Vented disc brake rotor

A ventilated, rotor technology, applied in the direction of the brake disc, etc., can solve the problem that the designer cannot fully understand the brake whistle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

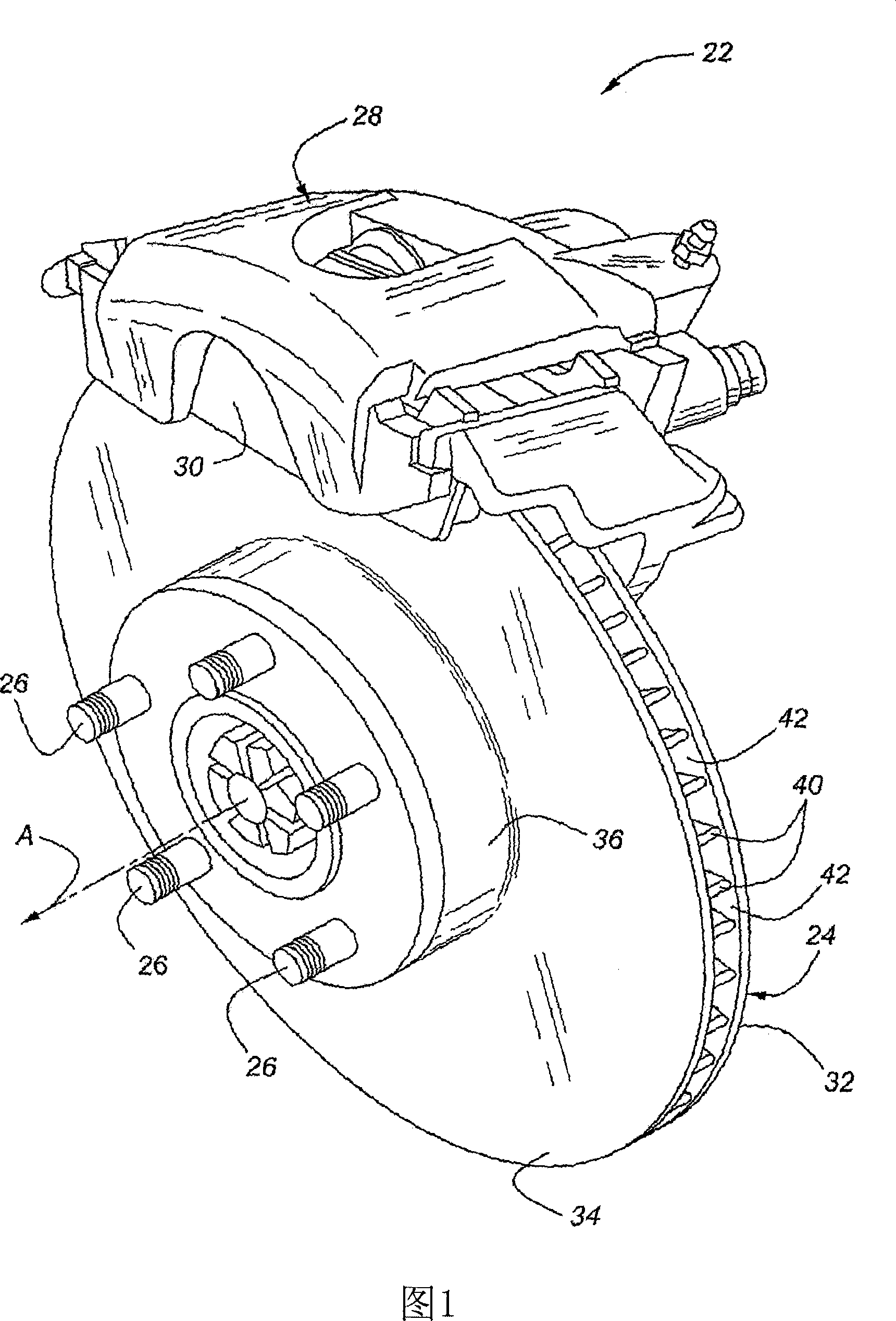

[0026] Referring to the drawings, wherein like numerals refer to like or corresponding parts throughout, a disc brake rotor assembly 22 is shown in FIG. Wheels, not shown, are attached above lug bolts 26 . Calipers 28 support a pair of brake pads 30 on opposite sides of rotor 24 . In response to hydraulic, wind, electromagnetic or other actuation initiated by the vehicle operator, disc brake pads 30 are compressed and clamped into contact with opposing friction surfaces of rotor 24 to prevent wheel rotation.

