Double-walled carbon nanotube, bulk structure of the same, method and apparatus for producing them

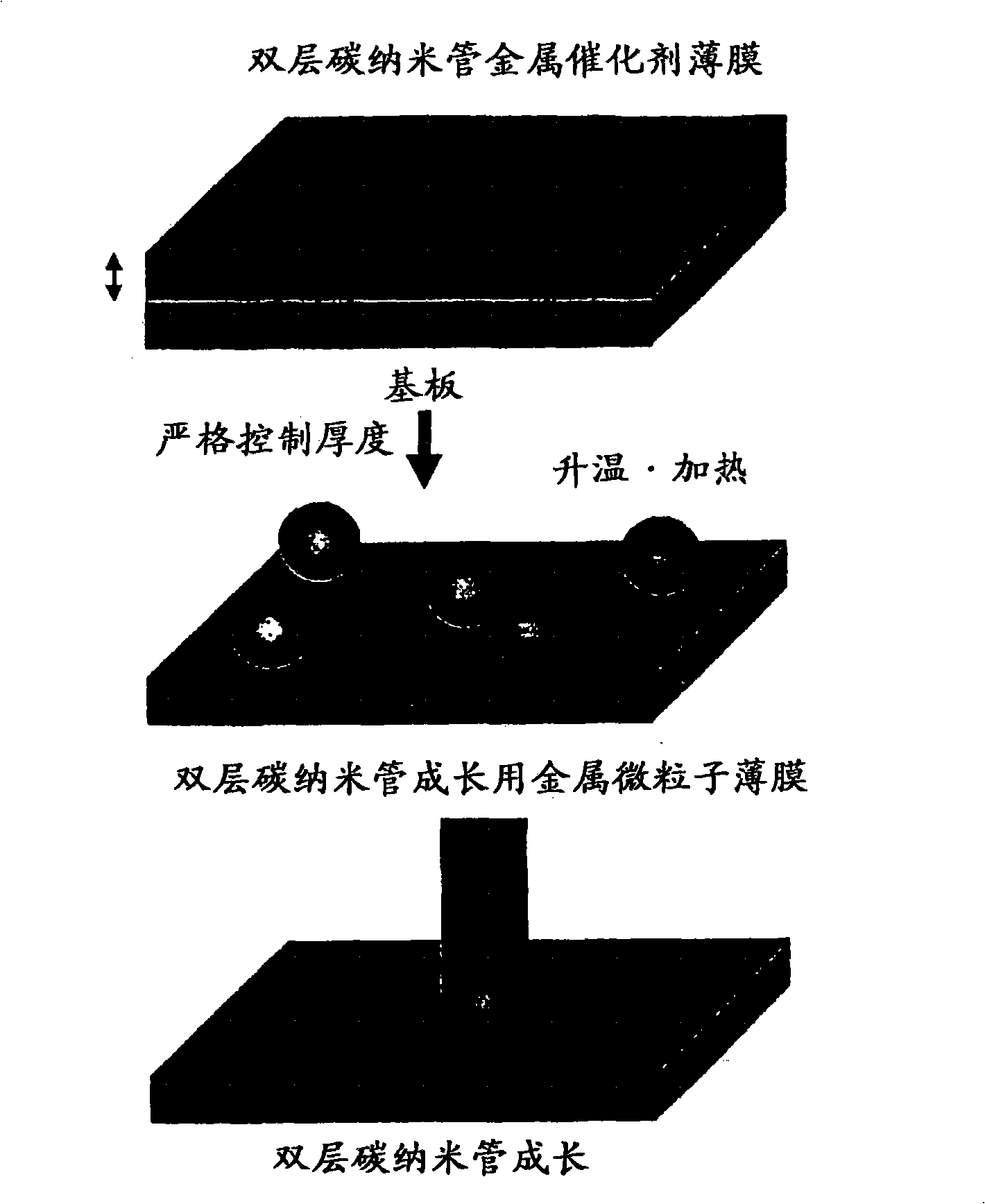

A multi-layer carbon nanotube, carbon nanotube technology, applied in nanostructure manufacturing, carbon nanotubes, oriented carbon nanotubes and other directions, can solve the problems of difficult control, non-orientation, difficult to precise control, etc., to achieve mass production Effects of production, high growth rate, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

