Patents

Literature

90results about "Work trasfer apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine Tool

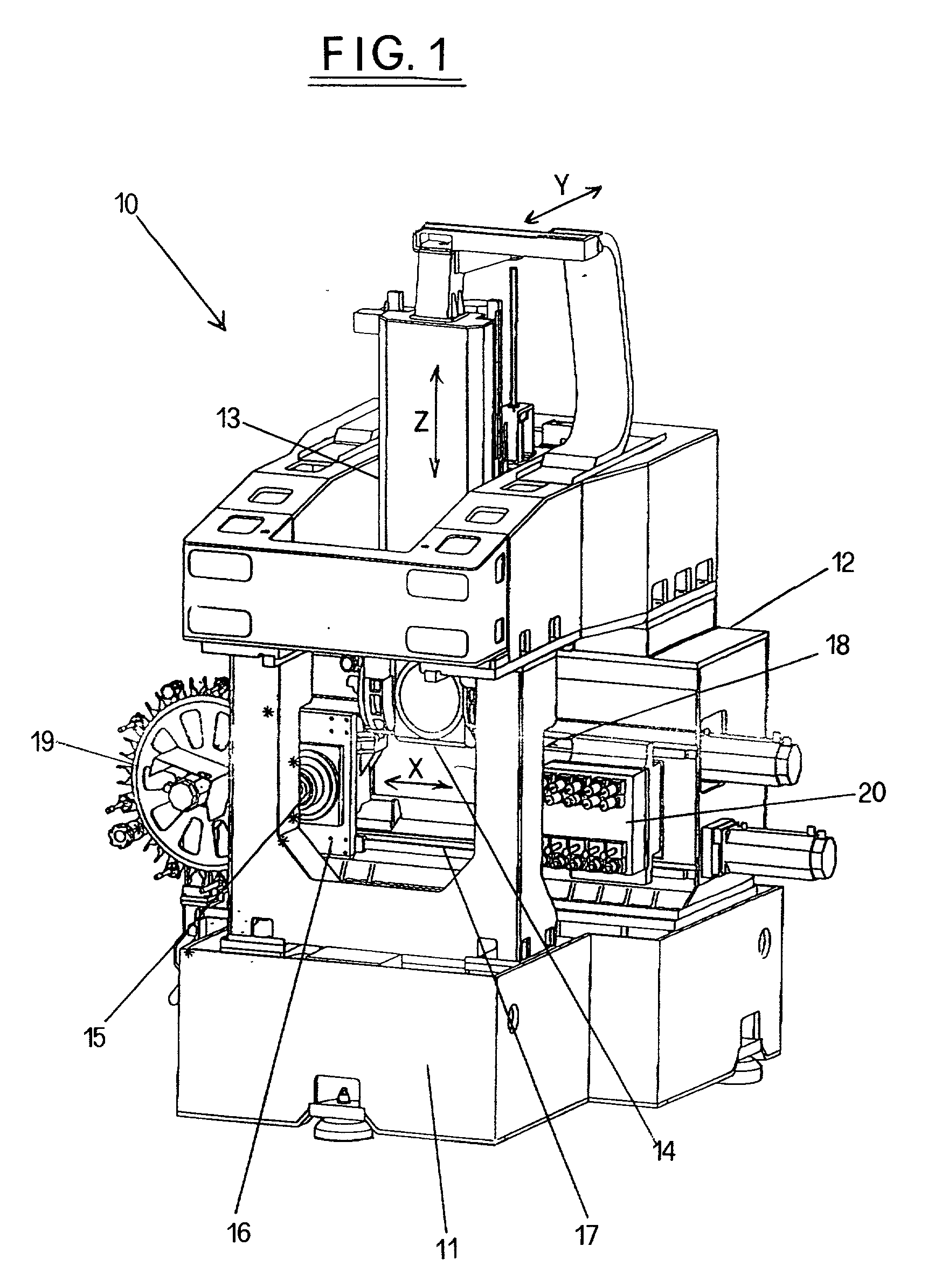

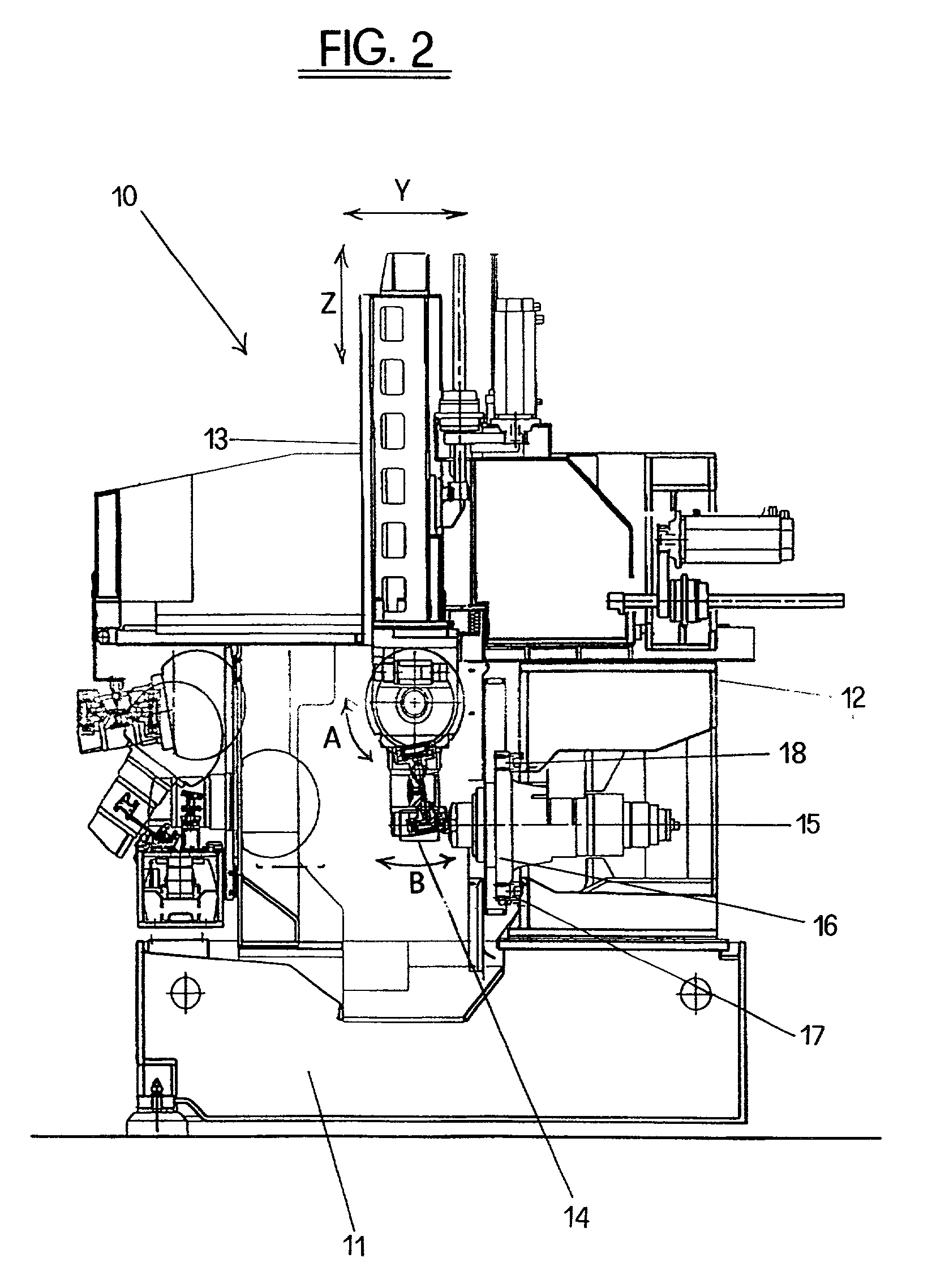

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

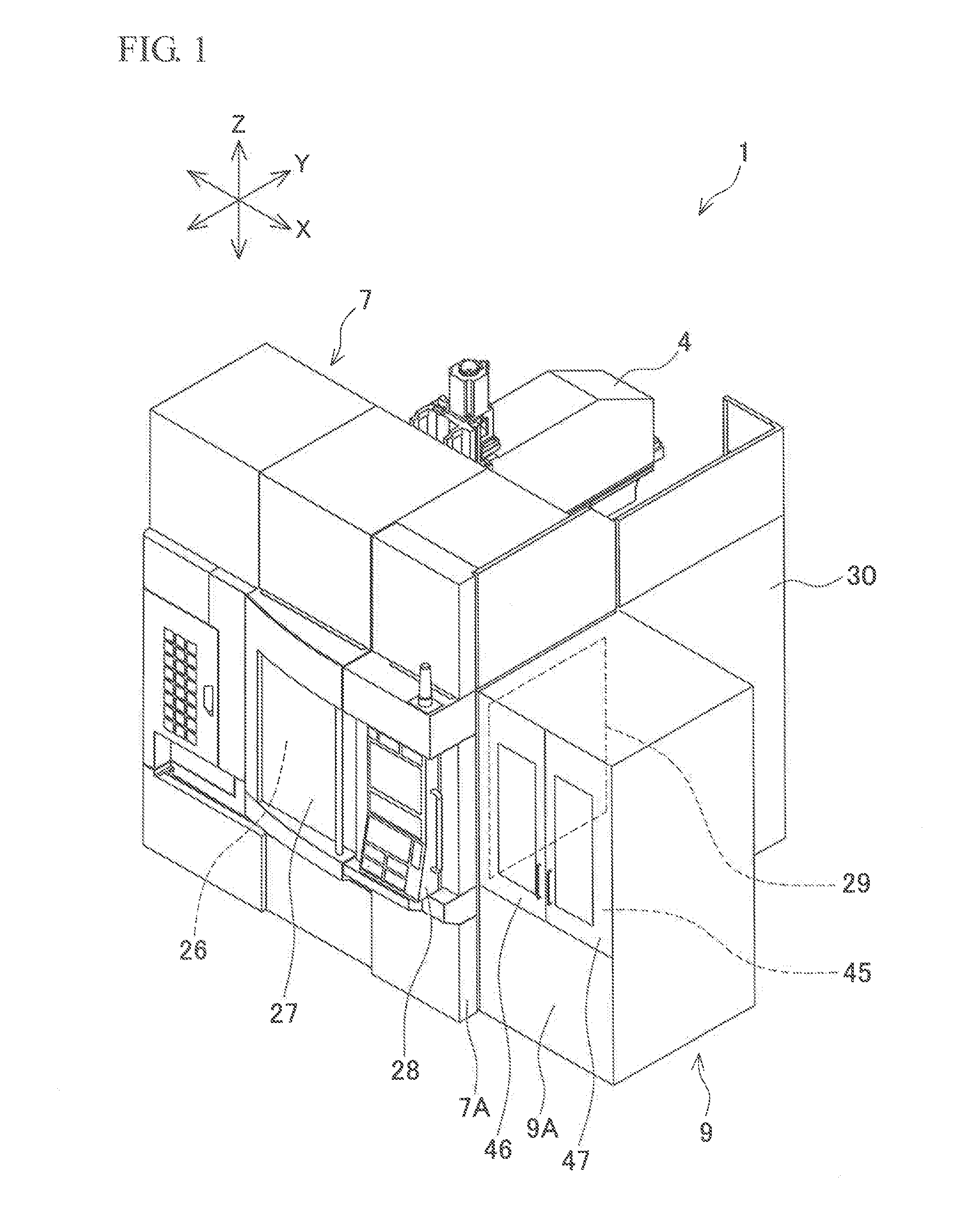

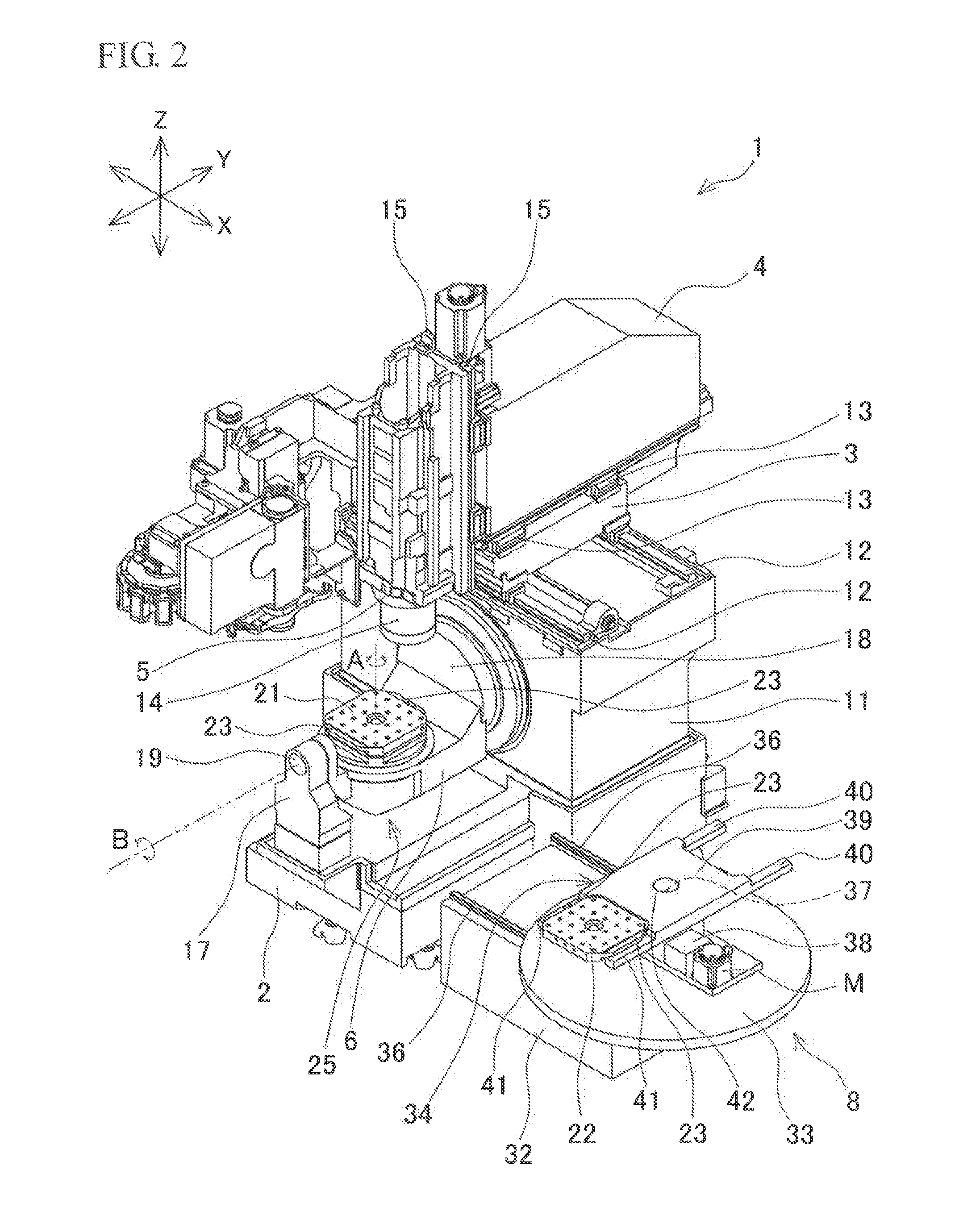

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

CNC machine tool

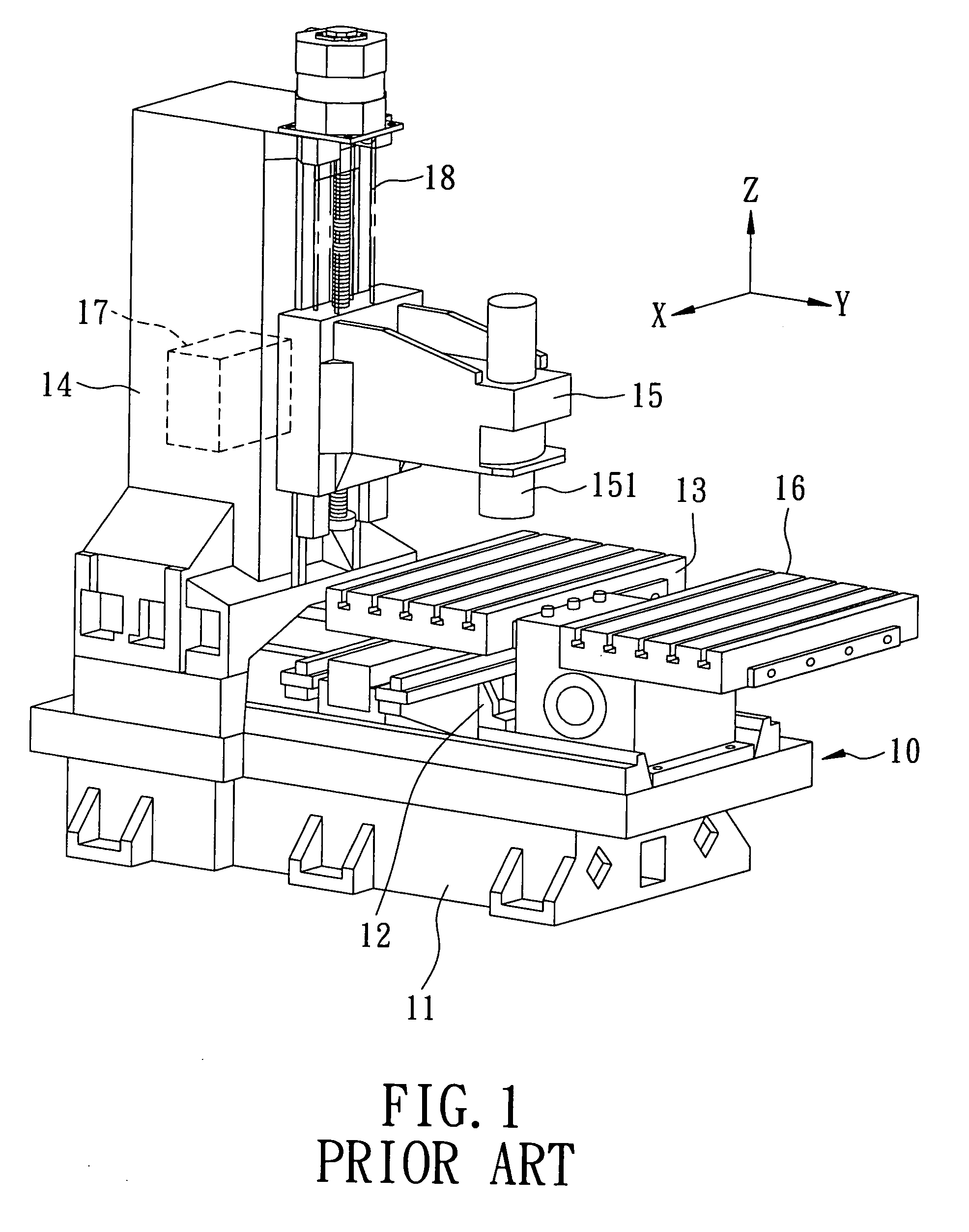

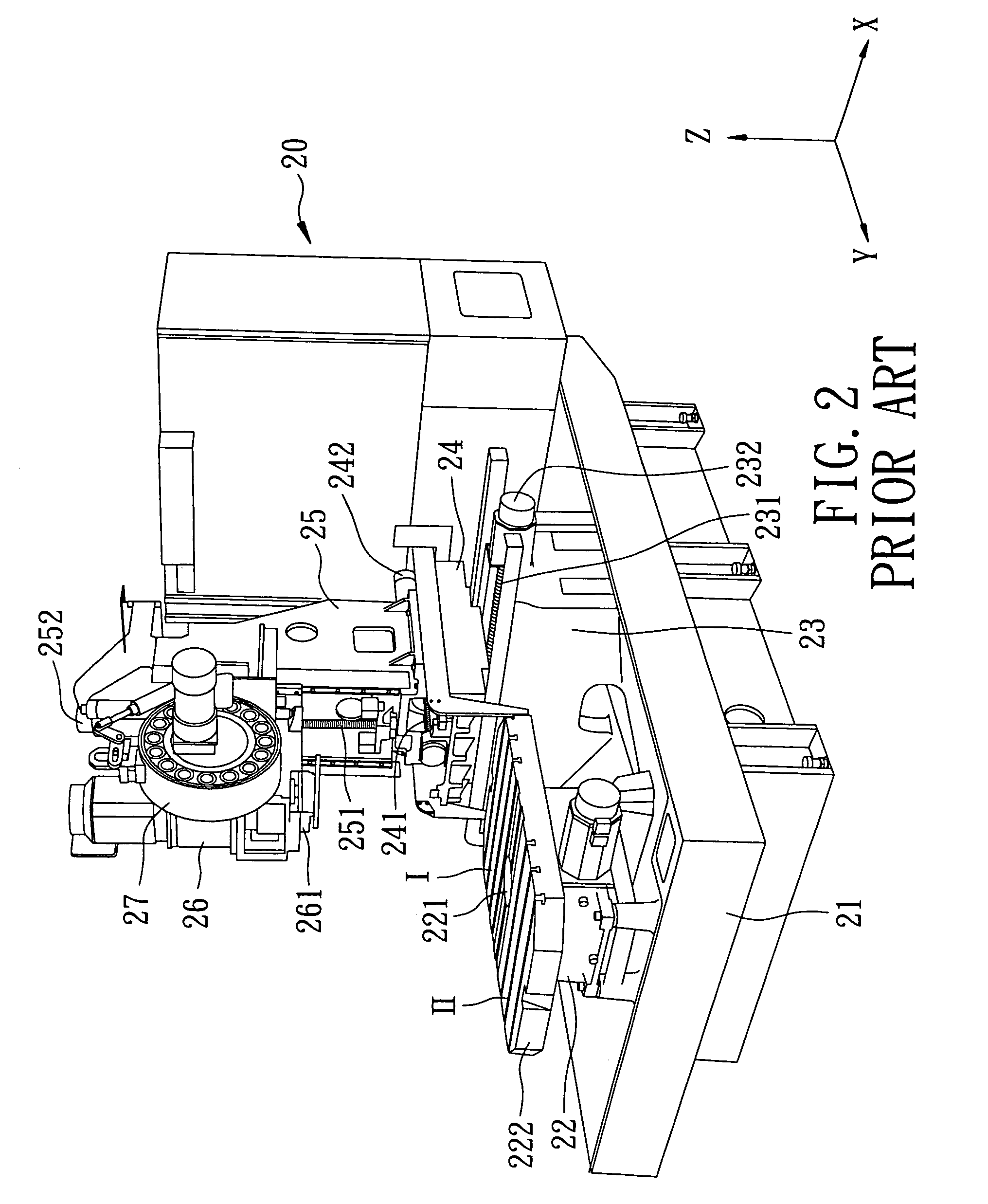

InactiveUS7147595B1Reduce loadUnnecessary movementPlaning/slotting machinesMilling machinesNumerical controlEngineering

A CNC machine tool includes a worktable supporting two workpieces and rotatable on a base so as to exchange the positions of the workpieces. A post member is fixed on the base. A first horizontal rail unit is movable vertically on the post member. A second horizontal rail unit is movable on the first horizontal rail unit along a first horizontal direction. A spindle head unit is movable on the second horizontal rail unit along a second horizontal direction perpendicular to the first horizontal direction.

