Reversing device capable of grabbing and placing

A technology of reversing device and placement position, which is used in packaging, transportation and packaging, conveyor objects, etc., can solve the problems of complex overall structure layout, cumbersome movements, slow production rhythm, etc., to save procurement costs and maintenance costs, Improve reliability and stability, and solve the effect of space placement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

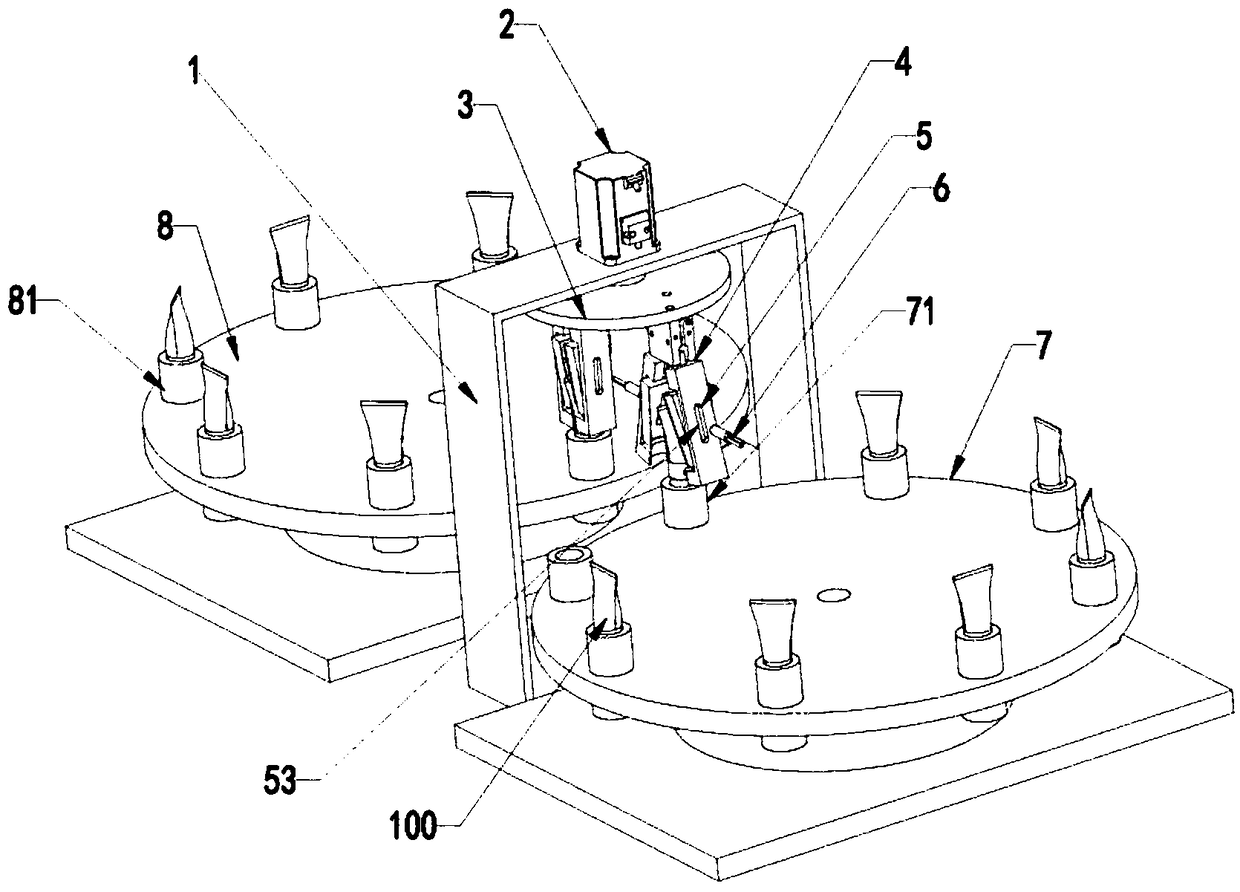

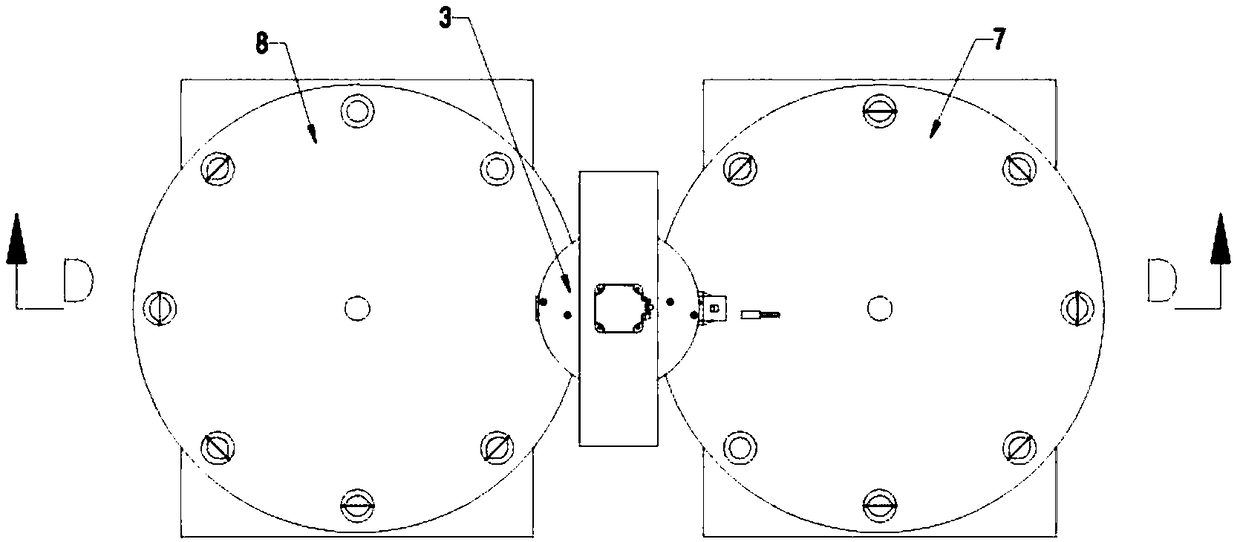

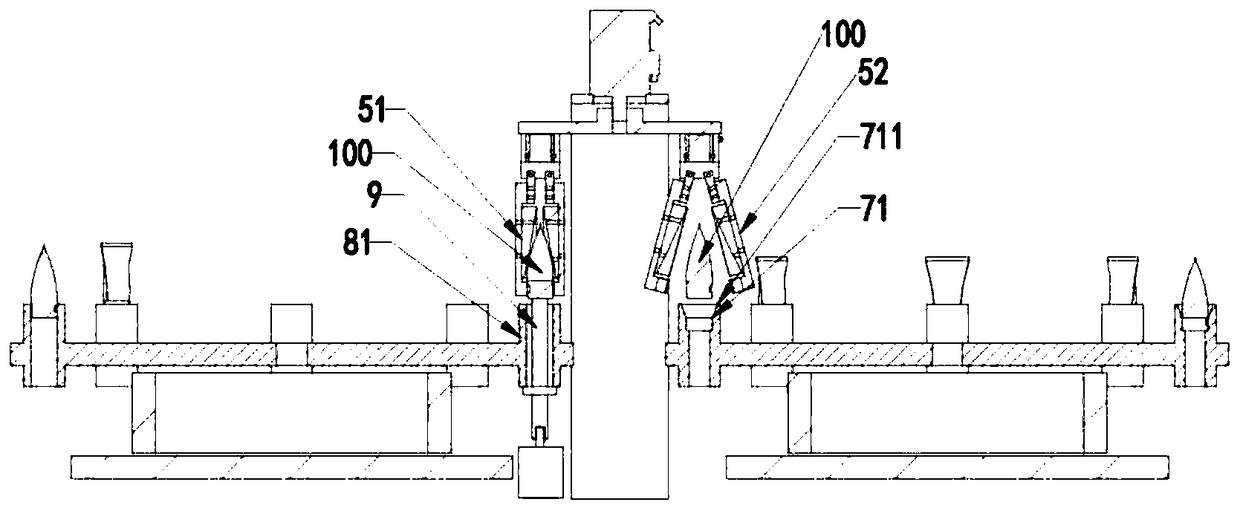

[0027] Such as Figure 1 to Figure 3 As shown, a reversing device for grabbing and placing includes a first turntable 8 and a second turntable 7, a reversing mechanism is provided between the first turntable 8 and the second turntable 7, and the turnaround mechanism includes Support 1, rotary drive device 2, index plate 3 and jaw cylinder 4, rotary drive device 2 is preferably a rotary motor, and described rotary drive device 2 is fixed on the described support 1, and described rotary drive device 2 and described The indexing plate 3 is connected, the jaw cylinder 4 is fixed on the indexing plate 3, the first turntable 8 is provided with a first clamp 81 for placing the product 100, and the second turntable 7 is provided with a For the second fixture 71 of the product 100, the rotary driving device 2 drives the jaw cylinder 4 to reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com