Magnetic levitation shockproof device and hard disc module

A magnetic levitation and hard disk technology, used in magnetic springs, mechanical equipment, springs/shock absorbers, etc., can solve problems such as hard disk damage, and achieve the effect of prolonging service life and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

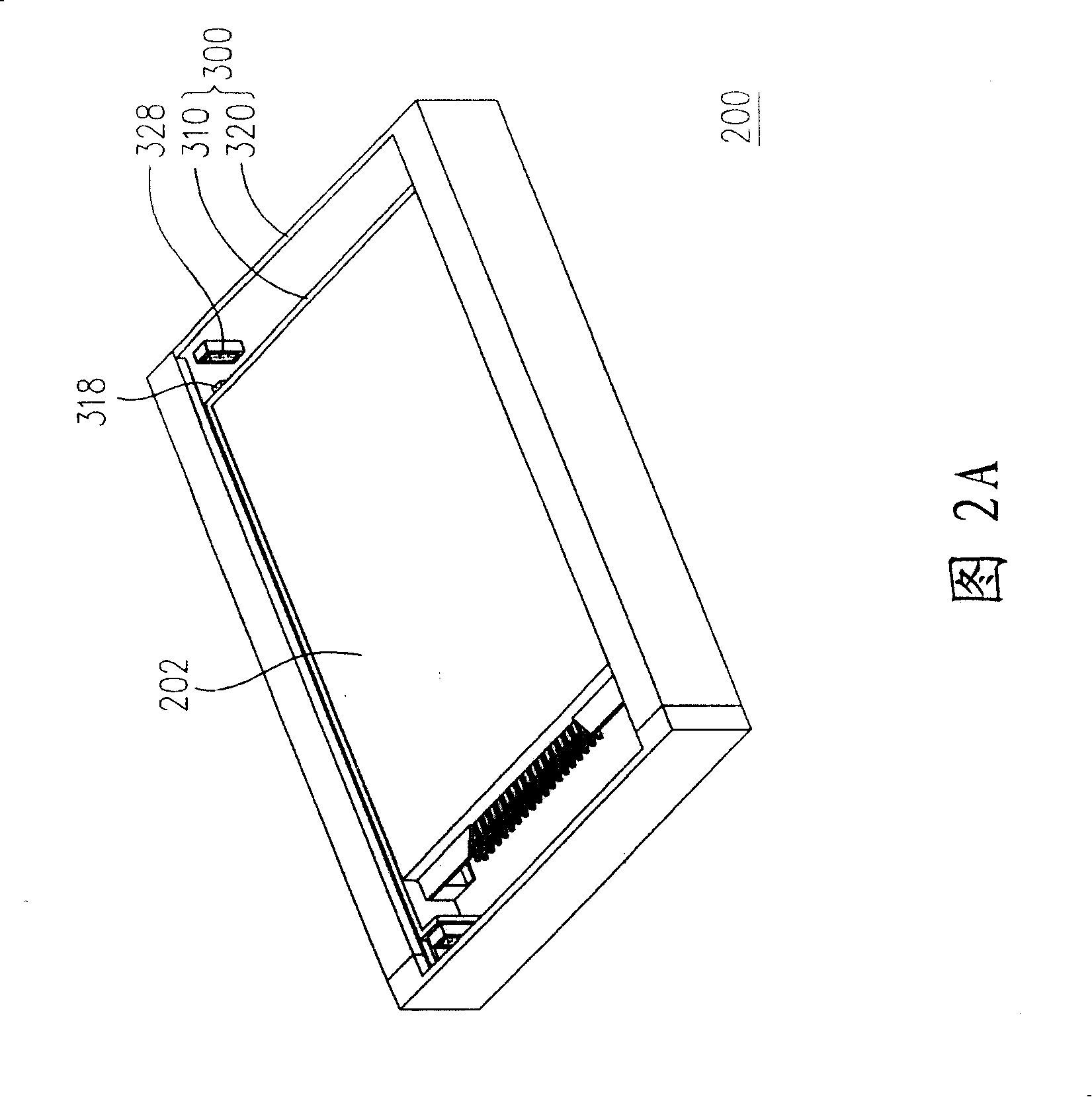

