Preparation method of super low-sulfur oil

An ultra-low sulfur, gasoline technology, applied in the direction of refining with oxygenates, etc., can solve the problems of reducing operating costs, disadvantage, and oil products can not meet the requirements of ultra-low sulfur gasoline, and achieve the effect of reducing production costs and operating costs.

Inactive Publication Date: 2010-12-01

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

UOP's patent USP6,368,495 discloses an oxidation / decomposition combined desulfurization technology, which first oxidizes the sulfur-containing organic compounds in the oil to sulfones, and then catalytically decomposes the oxidized organic sulfur species into hydrocarbons and sulfur Compounds (such as SO2), but the decomposition of sulfone in this process needs to be carried out under higher temperature and pressure, which is not conducive to reducing operating costs, and the resulting oil cannot meet the requirements of ultra-low sulfur gasoline

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

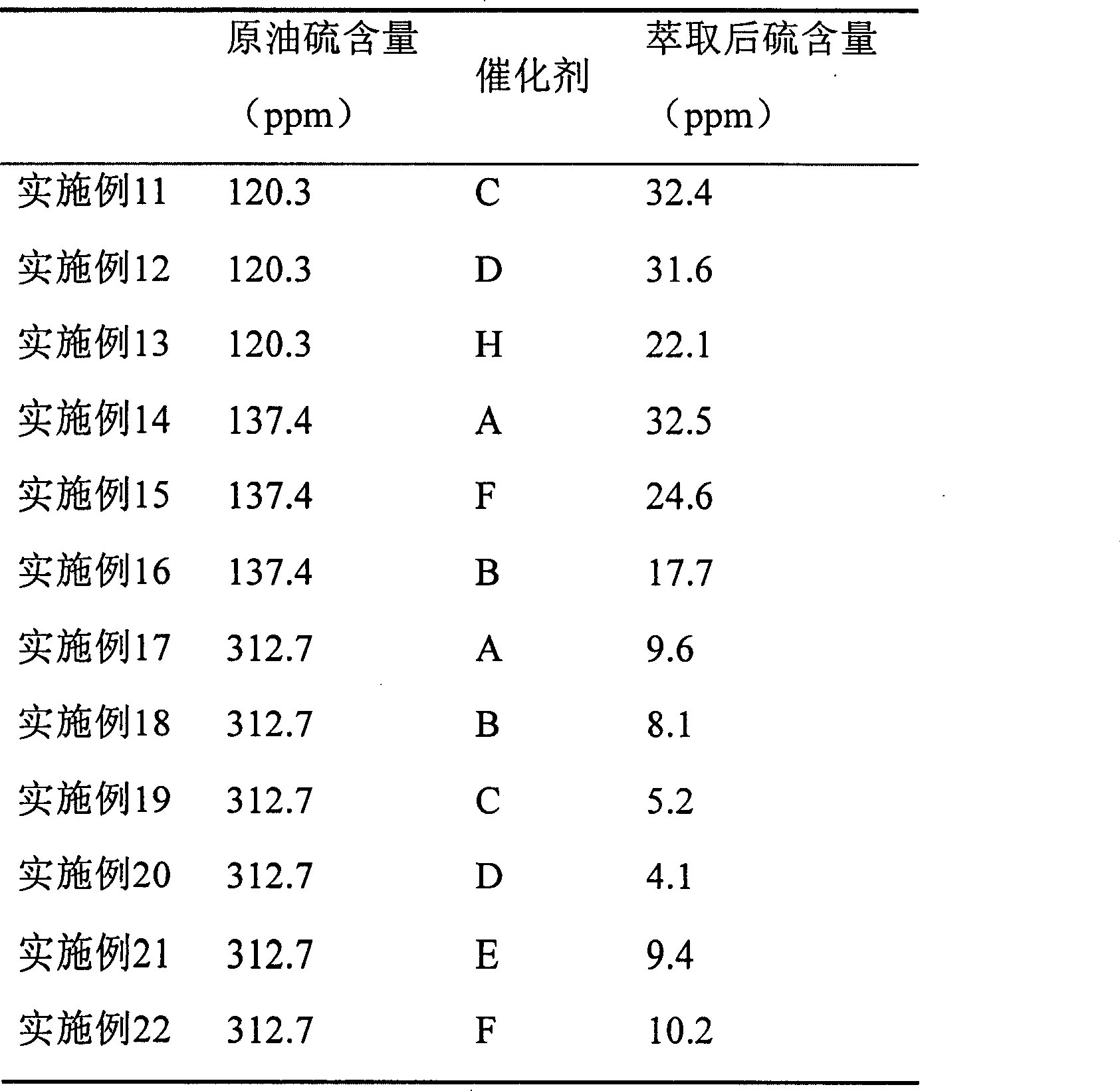

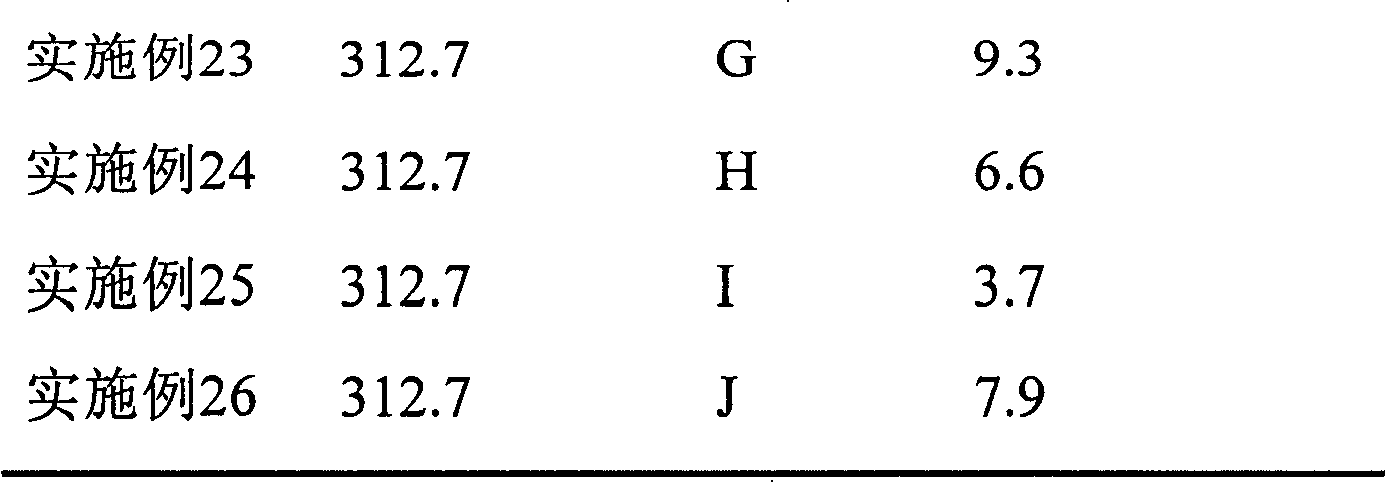

The process of preparing gasoline with very low sulfide content includes the following steps: mixing gasoline, catalyst Q+[MWxOy]- and hydrogen peroxide in the molar ratio of 1 to 80-100 to 600-800, and reaction at 60 deg.c to convert the other sulfide in the gasoline into SO2 and sulfone and obtain oxidized gasoline with sulfur content lower than 50 ppm; separating the catalyst from the oxidizedgasoline and recovering the catalyst; and washing the oxidized gasoline with water to eliminate sulfone and obtain oxidized gasoline with sulfur content lower than 50 ppm.

Description

A kind of preparation method of ultra-low sulfur gasoline technical field The invention relates to a preparation method of ultra-low sulfur gasoline. Background technique With the strengthening of people's awareness of environmental protection, the problem of automobile exhaust pollution has been paid more and more attention. Government organizations of various countries have enacted new environmental regulations one after another, stipulating new standards for various types of fuel oil, and strictly restricting the sulfur content, benzene content, aromatic hydrocarbon content, and olefin content. Especially the sulfur content. Taking gasoline as an example, the sulfur content standard implemented in the United States from the late 1980s was 1000ppm. In 1995, the sulfur content standard had dropped to less than 330ppm. In 2006, the sulfur content should be reduced to below 30ppm; It has dropped from 1000ppm in 1989 to less than 50ppm at present. Germany passed legislatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G27/12

Inventor 李灿景飞蒋宗轩吕宏缨

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com