Method for identifying high accuracy servo system friction parameter by using ant colony algorithm

A servo system and friction parameter technology, applied in general control systems, control/regulation systems, calculations, etc., can solve problems that cannot truly reflect the dynamic process of friction phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

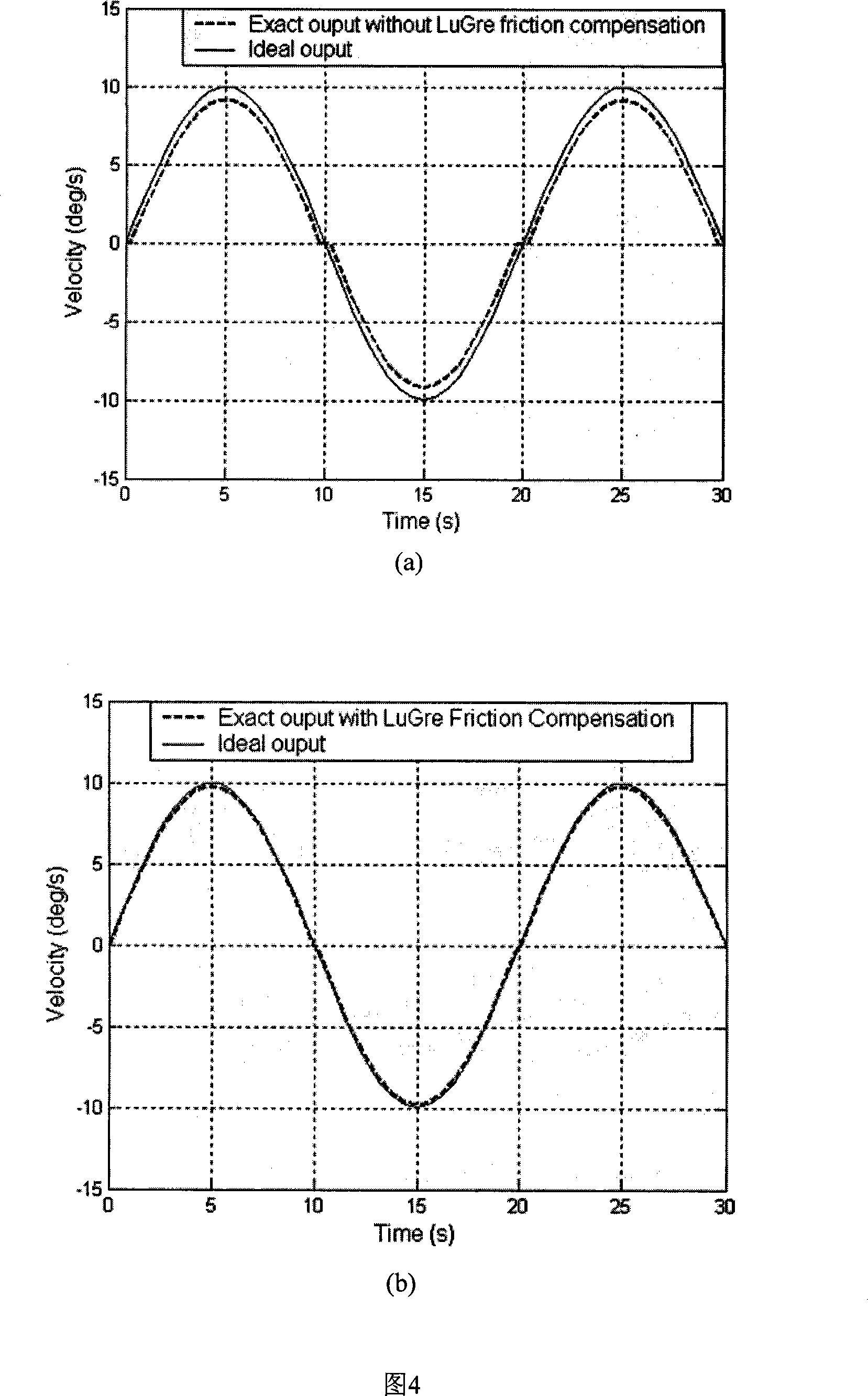

[0081] The present invention takes a certain type of closed-loop high-precision servo system as an example to carry out LuGre friction parameter identification, and the initialization parameter is: k p =0.3,k i =0.5,k d =0.8, m=50, F=200, α=1.2, β=2.5, ρ=0.6, Q=300. The LuGre friction parameter identification method based on the ant colony algorithm is as follows:

[0082] (1) Static parameter identification

[0083] Let the closed-loop servo system run at a constant speed motion, get the corresponding control torque sequence {u} i=1 N . By formula (6), when θ · · = 0 , There is F=u. therefore, and {u} i=1 N These two sequences determine the steady-state correspondence between friction torque and rotational speed. Let the parameter vector to be identified be x s for

[0084] x s = [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com