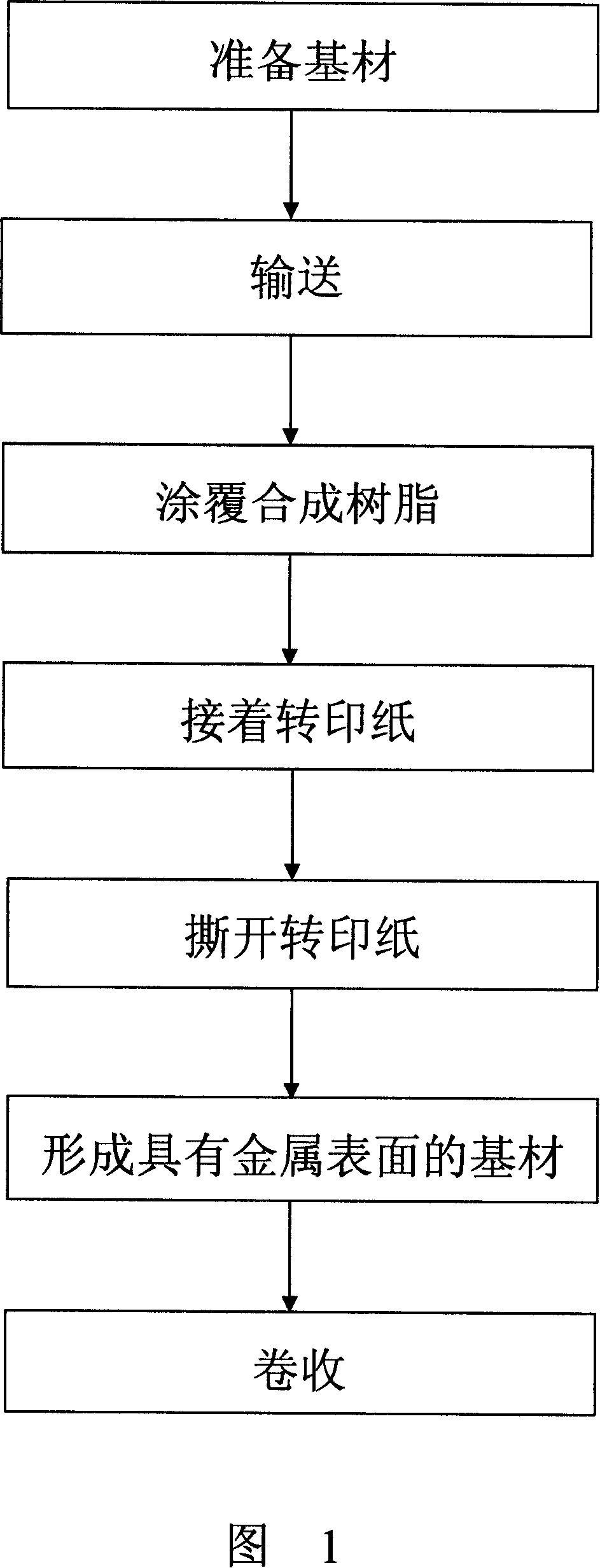

[0018] The synthetic leather system procedure of tool metal surface provided by the present invention is as follows:

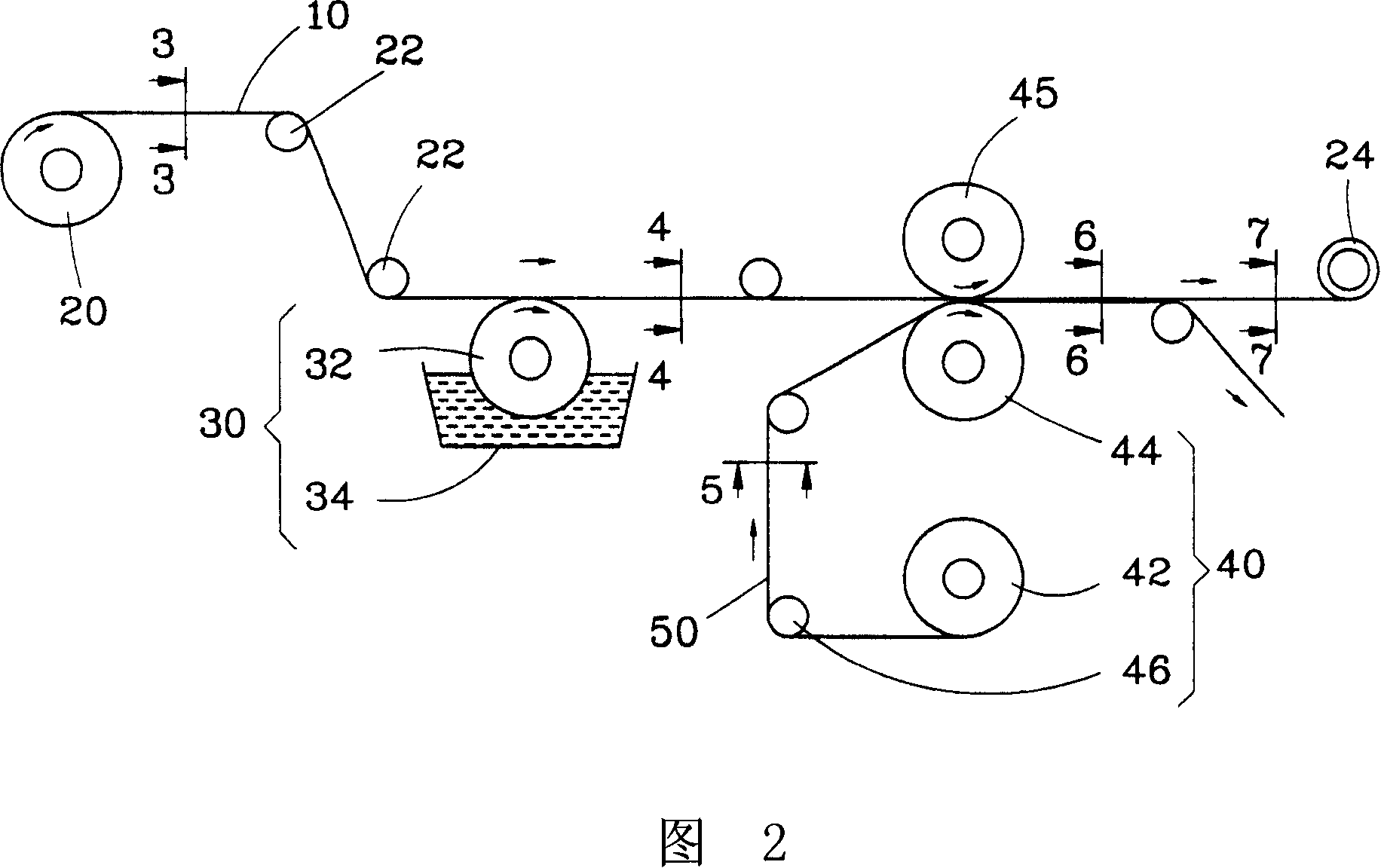

[0019] First, as shown in Figures 1 and 2, a substrate 10 is a workpiece, one end of the substrate 10 is wound on an output shaft 20, and the other end is wound around a plurality of rollers 22 and then connected to a rolling bar 24 above. The rolling bar 24 and the output shaft 20 are driven by a motor (not shown in the figure) to guide the substrate 10 to a predetermined direction of the rolling bar 24 .

[0020] As shown in FIGS. 2 to 4 , during the conveyance of the substrate 10 , a coating mechanism 30 is disposed between the output shaft 20 and the rolling bar 24 . The coating mechanism 30 has a roller 32 and a storage tank 34 . Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com