Curtain coating machine and curtain coating method

A coating and curtain technology, applied to the surface coating liquid device, coating, spraying device, etc., can solve the problem of polluting the edge guide, etc., and achieve the effect of easy change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

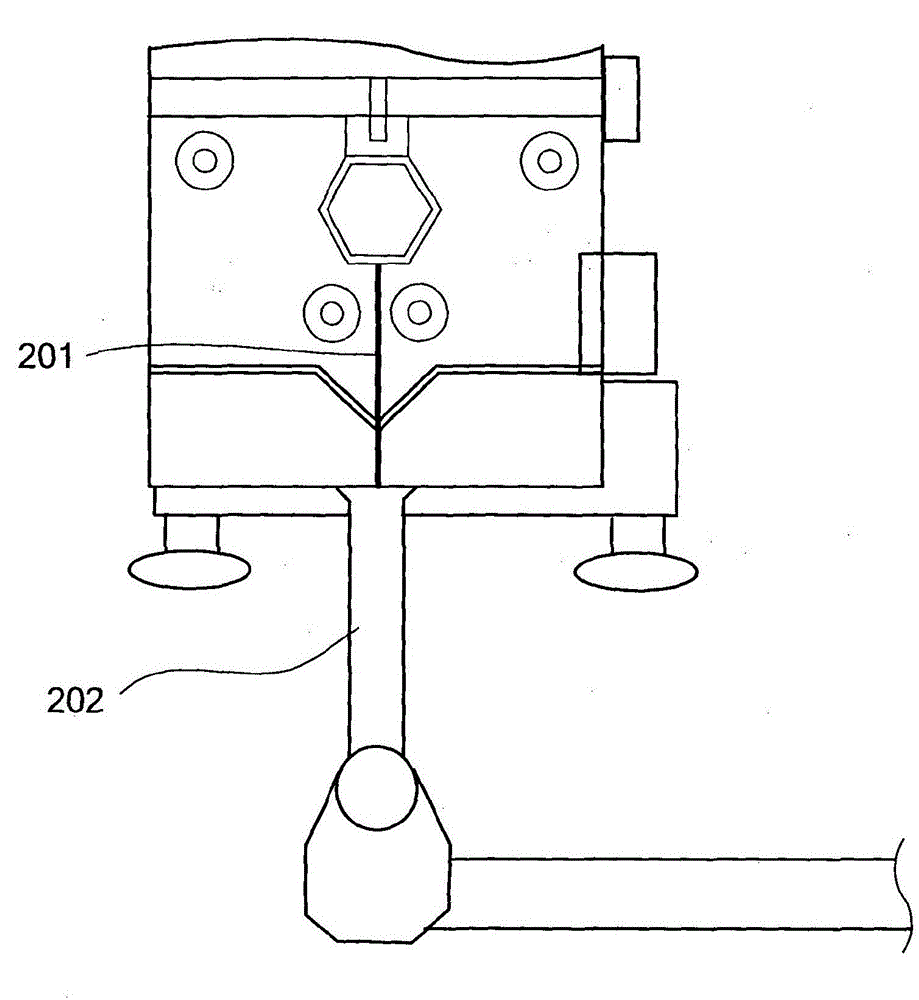

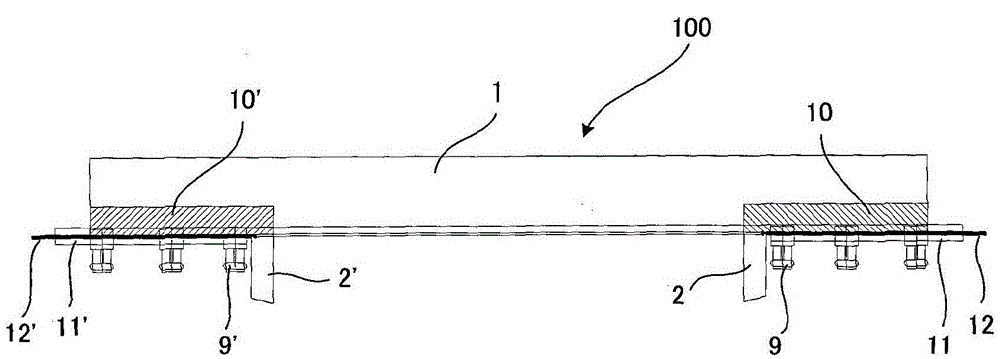

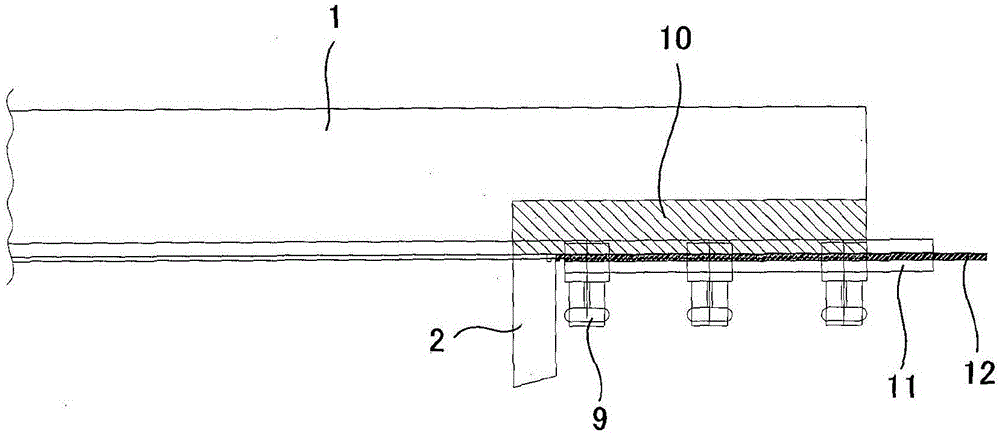

[0181] about Figure 2 to Figure 7 In the shown curtain coating machine, the edge fixing device 10 is inserted into the slit of the slit lamination 1, the discharge port of the slit lamination 1 is covered with a sheet 14 as a fall prevention member, using the fixing member 12 and the tight The contact member 11 presses the sheet 14 onto the discharge port of the slit lamination, and performs curtain coating and curtain film coating width change.

[0182] In Example 1, the ratio (A / B)×100 is 90%, where A represents the thickness of the discharge width regulating member, and B represents the width of the discharge port of the curtain coating member.

[0183] In Example 1, the surface of the discharge port of the curtain coating member had a flat portion of 2 mm. The length of the discharge port in the width direction was 600 mm.

[0184] The edge fixing device 10 as a discharge width regulating member is a sheet-type member having a thickness of 0.488 mm and a length of 75 mm...

example 2

[0191] Curtain coating and curtain film coating width change were performed in the same manner as in Example 1, except that the sheet 14 was pressed to the slit using an edge guide 2 and a close contact member (integrated with a fixing member) On the discharge port of the laminated film. When the curtain coating and the change of the coating width of the curtain film were performed with the curtain coating machine of Example 1, the liquid leakage from the discharge port of the slit lamination, the easiness of changing the coating width, and the edge guide were evaluated The contamination state of the curtain film down the flow surface. The results are shown in Table 1.

example 3

[0203] Curtain coating and change of curtain film coating width were performed in the same manner as in Example 1, except that the ratio (A / B)×100 was set to 99%. When the curtain coating and the change of the coating width of the curtain film were performed with the curtain coating machine of Example 1, the liquid leakage from the discharge port of the slit lamination, the easiness of changing the coating width, and the edge guide were evaluated The contamination state of the curtain film down the flow surface. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com