Liquid supplying device and liquid ejecting apparatus

A liquid supply, liquid technology, applied in printing and other directions, can solve problems such as hindering pump driving efficiency and slowly attracting ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

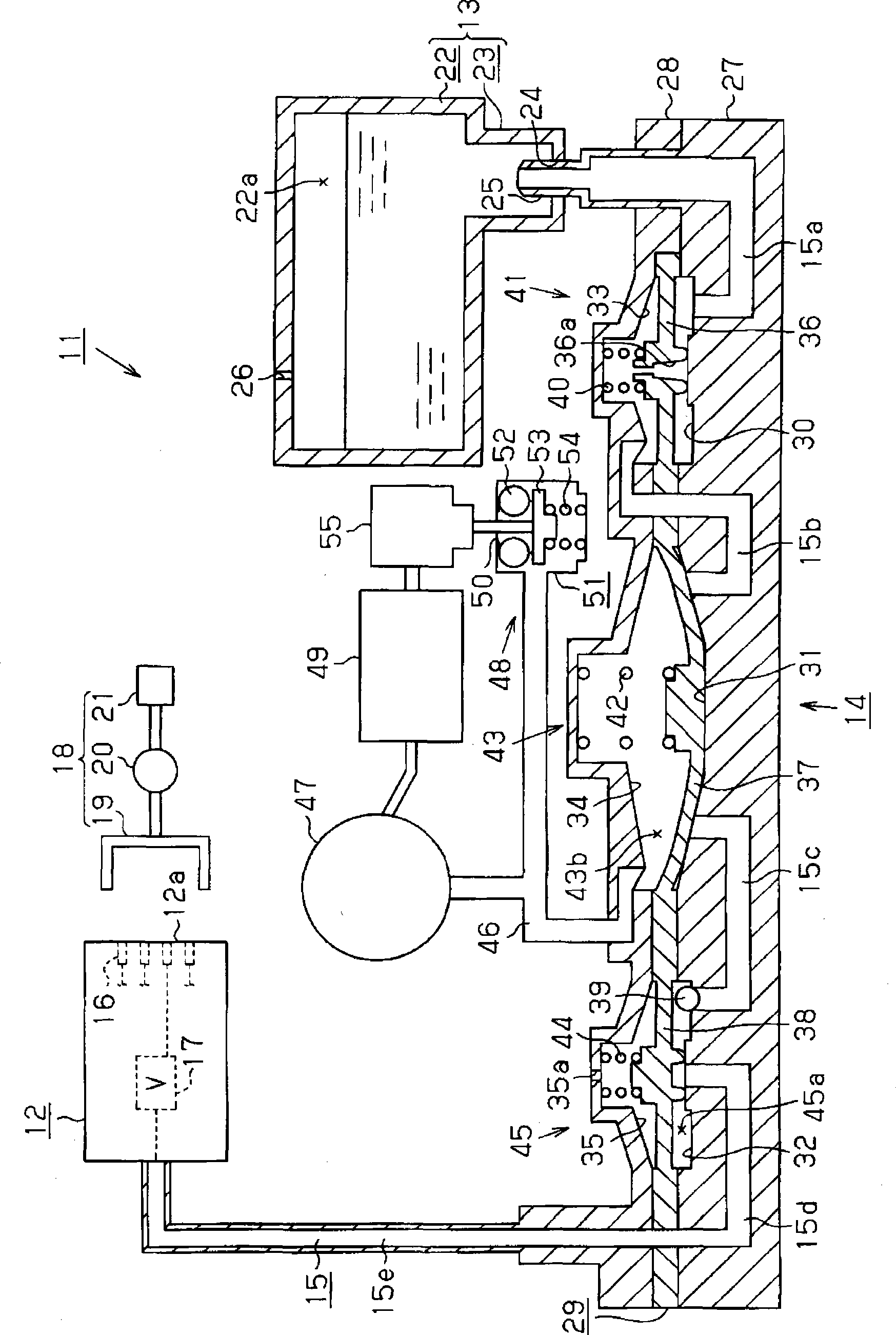

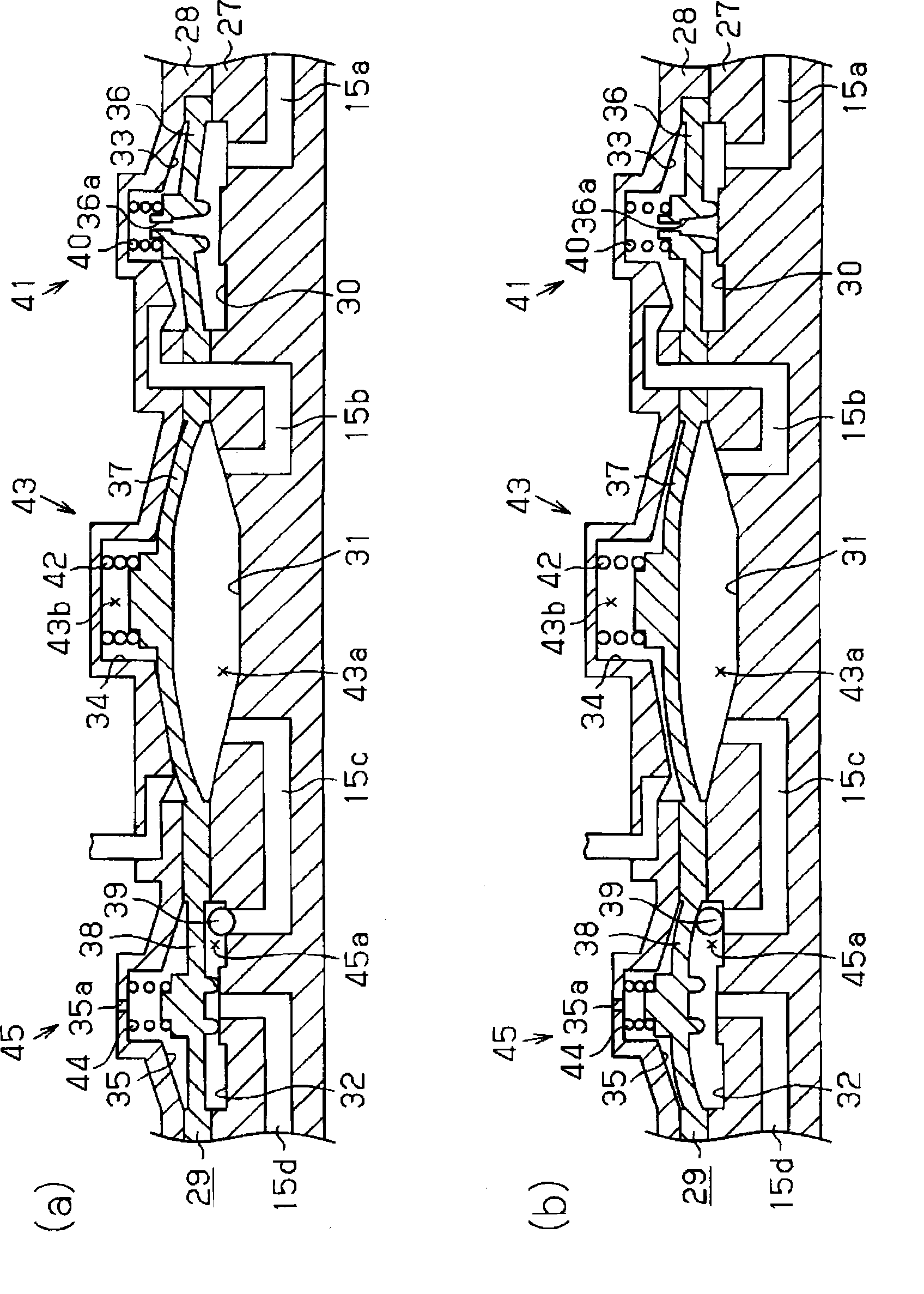

[0041] Below, refer to Figure 1 ~ Figure 3 Next, a first embodiment of an inkjet recording device (hereinafter referred to as a printer) that embodies the present invention as a type of liquid ejecting device will be described.

[0042] Such as figure 1 As shown, the printer 11 of this embodiment has: a recording head 12 serving as a liquid ejecting head that ejects ink (liquid) to a target (not shown); An ink supply device 14 serving as a liquid supply device for ink. The ink supply device 14 is provided with an ink flow that supplies ink from the upstream side on the ink cartridge 13 side to the downstream side on the recording head 12 side in a state where the upstream end is connected to the ink cartridge 13 and the downstream end is connected to the recording head 12. path (liquid supply flow path) 15.

