Solar heat-collector and manufacture method

A solar collector and collector tube technology, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problems of poor thermal insulation effect of solar collectors and inability to absorb solar energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

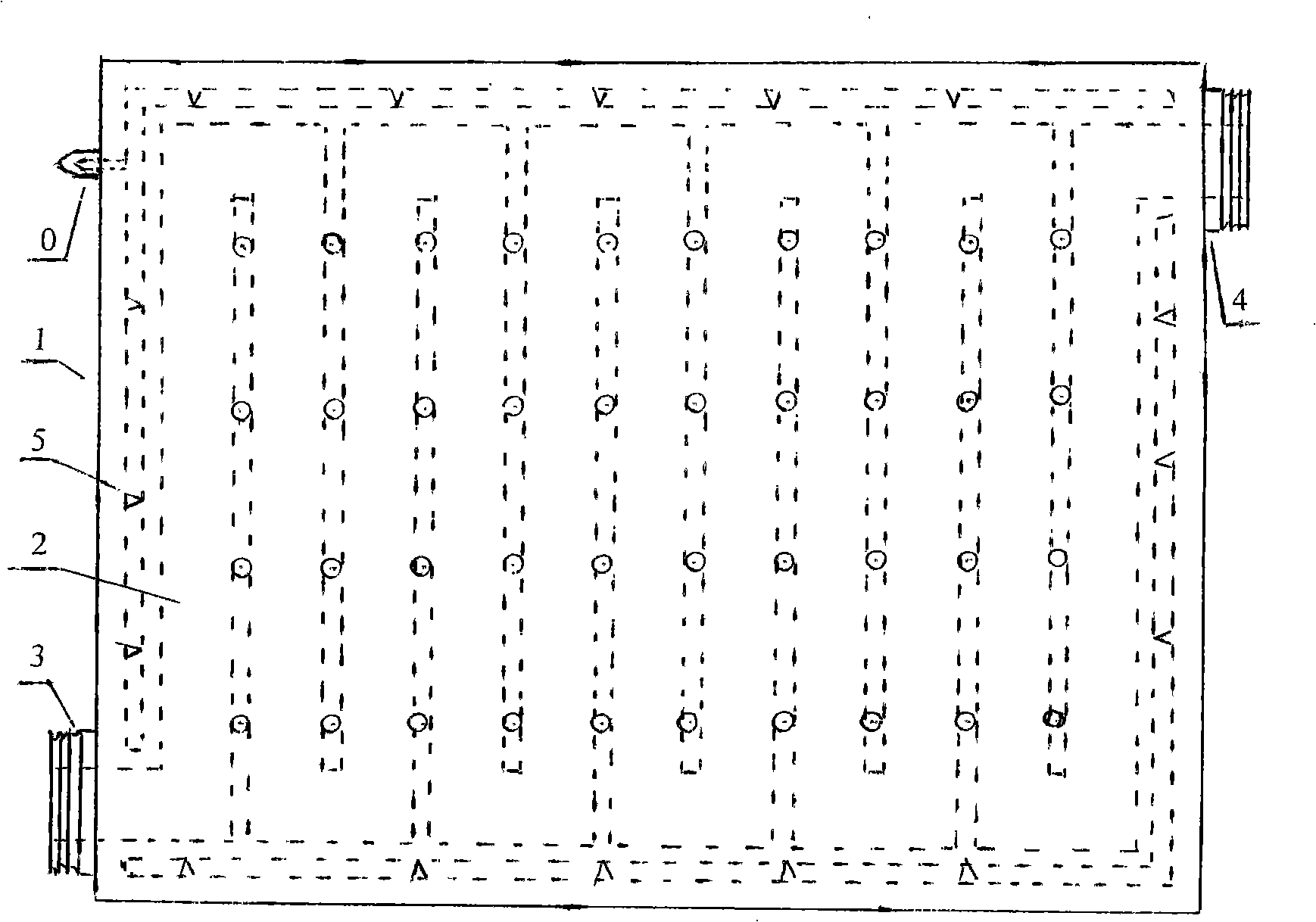

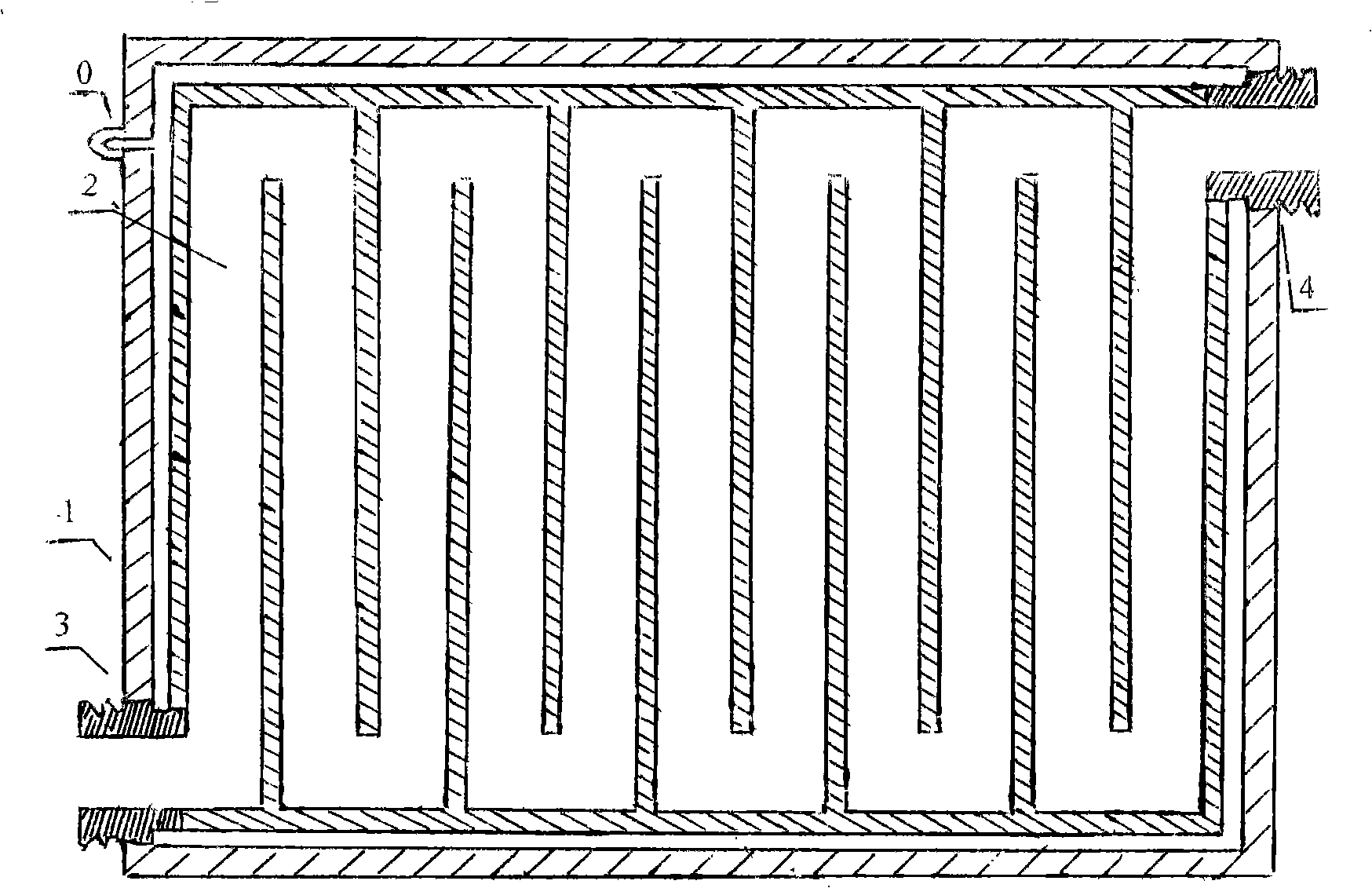

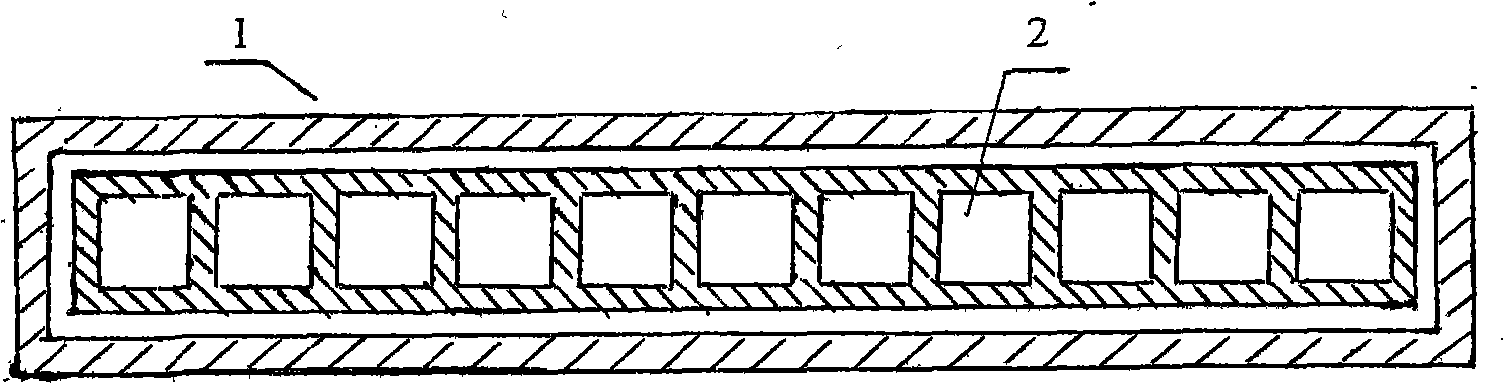

[0019] figure 2 , image 3 The solar heat collector of the present invention shown is to be made of glass, and it is made up of shell 1, heat collecting pipe assembly 2, water inlet pipe 3 and water outlet pipe 4. The heat collecting tube assembly 2 is composed of an odd number of square heat collecting tubes arranged side by side, and two adjacent heat collecting tubes share a side wall. It is connected with the next odd-numbered heat collecting tube, and the inner surface of the heat collecting tube is coated with a heat-absorbing metal film, and all the heat collecting tubes are connected in series to form a sealed flat cuboid. The shell 1 surrounds the heat collecting tube assembly 2 in the middle, the water inlet pipe 3 passes through the lower left side of the shell 1 and communicates with the water inlet of the heat collecting tube assembly 2, and the water outlet pipe 4 passes through the upper right side of the shell 1 and connects with the outlet of the heat collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com