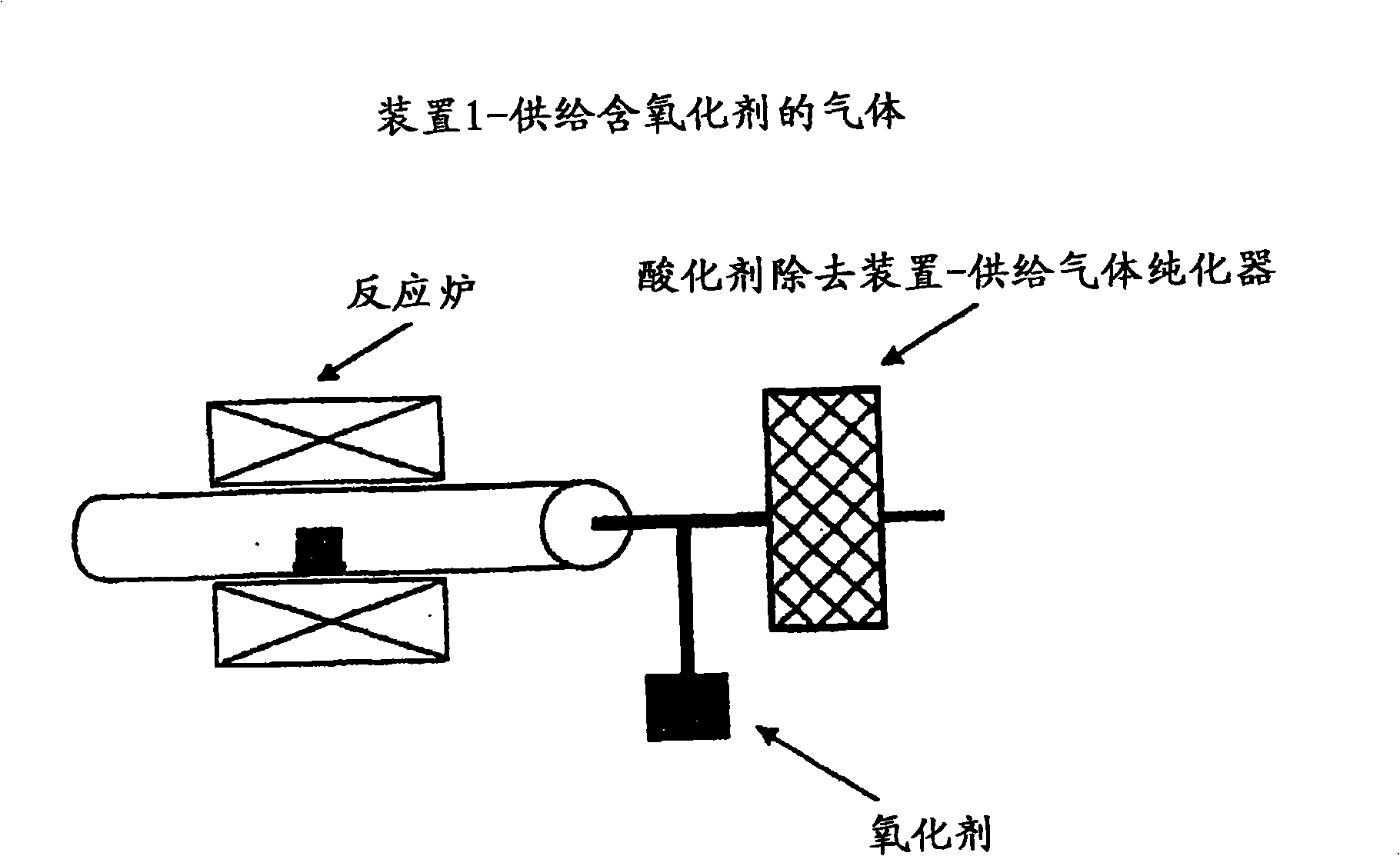

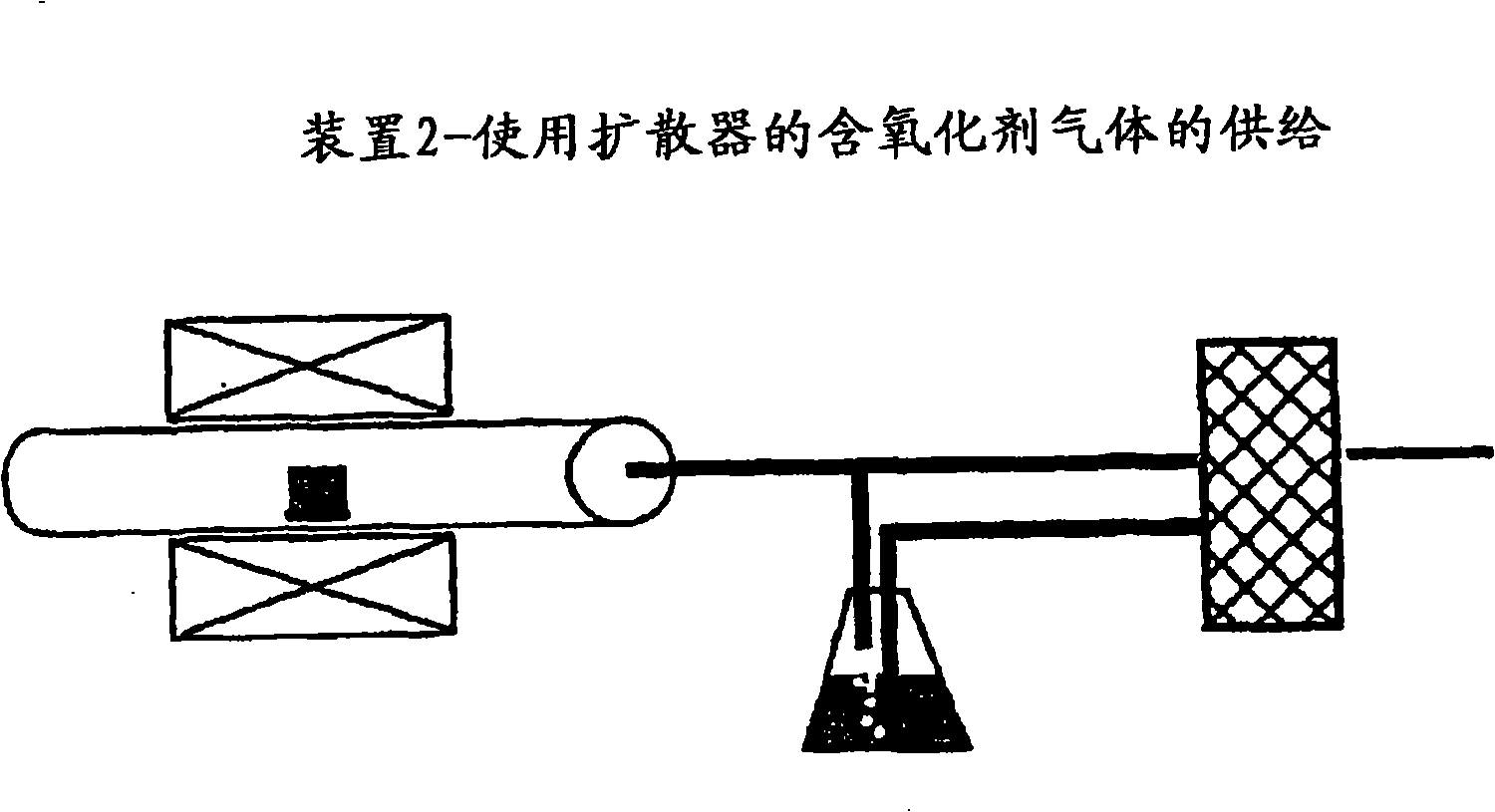

Method used

Image

Examples

Embodiment 1

[0173] Carbon nanotubes were grown by the CVD method under the following conditions.

[0174] Carbon compound: Ethylene, supply speed 200sccm

[0175] Atmosphere (Pa): Mixed gas of helium and hydrogen, supply speed 2000sccm

[0176] Pressure: atmospheric pressure

[0177] Water vapor addition amount (ppm): 300ppm

[0178] Reaction temperature (°C): 750°C

[0179] Response time (minutes): 30 minutes

[0180] Metal catalyst (existing amount): Iron thin film, thickness 1.69nm

[0181] Substrate: silicon wafer

[0182] In addition, the disposition of the catalyst on the substrate was vapor-deposited using a sputtering vapor-deposition apparatus.

[0183] Fig. 10 shows the appearance of the monolithic structure of vertically aligned double-layered carbon nanotubes grown according to the above conditions. The front in the figure is a ruler. A vertically oriented bilayer carbon nanotube film with a height of 2.2 mm is grown on the underlying silicon wafer. The SEM image of t...

Embodiment 2

[0186] Carbon nanotubes were grown by the CVD method under the following conditions.

[0187] Carbon compound: Ethylene, supply speed 100sccm

[0188] Atmosphere (Gas): Helium, hydrogen mixed gas, supply speed 1000sccm

[0189] Pressure: atmospheric pressure

[0190] Water vapor addition amount (ppm): 300ppm

[0191] Reaction temperature (°C): 750°C

[0192] Response time (minutes): 10 minutes

[0193] Metal catalyst (existing amount): Iron thin film, thickness 1.69nm

[0194] Substrate: silicon wafer

[0195] In addition, the disposition of the catalyst on the substrate was performed by sputtering vapor deposition.

[0196] Figures 12 to 14 show that the vertically aligned double-layered carbon nanotubes manufactured in Example 2 are peeled off from the substrate with a dot needle combination, and the sample dispersed in the solution is placed on the grid of an electron microscope (TEM), Photographs observed with an electron microscope (TEM). It is known that no catal...

Embodiment 3

[0201] Carbon nanotubes were grown by the CVD method under the following conditions.

[0202] Carbon compound: Ethylene, supply speed 100sccm

[0203] Atmosphere (Gas): Mixed gas of helium and hydrogen, supply speed 1000sccm

[0204] Pressure: atmospheric pressure

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com