Wig and process for producing the same

A manufacturing method and wig technology, applied in wigs, bald wigs, hair pieces and other directions, can solve the problems of reduced aesthetics, mottled mess, difficult operation, etc., and achieve better erection, improved production efficiency, and improved aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

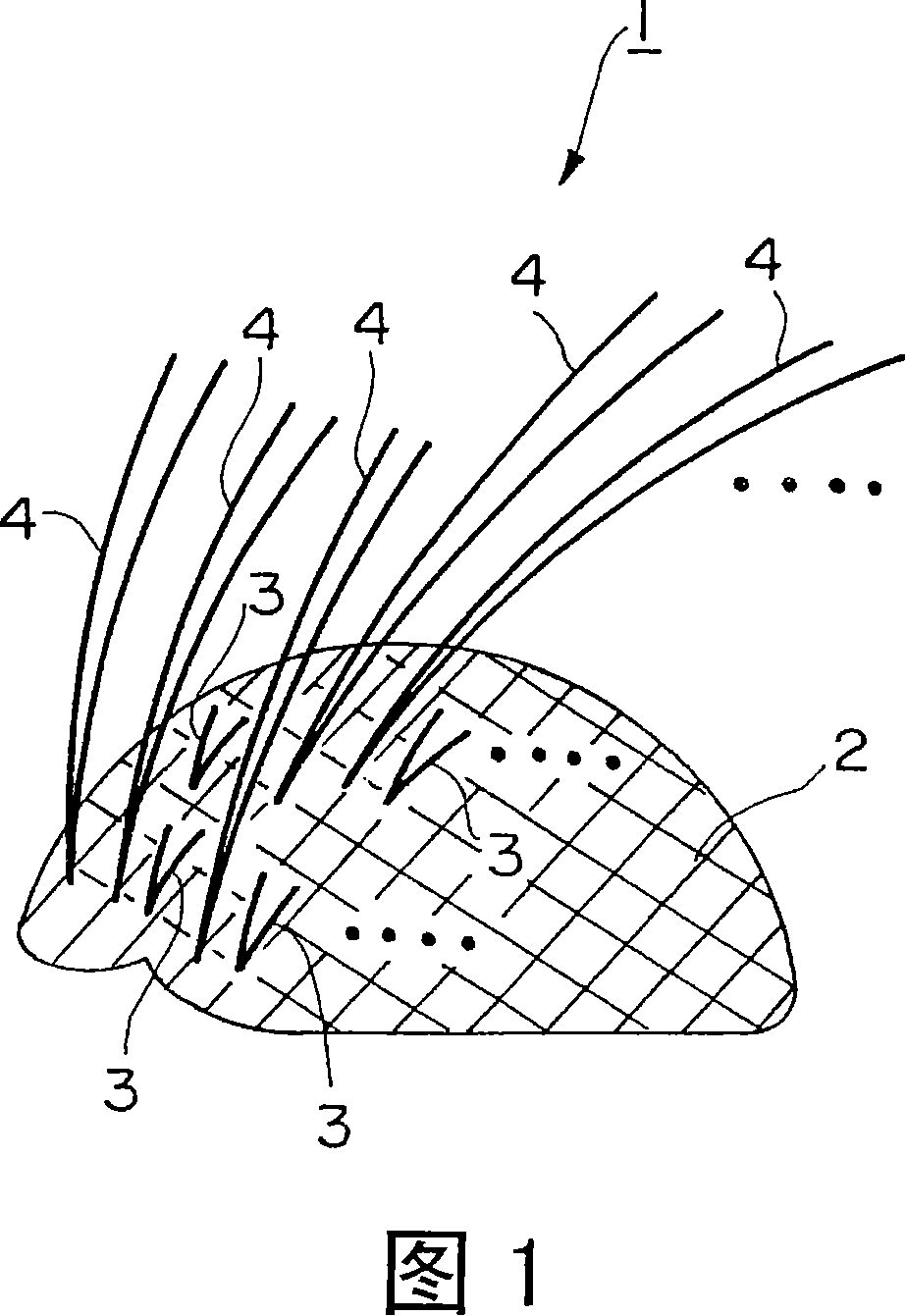

[0081] As Example 1, a wig 1 was manufactured using the present invention.

[0082] Using the pre-prepared plaster model of the head shape of the wig wearer, cover it with a net made of synthetic resin such as nylon or polyester, apply a thermosetting resin solution, heat it to about 100°C, and shape it to bend into the shape of the head form, thereby making the mesh matrix 2 as the wig matrix.

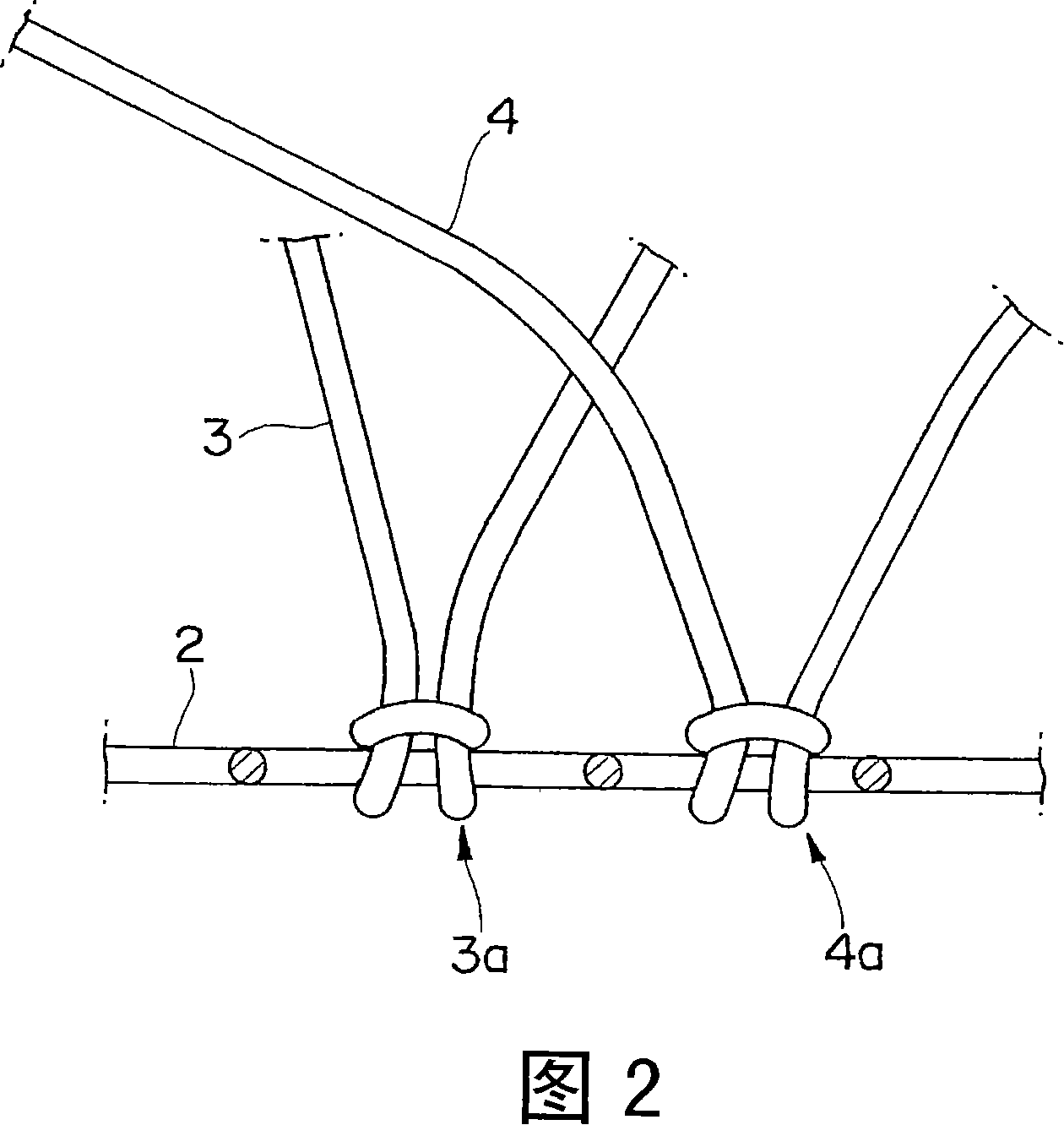

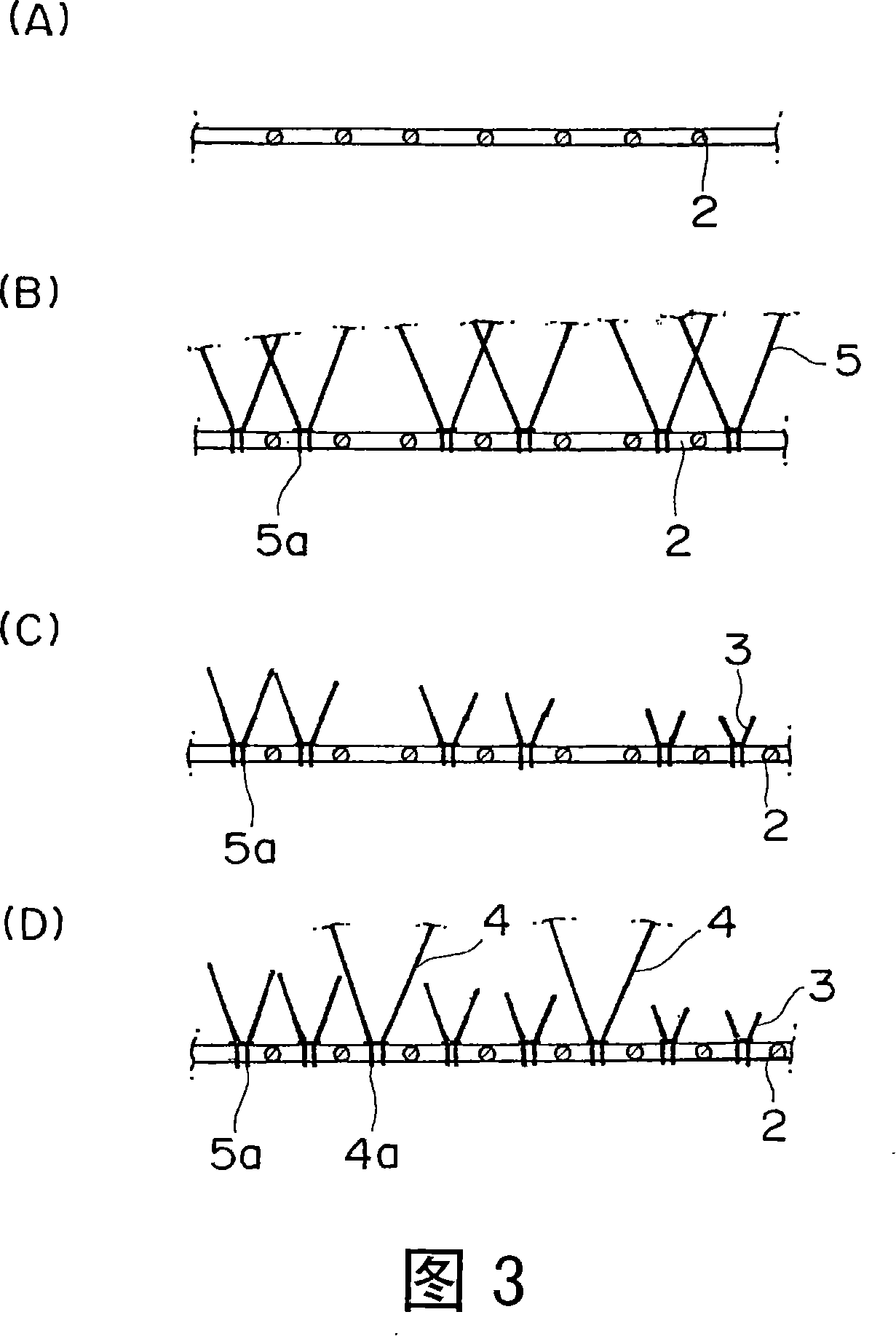

[0083] As the first step, for the above-mentioned net-like base 2, the curly hair 5 with a smaller curl diameter of about 30 cm long is planted on the vertical and horizontal filaments of the net-like base 2 and their intersections. The hair 5 is to fold the central part of one hair 5 in half, and hook the folded part of each hair that forms a pair with a special crochet needle, thereby forming a node 5a on the mesh base 2 for implantation. The initially implanted hair 5 has the same length as the long hair 4 of 15 cm. Since the planting area of the mesh substrate 2 is set to 300c...

Embodiment 2

[0088] Except that the ratios of short hair 3 and long hair 4 are respectively set to 33% and 67%, the wig 1 of the present invention is manufactured in the same manner as in Example 1.

Embodiment 3

[0090] Except that the color of the short hair 3 is set to be dark brown, and the color of the long hair 4 is set to be light brown, other operations are performed in the same manner as in Example 2 to manufacture the wig 1 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com