Material high-speed stretch tester and test methods thereof

A high-speed tensile and test device technology, applied in the direction of testing the ductility of materials, can solve the problem of low measurement accuracy of impact tensile velocity, inability to obtain accurate material critical impact tensile velocity, scarcity of critical impact tensile velocity data, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

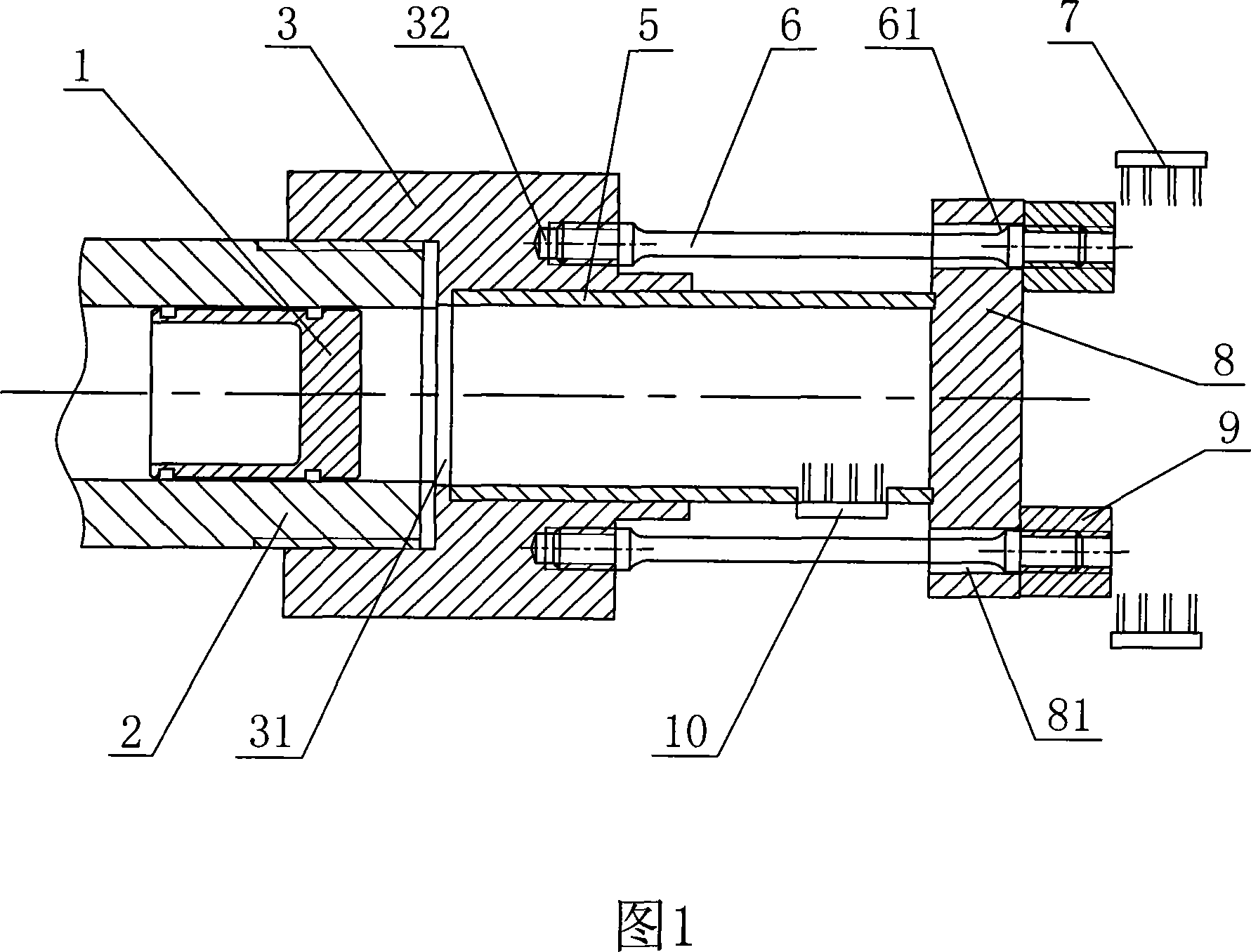

[0016] As shown in the figure, a high-speed tensile test device for materials includes a gas gun barrel 2 for high-speed launching projectiles 1. A base 3 is fixed at the exit of the gas gun tube 2, and a The coaxial central hole 31 of the gun barrel 2 is coaxially fixed with a sleeve 5 in the central hole 31, and the other end of the sleeve 5 is vertically provided with a plane target plate 8, and the end surface of the base 3 is provided with three Evenly distributed threaded holes 32, the axis of the threaded hole 32 is parallel to the axis of the central hole 31, the plane target plate 8 is provided with a through hole 81 coaxially corresponding to the threaded hole 32, and the outer end surface of the plane target plate 8 is provided with a The test piece 6 is screwed to the fixed block 9, and the side wall of the sleeve 5 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com