Owner:CHEN HSI KUAN

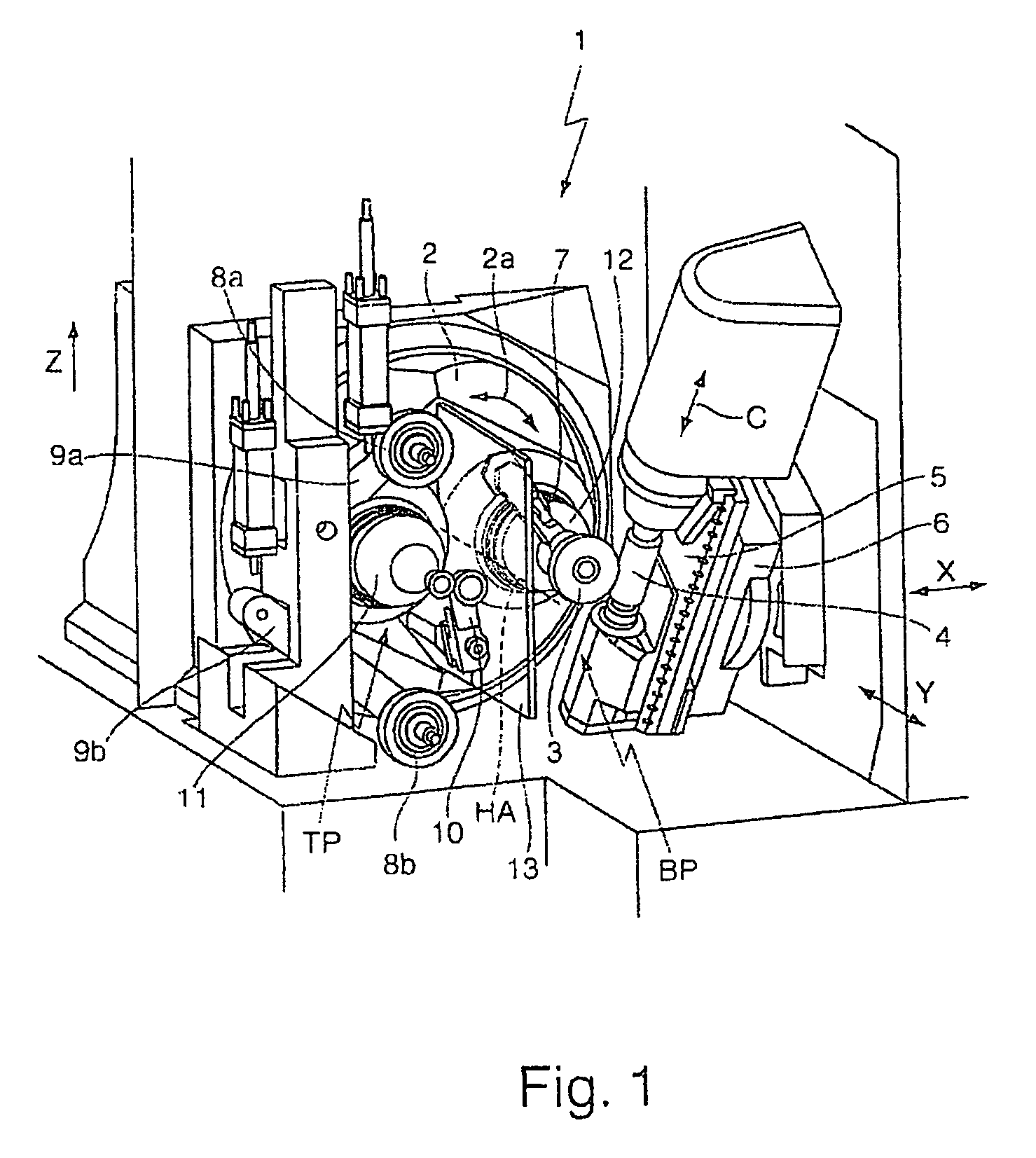

Machine tool, in particular a drilling and milling machine

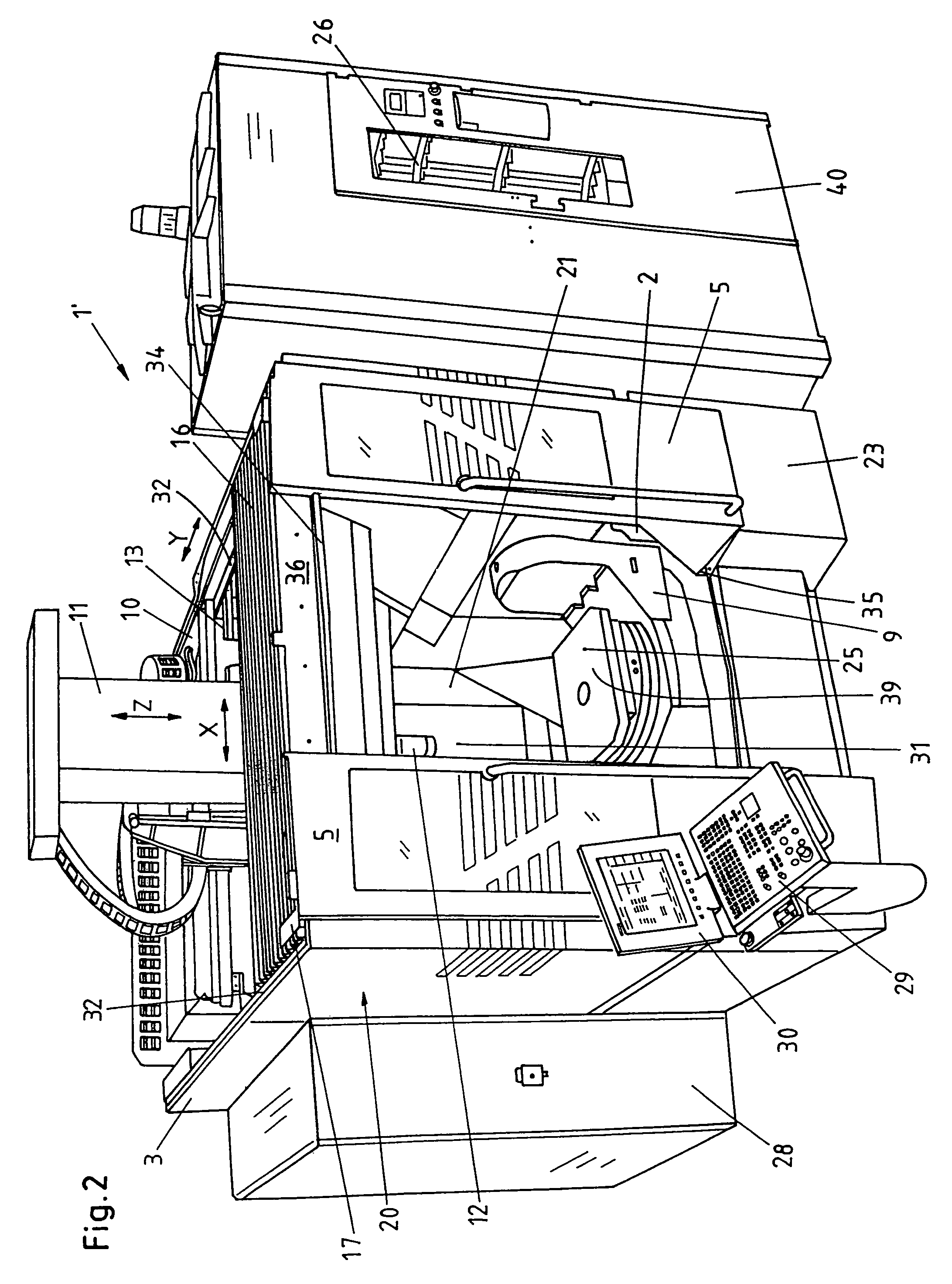

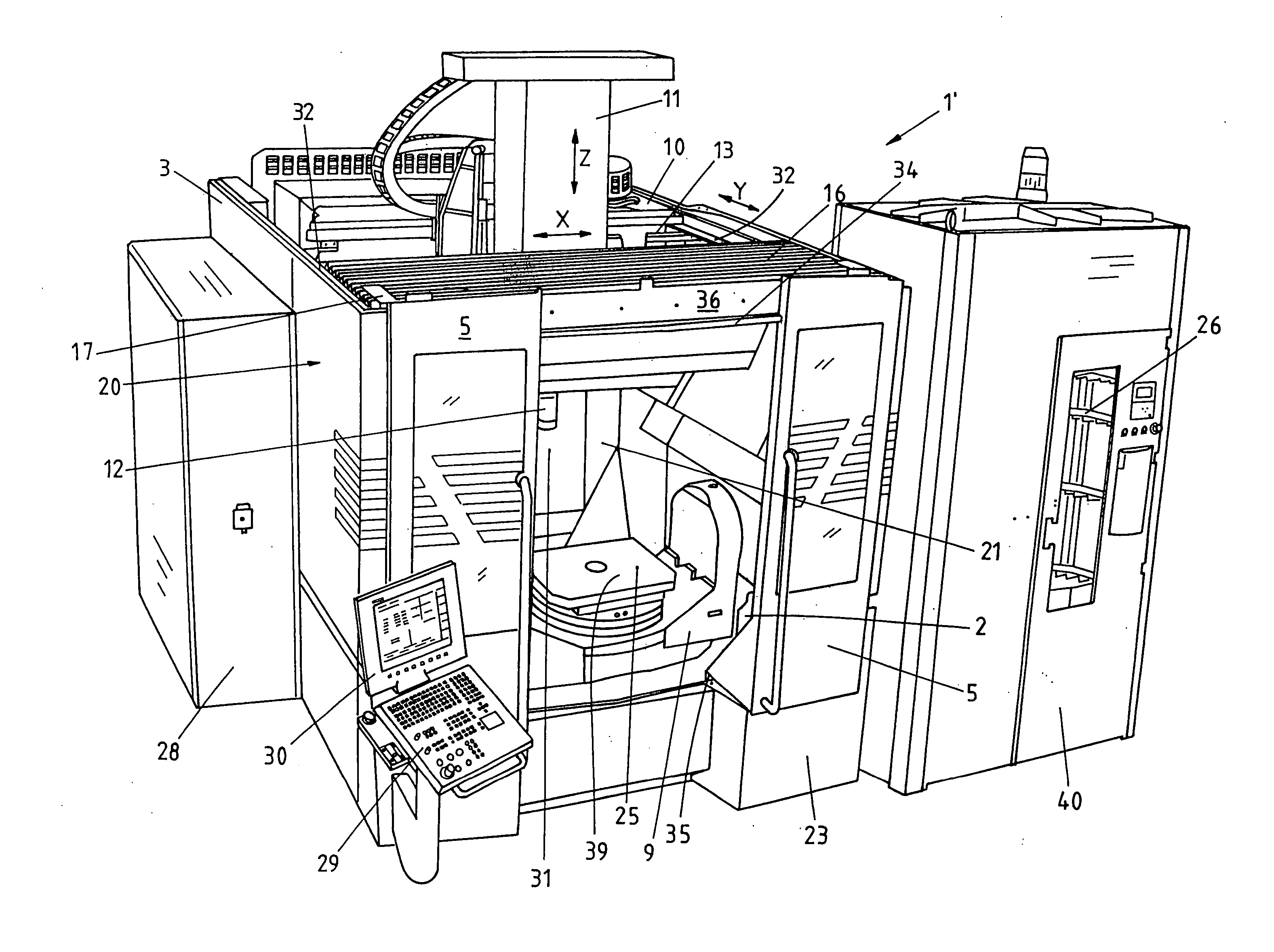

