Back light module unit and LCD

A backlight module and liquid crystal panel technology, applied in static indicators, light guides, optics, etc., can solve the problem of low light uniformity of the backlight module, and achieve the effect of uniform light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

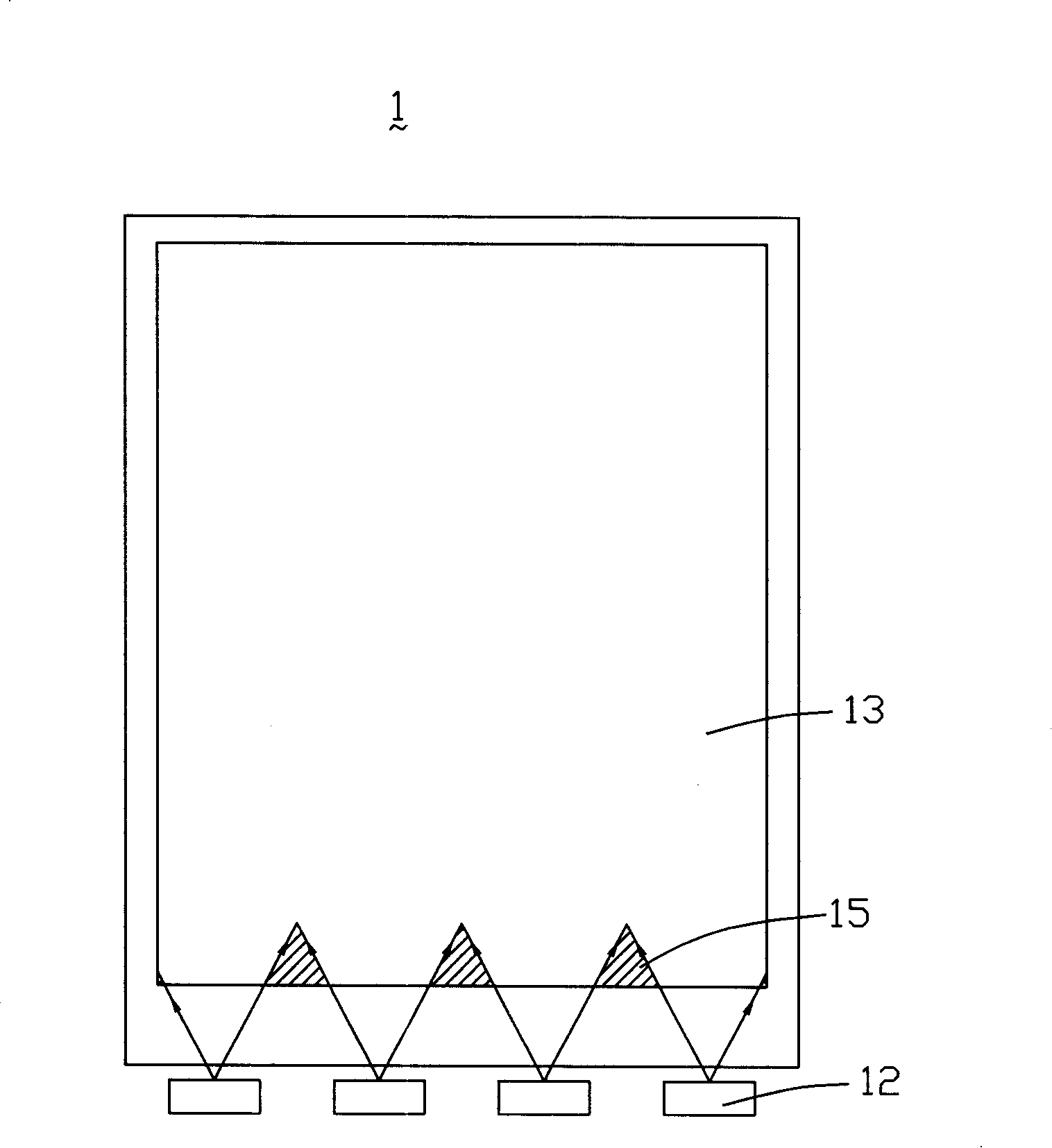

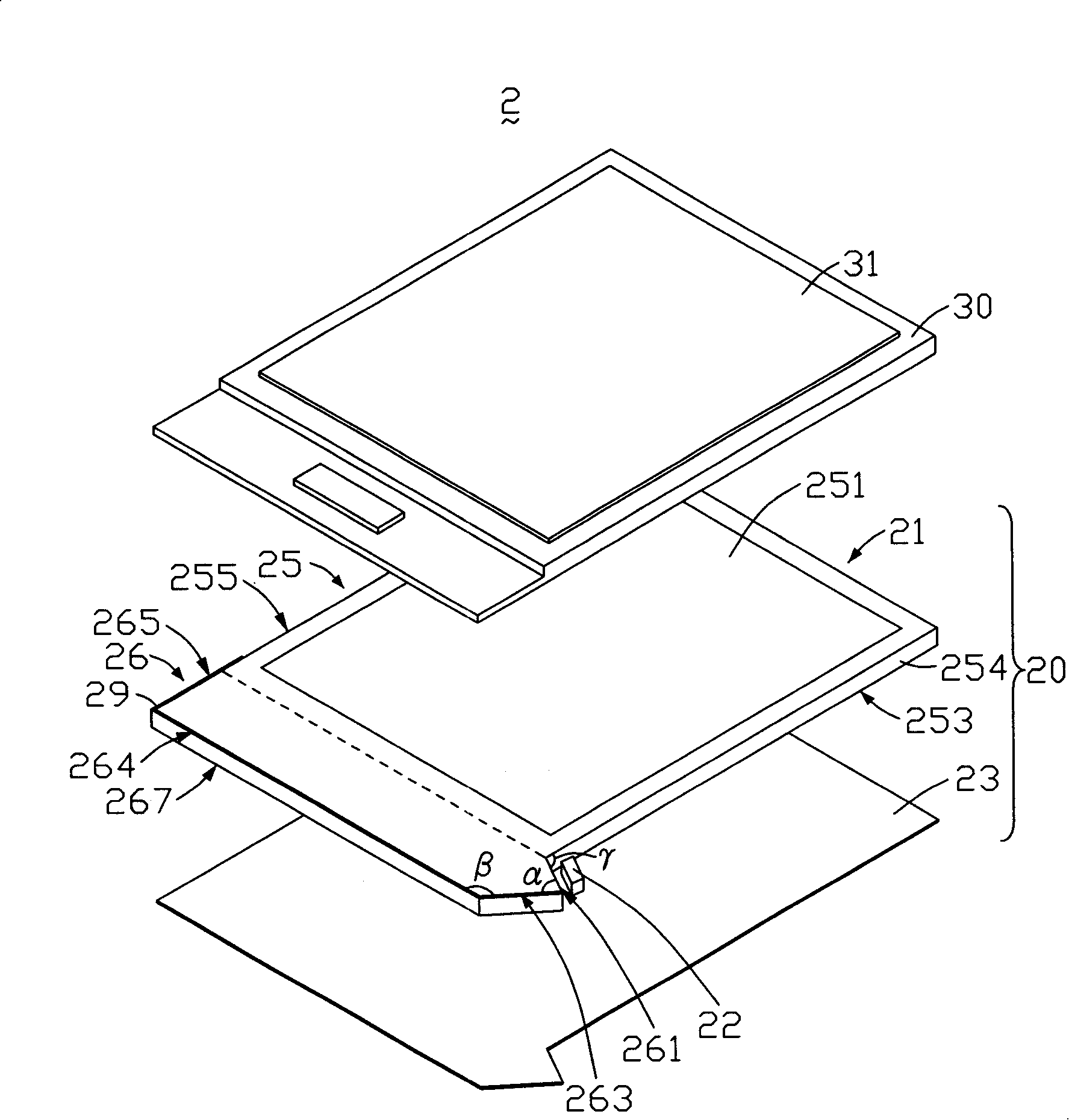

[0018] see figure 2 , is a three-dimensional exploded schematic view of the first embodiment of the liquid crystal display of the present invention. The liquid crystal display 2 includes a backlight module 20 and a liquid crystal panel 30 stacked with the backlight module 20 .

[0019] The liquid crystal panel 30 includes a display area 31 for displaying images.

[0020] The backlight module 20 includes a light guide plate 21 and a light source 22 . The light source 22 is a light emitting diode. The light guide plate 21 guides the transmission direction of the light beam emitted by the light source 22 , and converts it into planar light to exit from the light guide plate 21 .