[0043] In addition, in the printer 11 , a plurality of ink supply devices 14 are provided corresponding to the number (type) of colors of ink used in the printer 11 ....

no. 2 approach

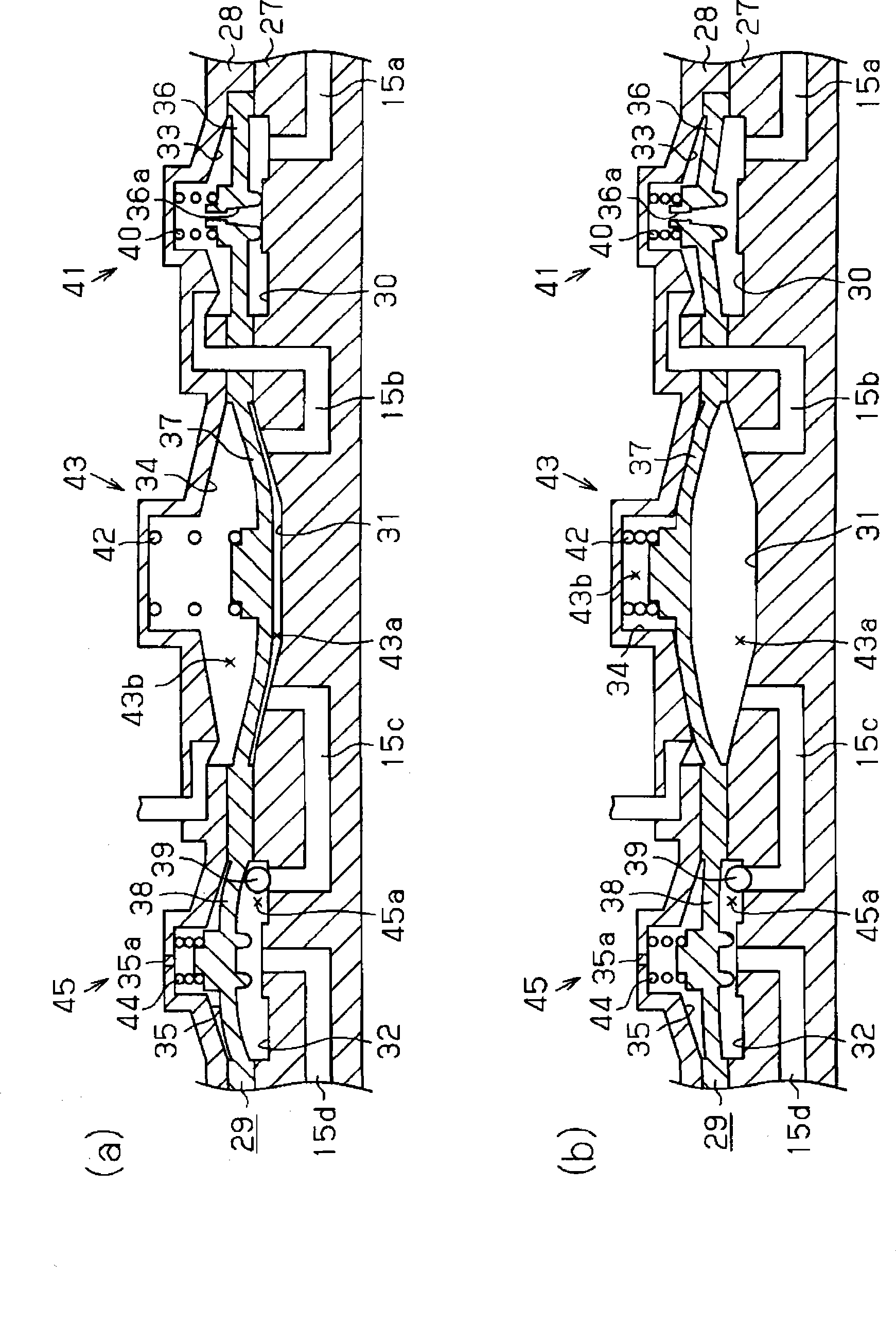

[0091] Below, refer to Figure 4 A second embodiment of the present invention will be described. However, since the second embodiment differs from the first embodiment only in that the shape of the suction side valve 41 is changed, and other structures are common, the same components are given the same reference numerals and detailed descriptions are omitted.

[0092] Such as Figure 4 As shown, when the suction-side valve body 36 of this embodiment is located at the top dead center position, the opening portion serving as the downstream end of the through-hole 36a abuts against the inner surface of the recess 33, and the through-hole 36a forming a part of the ink flow path 15 is closed. closed state (see Figure 4 (c)). And, in the surface of the outer surface of the suction side valve body 36 that faces the inner surface of the recessed part 33, there is formed an upstream valve body that is located at the top dead center position and is in contact with the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com