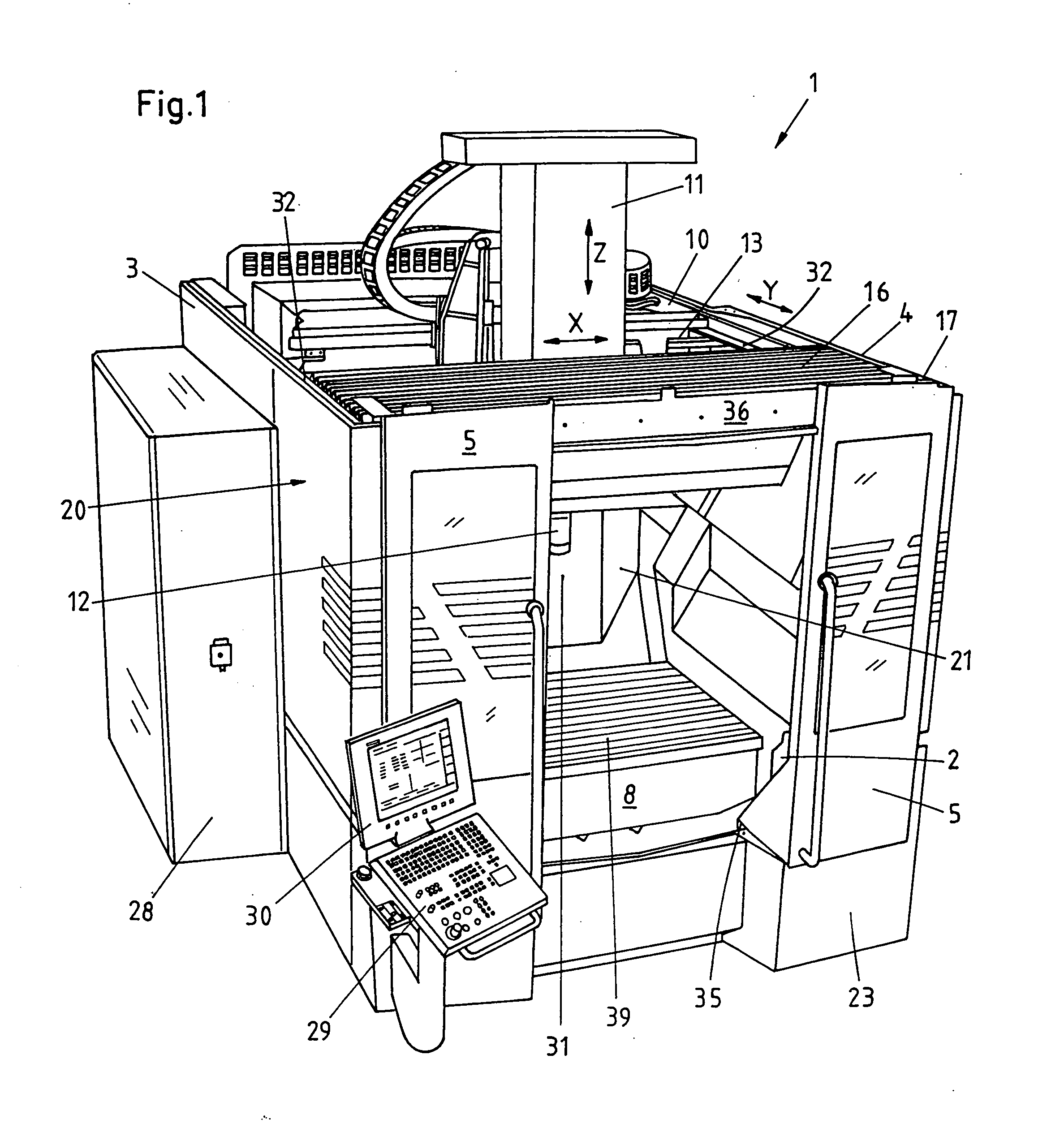

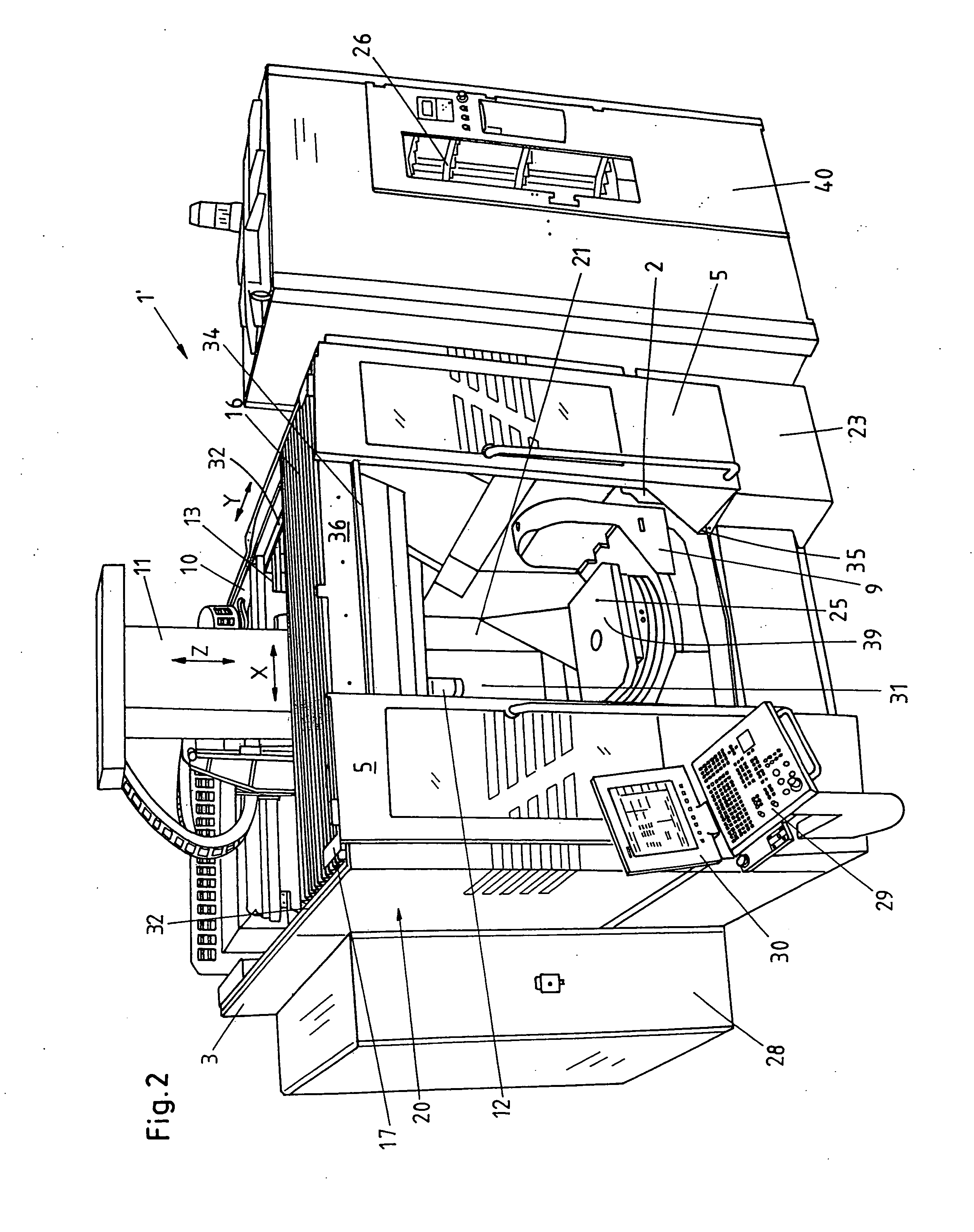

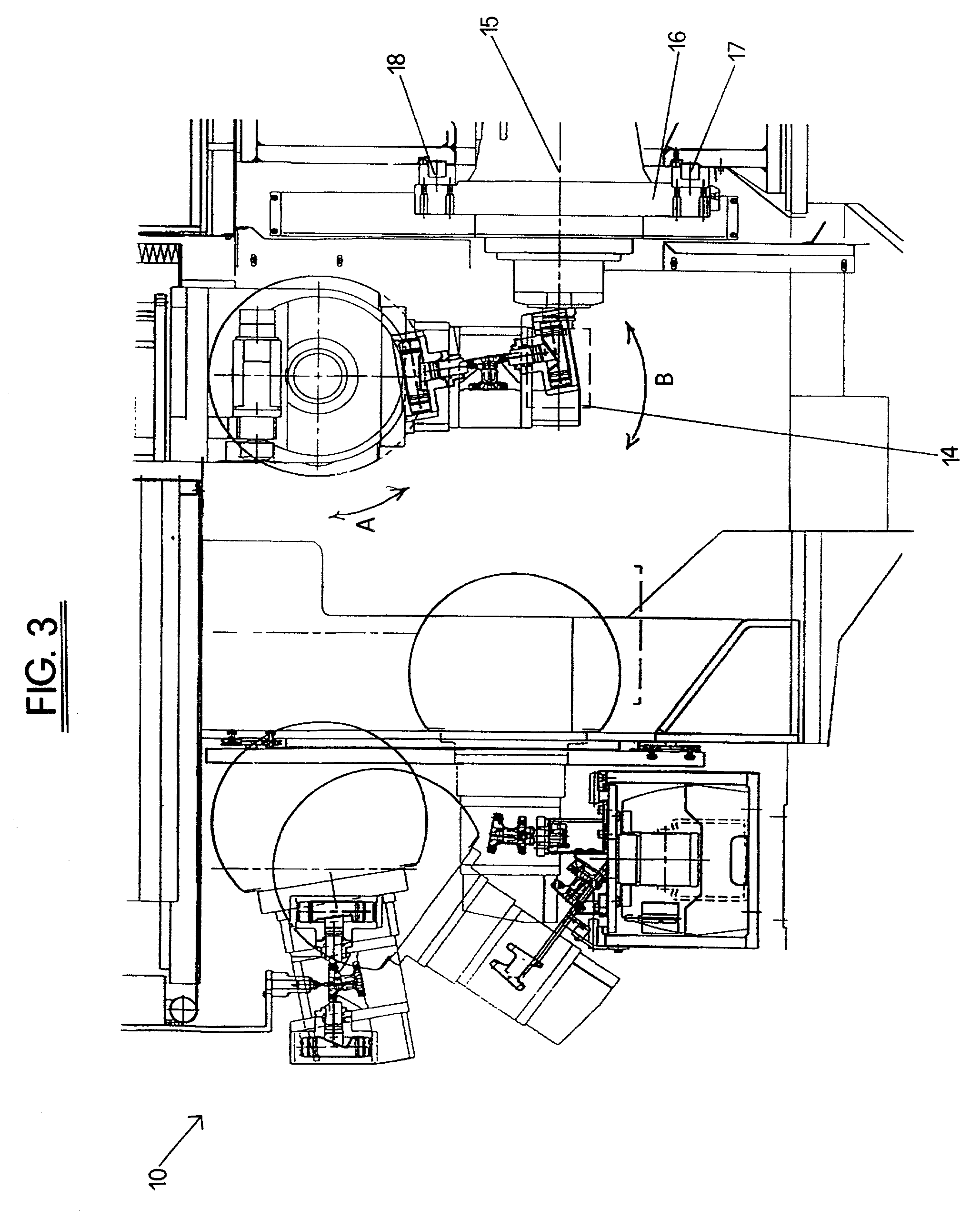

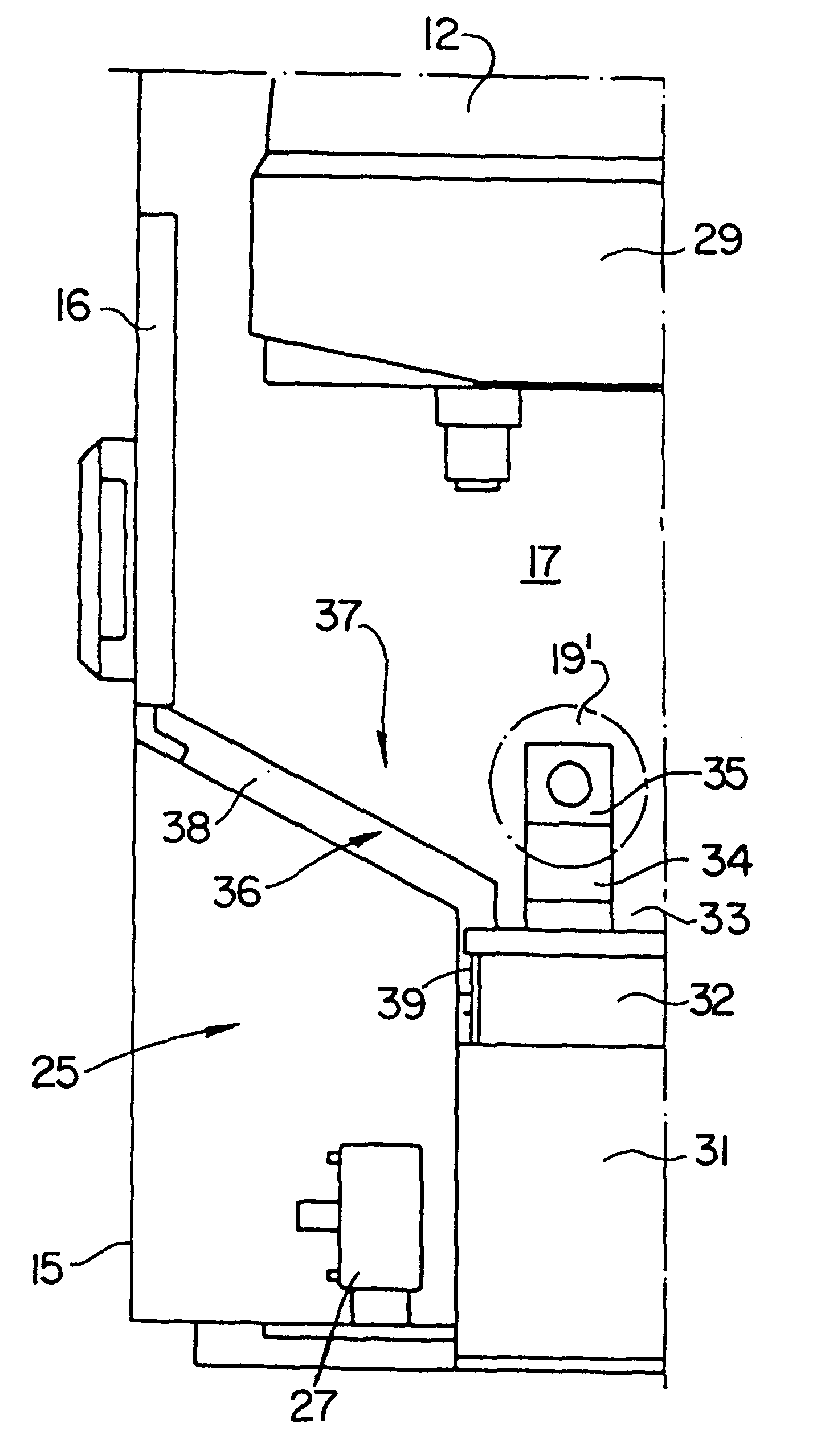

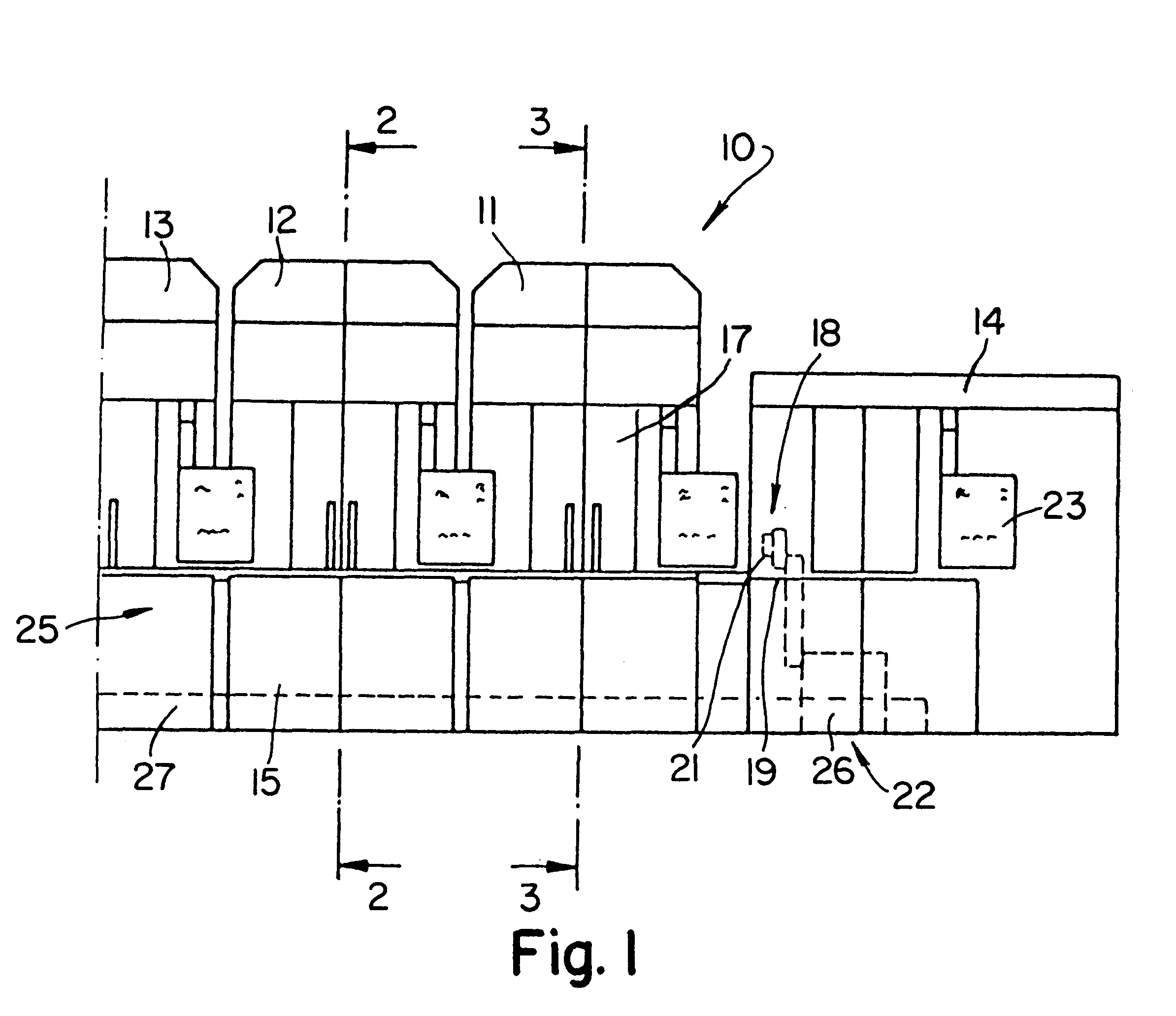

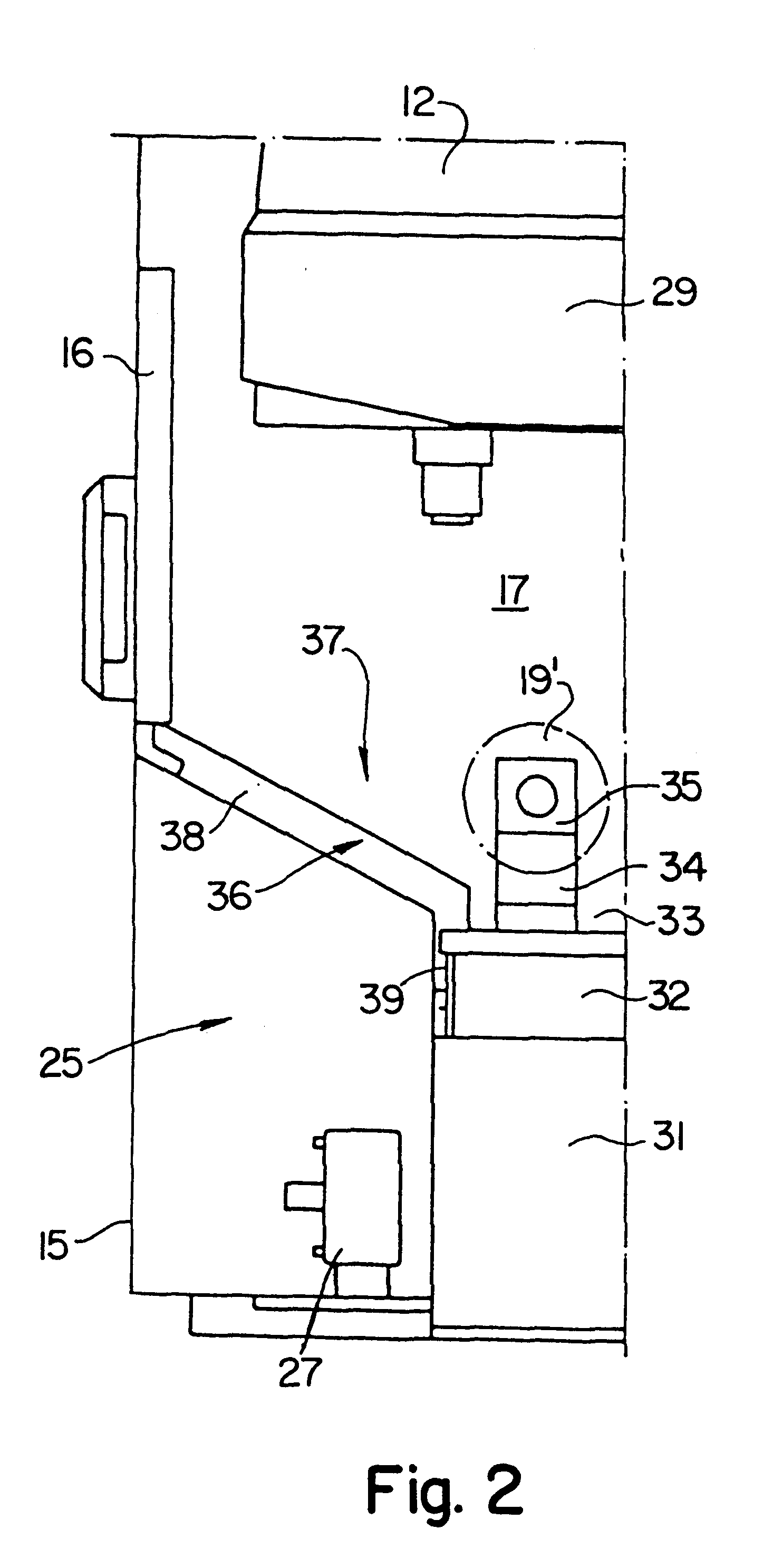

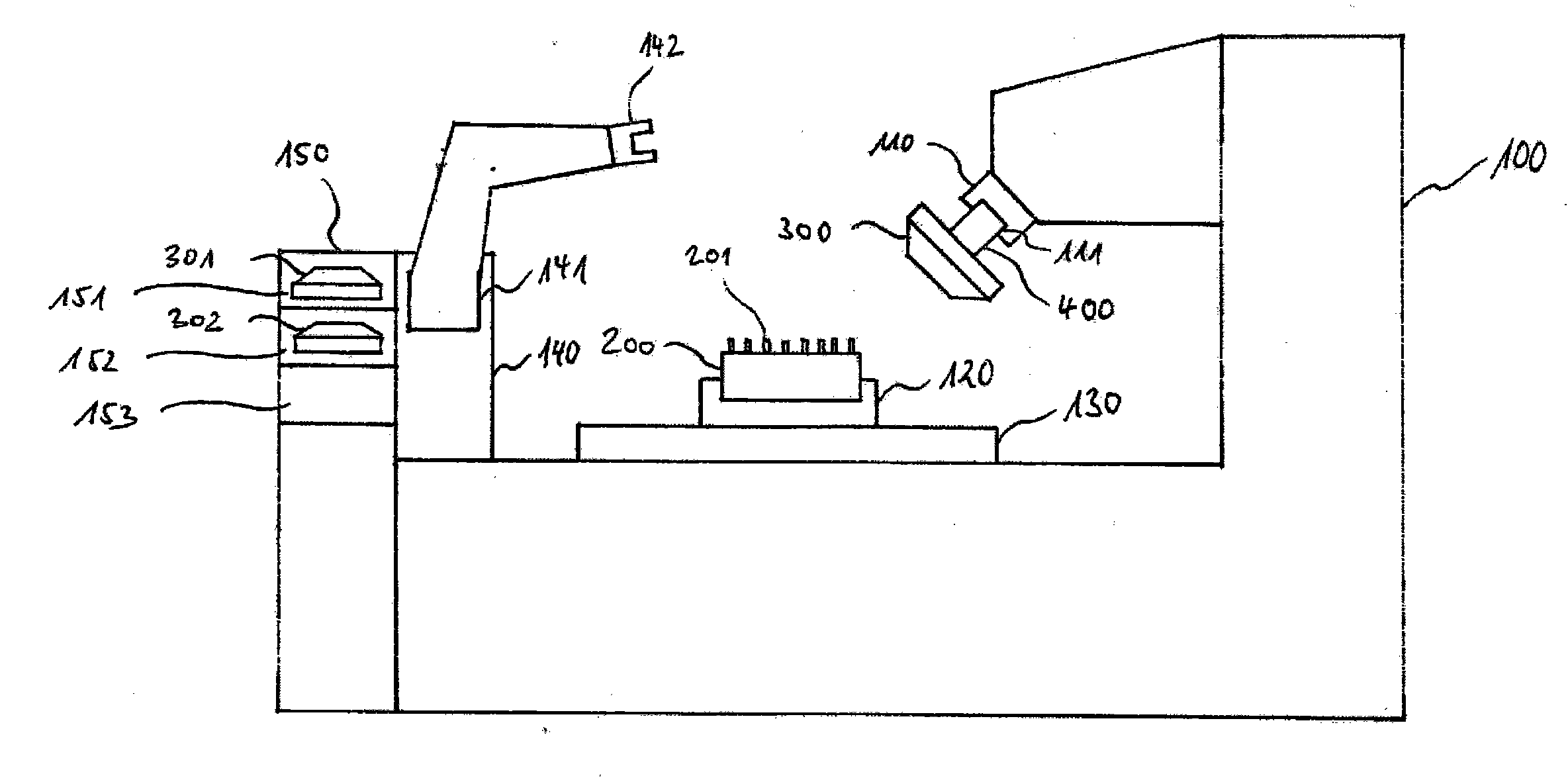

ActiveUS7226403B2Simple processing technologyCharge manipulationMilling machinesEngineeringMachine tool

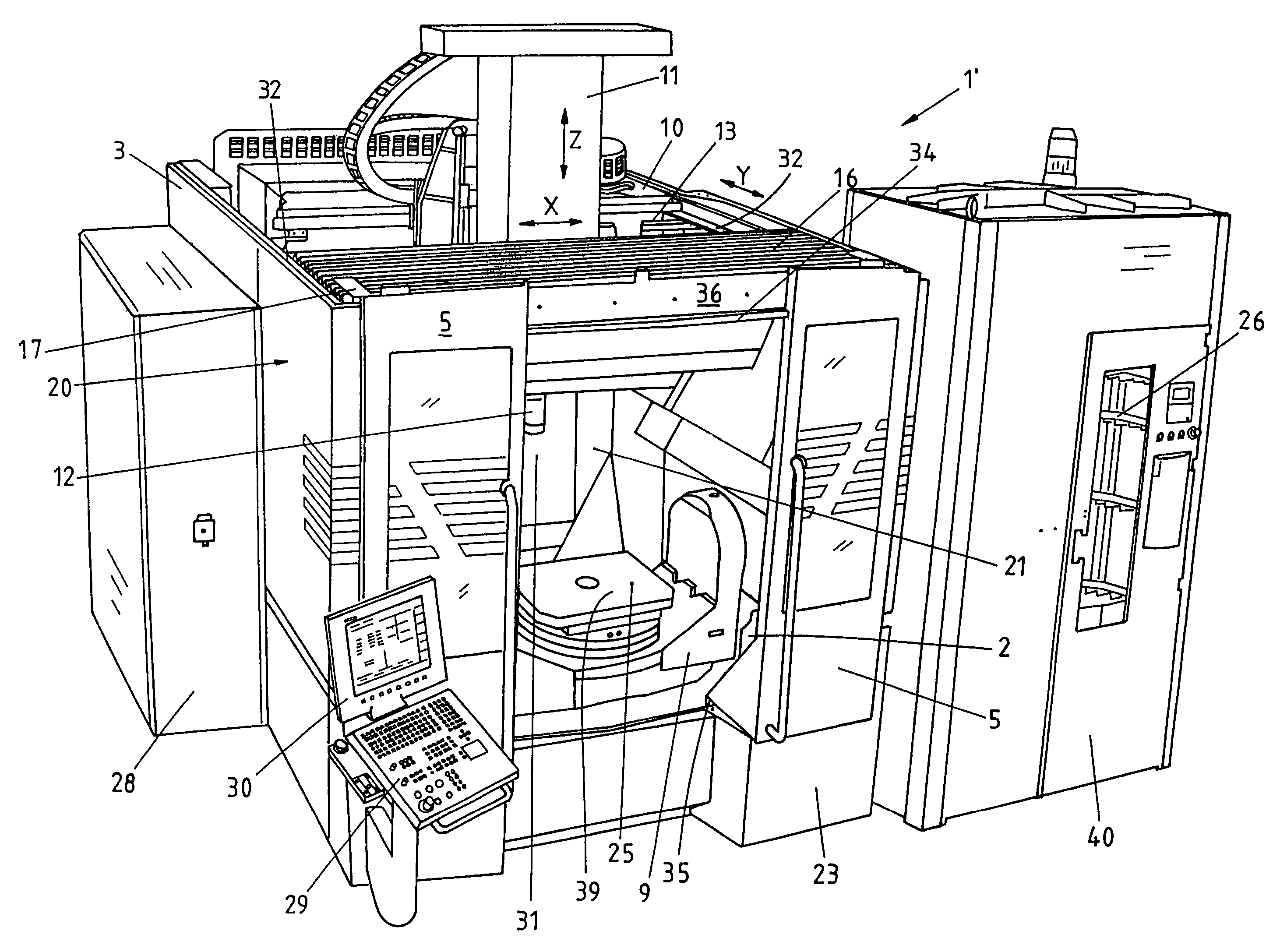

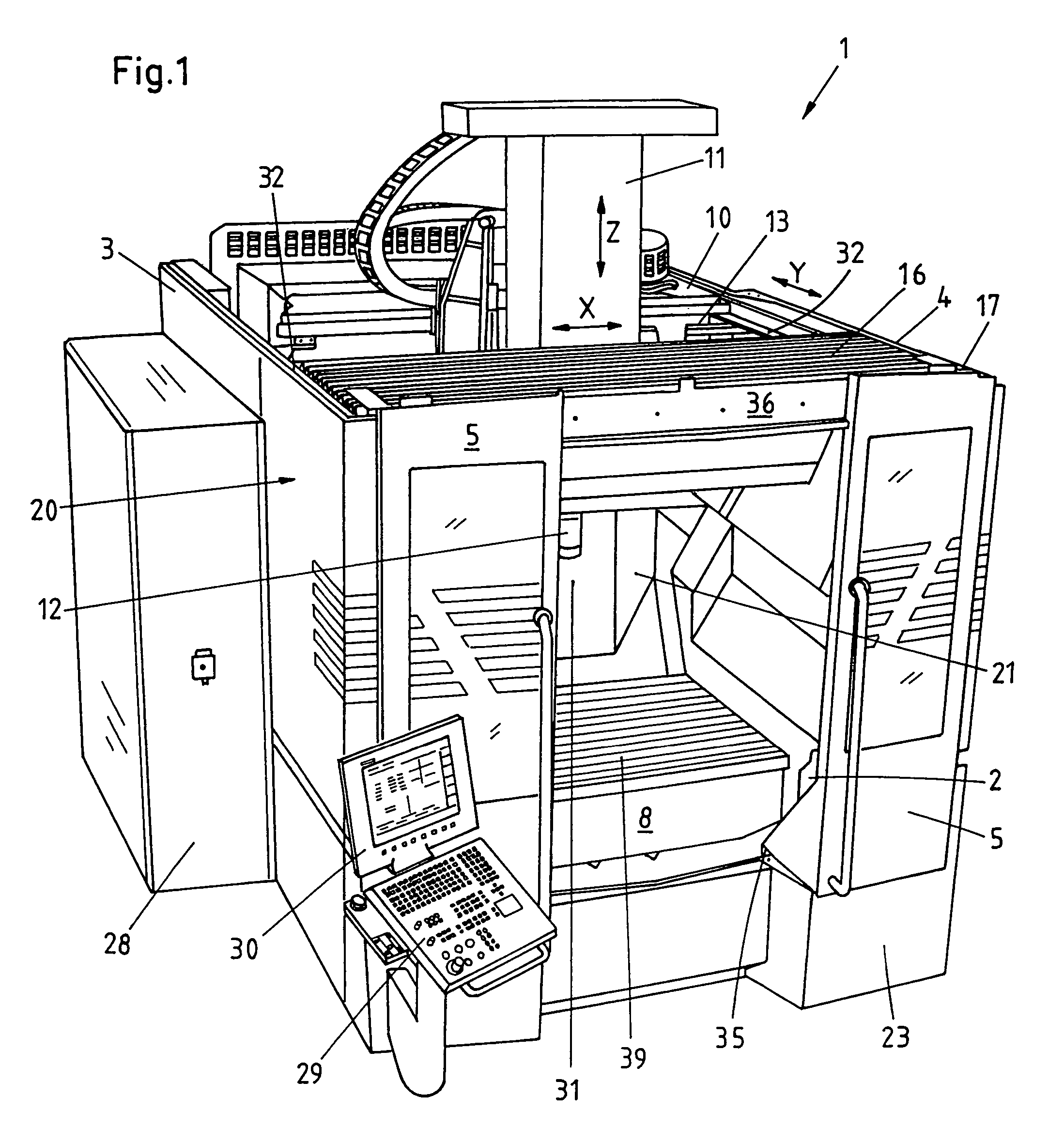

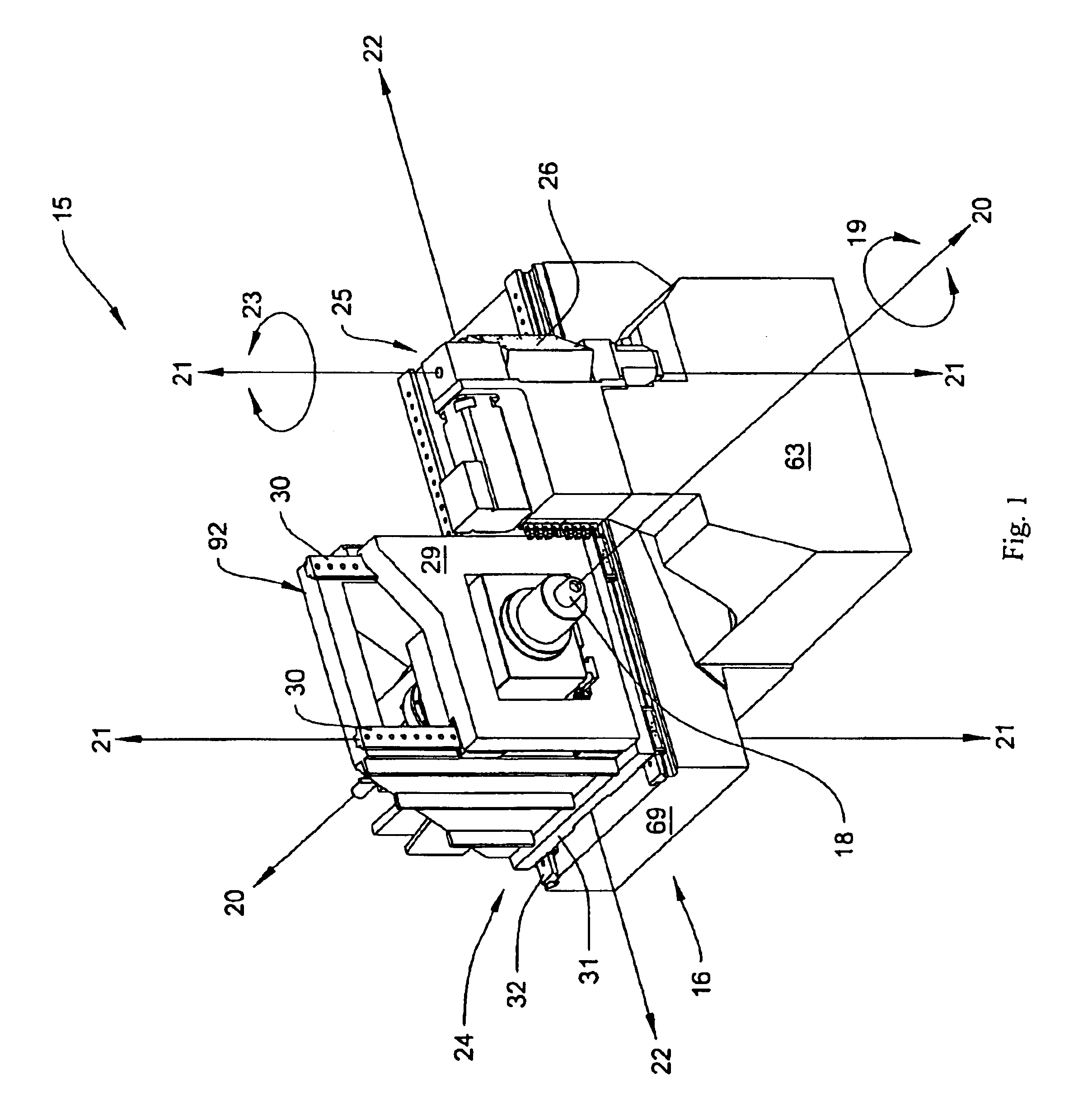

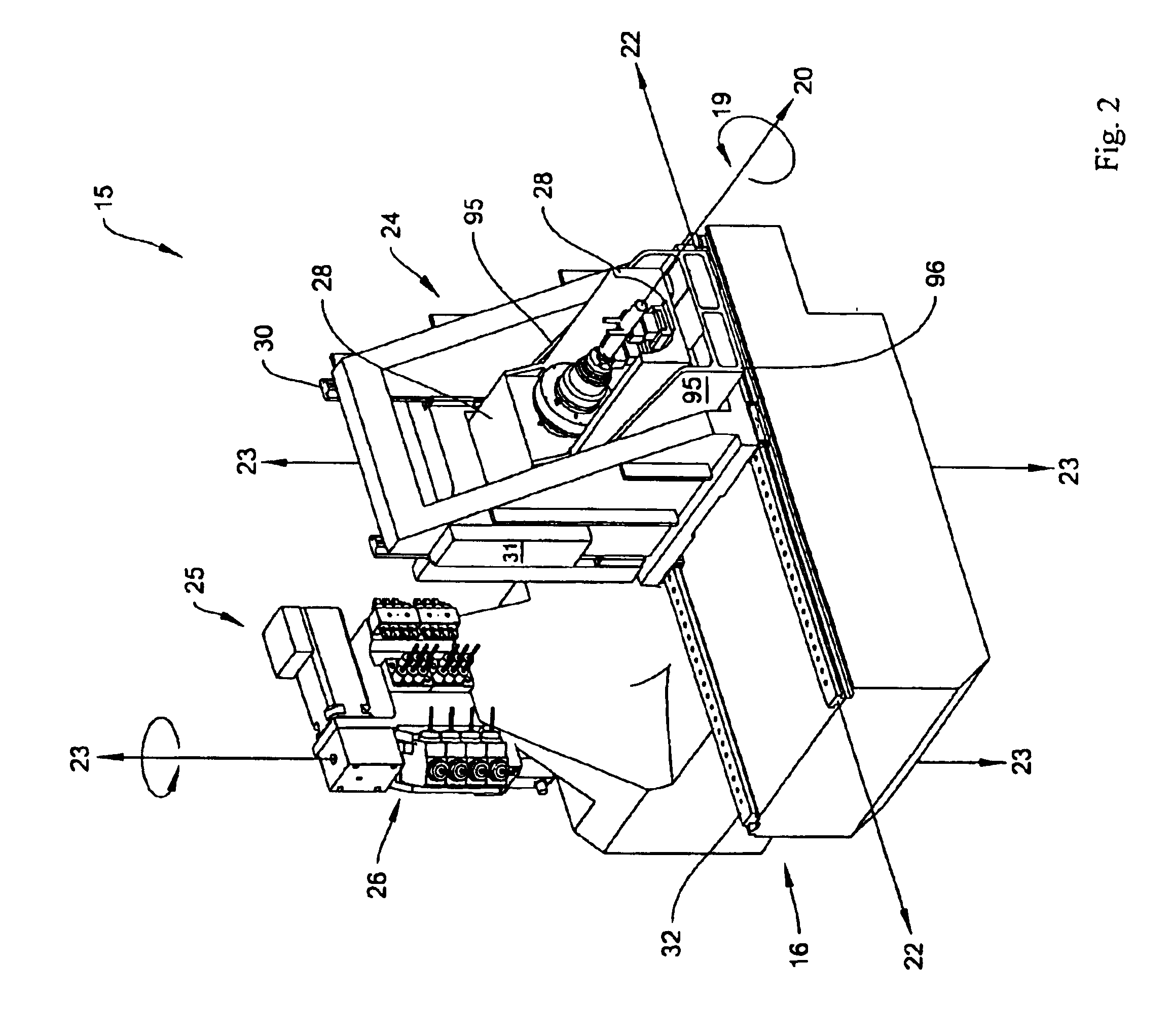

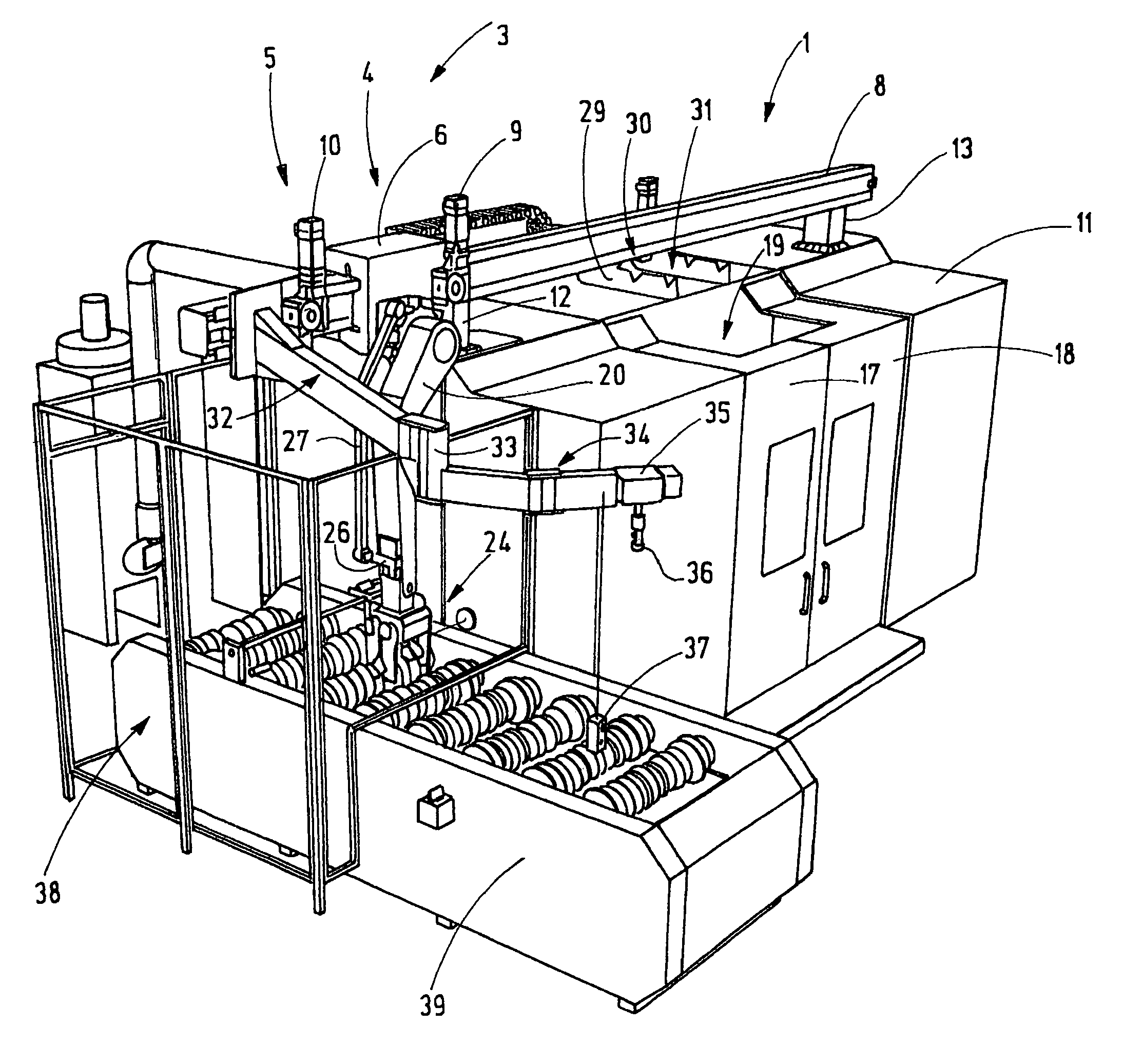

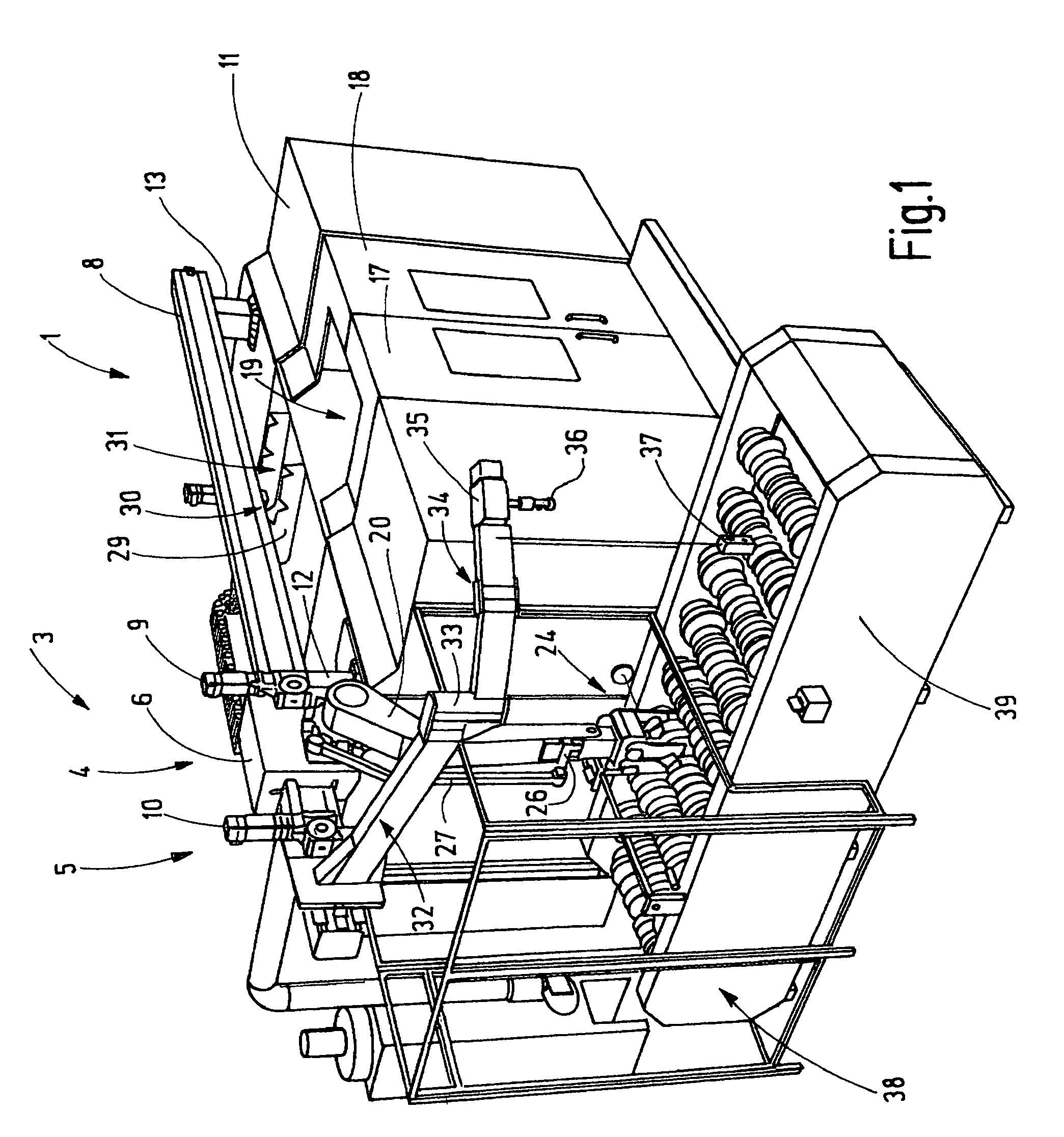

A machine tool (1, 1′), in particular a drilling and milling machine, comprising a housing (20) having a machine bed (2), together with side walls (3, 4) and doors (5, 6, 7), comprising a fixed, pivotable or rotatable work table (8, 9), and comprising a slide (10), transportable in the y direction, for the reception of a spindle head (11), transportable in the x-z direction, for the reception of tools (12), wherein the front door (5), for the enlargement of the working and loading area (21) in the upward direction, is of transomless configuration, the roof region (13) of the machine (1, 1′) has an automatically operable cover (16), the rear region (22) of the machine (1, 1′) has an integrable automatic pallet changer (14), and the machine (1, 1′) is assigned an automatic tool changer (15).

Owner:MIKRON AGIE CHARMILLES

Machine tool, in particular a drilling and milling machine

ActiveUS20070042882A1Simple processing technologyCharge manipulationMilling machinesMachine toolDrilling machines

A machine tool (1, 1′), in particular a drilling and milling machine, comprising a housing (20) having a machine bed (2), together with side walls (3, 4) and doors (5, 6, 7), comprising a fixed, pivotable or rotatable work table (8, 9), and comprising a slide (10), transportable in the y direction, for the reception of a spindle head (11), transportable in the x-z direction, for the reception of tools (12), wherein the front door (5), for the enlargement of the working and loading area (21) in the upward direction, is of transomless configuration, the roof region (13) of the machine (1, 1′) has an automatically operable cover (16), the rear region (22) of the machine (1, 1′) has an integrable automatic pallet changer (14), and the machine (1, 1′) is assigned an automatic tool changer (15).

Owner:MIKRON AGIE CHARMILLES

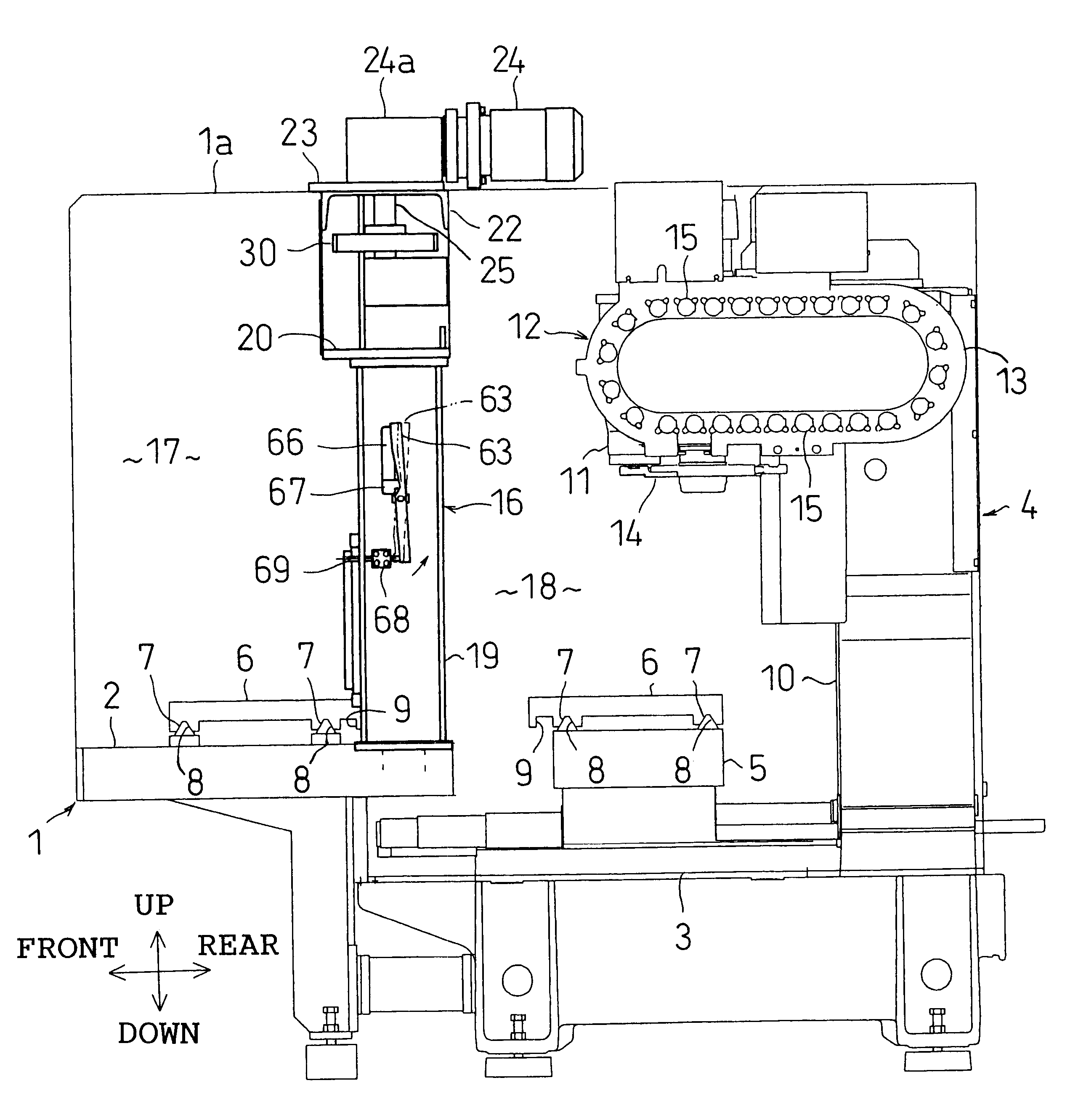

Deep drilling device

InactiveUS6287245B1Improve productivityLarge movementAutomatic control devicesRevolution surface grinding machinesEngineeringMechanical engineering