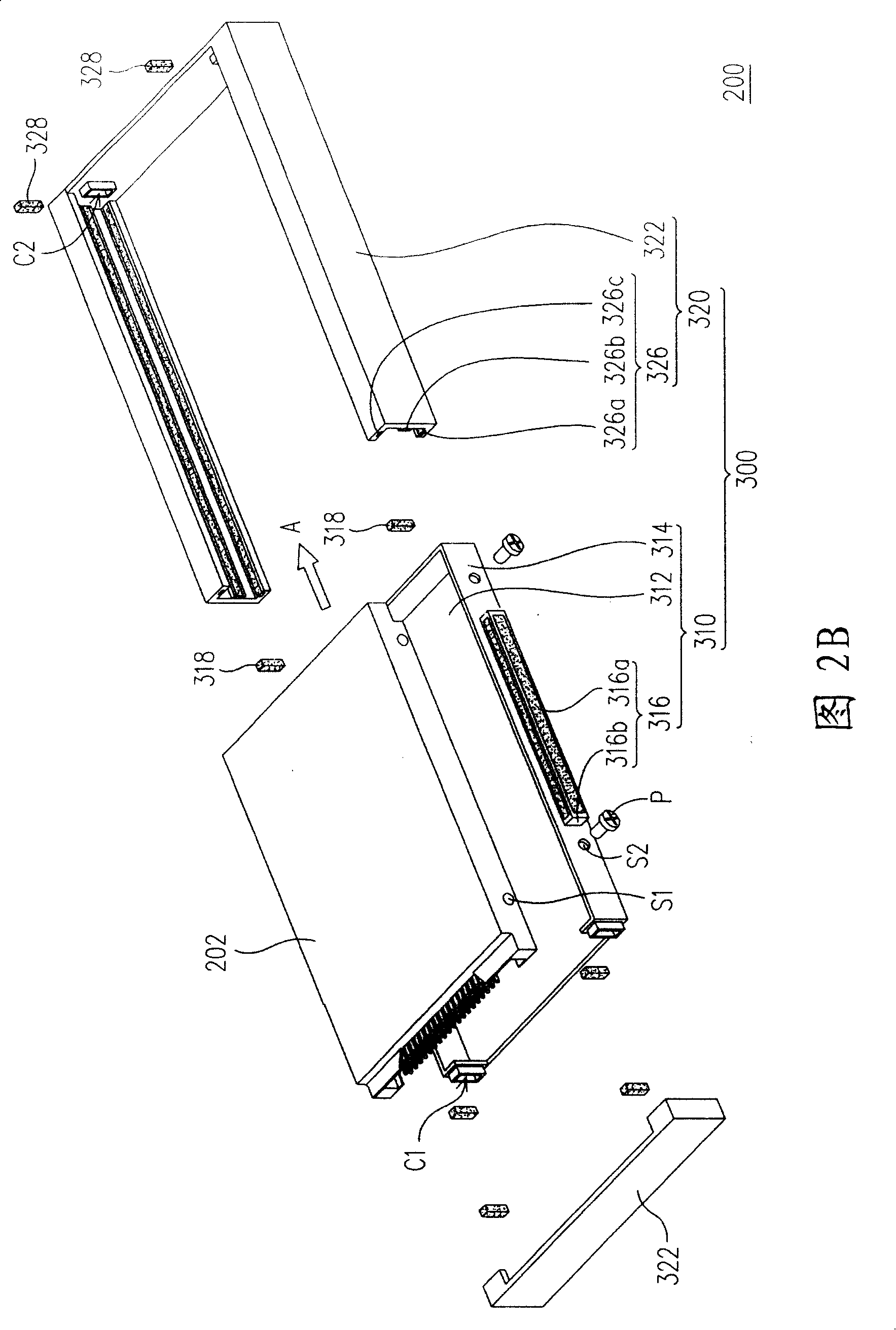

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, and structure of the maglev shock-proof mechanism and hard disk module proposed in accordance with the present invention will be given in conjunction with the accompanying drawings and preferred embodiments. The characteristics and effects are described in detail later.

