Droplet jetting applicator and method for manufacturing coated body

A droplet spraying and coating device technology, applied in printing and other directions, can solve problems such as poor jetting, ink oozing, bubble suction, etc., and achieve the effect of suppressing poor jetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

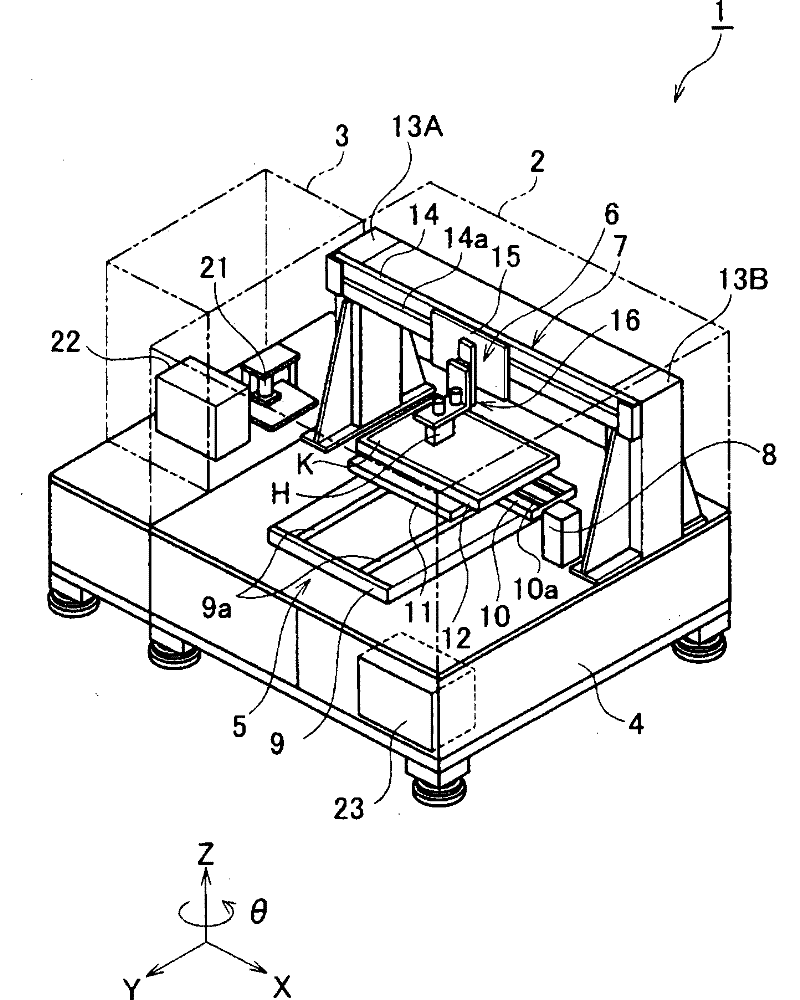

[0022] Below, refer to Figure 1 to Figure 3 The first embodiment of the present invention will be described.

[0023] like figure 1 As shown, the droplet ejection application device 1 according to the first embodiment of the present invention includes an ink application cartridge 2 and an ink supply cartridge 3 . The ink application cartridge 2 applies ink, which is a liquid, onto the substrate K of the object to be coated as droplets. The ink supply cartridge 3 supplies ink to the ink application cartridge 2 . The ink application cartridge 2 and the ink supply cartridge 3 are fixed adjacently on the upper surface of the stand 4 .

[0024] Inside the ink application cartridge 2, there are provided a substrate moving mechanism 5 that holds the substrate K and moves it in the X-axis direction and the Y-axis direction, and has a droplet ejection head that ejects droplets to the substrate K on the substrate moving mechanism 5. A droplet ejection head unit 6 of H, a unit movin...

