Hexafluoride sulphur circuit breaker with heating protecting equipment

A technology of sulfur hexafluoride and heating protection, applied in high-voltage air circuit breakers, ohmic resistance heating parts, circuits, etc., can solve problems such as insulation strength reduction, accident expansion, large electric arcing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

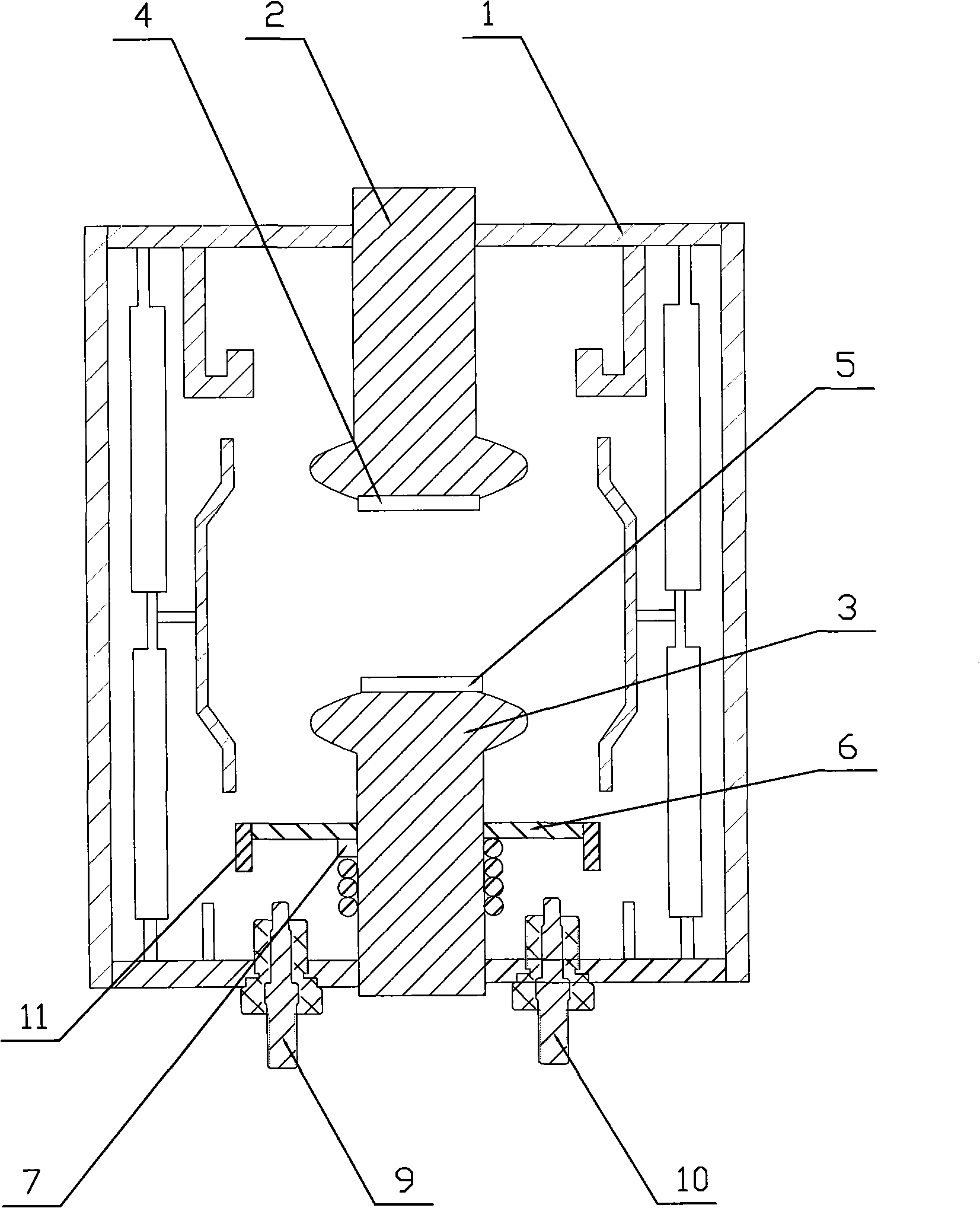

[0012] like figure 1 Shown: Same as the prior art, there is an insulating sealed casing 1, and an upper insulating pull rod 2, a lower insulating pull rod 3, and an upper insulating pull rod 2 and a lower insulating pull rod 3 are respectively fixed in the insulating sealing casing 1. The contact 4 and the lower contact 5 are different from the prior art in that a transverse insulating plate 6 is provided below the lower contact 5, and there are temperature sensing elements 7 and electric heating elements 8 below the transverse insulating plate 6. The insulating plate 6, the temperature sensing element 7 and the electric heating element 8 do not affect the up and down movement of the lower insulating rod 3, and the temperature sensing element terminal 9 connected with the temperature sensing element 7 is sealed and fixed on the bottom panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com