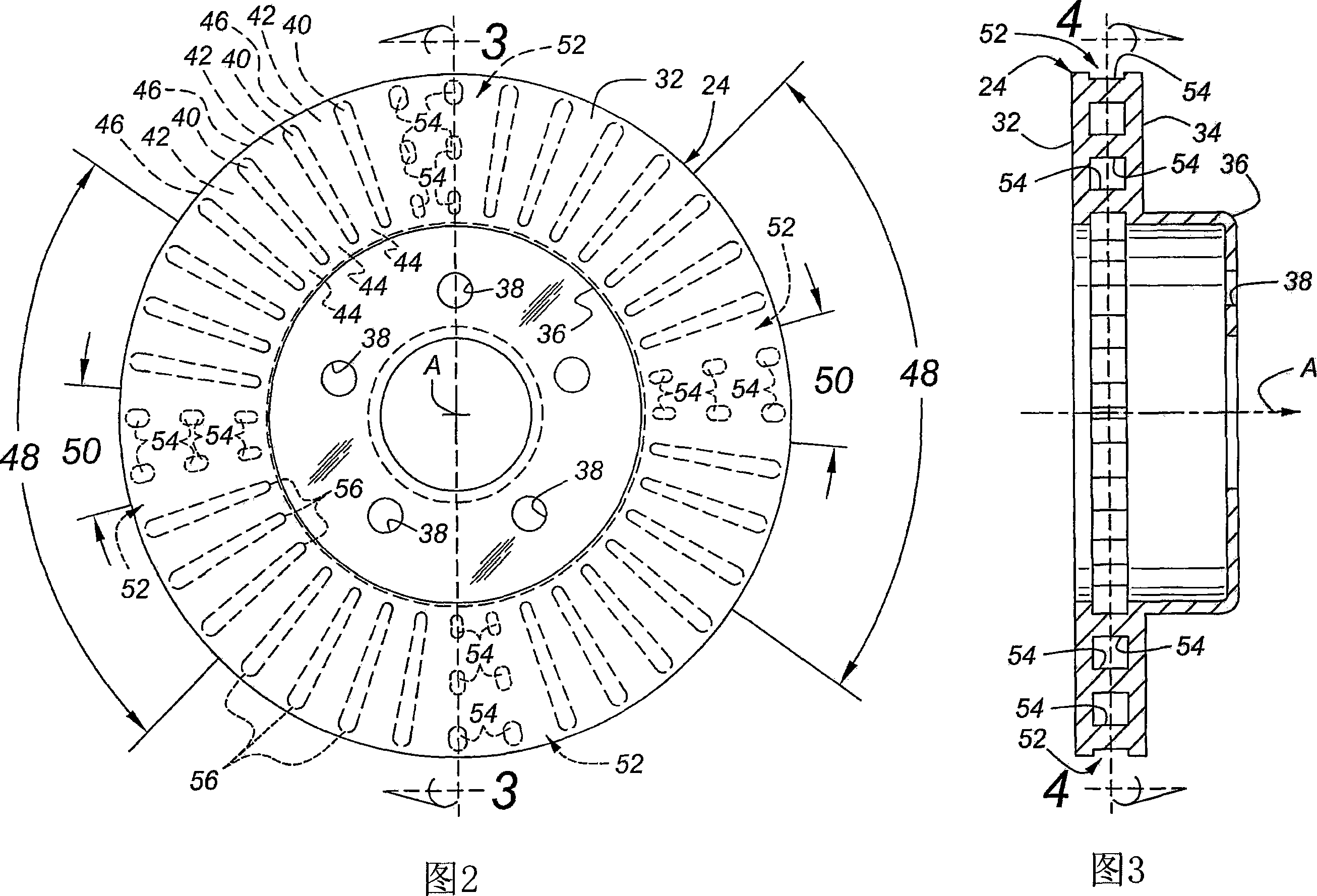

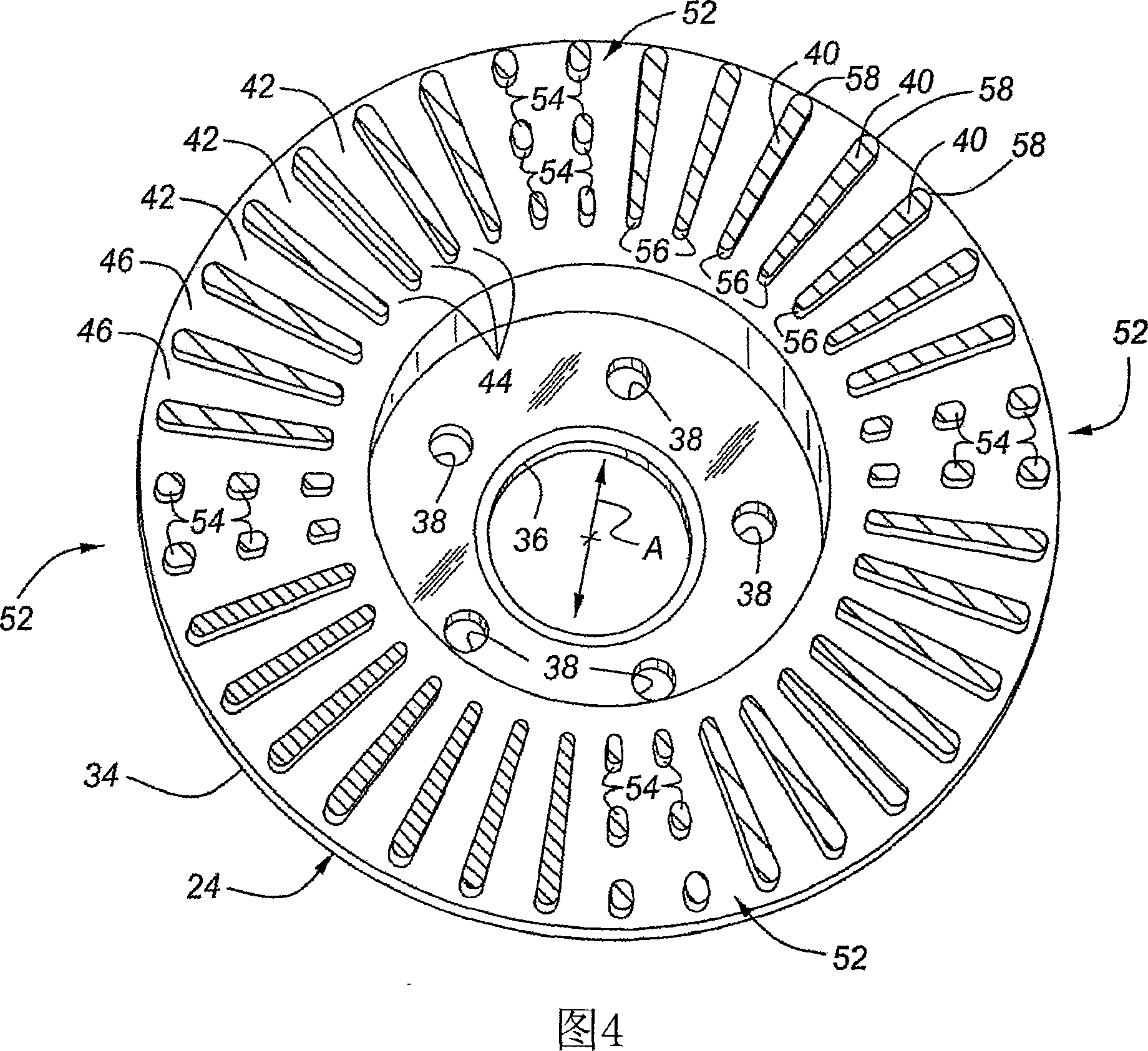

[0027] In a possibly preferred embodiment as shown in Figures 2-4 and 7A, the rotor 24 is of the ventilated type and includes an annular inner friction plate 32 centered on a central axis A. The central axis A coincides with the axis of rotation of the associated wheel. The annular outer friction plate 34 is spaced apart from the inner friction plate 32 and concentrically arranged around the central axis A. As shown in FIG. The inner edge of the outer friction plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com