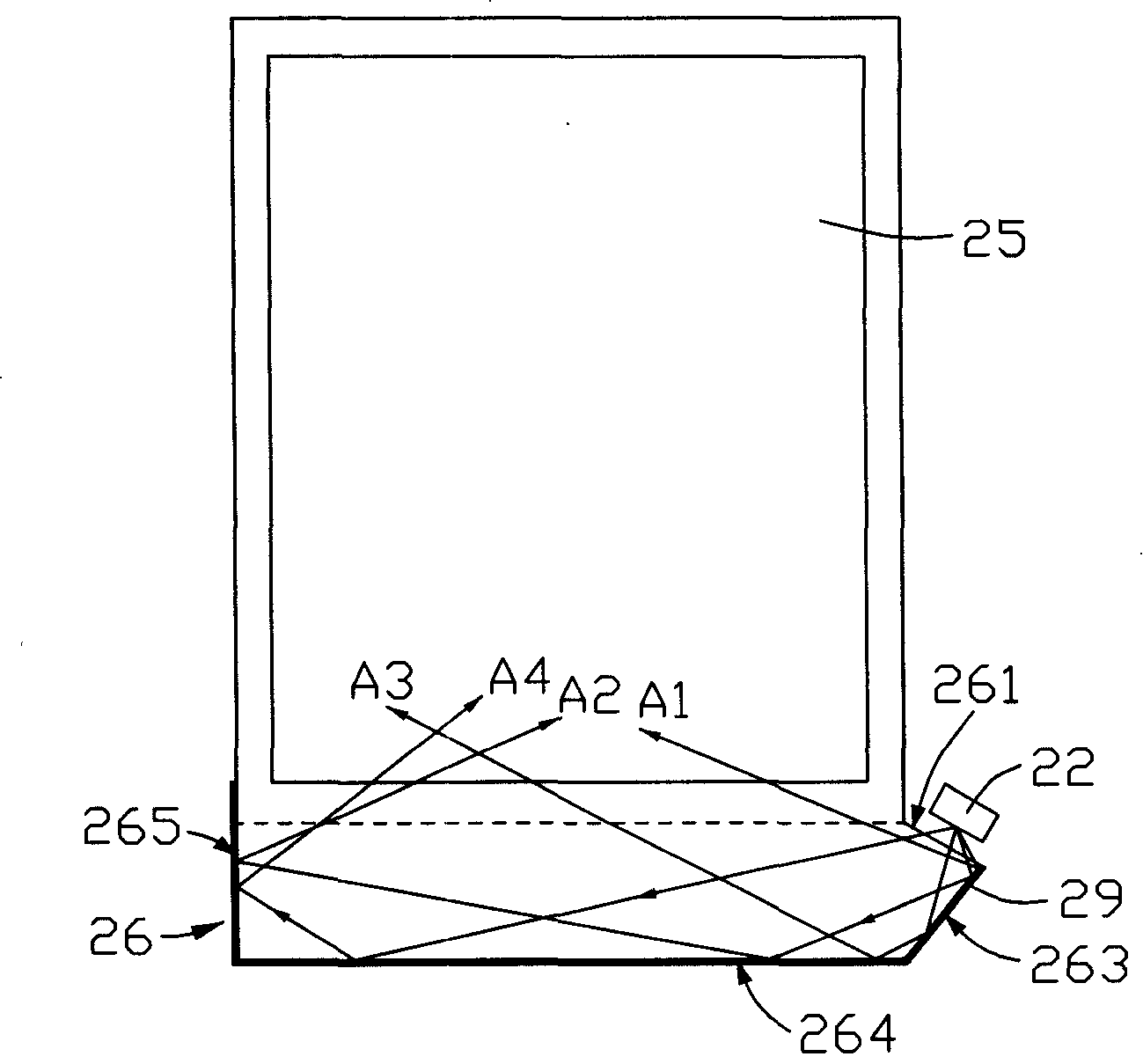

[0021] The light guide plate 21 includes a main body 25 and an extension portion 26 extending from one end of the main body 25 in a direction away from the main body 25 . The body 25 includes a light-emitting surface 251, a bottom surface 253 opposite to the light-emitting surface 251, a first side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com