Method and device for applying adhesive threads and points to a substrate, web of material comprising a fleece and a layer composed of adhesive threads, and products made therefrom

A coating and glue line technology, applied in the field of coating glue lines on the substrate, can solve problems such as excessive glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

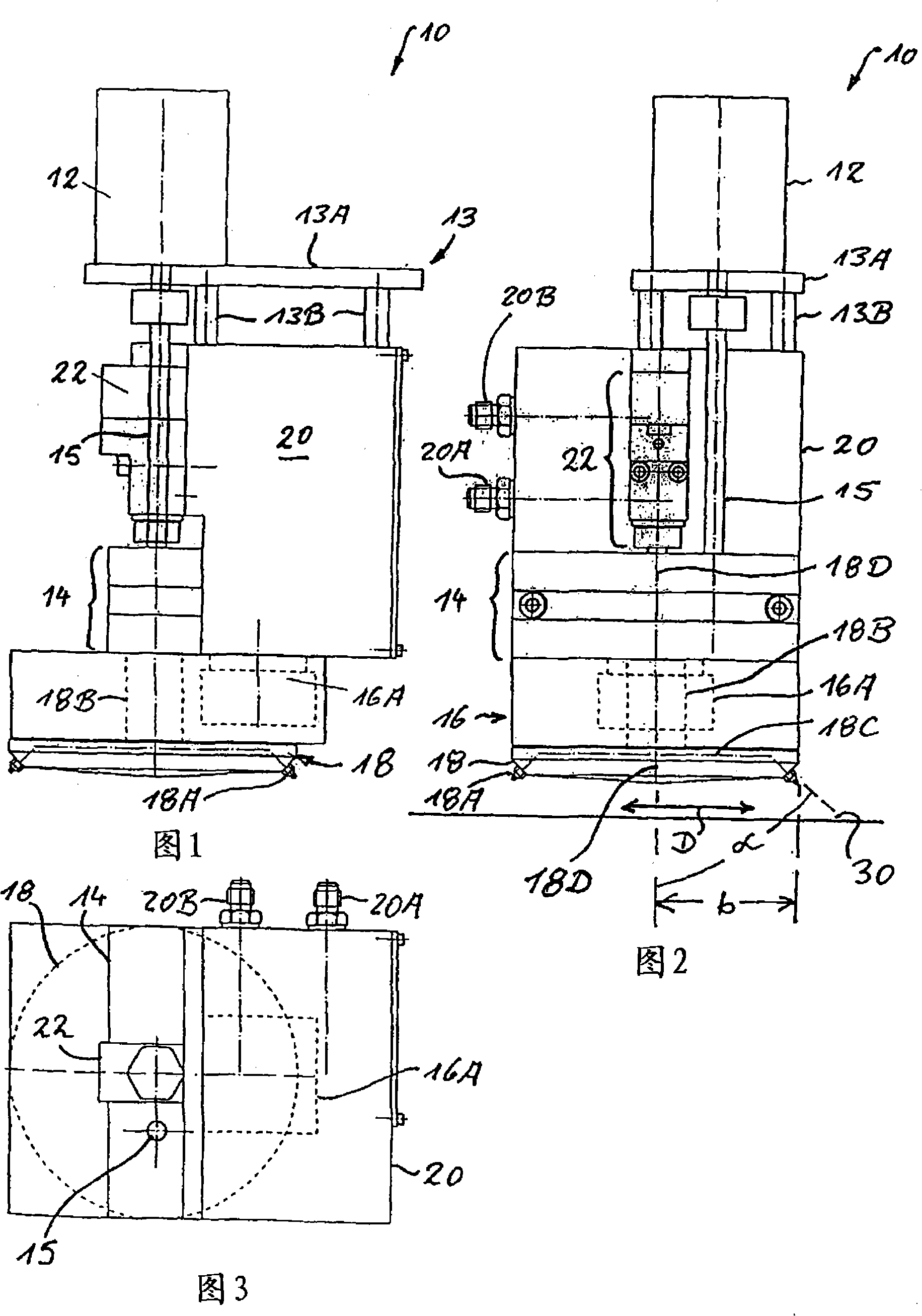

[0034] As seen in Figures 1 to 3, a compact glue line coating device comprises a drive motor 12 (omitted in Figure 3), a transmission 14, a heating unit 16, a rotatable coating head 18, for A glue unit 20, and a valve fitting 22 for feeding glue such as hot melt and cold glue to the glue applicator head.

