Hinge and method for manufacturing a hinge

A technology of hinges and pivots, applied in the field of manufacturing hinges, can solve problems such as disadvantages and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

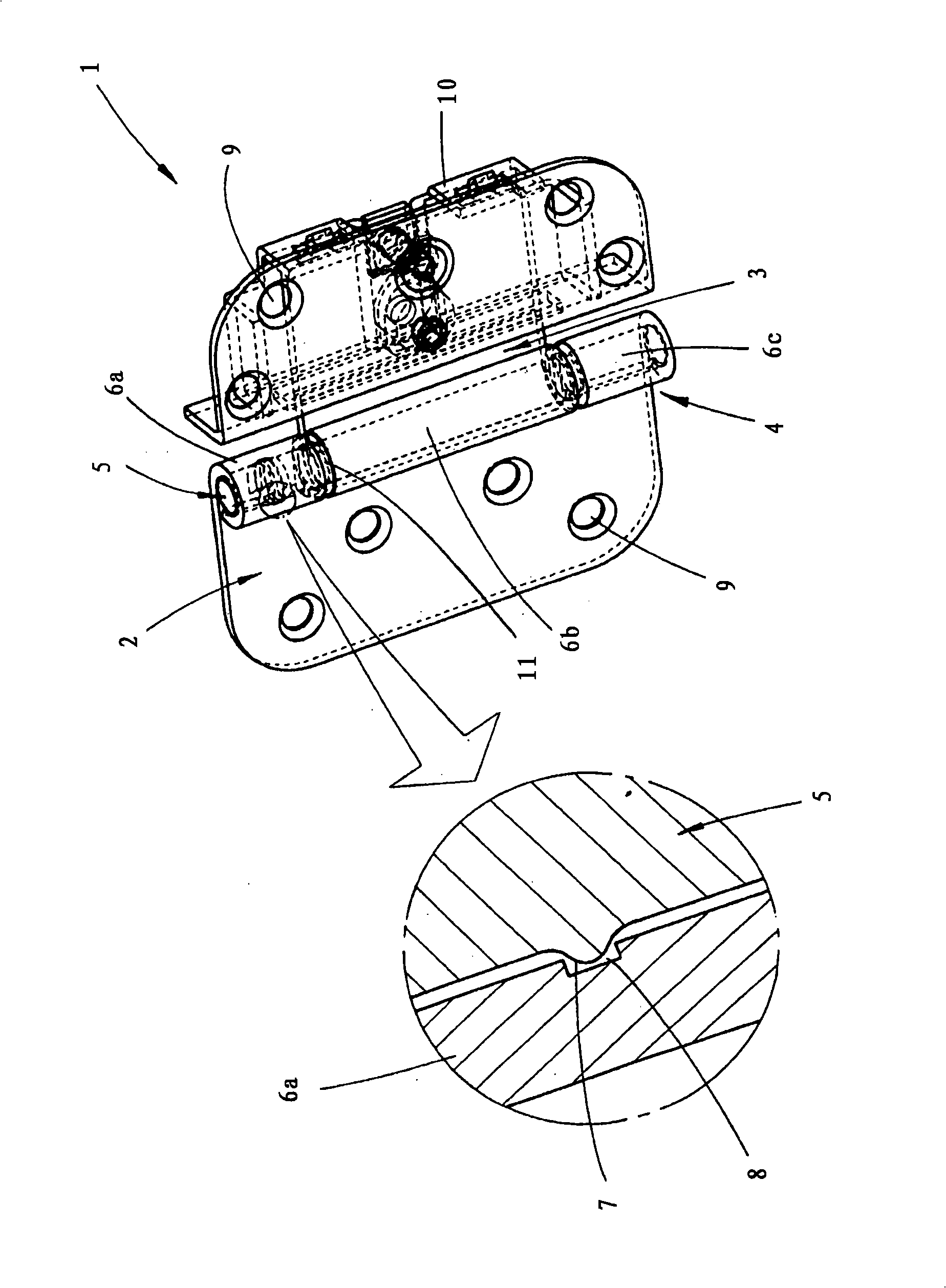

[0010] The hinge 1 shown in the figure comprises a first hinge 2 and a second hinge 3 , both of which are made of sheet metal and connected at a pivot 4 by a pivot pin 5 . An inner pivot eyelet 6b of the second hinge 3 fits between two outer pivot eyelets 6a and 6c of the first hinge. Said pivot eyelets 6a, 6b and 6c are formed by bending those pieces of sheet metal from the first hinge 2 and the second hinge 3, while the pivot eyelets 6a, 6b, 6c are not fully closed. The pivot pin 5 has a radially outwardly protruding thickened region 7 produced by longitudinal compression of the pivot pin 5, thereby forming a circumferential flange as the radially outwardly projected thickened region 7. This radially outwardly protruding thickened region 7 engages in a corresponding inwardly opening groove 8 of a corresponding pivot eye 6a of the first hinge 2 in such a manner that it cannot become loose. The first hinge 2 comprises a second outer pivot eyelet 6c in addition to the first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com