Substrate cleaning apparatus, substrate cleaning method, and computer-readable storage medium

A technology for cleaning devices and substrates, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as damage to the periphery of wafers, and achieve the effect of compact developing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In the embodiments described below, a cleaning device of a type provided on a coating and developing device as an example of a substrate cleaning device (hereinafter referred to as a cleaning device) will be described. A specific example of the photolithography process including the cleaning process of this cleaning device will be described later, but this cleaning device is installed near the exit of the coating and developing device, for example, to clean the back surface of the wafer on which the resist film is formed. After cleaning, the wafer is transported to the subsequent exposure equipment.

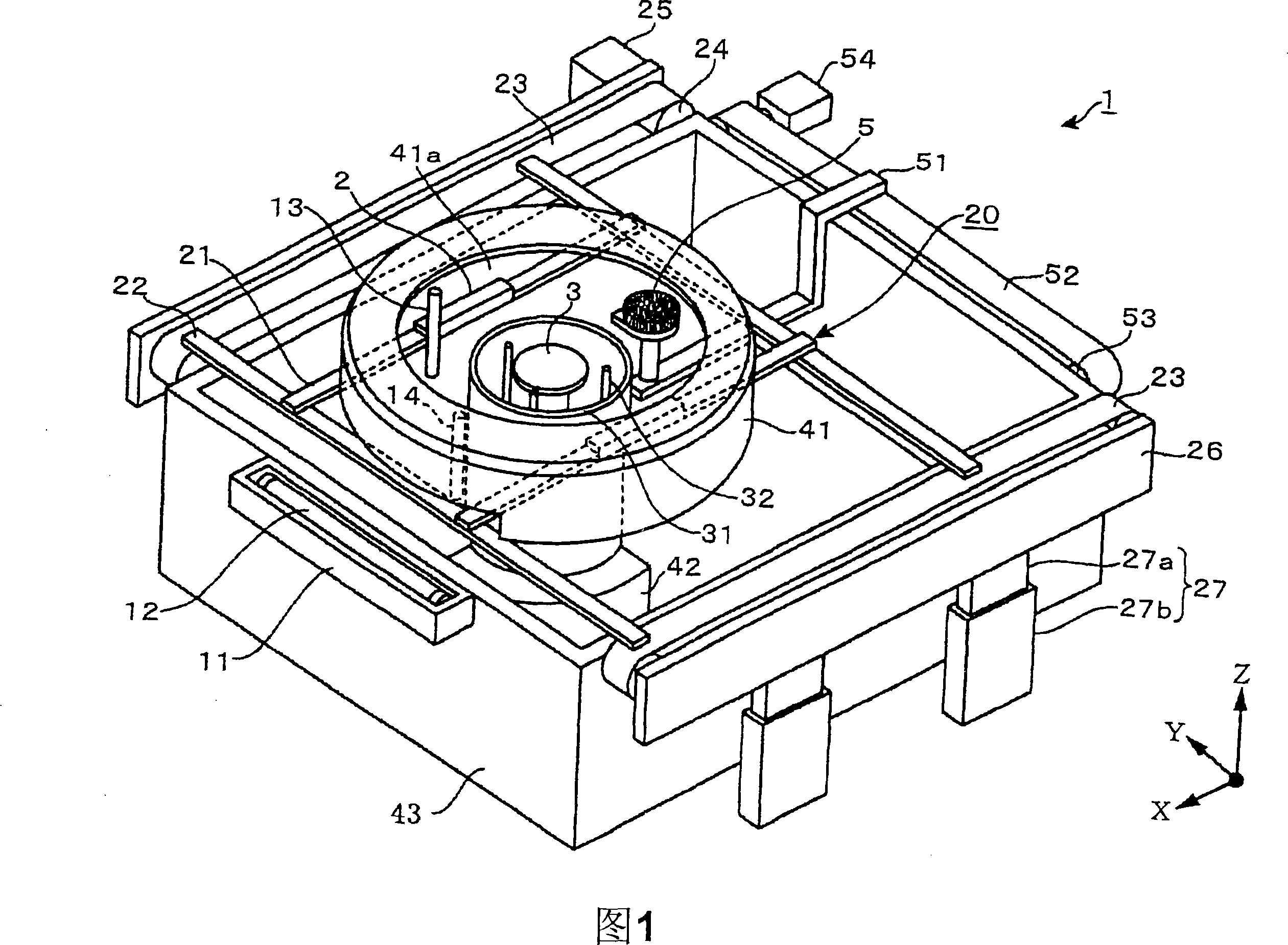

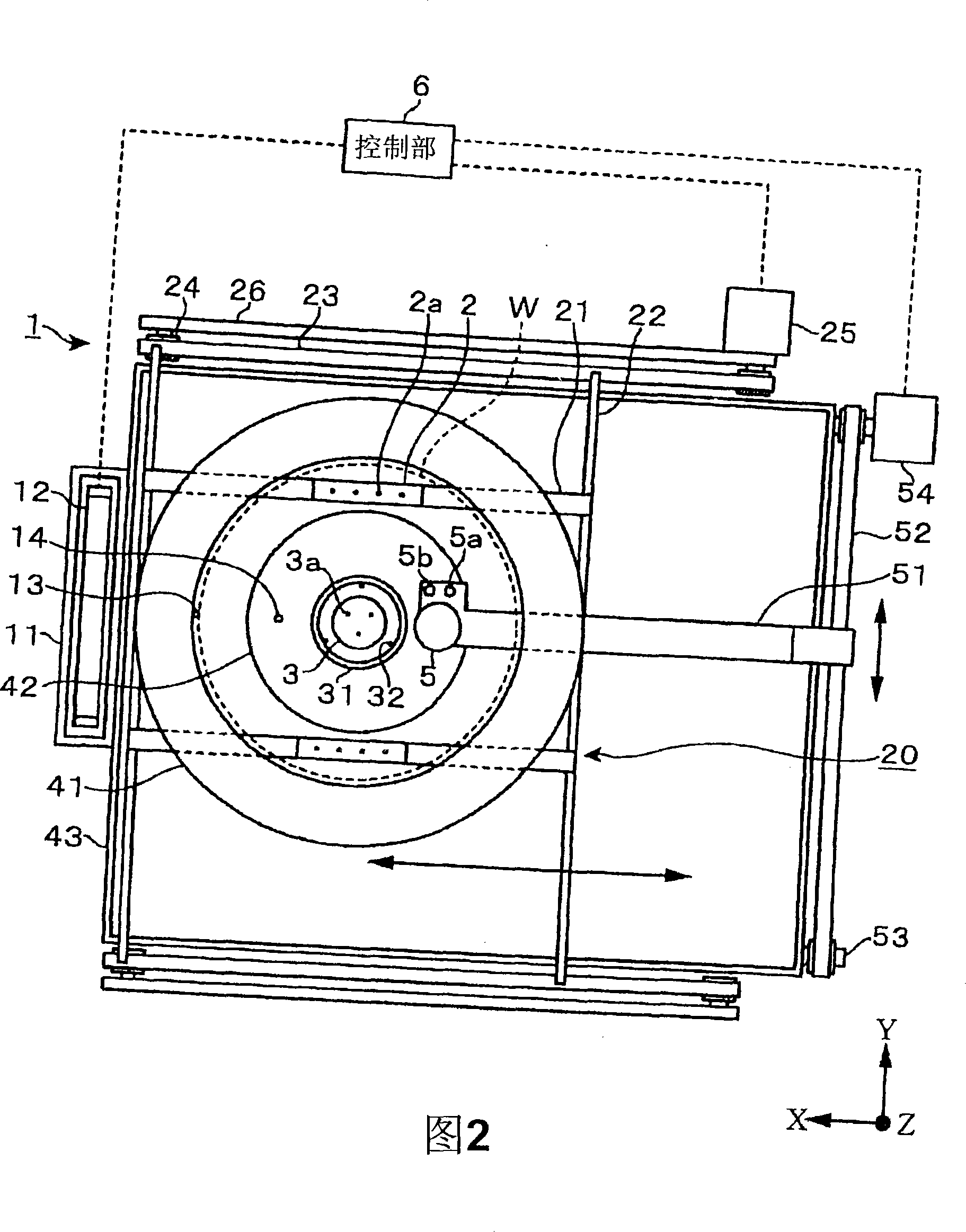

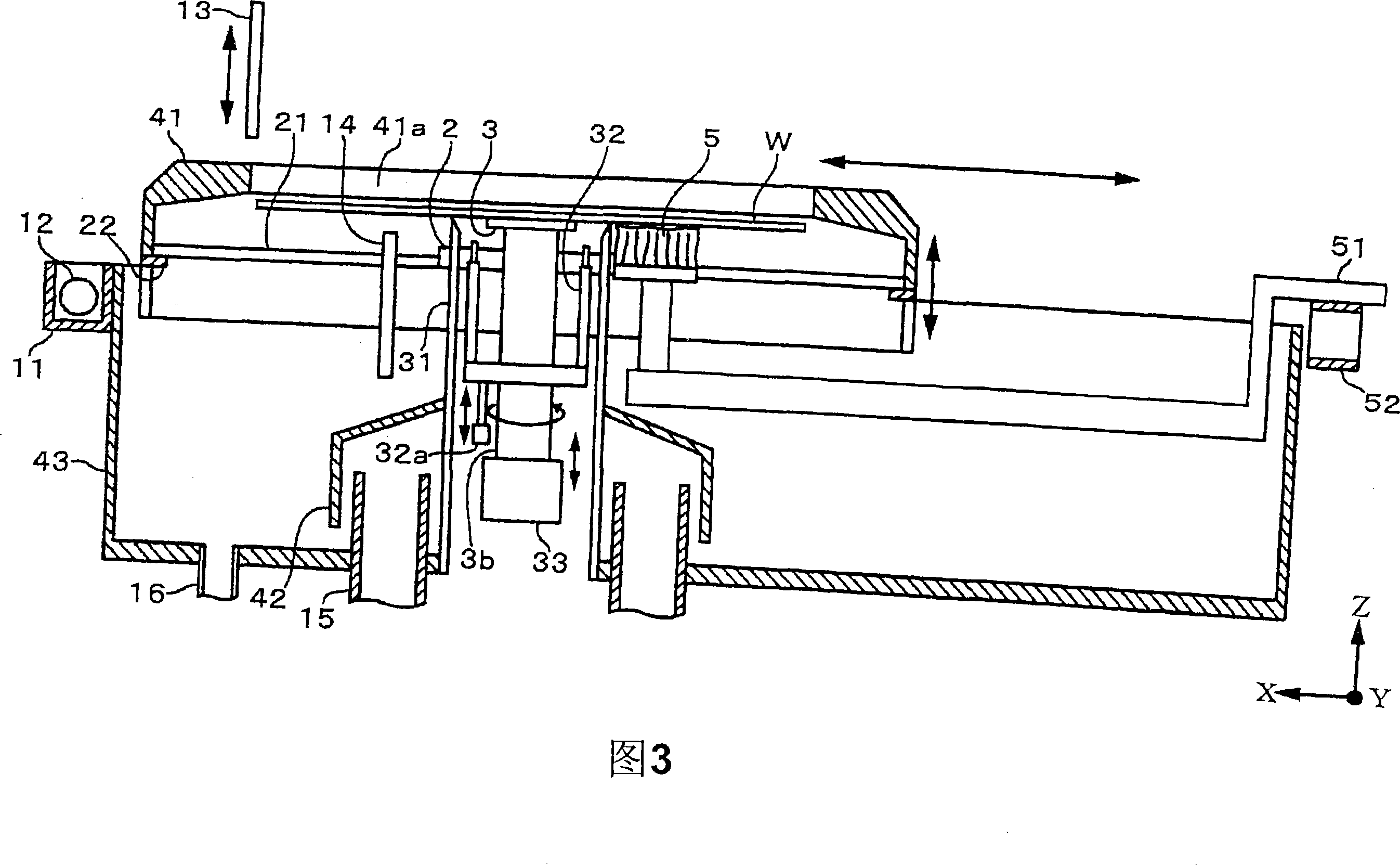

[0103] First, the configuration of the cleaning device according to the present embodiment will be described with reference to FIGS. 1 to 3 . FIG. 1 is a perspective view showing a cleaning device 1 , FIG. 2 is a plan view showing it, and FIG. 3 is a longitudinal sectional view showing it.

[0104] As shown in FIG. 1 , the cleaning device 1 is a first substrate holding un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap