Telescopic dental formula residual film gathering method and mechanism of non-circular gear planets

A technology for picking up non-circular gears and residual film, which can be used in collectors, agricultural machinery and implements, and applications, and can solve problems such as serious cam wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

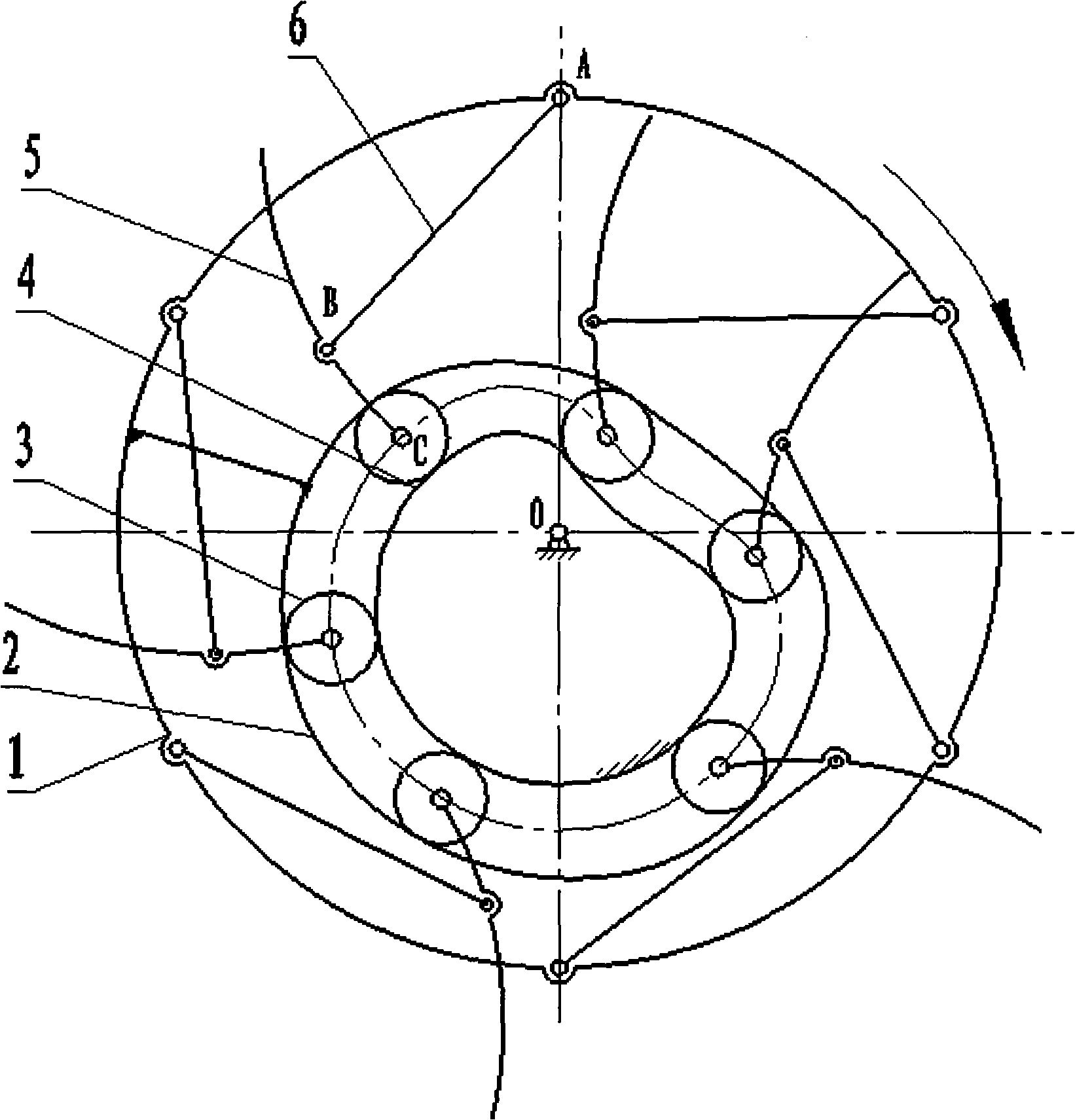

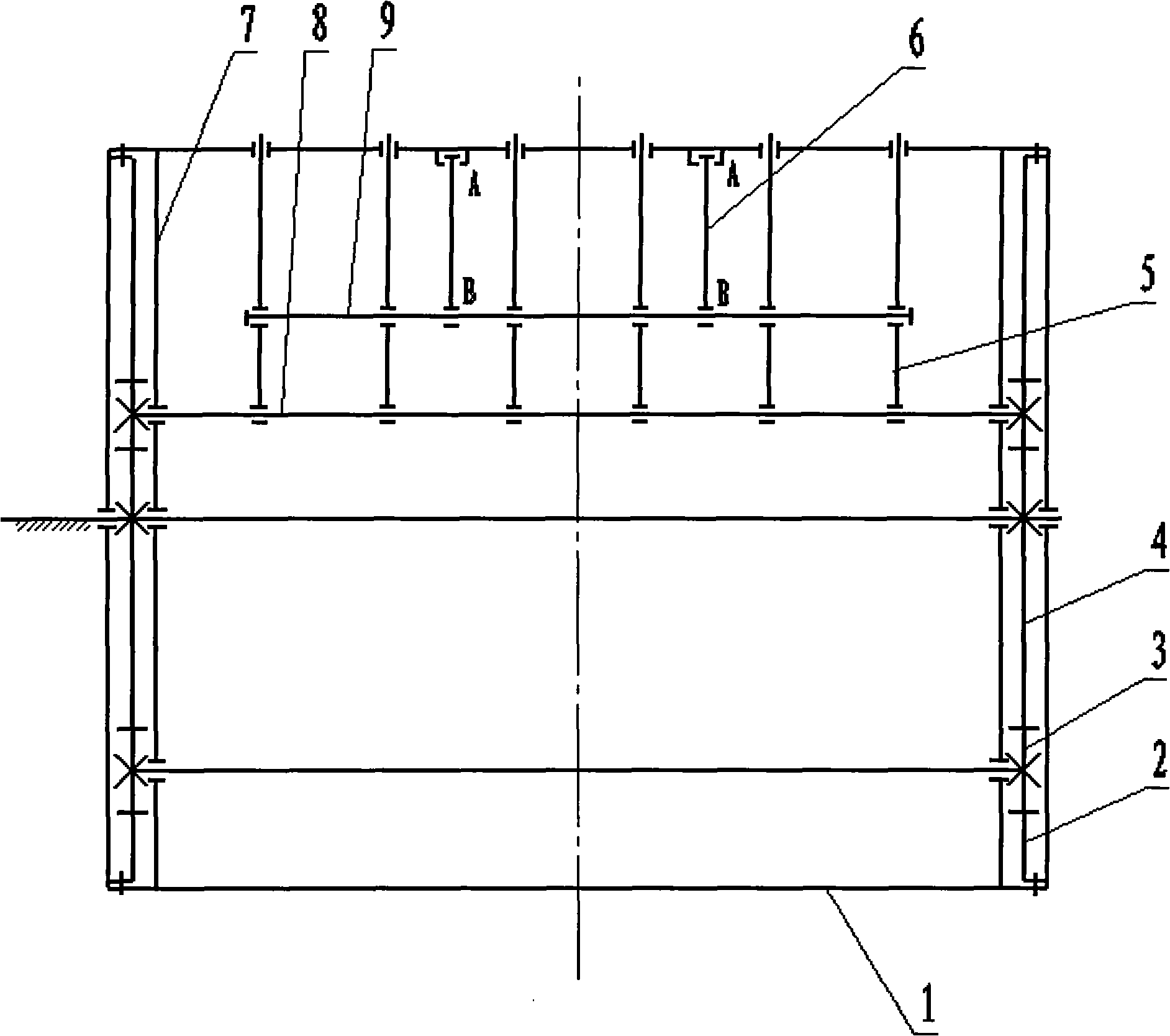

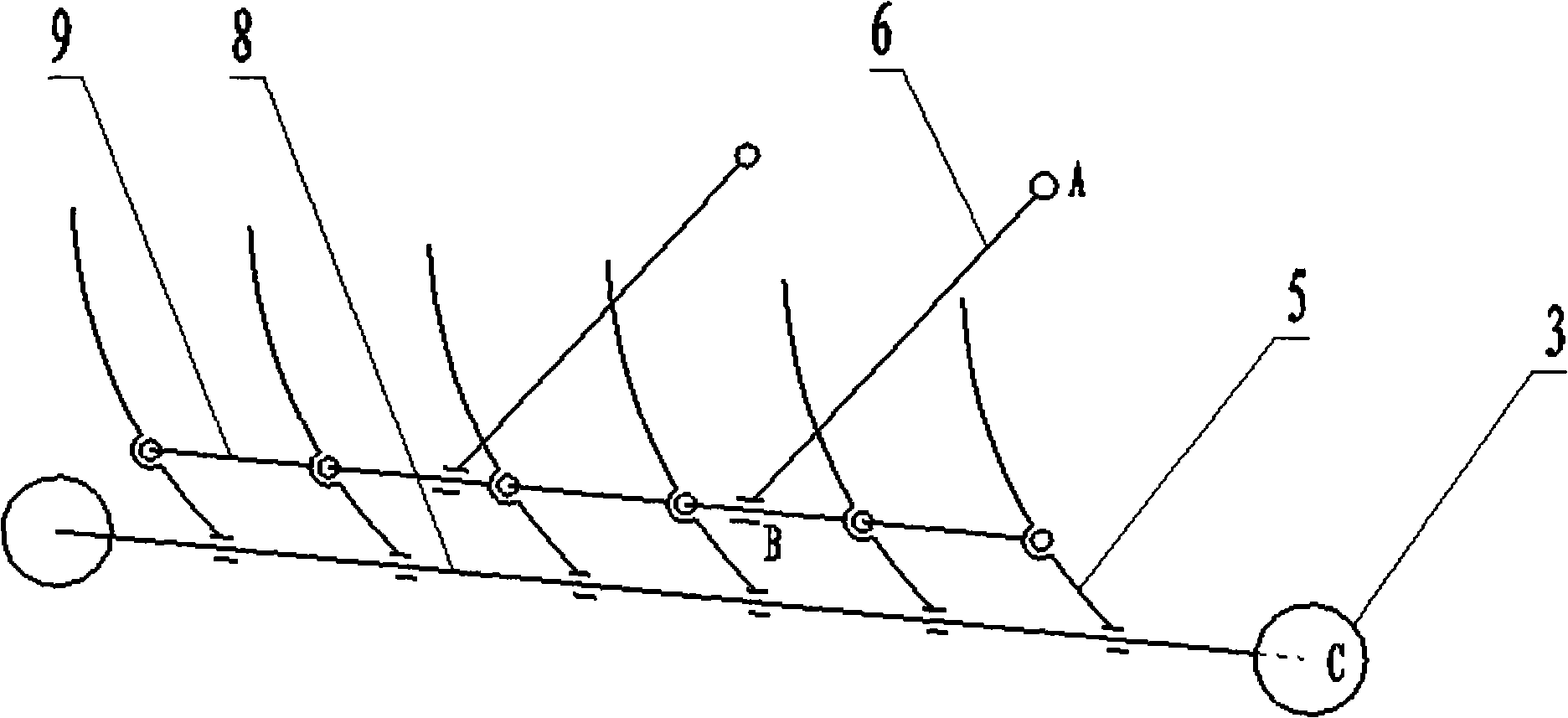

[0020] like figure 1 , figure 2 , image 3 As shown, a non-circular internal gear 2 is fixed in the residual film pick-up drum 1, the non-circular internal gear 2 and the planetary cylindrical gear 3 are internally meshed, the planetary cylindrical gear 3 and the central sun non-circular gear 4 are externally meshed, and the film-picking gear 5 The looper is set on the planetary shaft, the film pick-up tooth 5 is connected with the rod 6 at the position B by a hinge, and the other end A of the rod 6 is connected with the drum 1 by a hinge.

[0021] The central sun non-circular gear 4 is fixed during operation, and its pitch curve is the movement track of the wheel center of the planetary cylindrical gear 3, which is coaxial with the non-circular internal gear 2.

[0022] The average revolution speed of the planetary cylindrical gear 3 is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com