Multi-head embroidery machine

An embroidery machine, multi-head technology, applied in the direction of embroidery machine, embroidery machine mechanism, automatically controlled embroidery machine, etc., can solve problems such as troublesome adjustment of pressing cloth height, influence of processing cloth movement, excessive running speed, etc., to achieve fast automatic Correcting the effect of the height of the presser foot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

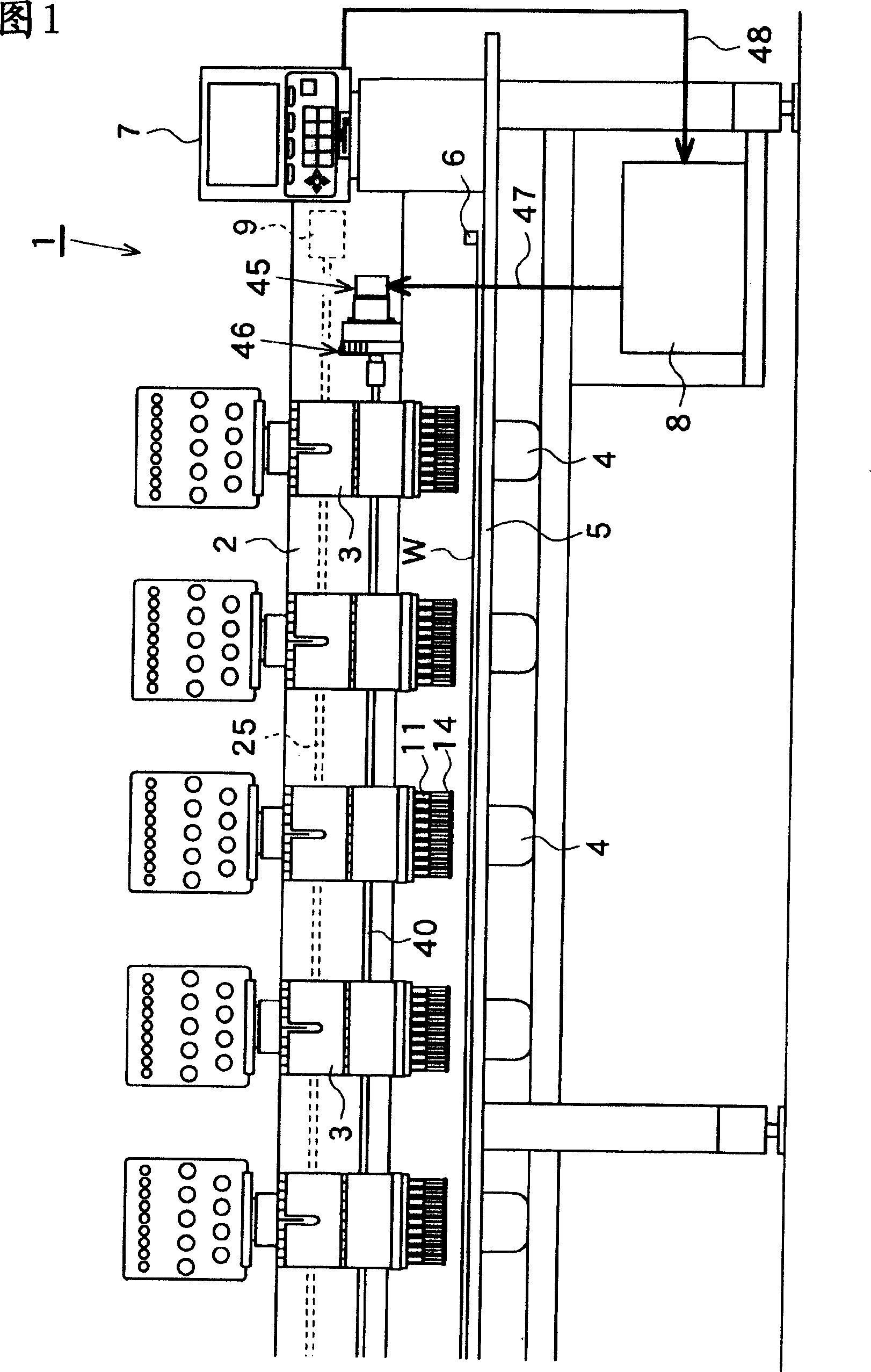

[0025] Next, the structure of each part of the multi-head embroidery machine 1 will be described in detail based on the embodiment. As shown in FIG. 1 , a plurality of heads 3 are arranged side by side on a frame 2 of a multi-head embroidery machine 1 , a base 4 is provided on the underside of each head 3 , and a table 5 is provided at the same height as the base 4 . Place the sewing frame 6 on the table 5 for conveying the processed cloth W forward, backward, left, and right, an operation panel 7 with the function of editing embroidery pattern data is set at the right end of the table 5, and all electric appliances for controlling the embroidery machine 1 are set on the lower side of the table 5 Control panel 8 of the device.

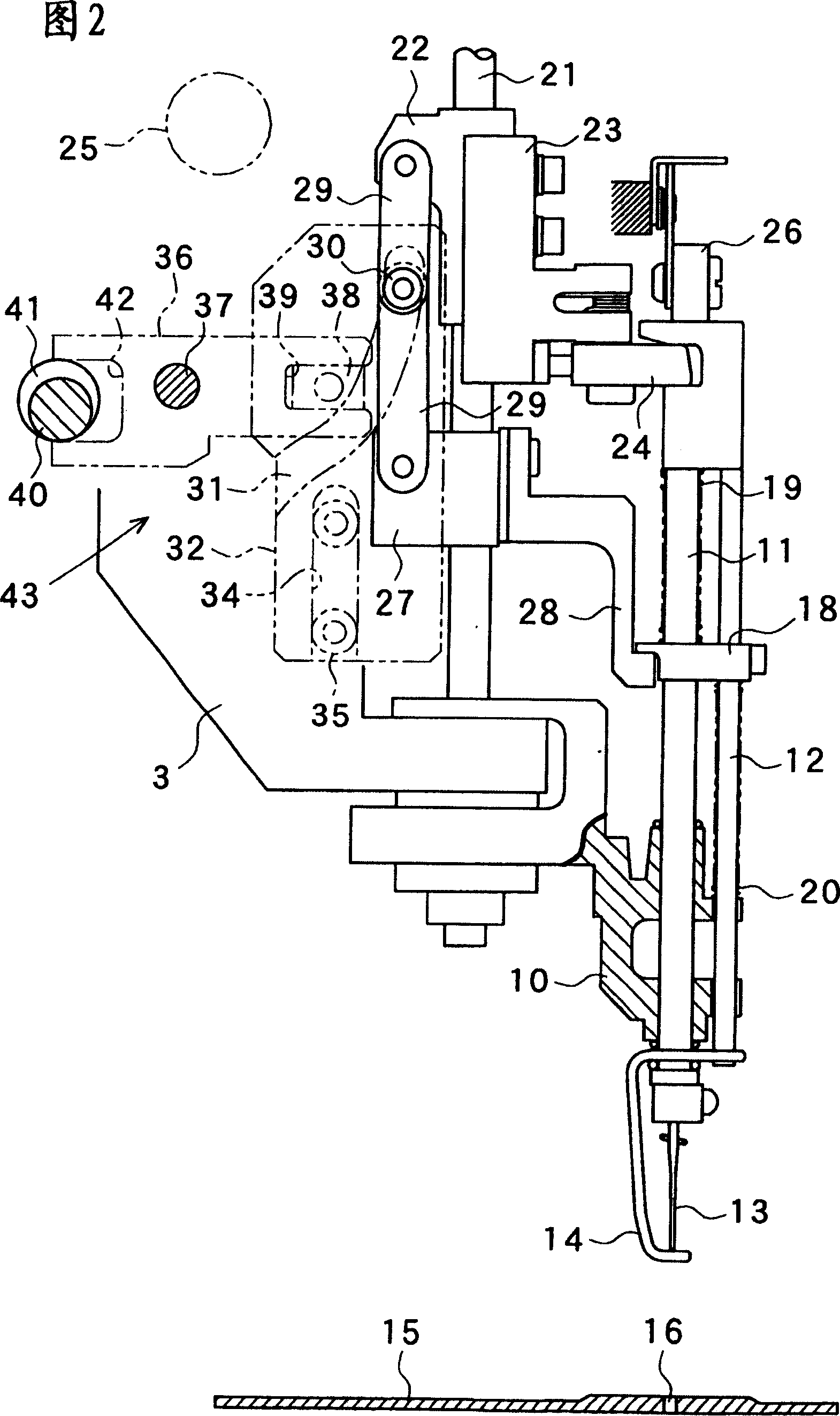

[0026] As shown in FIG. 2, a rotating body 10 is provided at the lower part of the machine head 3, and is rotated in a horizontal plane by a color changing mechanism not shown in the figure. A plurality of needle bars 11 and cloth pressing bars 12 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap