Positioning device for landing containers in use for automatic wharf of containers

An automated terminal and positioning device technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of excessive container swing, positioning error, electric trolley wheel locking and slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

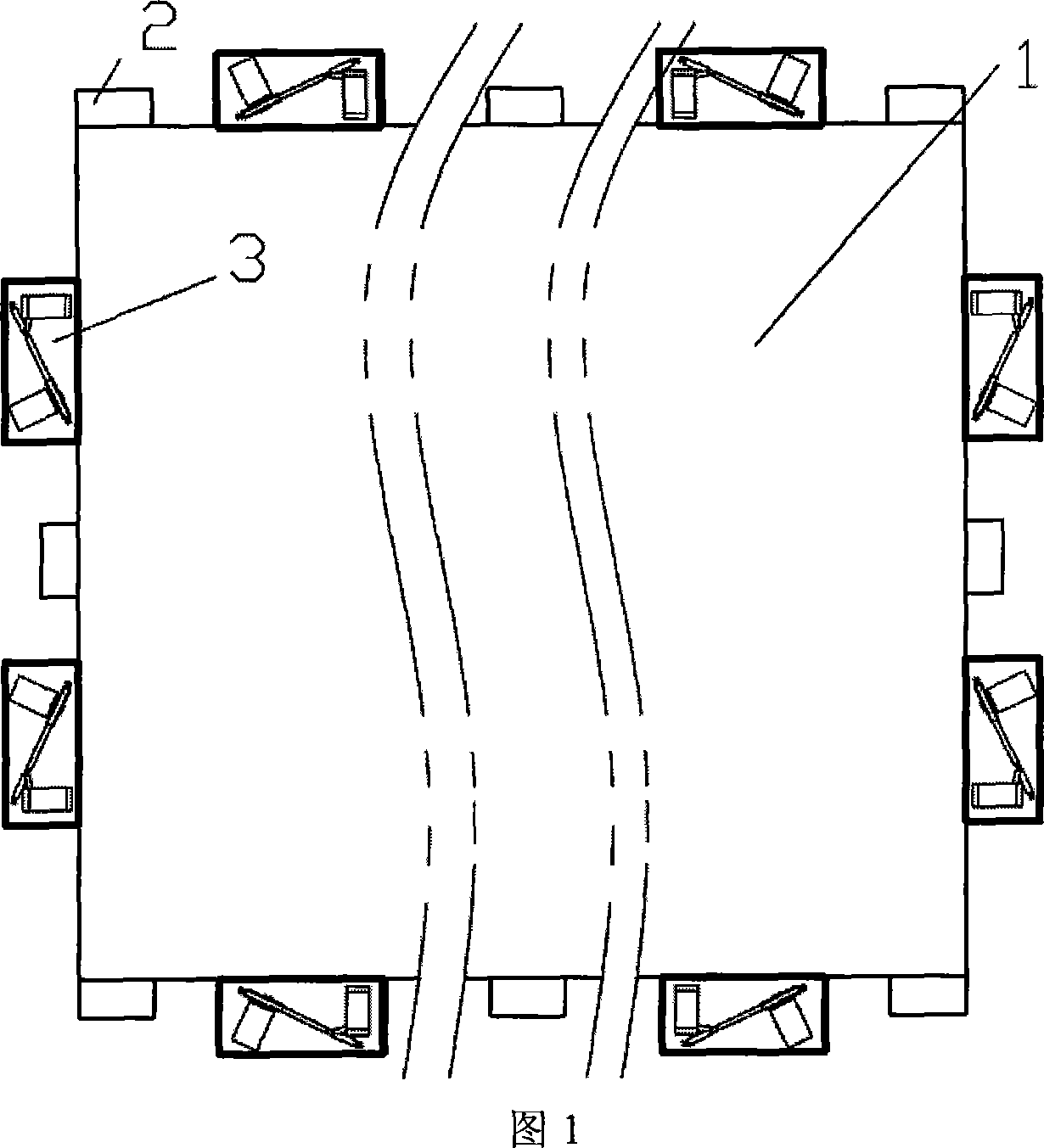

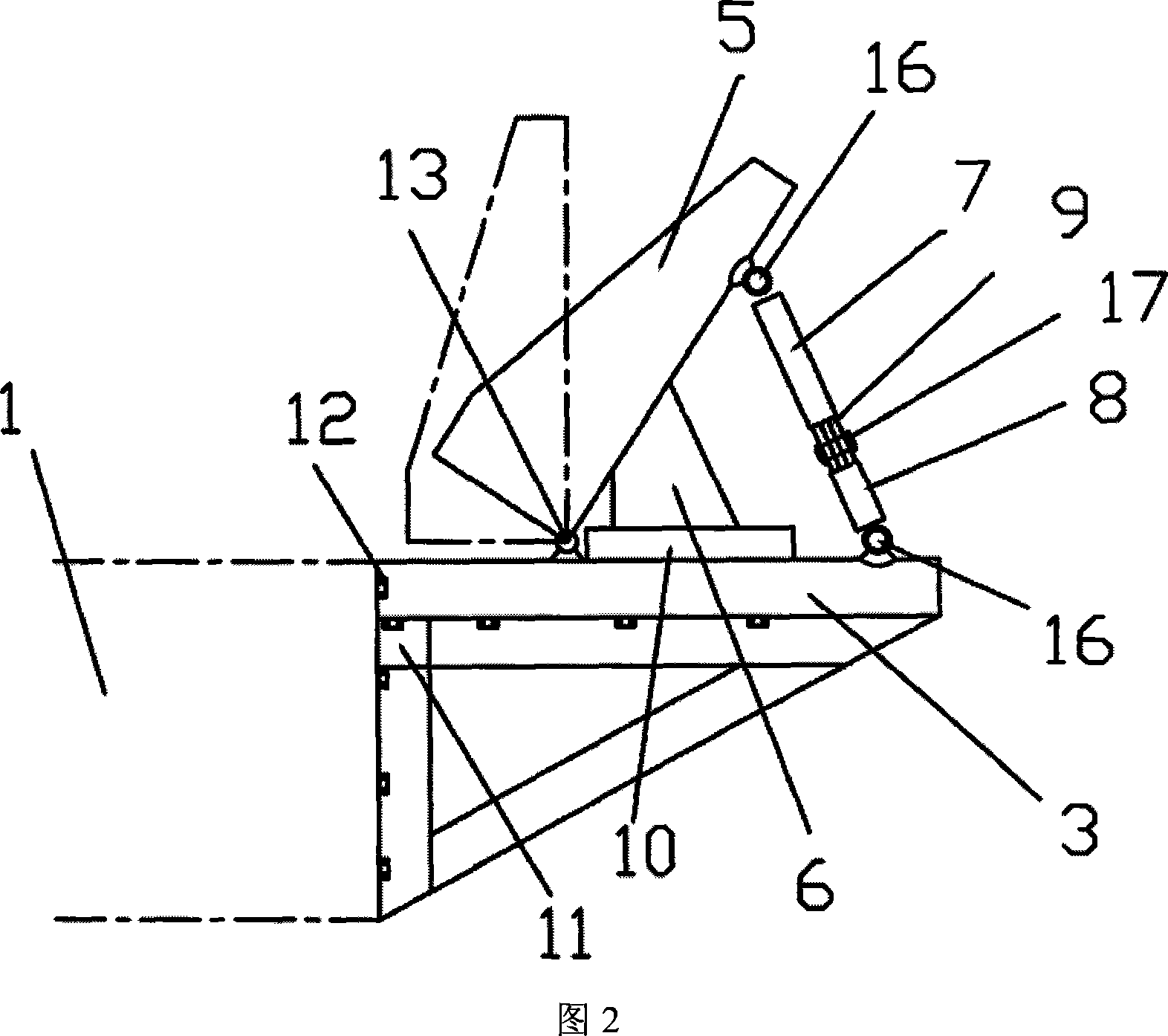

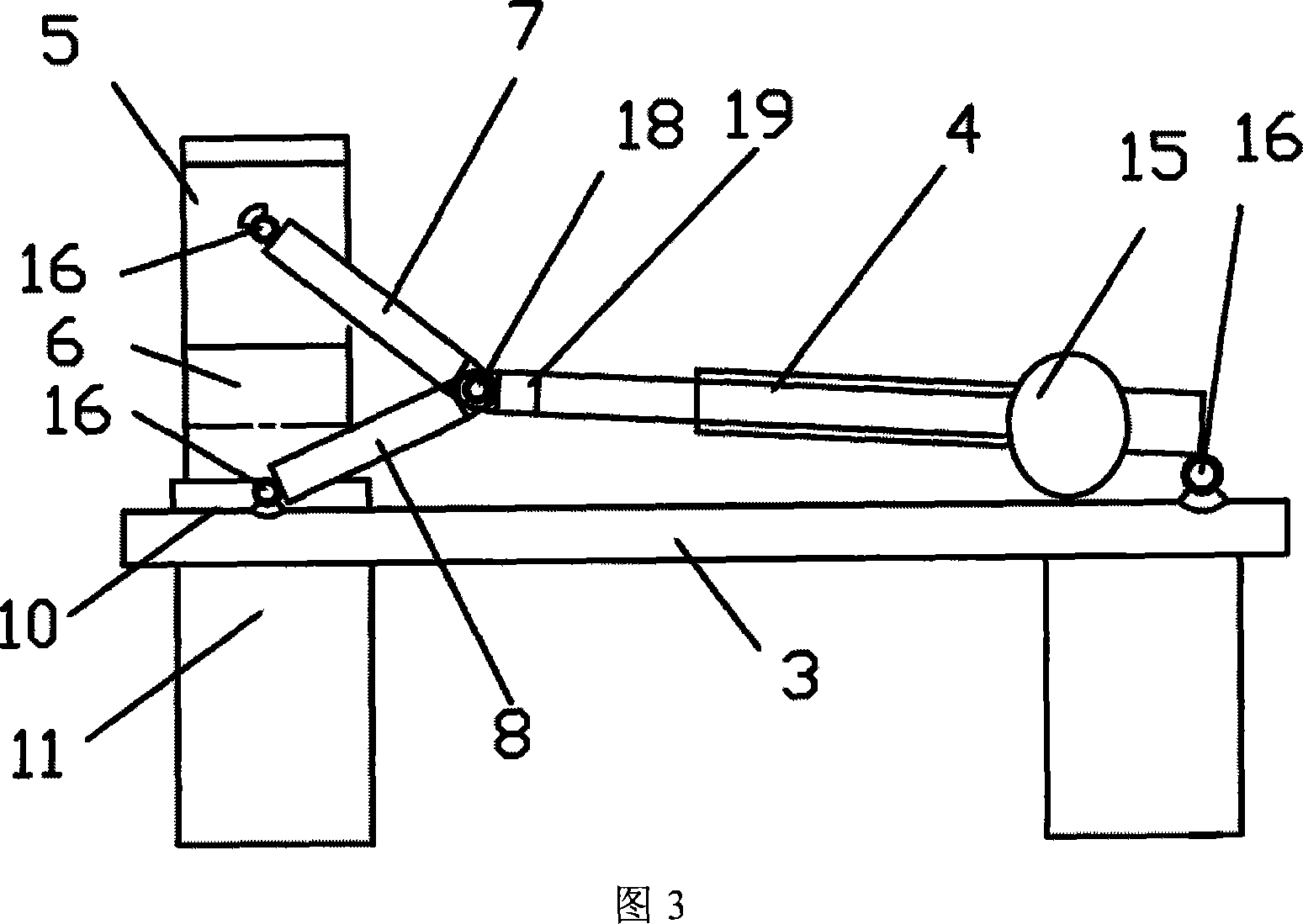

[0026] Further illustrate the present invention below in conjunction with accompanying drawing.

[0027] Connect the following components as shown in Figure 1-Figure 5, and those skilled in the art can implement it smoothly.

[0028] The extended bottom plate 3 adopts 45×45×5mm angle steel welded into a square frame of 800×400mm, and the upper surface is covered with 800×400×10mm steel plate as the plane of the extended bottom plate. 200×75×9mm channel steel is welded into two triangular support frames 11 with a side length of 300×400×500, which are supported under the plane of the extended bottom plate 3. When in use, the bottom of the extended bottom plate 3 can be connected to the electric trolley 1 through the triangular support frame 11 , and the expansion base plate 3 is fixed around the electric trolley 1 by bolts 12,

[0029] An electric push rod 4 , a wedge 5 , a buffer block 6 , a long connecting rod 7 and a short connecting rod 8 , a spherical joint lug 16 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com