no. 2 Embodiment approach

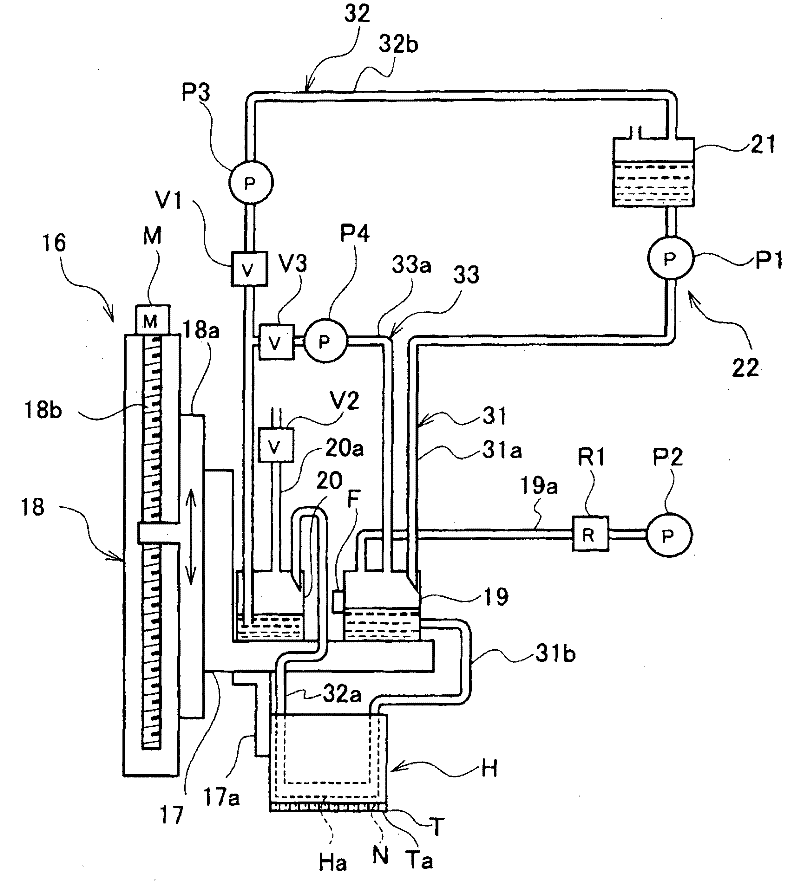

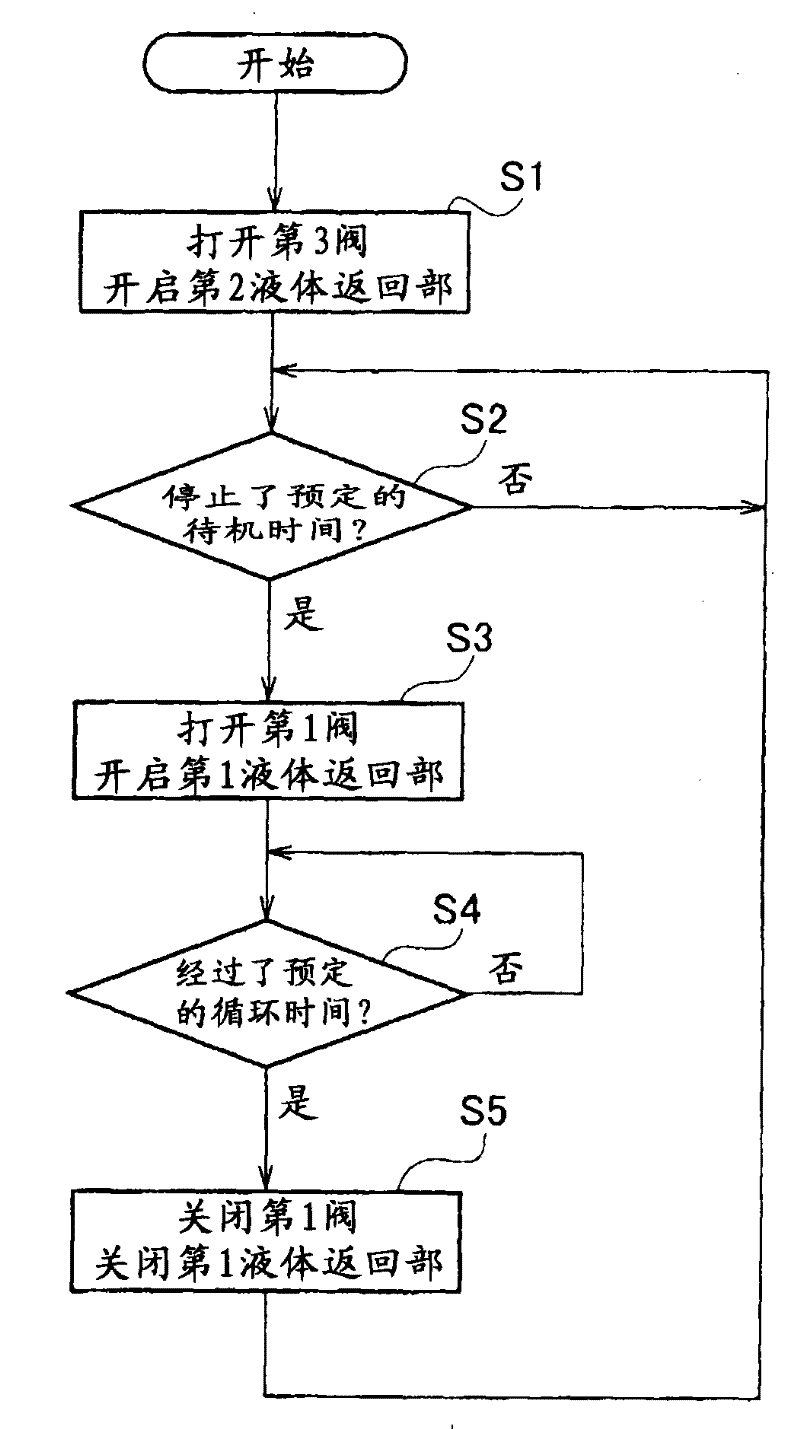

[0072] Below, refer to Figure 4 to Figure 6 , and the second embodiment of the present invention will be described.

[0073] The second embodiment of the present invention is a modified example of the first embodiment. Therefore, only the parts that are different from the first embodiment, that is, the parts related to the ink circulation and the ink circulation operation of the droplet ejection coating apparatus 1 will be described. In the second embodiment, descriptions of the same parts as those in the first embodiment are omitted.

[0074] In the droplet spray coating device 1 according to the second embodiment of the present invention, as Figure 4 As shown, in the liquid supply channel 31, a liquid supply part P1, a fourth valve V4, and a first buffer tank 19 (first buffer liquid storage part) are provided in this order from the liquid storage part 21 side. Therefore, the liquid supply flow path 31 includes the first buffer tank 19, includes a flow path 31c communica...

no. 3 Embodiment approach

[0100] Below, refer to Figure 7 A third embodiment of the present invention will be described.

[0101] The third embodiment of the present invention is a modified example of the first embodiment. Therefore, only the discharge mechanism 51 which is a part different from the first embodiment will be described. In this third embodiment, the description of the same parts as those in the first embodiment is omitted.

[0102] In the droplet spray coating device 1 according to the third embodiment of the present invention, as Figure 7 As shown, a discharge mechanism 5 is provided in the ink application cartridge 2 . The discharge mechanism 5 discharges the trial coating substrate (coating object for trial coating) Ka to the outside on which the liquid droplet jetting head H has trial coated (test jetted) the liquid droplets. The sample coating substrate Ka ejected by the ejection mechanism 51 is received by the sample extraction cassette 52 for extraction.

[0103]The dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com