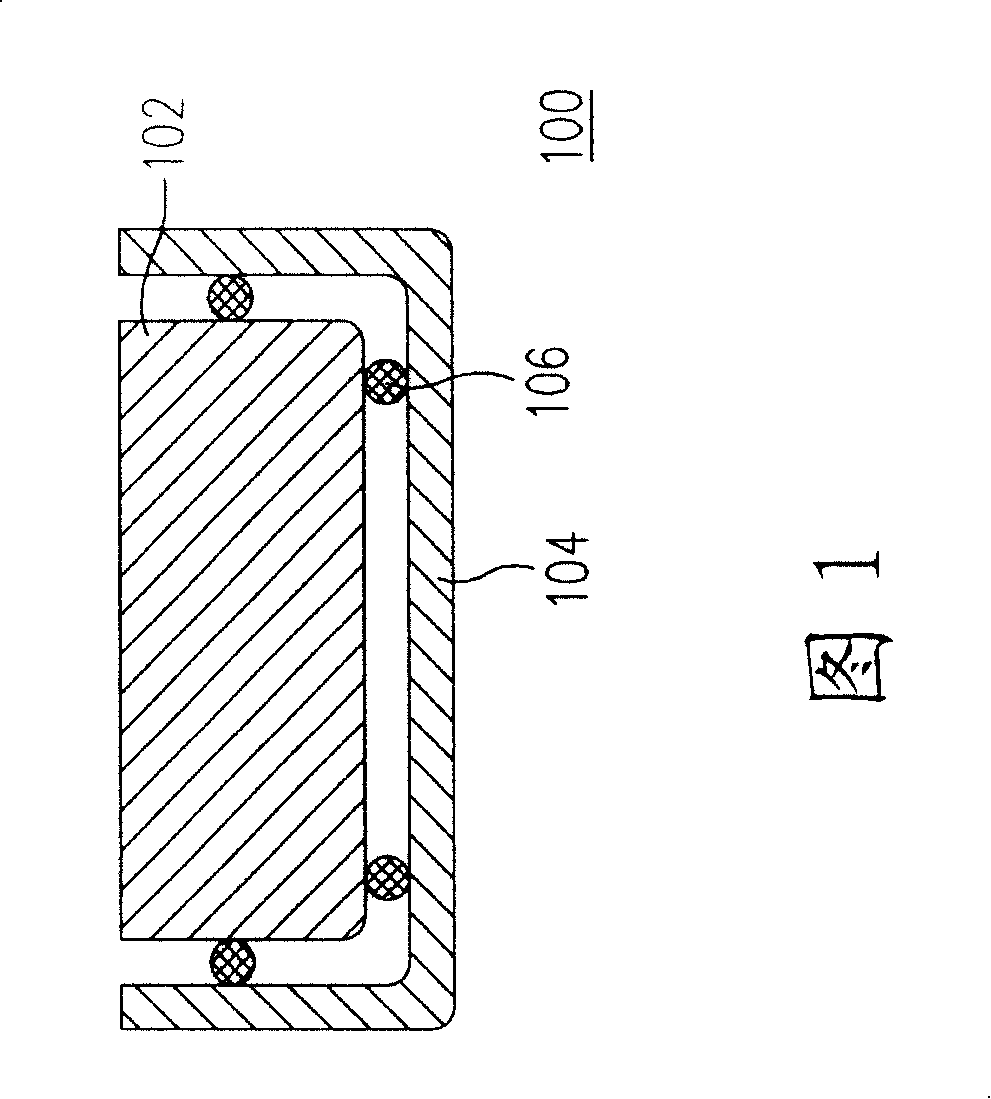

[0033] 2A is a schematic diagram of the hard disk module of the present invention, and FIG. 2B is an exploded view of the hard disk module of the present invention. 2A and 2B at the same time, the hard disk module 200 of the present invention includes a hard disk 202 and a magnetic shockproof mechanism 300. The hard disk 202 is suitable for being assembled into the maglev anti-vibration mechanism 300 to protect the hard disk 202 from damage caused by external impact. The magnetic suspension anti-vibration mechanism 300 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com