Ink supplying container suitable for continuous ink-supplying system

An ink supply and container technology, applied in printing and other directions, can solve the problems that the ink cartridge cannot supply ink smoothly, consume a certain weight, and cannot clearly observe the ink consumption at any time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the invention is capable of various changes in different aspects without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

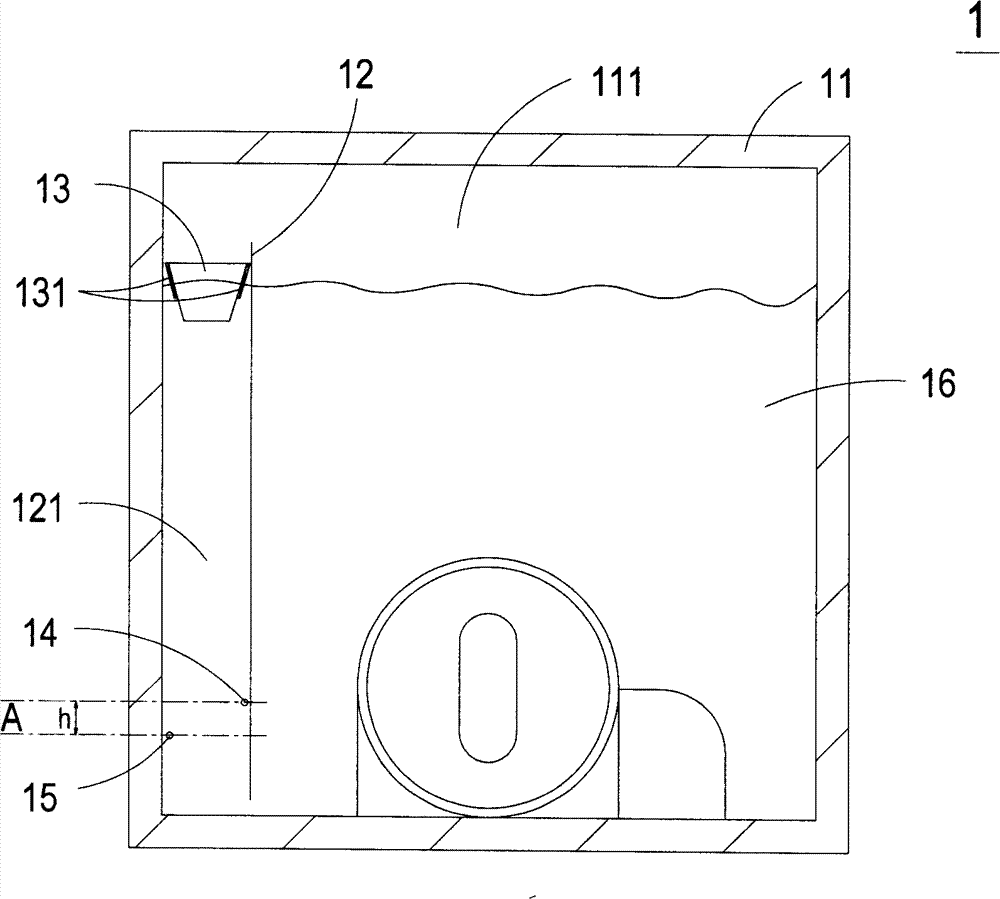

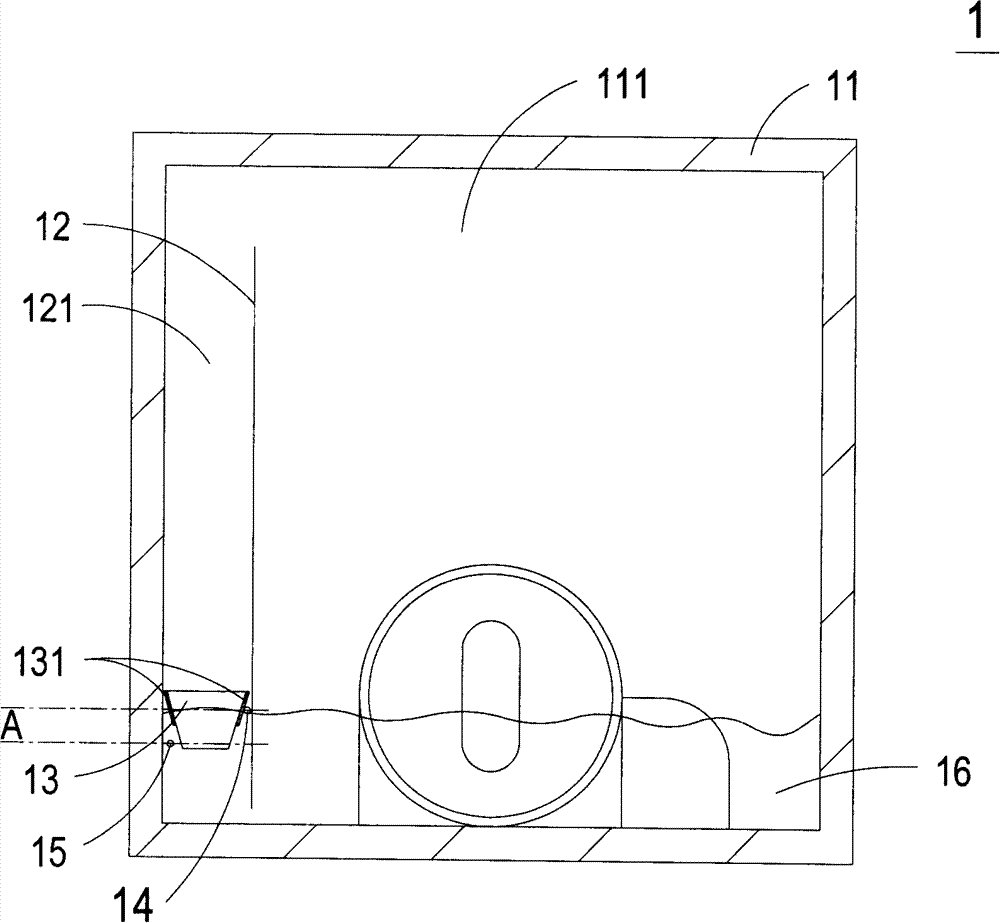

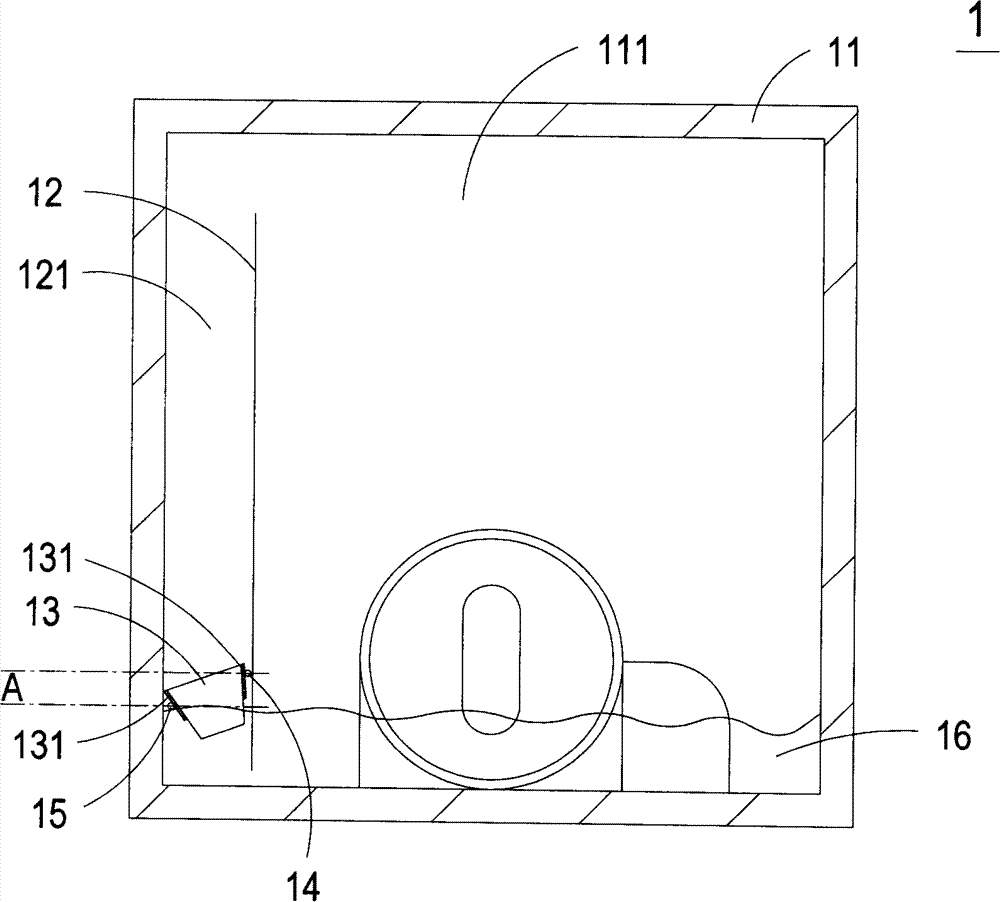

[0019] The present invention is an ink supply container, which is suitable for business machines using continuous ink supply system, such as inkjet printers. , to continuously provide the inkjet head of the ink cartridge for printing, mainly rely on the buoyancy of the floating element and the different heights of the two ends of the contact body to detect, so as to achieve a more stable output signal to notify that the ink cartridge needs to be replaced , and the amount of residual ink is also less.

[0020] see figure 1 , which is a structural diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com