PCB (printed circuit board) structure available for grafting and transplanting and PCB structure grafting method

A PCB board and motherboard technology, which is applied to the graftable and transplantable PCB board structure and the field of grafting, can solve the problems of weak connection of the circuit board, poor appearance quality, increased production cost, etc., and achieves great economy and environmental protection. Simple structure and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

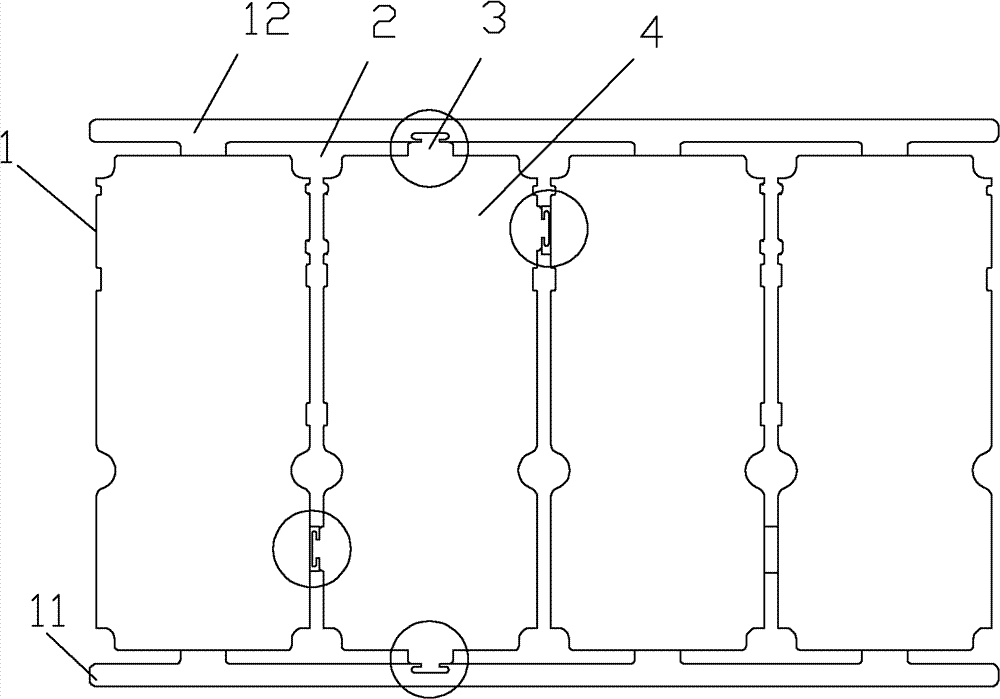

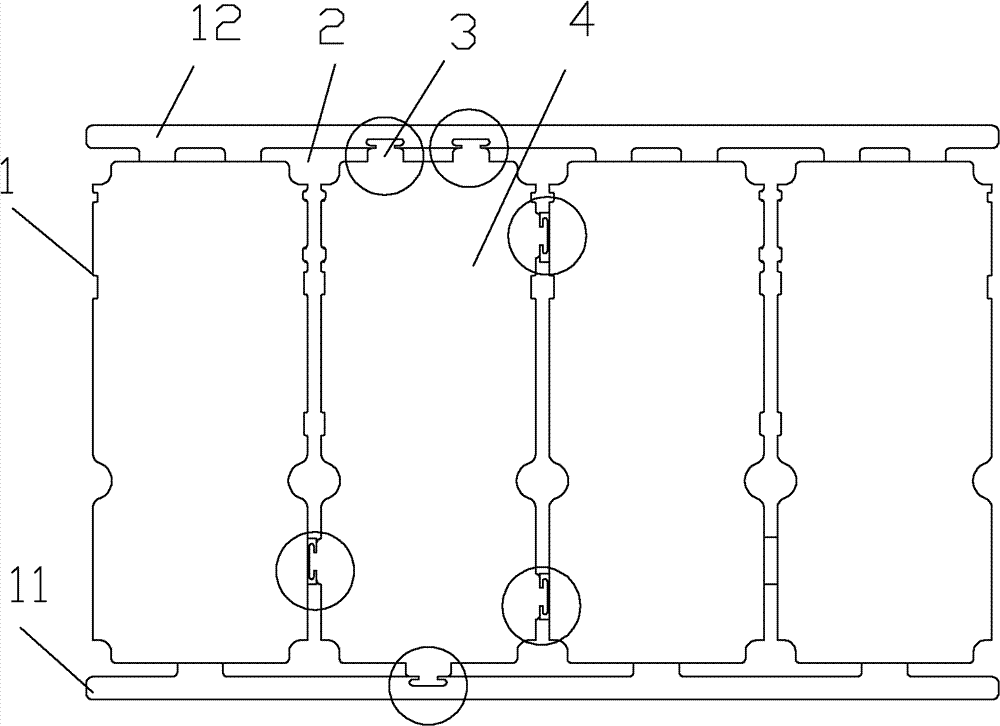

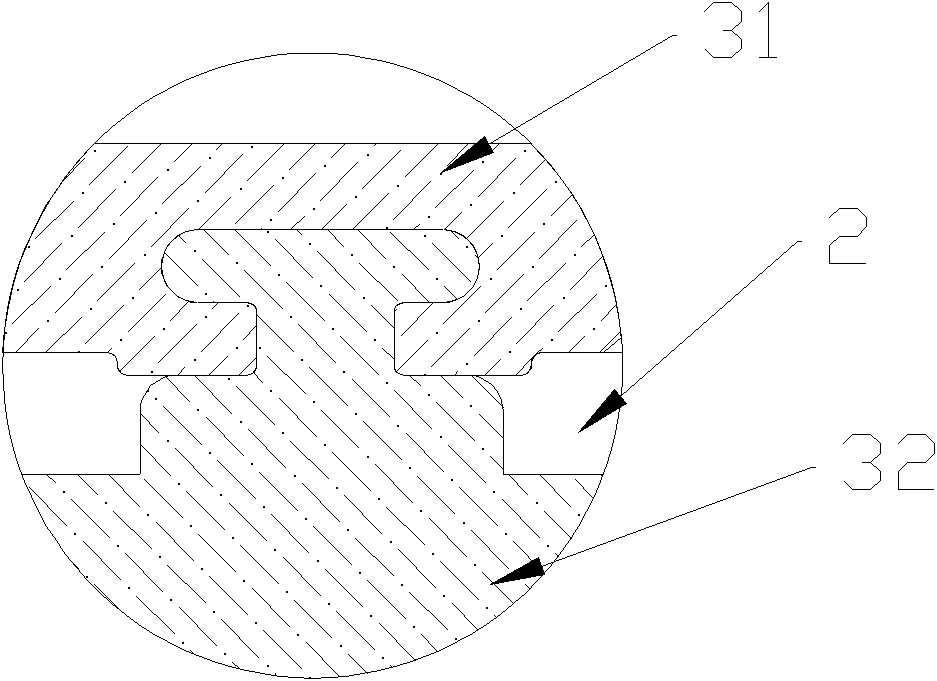

[0025] Such as figure 1 As shown, the embodiment of the present invention provides a graftable PCB board structure, including a grafting mother board 1 and a grafting daughter board 4, the grafting mother board 1 is a multi-piece PCB board to be grafted, and the grafting daughter board 4 is a qualified PCB board unit. The grafting mother board 1 is provided with a working side A11 and a working side B12. The working side is respectively provided with a concave groove 31, and the grafting sub-board 4 is provided with a working side Corresponding two convex interfaces 32; the grafted sub-board 4 overlaps with the concave slot 31 on the grafted motherboard 1 through the convex interface 32; on the grafted motherboard 1, two adjacent units of the PCB board unit to be grafted A concave slot 31 is provided respectively, and two convex interfaces 32 matched with the concave slot 31 of the PCB unit to be grafted are also provided on the graft sub-board 4 , and the graft sub-board 4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com