Injection made showerhead

A nozzle and nozzle technology, applied in the field of injection nozzles with self-locking function, can solve the problems of falling off, easy loosening and damage of the nozzle, and achieve the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

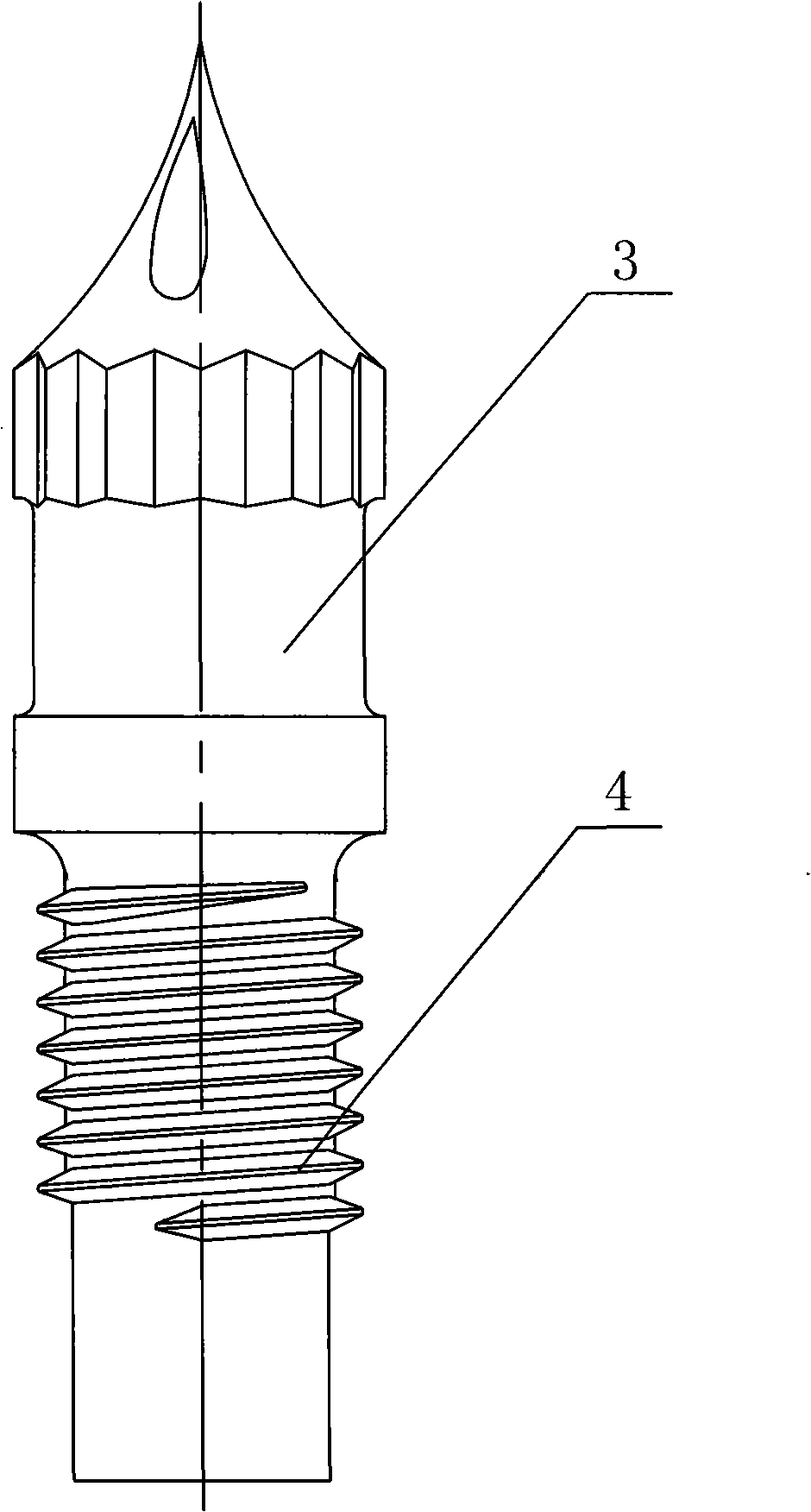

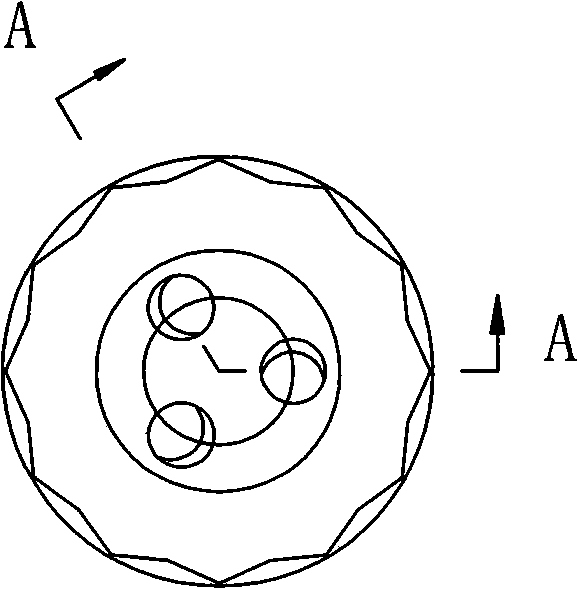

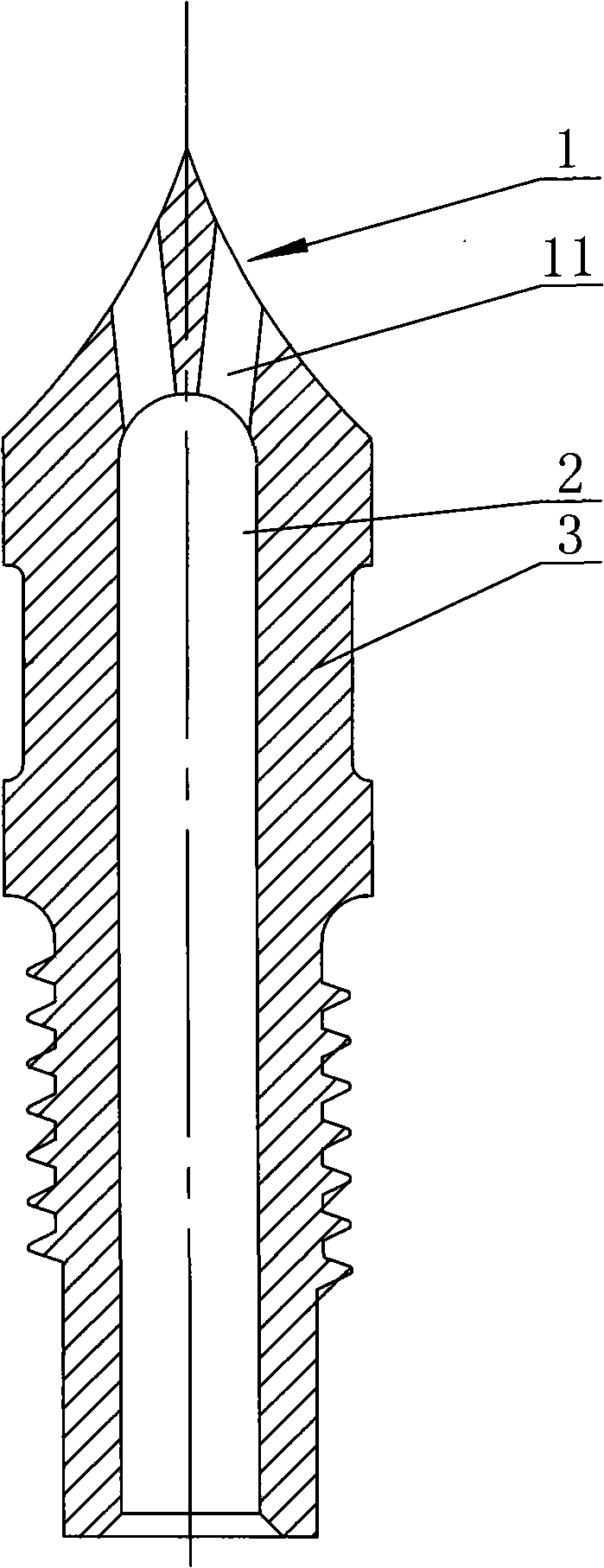

[0012] As shown in Figures 1, 2, and 3, an injection nozzle includes a nozzle body 3, a cavity 2 arranged in the middle of the nozzle body 3 and communicated with the outside of the nozzle body 3, a thread 4 arranged on the lower surface of the nozzle body 3, and a set At least two nozzles 1 are evenly arranged on the upper end of the nozzle body 3, and discharge channels 11 are respectively arranged between the nozzles 1 and the cavity 2, and the discharge channels 11 are respectively arranged on one side of the central axis of the nozzle body 3 , and form a certain inclination angle with the central axis, the direction of the inclination angle of the discharge channel 11 is the same as the direction of rotation of the screw thread 4 . If the injection molding nozzle adopts right-handed thread, the discharge channel and the central axis form a certain inclined angle, and the direction is to the right. Conversely, if the injection nozzle adopts left-handed thread, the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com