Blu-ray ld multi-tooth reflective conduction backlight module structure

A technology of backlighting, reflection and conduction, used in light guides, optics, optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

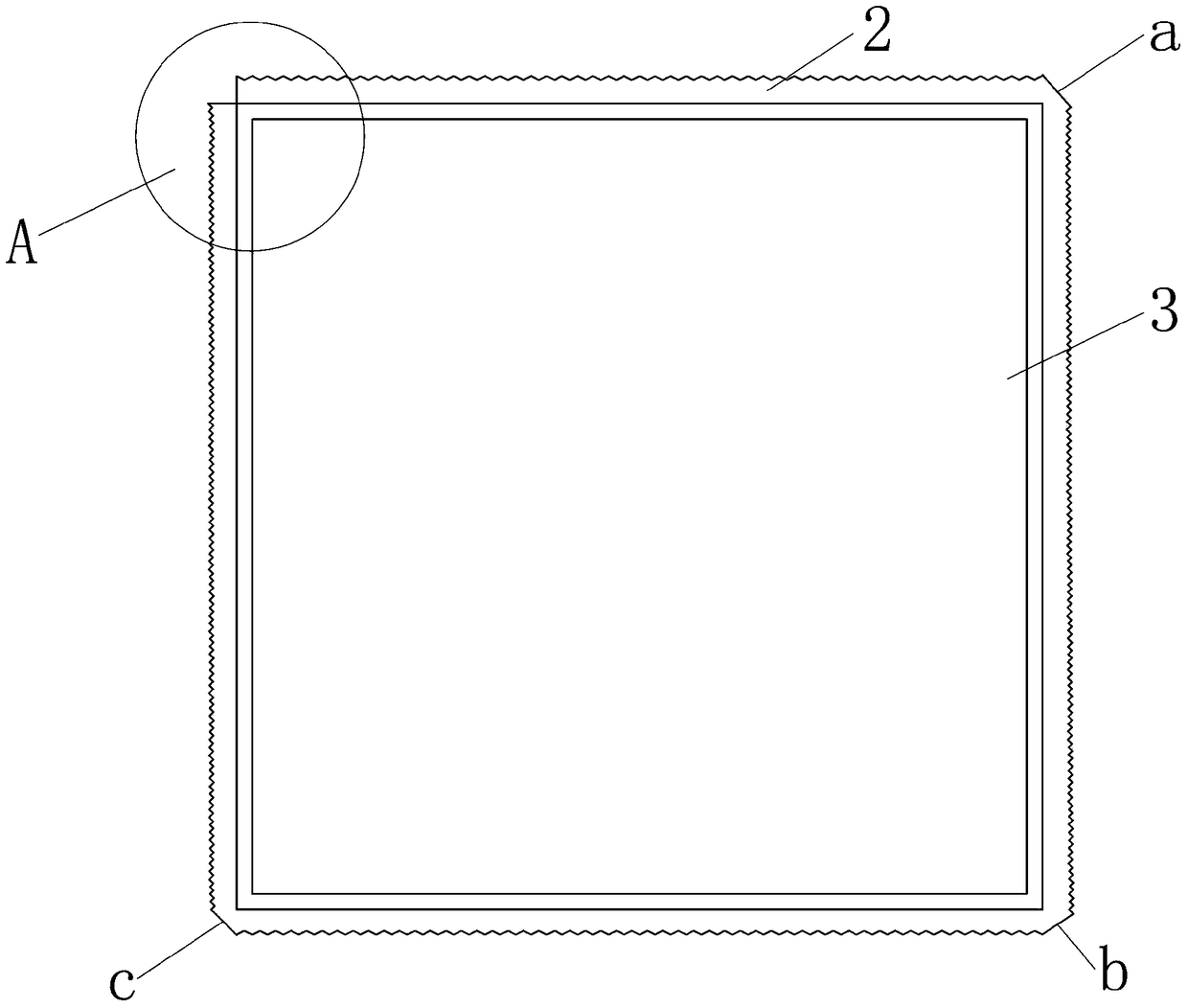

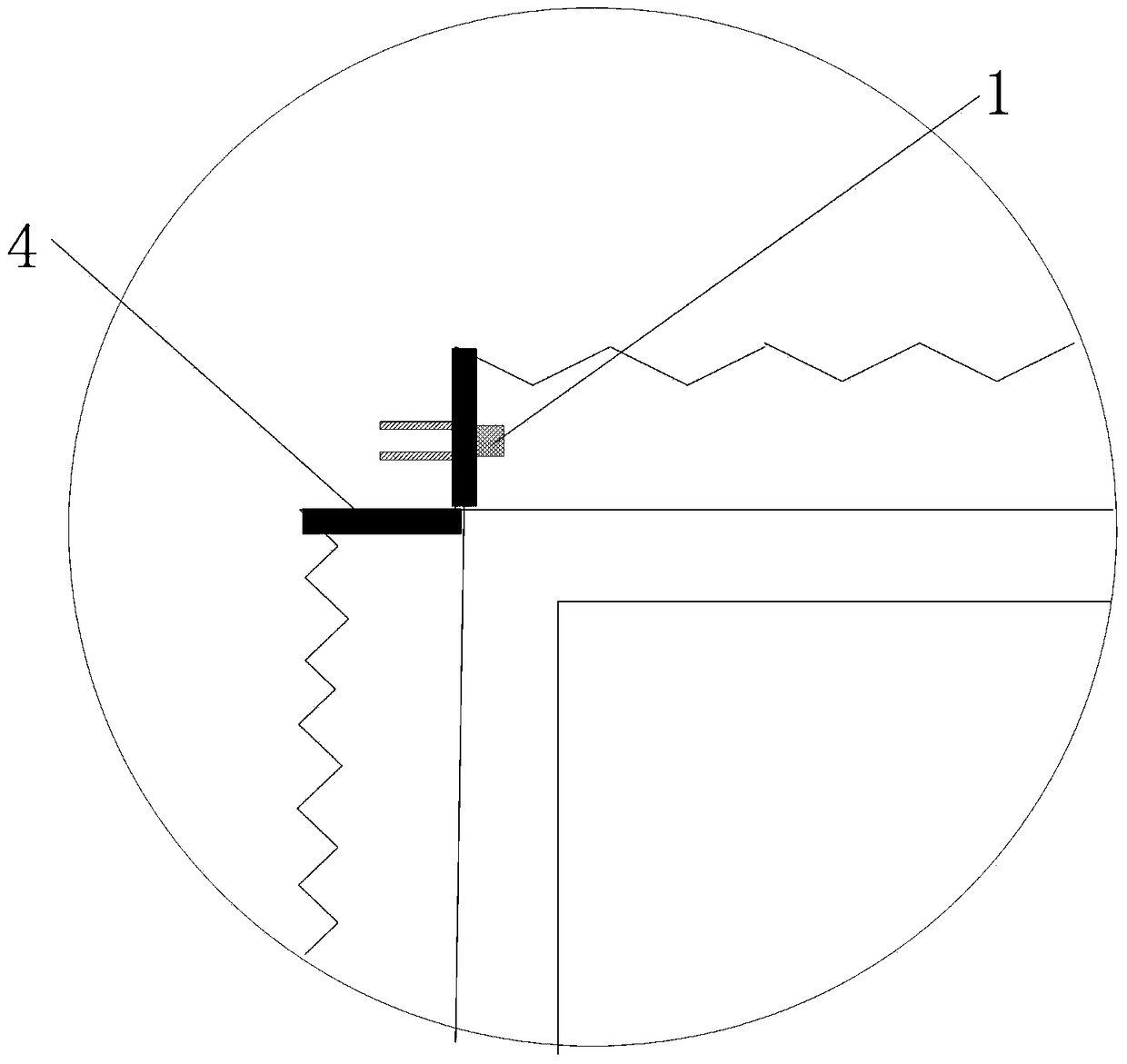

[0013] Such as Figure 1-2 As shown, it will be introduced through specific embodiments below. Blu-ray LD multi-tooth reflective backlight module structure, which is used in conjunction with LCD screens, such as figure 1 . The outer surface of the multi-tooth reflection system 2 is made into a tooth shape and the non-light-emitting surface is coated with a total reflection film layer for light reflection. When the light emitted by the blue light LD 1 passes through the multi-tooth reflective system 2 , the light will be reflected to the tooth surface, so that the light will be emitted from the opposite surface of the multi-tooth reflective system 2 . The opposite surface is evenly coated with a transparent jelly mixed with red and green phosphors, so the light emitted from this surface will excite the phosphors on it, and mix and output white light. The output white light enters the back panel, and under the special action of the light guide plate in the back panel, the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com