Gas supply system and integrated unit for semiconductor manufacturing device

A technology for gas supply and manufacturing equipment, which is applied in semiconductor/solid-state device manufacturing, electrical components, and gases from chemical reactions, etc. It can solve problems such as pattern defects and deterioration of electrical characteristics, and achieve the effect of suppressing incorporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0026] (Structure Example of Semiconductor Manufacturing Equipment)

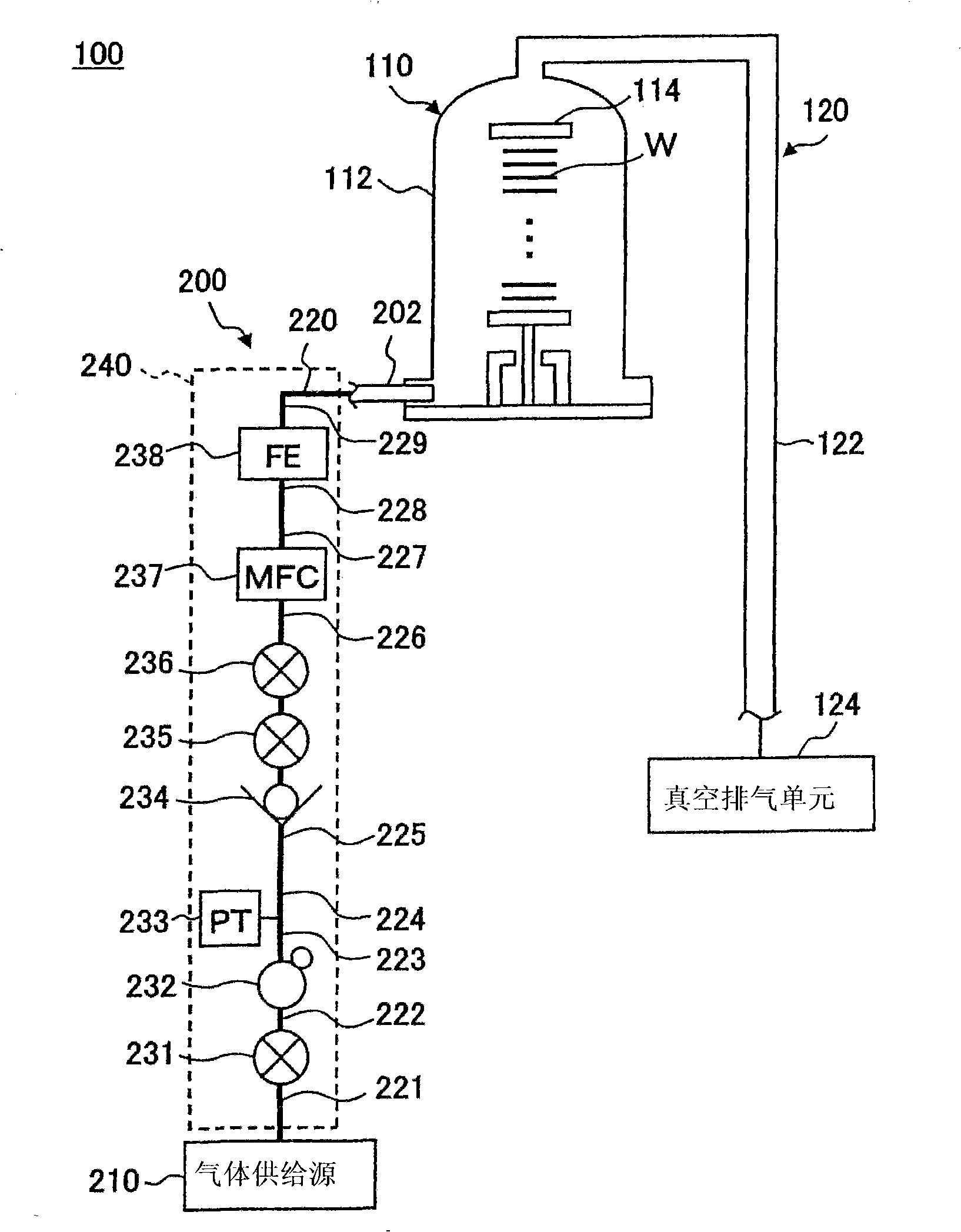

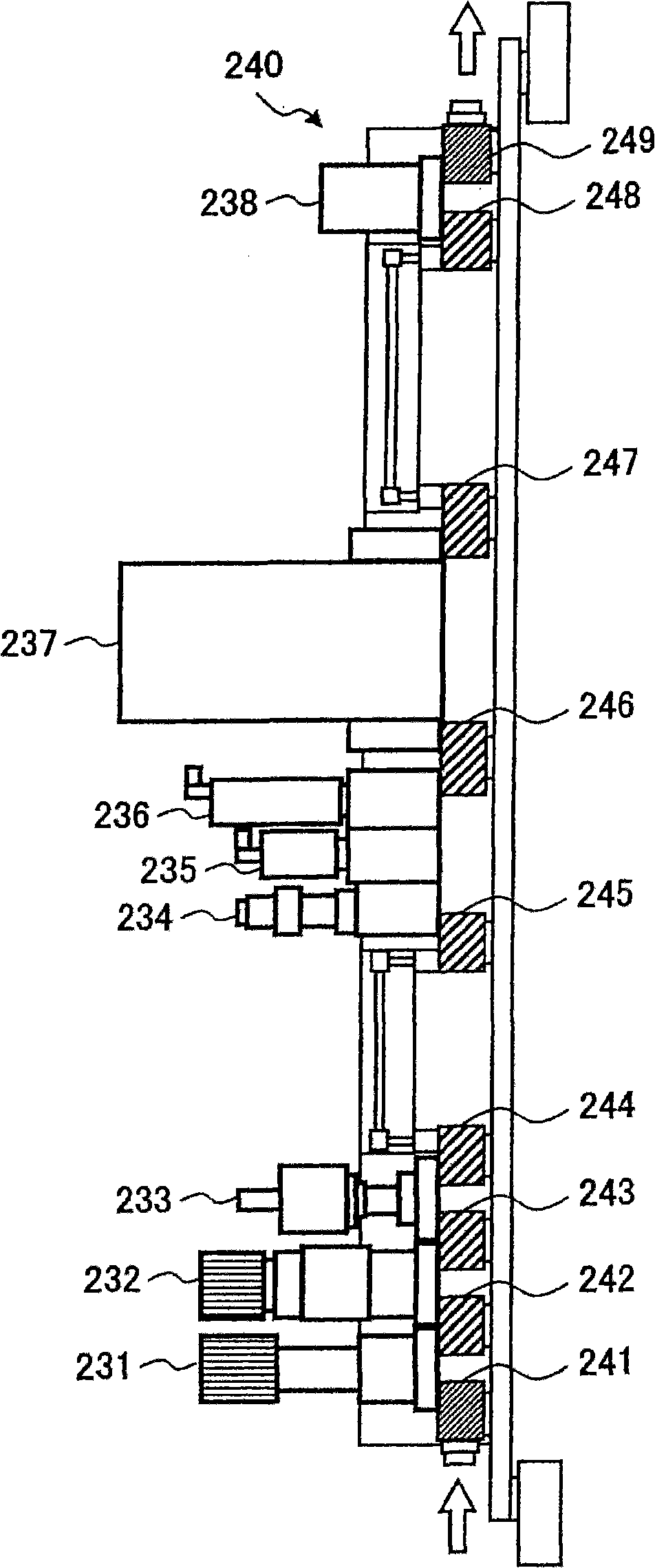

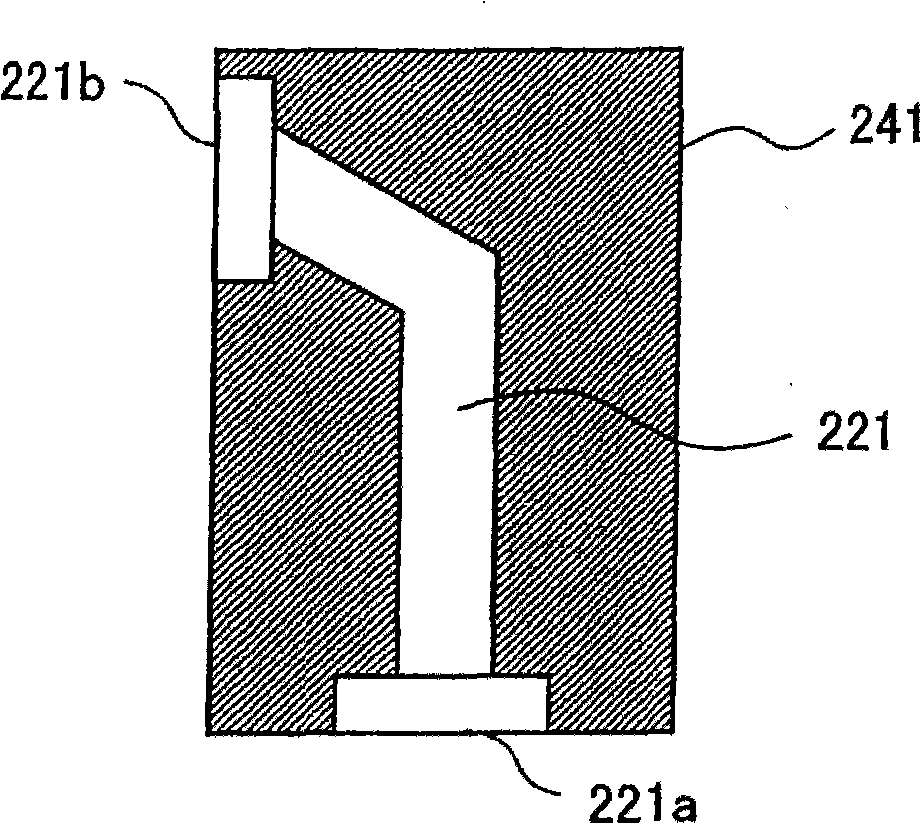

[0027] First, an embodiment in which the gas supply system of the present invention is applied to a semiconductor manufacturing apparatus will be described with reference to the drawings. Here, as a semiconductor manufacturing apparatus, a heat treatment apparatus for performing predetermined heat treatment on a substrate such as a semiconductor wafer (hereinafter also referred to simply as “wafer”) will be described as an example. figure 1 It is a figure which shows the structural example of the heat processing apparatus of this embodiment.

[0028] The heat treatment apparatus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com