Method for manufacturing cement table top board of table tennis table

A table tennis table and the technology of the manufacturing method are applied in the direction of manufacturing tools, ceramic molding machines, etc., which can solve the problems of short service life, inconvenient maintenance, and insufficient training of table tennis players.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

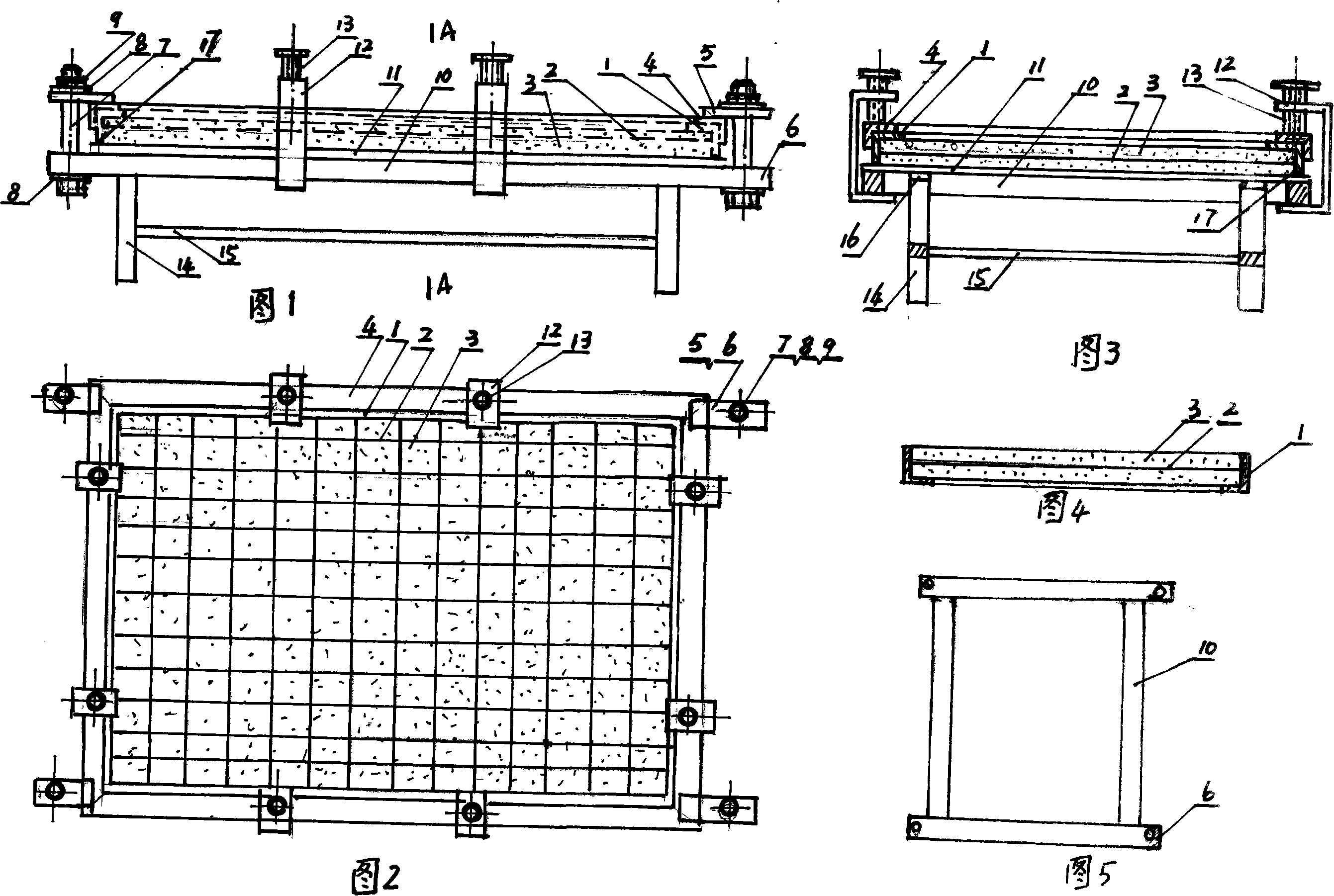

[0007] In conjunction with Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the production method and product situation of the present invention will be described in detail. The cement table top is a frame (1) made of angle steel. In the frame, steel bars (2) are used to make the ribs, and the frame (1) is poured with cement (3). After the cement solidifies, it has just become the cement table top of the table tennis table. The cement countertop should be smooth, and it needs a set of methods and tools to complete it. At first weld the frame (1) with angle steel, fix the well-shaped steel bar (2) in the frame, then use a support that has four legs (14) and pull rods (15) to form, the top of the leg is fixed with rubber pads (16), glue Put a piece of flat glass (11) on the pad, put frame (1) on the flat glass, cushion (17) is placed between the frame and the flat glass, the upper clamping frame (4) that four angle steels are placed on the frame ), the connecting plate (5) with holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com