Minisize drill bit for PCB plate drilling hole

A micro-drill and PCB board technology, applied in drilling/drilling equipment, boring machine/drilling machine components, drill repairing, etc., can solve the problems of insufficient chip removal ability, affecting rigidity, small helix angle, etc., to improve the hole wall The effect of quality, improved dust removal capacity, and large chip removal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

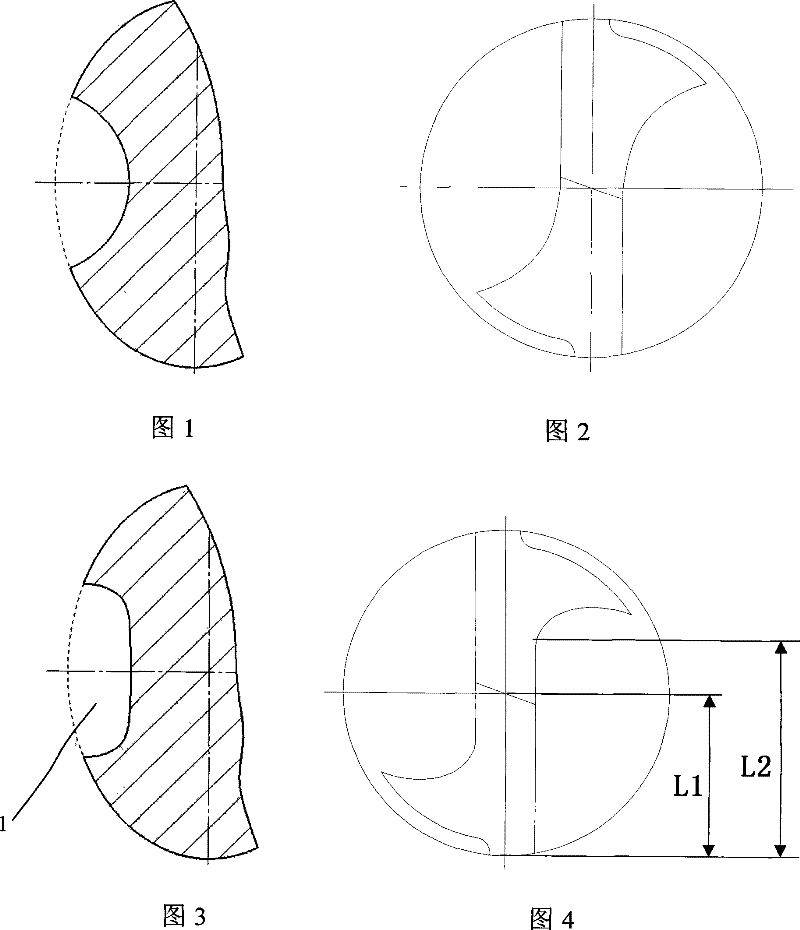

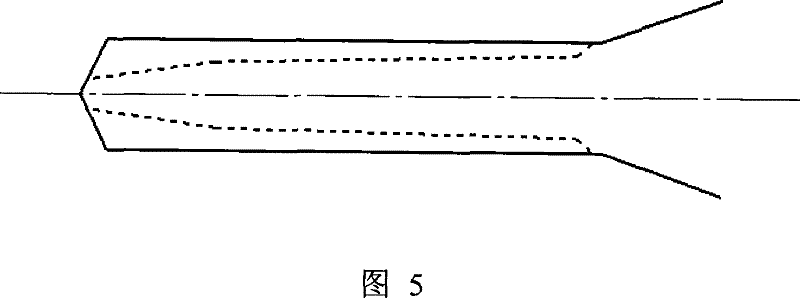

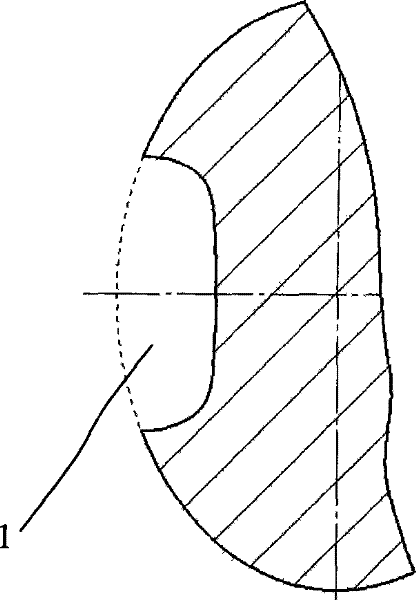

[0026] Such as Figure 3 to Figure 5 As shown, the present invention provides a micro-drill used for drilling holes in PCB boards, the cylindrical surface of which is provided with a spirally rising groove 1 . The main difference between the present invention and existing miniature drill bit is:

[0027] 1. The groove is optimized, and the cross section of the groove perpendicular to the helix is designed as a discontinuous arc, such as image 3 In the illustrated embodiment, viewed from the cross section perpendicular to the helix, the cross-sectional profile of the groove 1 is generally U-shaped with a wide bottom, including the bottom line at the bottom of the groove and two lines on both sides of the groove. The side line that smoothly connects with the bottom line, wherein the bottom line is a straight line segment or an arc line segment with a large radius of curvature, and when the arc line segment with a large radius of curvature is used, the bottom line is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com