Rope cable joint for safety belt connector and component containing the rope cable joint and the rope cable

A technology for connecting parts and seat belts, which is applied in the directions of seat belts, transmission elements or pulleys, textile cables, etc., can solve problems such as increasing the production cost of fastening components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

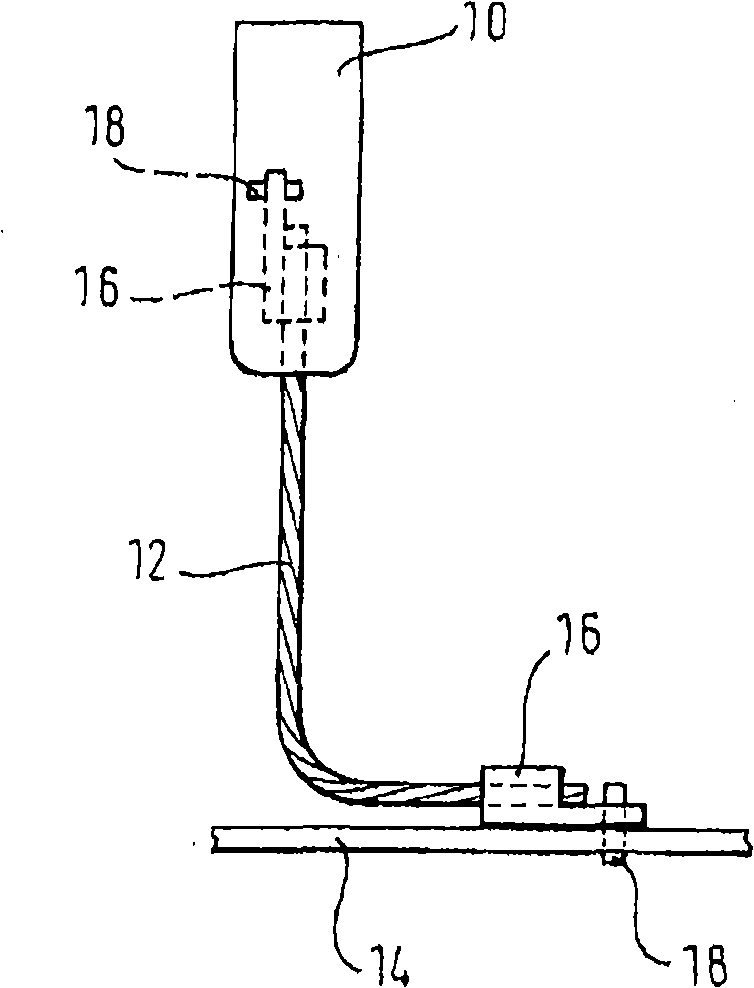

[0021] figure 1 A belt buckle 10 is schematically shown into which a seat belt insert tongue (not shown) is inserted. The belt buckle 10 is fastened to a vehicle body sheet metal part 14 by means of a cable 12 . To this end, first and second ends of the cable 12 are received in first and second cable joints 16, respectively. The first and second cable joints 16 are adapted to receive a fastening device 18 which fixes the belt buckle 10 in place at the first cable joint 16 and by which the second rope can be fastened. The cable joint 16 is fastened to the vehicle body sheet metal part 14 .

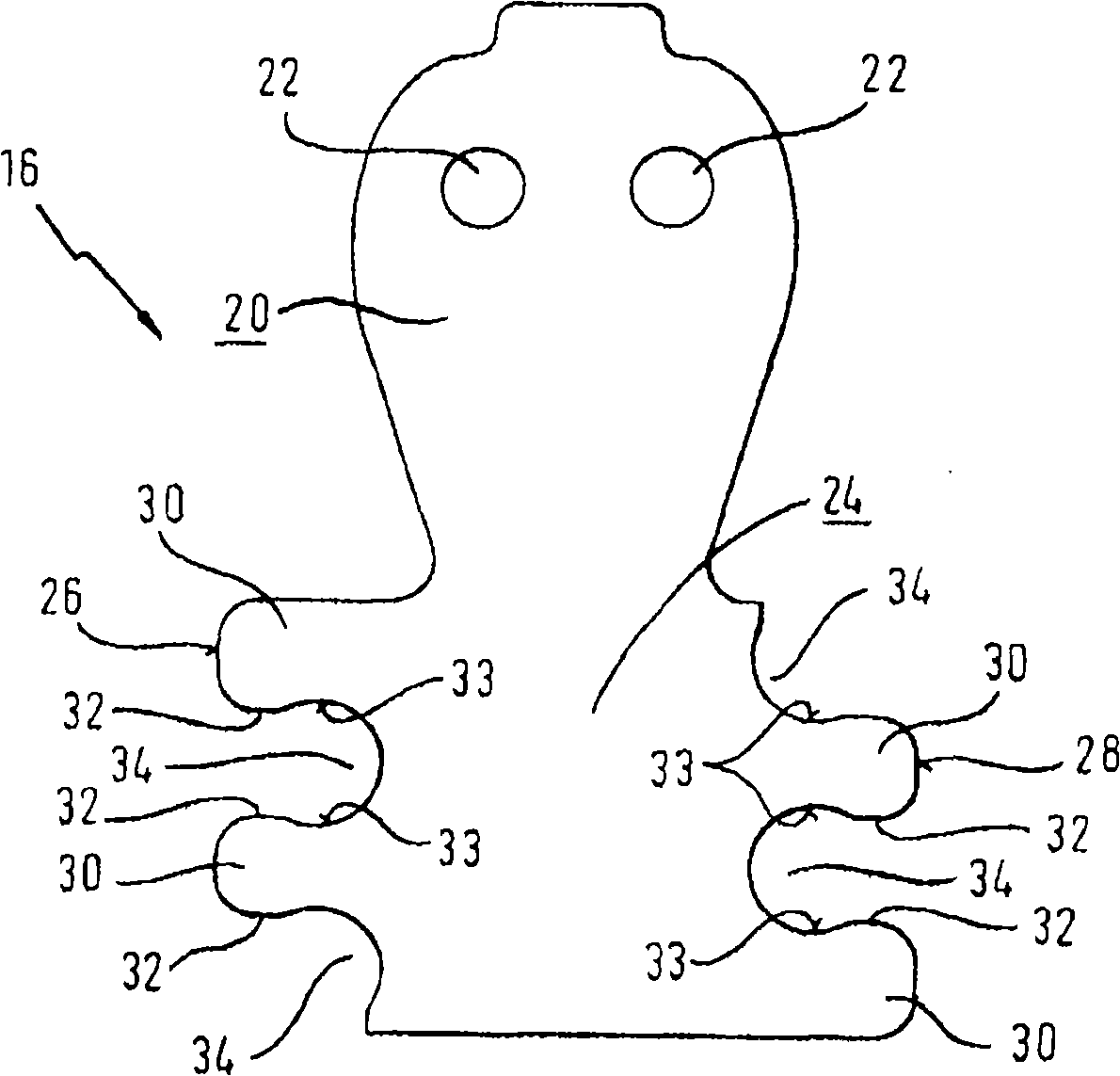

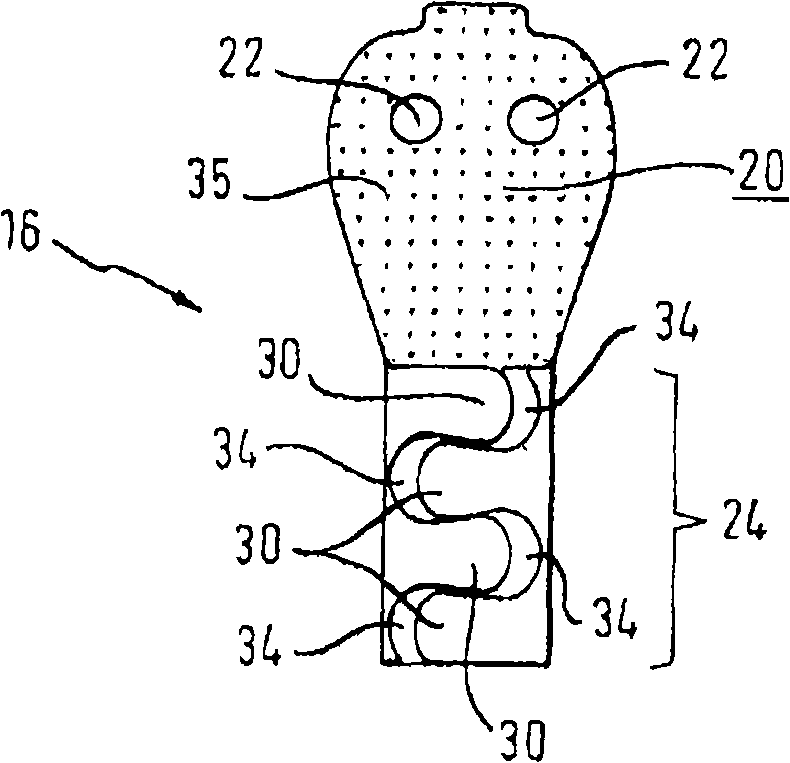

[0022] The cable connector 16 that couples the belt buckle 10 to the cable 12 and the cable connector 16 that secures the cable 12 to the vehicle body are of the same design and each comprise a stamped sheet metal part that is figure 2 is shown still in the unbent state. The cable connector 16 has a fastening section 20 with a pair of openings 22 adapted to receive the fastening device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com