Flat sheet-printing material

A printing sheet and plane technology, applied in the field of plane printing sheet materials and writing devices, can solve the problems of immutability of information printed at one time, affecting the quality of copies, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

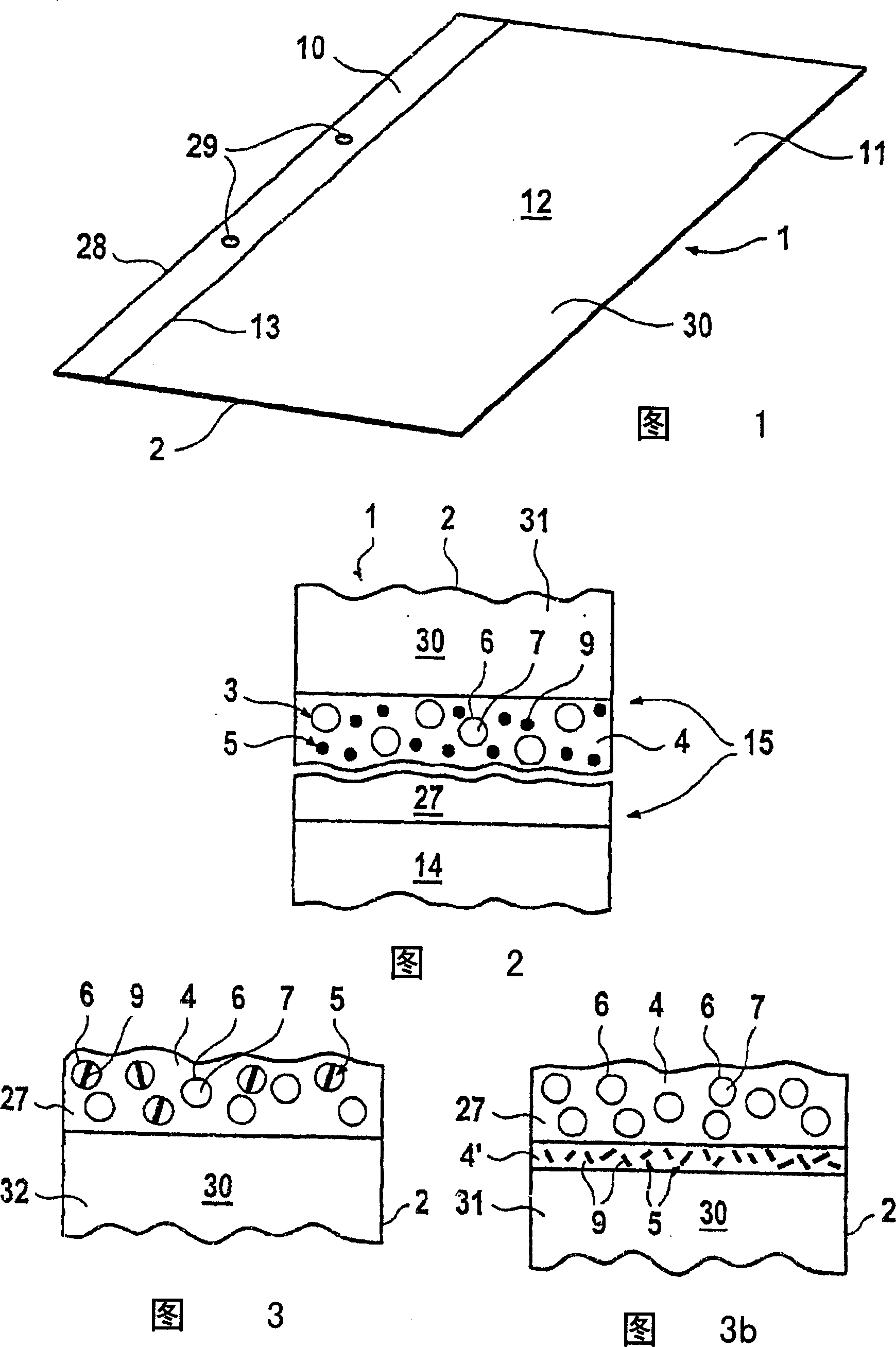

[0055] FIG. 1 shows a printed sheet 1 cut from a printed sheet material 2 with a washcoat 30 , which is divided into two subregions 10 , 11 . The subregion 10 extends along a long edge 28 and has a hole 29 . The other partial area 11 forms a read / write area 12 and is identified by a printed marking 13 . The printed sheet 1 can be of any size, but in the example shown it is of DIN A4 size.

[0056]FIG. 2 shows in an enlarged sectional view a cross-section through a copy set 15 with the printed sheet 1 of FIG. Cardboard or cardboard can also be used. A coating 4 is applied to the carrier layer 30 , in which the cavities 3 and electrically and / or magnetically activatable particles 5 are embedded. The cavities 3 can be formed by a suitable crystalline structure of the coating 4 , in the example shown the cavities 3 are micro-cavities 6 which are filled with pigment components 7 . The activatable particles 5 may be carbon particles or other conductive particles, in the example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com