Filter unit for an extruder system, filter arrangement and sieve changing device

A technology of filter and extruder, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc. It can solve the problems of filter unit pressure drop, etc., and achieve the effect of simple replacement and optimized production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

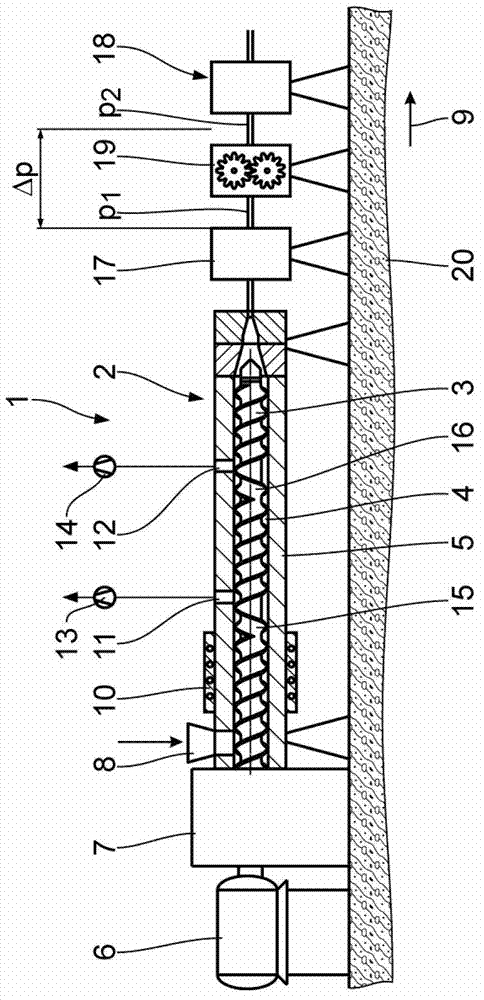

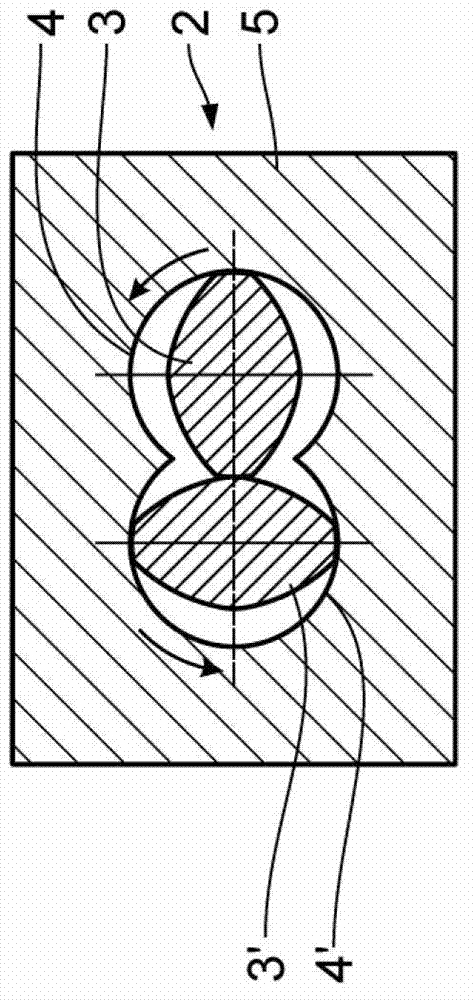

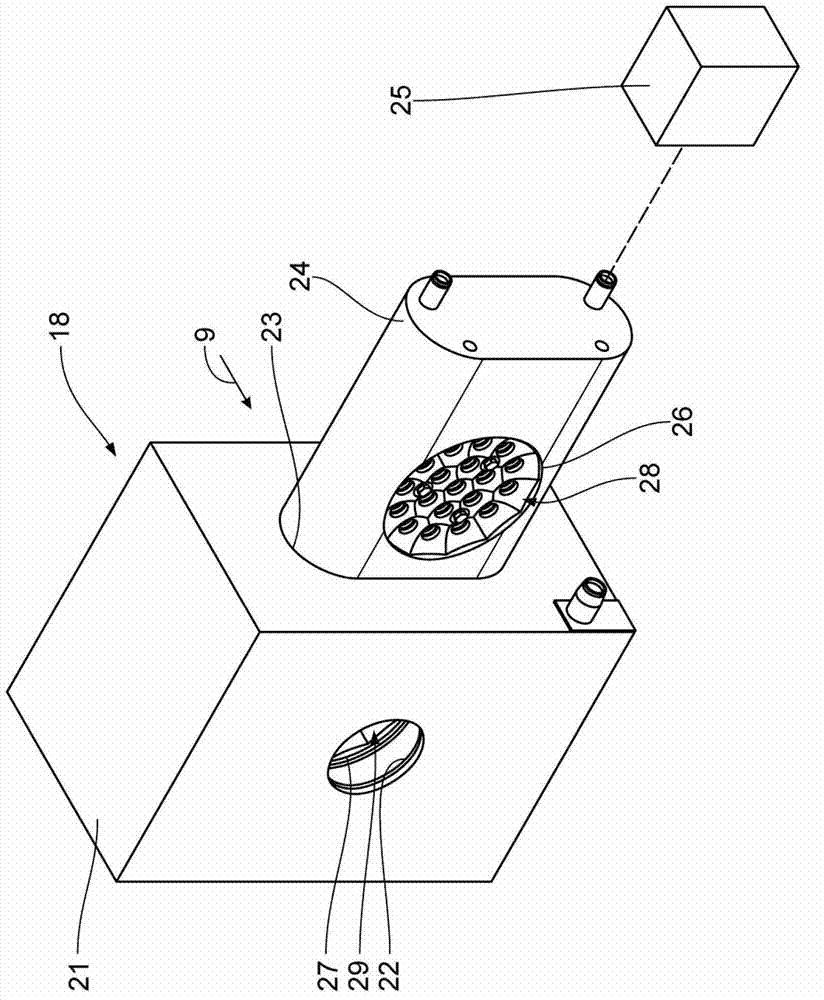

[0030]For processing plastics, the extruder system 1 has a twin-screw extruder 2 which is constructed in a conventional manner. The extruder 2 has two worm shafts 3, 3'. These worm shafts are arranged in corresponding bores 4, 4' The worm shafts 3, 3' are configured to closely mesh and rotate in the same direction. The worm shafts 3, 3' are driven by an electric motor 6 through a reduction and distribution gear unit 7 to which the housing 5 is flanged.

[0031] In the vicinity of the gear unit 7 , in other words at the upstream end of the extruder 2 , a feed funnel 8 opens into the housing 5 . The housing 5 is provided with a heater 10 in the conveying direction 9 after the funnel 8 . Thereafter two degassing openings 11 , 12 opening outwards from the housing 5 are provided consecutively in the conveying direction 9 , which are connected to vacuum pumps 13 , 14 respectively. A damming mechanism 15 , 16 in the form of a worm section conveying opposite the conveying dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com