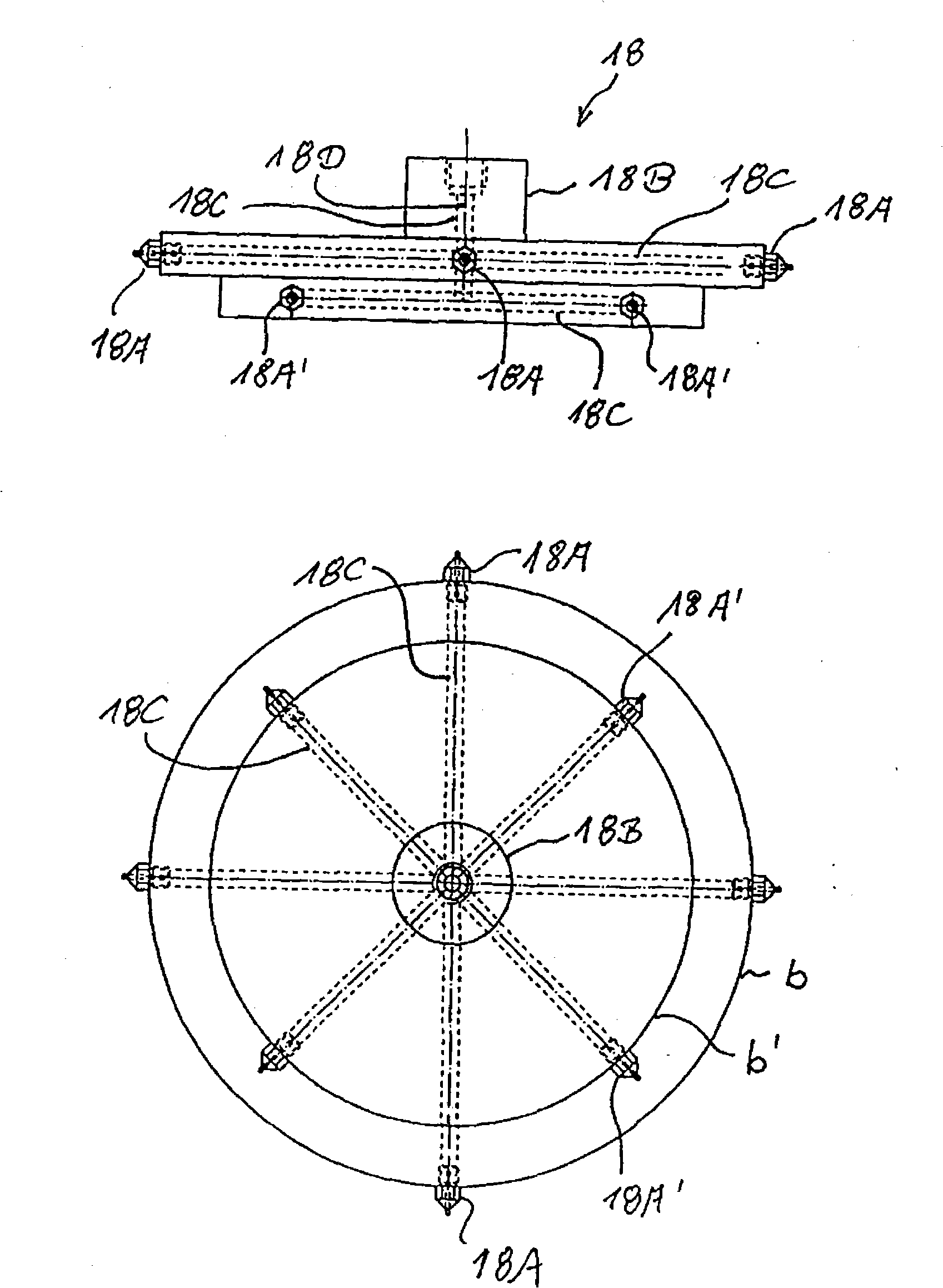

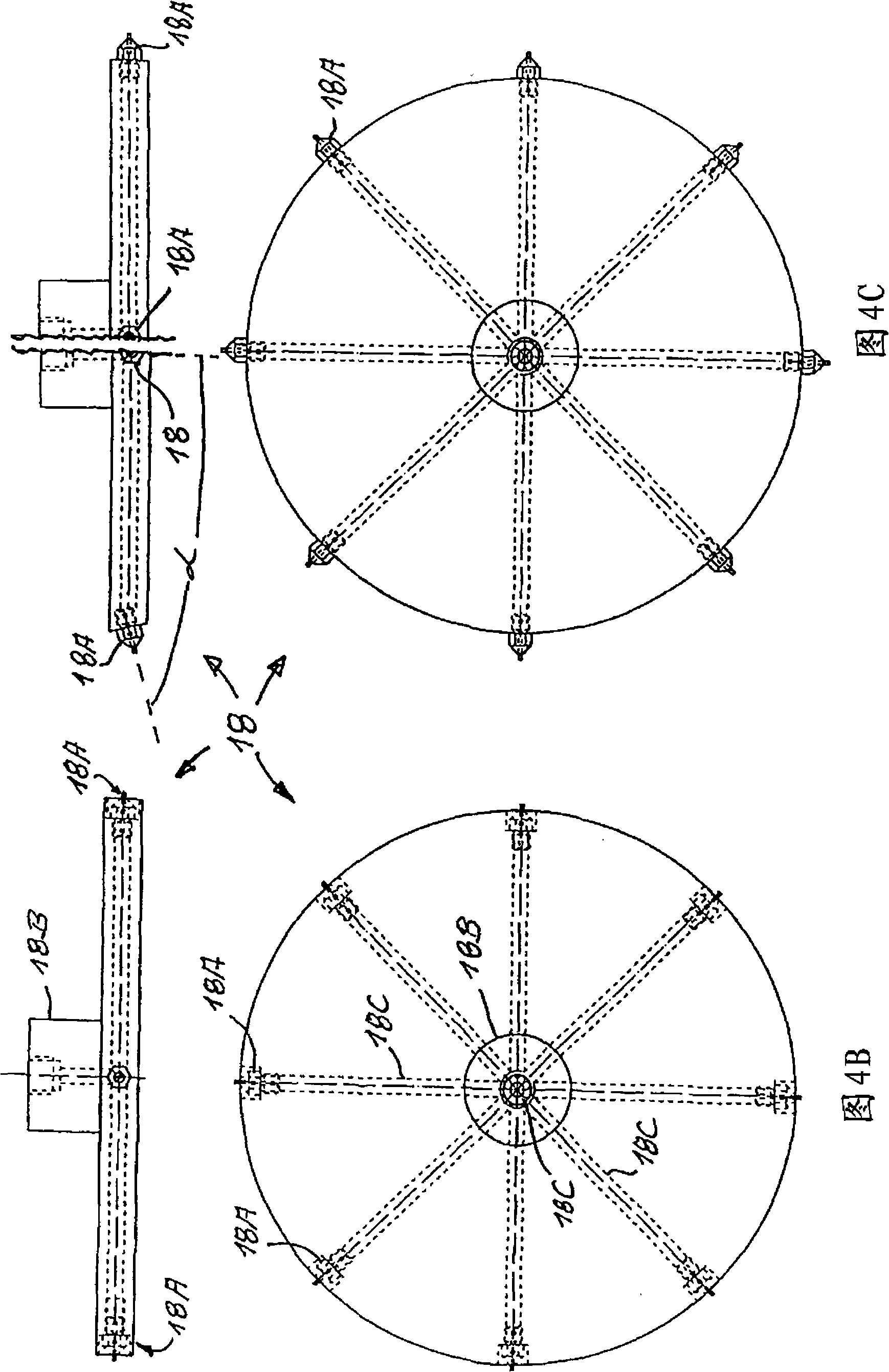

[0035] In the preferred illustrated embodiment of this aspect, the drive motor 12 is supported on the housing top side of the glue supply unit 20 by means of a support member 13 such as a chassis 13A and a support or spacer 13B, and the chassis 13A is on the glue supply unit. Prominent sideways. In this way, the drive shaft 15 , which is pluggably connected to the drive motor 12 , passes by the glue supply unit 20 and is guided to the transmission 14 . The transmission device 14 screwed on the side wall of the glue supply unit 20 is responsible for transmitting the torque of the drive shaft 15 made of solid material to the hollow shaft rod 18B (see Figure 4A to 4C), so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com