Device for repeatedly machining

一种多次加工、驱动装置的技术,应用在工件领域,能够解决批量不经济等问题,达到简单结构、高生产速度、紧凑结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

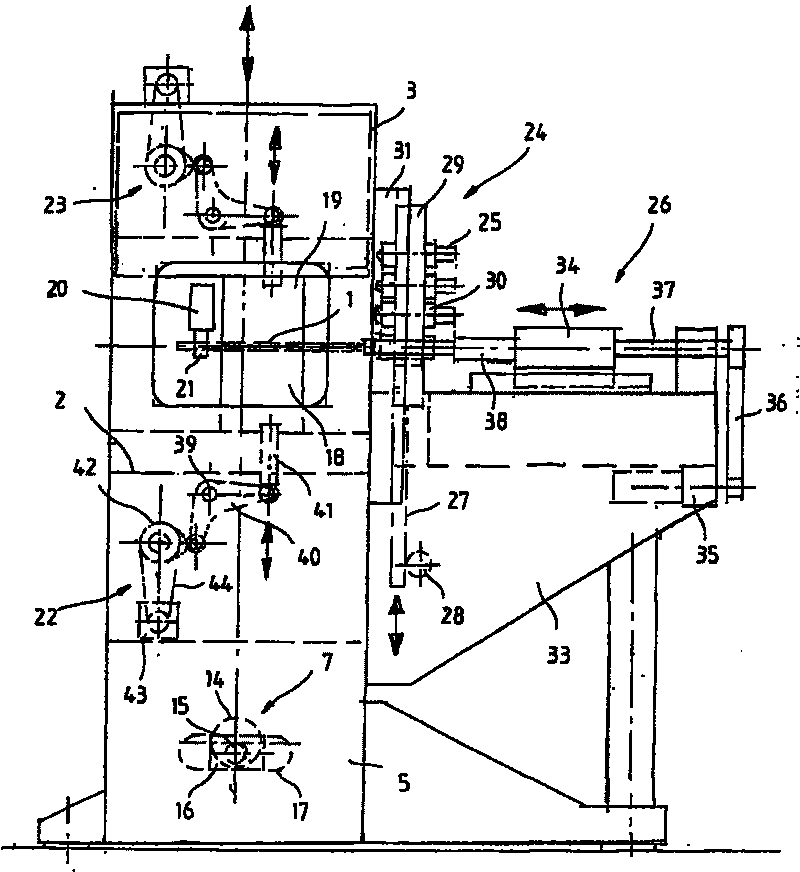

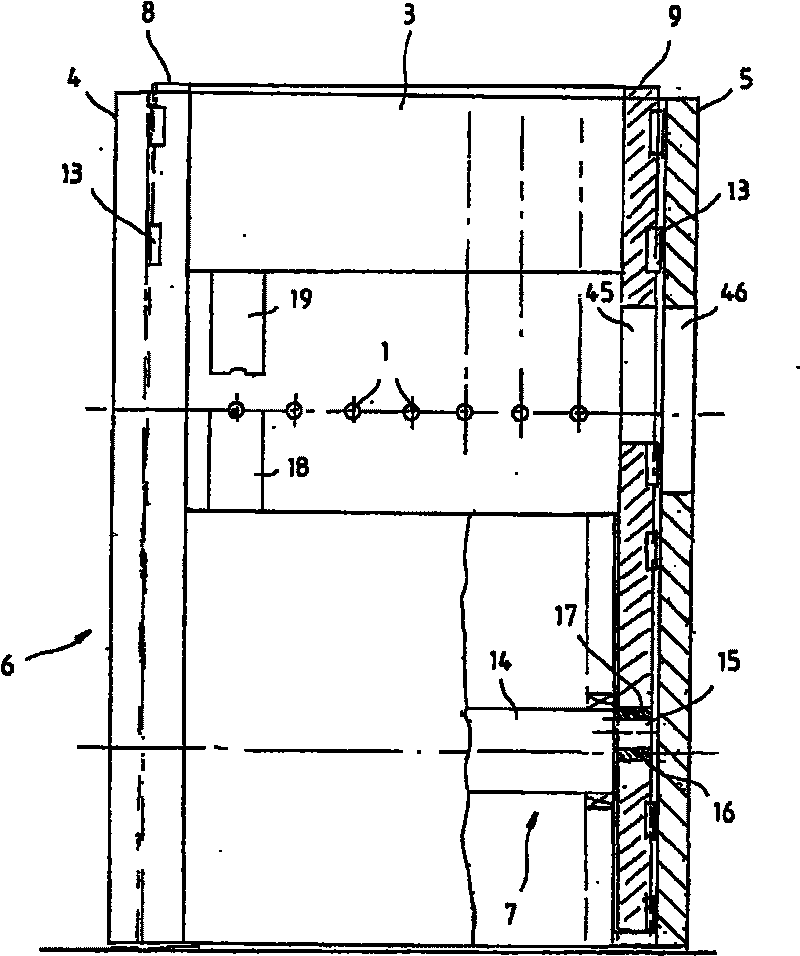

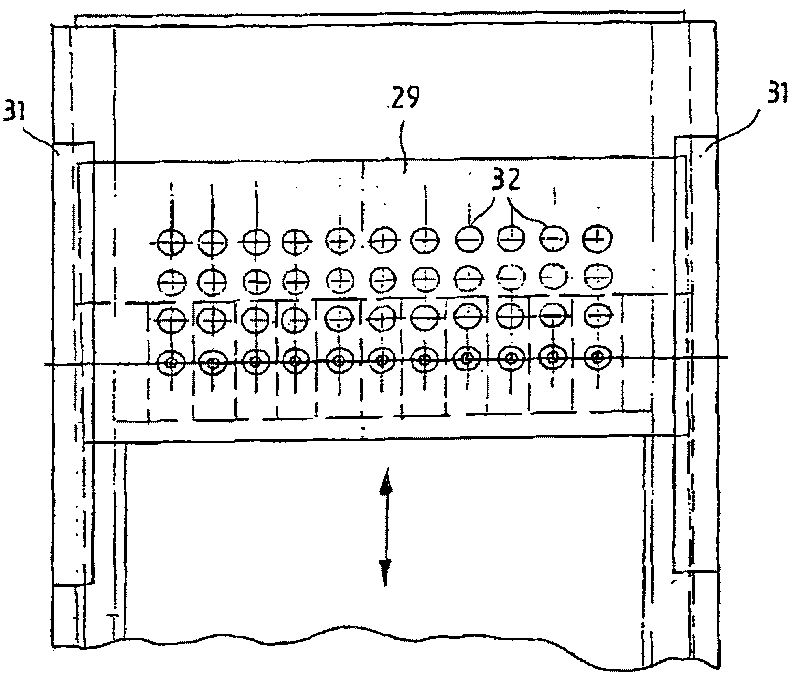

[0028] figure 1 and 2 The device for the multiple machining of a plurality of workpieces 1 arranged side by side, shown schematically in side and front view in , is especially designed for the complete machining of rod-shaped or tubular workpieces, for example for the manufacture of Belt and lock tensioner (Schlossstraffer) pipes, brake and fuel lines, filler pipes, injection lines, etc. The device comprises a lower part 2 designed as a press table and an upper part 3 designed as a pressure slide, which can be moved relative to the lower part 2 between two side parts 4 and 5 of a frame 6 Guided and can move vertically through the lifting drive 7.

[0029] like figure 2 As shown, the upper part 3 designed as a pressure slide is vertically displaceable on the two side parts 4 and 5 of the frame 6 via the two side walls 8 and 9 fixedly connected thereto. The two side parts 4 and 5 have in the shown embodiment a Figure 4 A U-shaped cross section can be seen in , which has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com