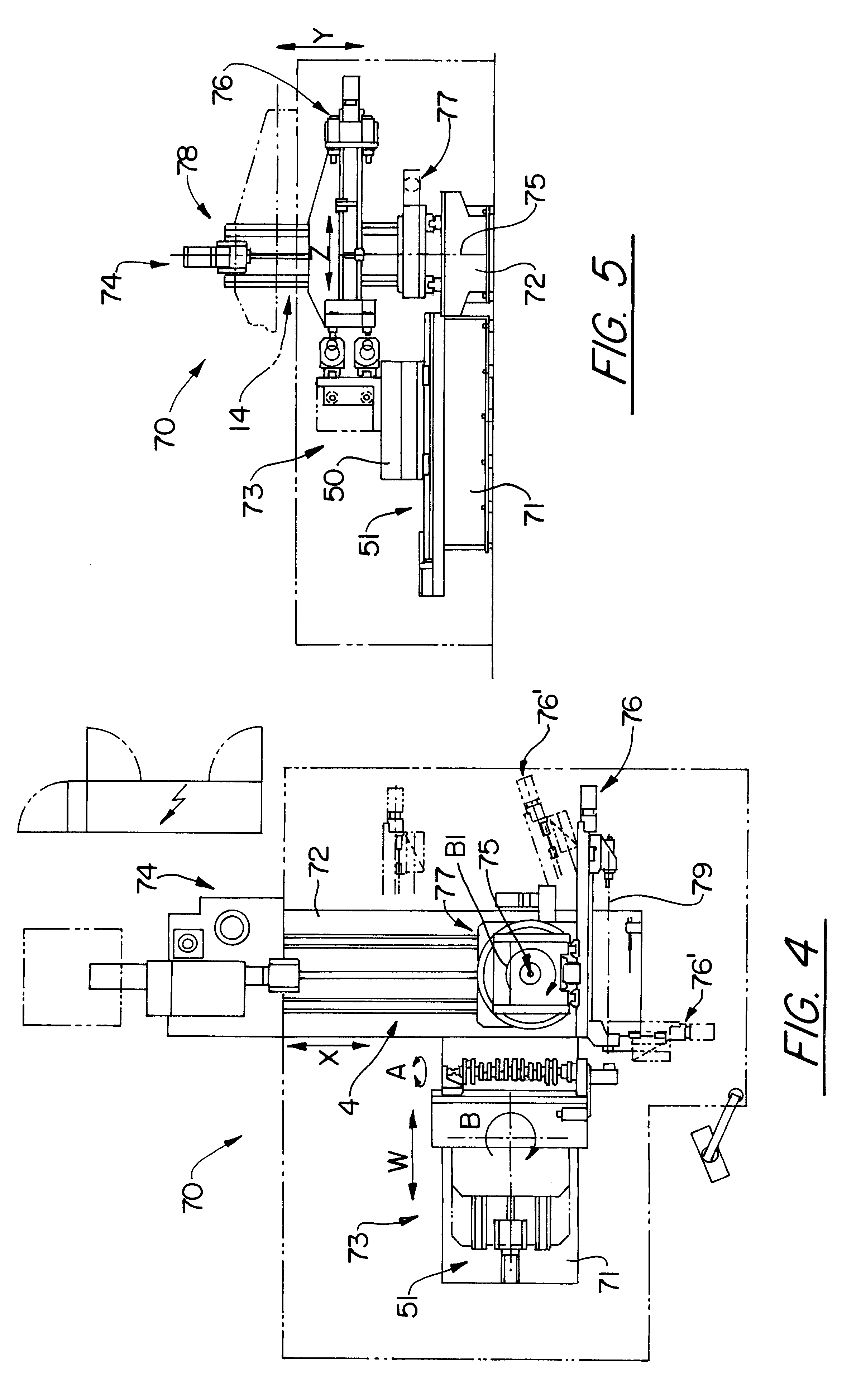

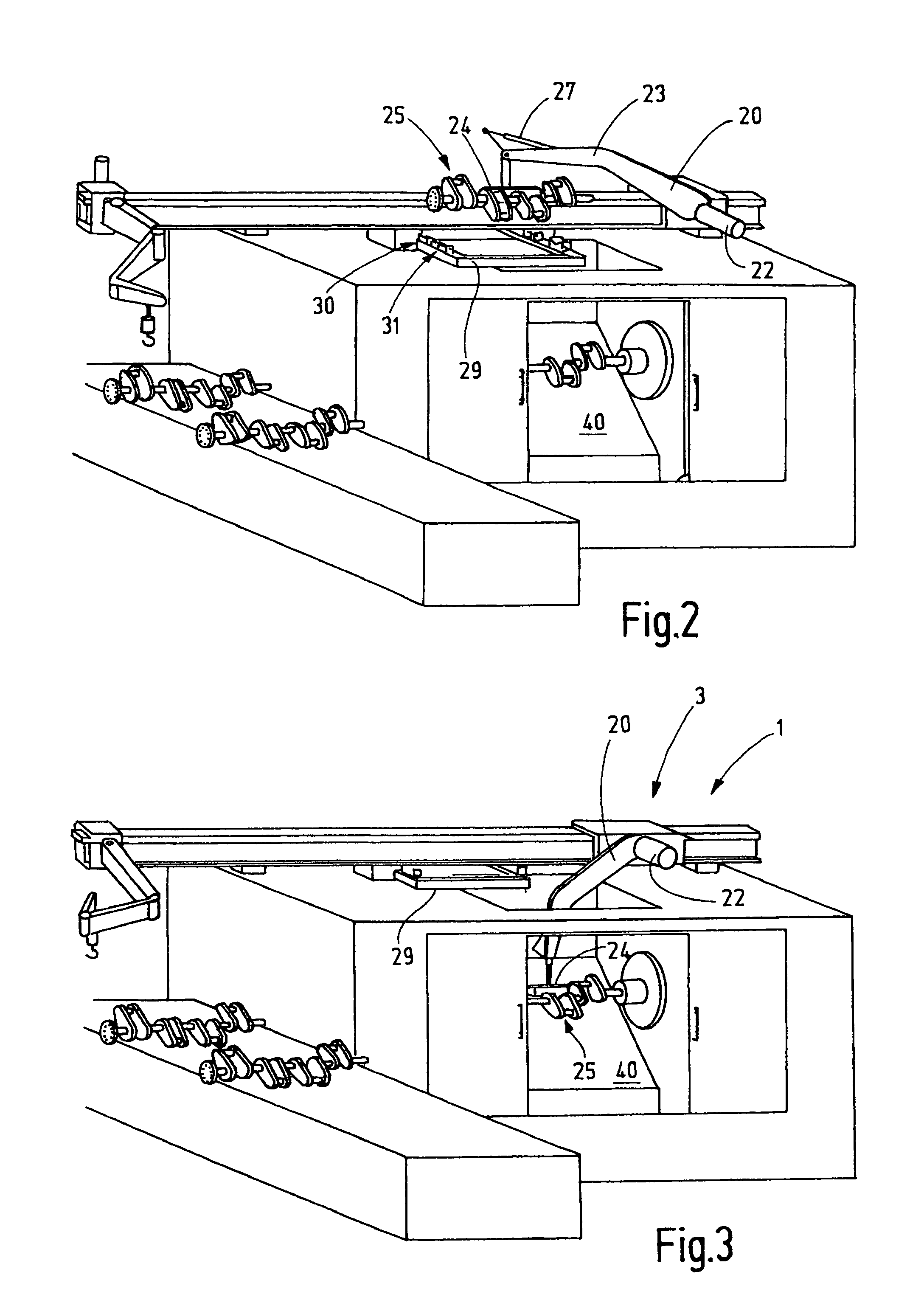

A deep drilling device suitable for drilling in workpieces, particularly crankshafts, holes at different positions and / or in different orientations relative to a work longitudinal axis, has a deep drilling unit and a work holding unit cooperating therewith. The deep drilling unit permits parallel displacements of the deep drilling tools in a horizontal X direction and a vertical Y direction, as well as a tool feed parallel to the spindle axis. The tool holding device receives one or more crankshafts in such a way that their longitudinal axis is horizontally oriented and permits a rotation about the longitudinal axis and a swivelling of the workpieces about a vertical rotary axis. As a result both different tilt angles of the holes relative to the work longitudinal axis and also different positions of the holes relative to the circumference of the workpieces can be obtained.

Owner:TBT TIEFBOHRTECHN

Machine tool

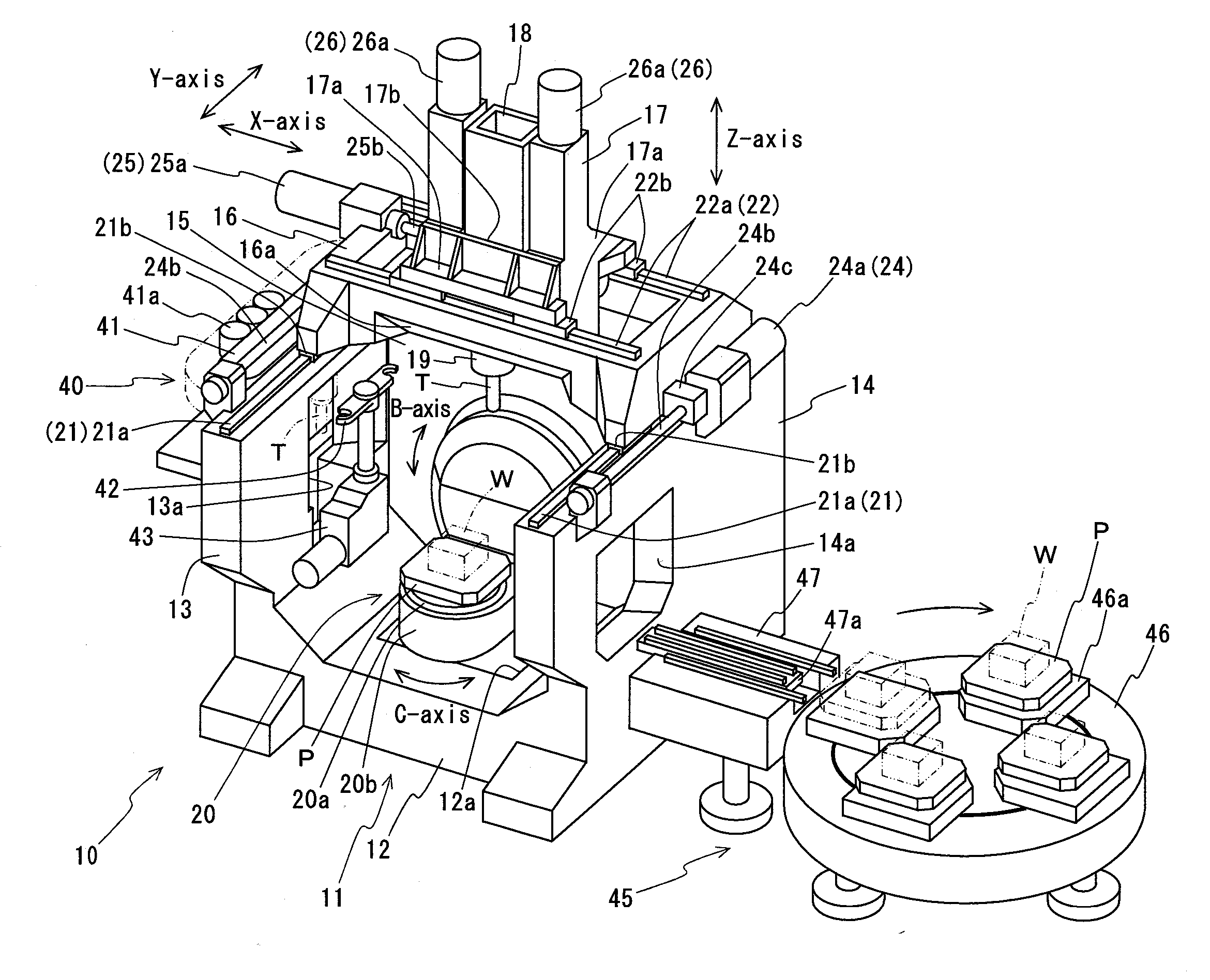

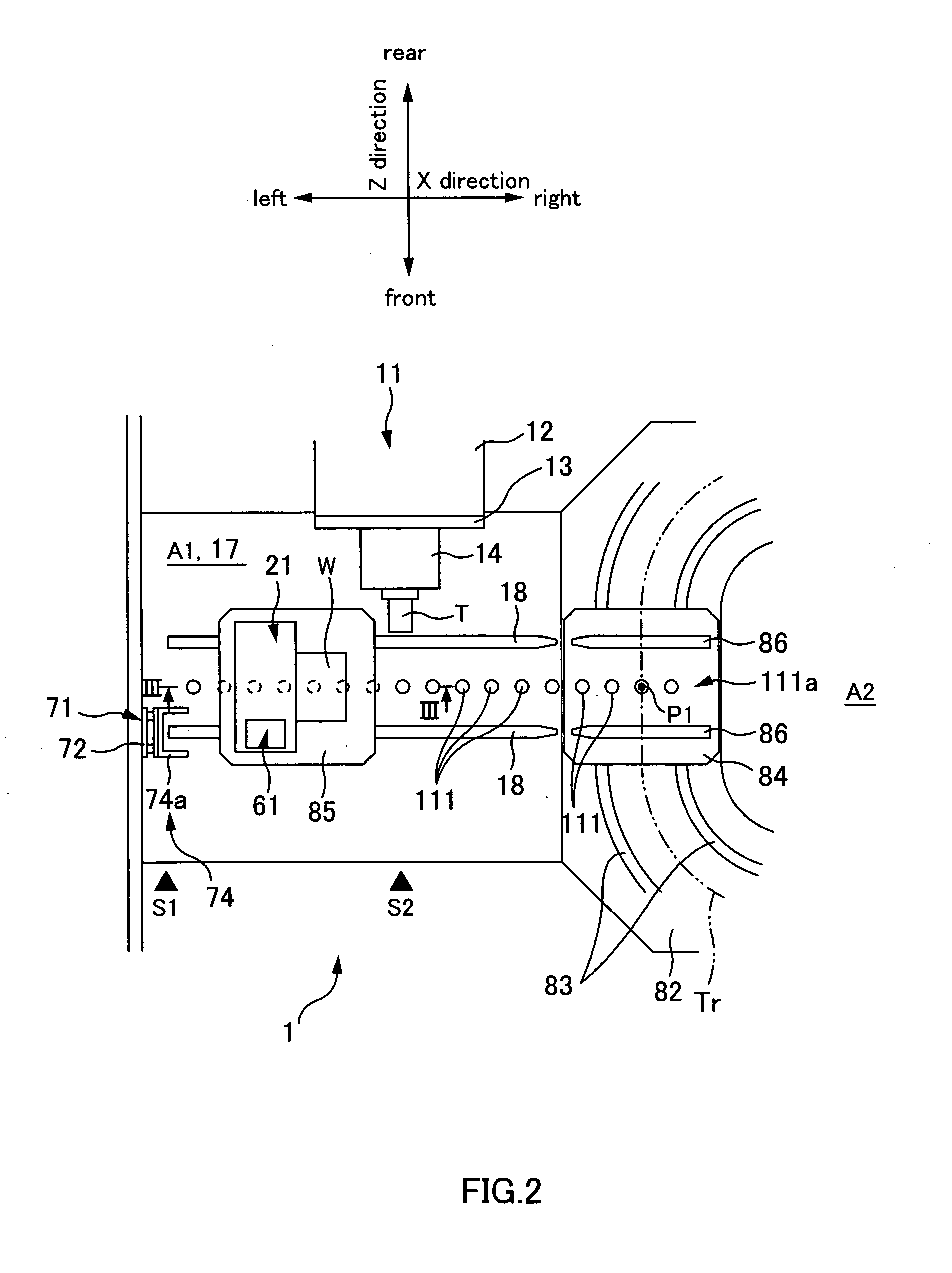

A machine tool includes: a main spindle adapted to be rotatable with a workpiece chucked thereby; a tool spindle capable of moving in directions of three axes perpendicular to each other and capable of pivoting about one of the axes, the axis being perpendicular to the main spindle; an automatic tool changer adapted to detachably attach a first tool and a chucking unit to the tool spindle, the first tool being used for machining the workpiece chucked by the main spindle, the chucking unit being used for chucking the workpiece; and a tool post having a second tool mounted thereon, the second tool being used for machining the workpiece chucked by the chucking unit attached to the tool spindle.

Owner:STAR MICRONICS

Machine tool

ActiveUS7357769B2Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesEngineeringSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI CO LTD

Machine tool

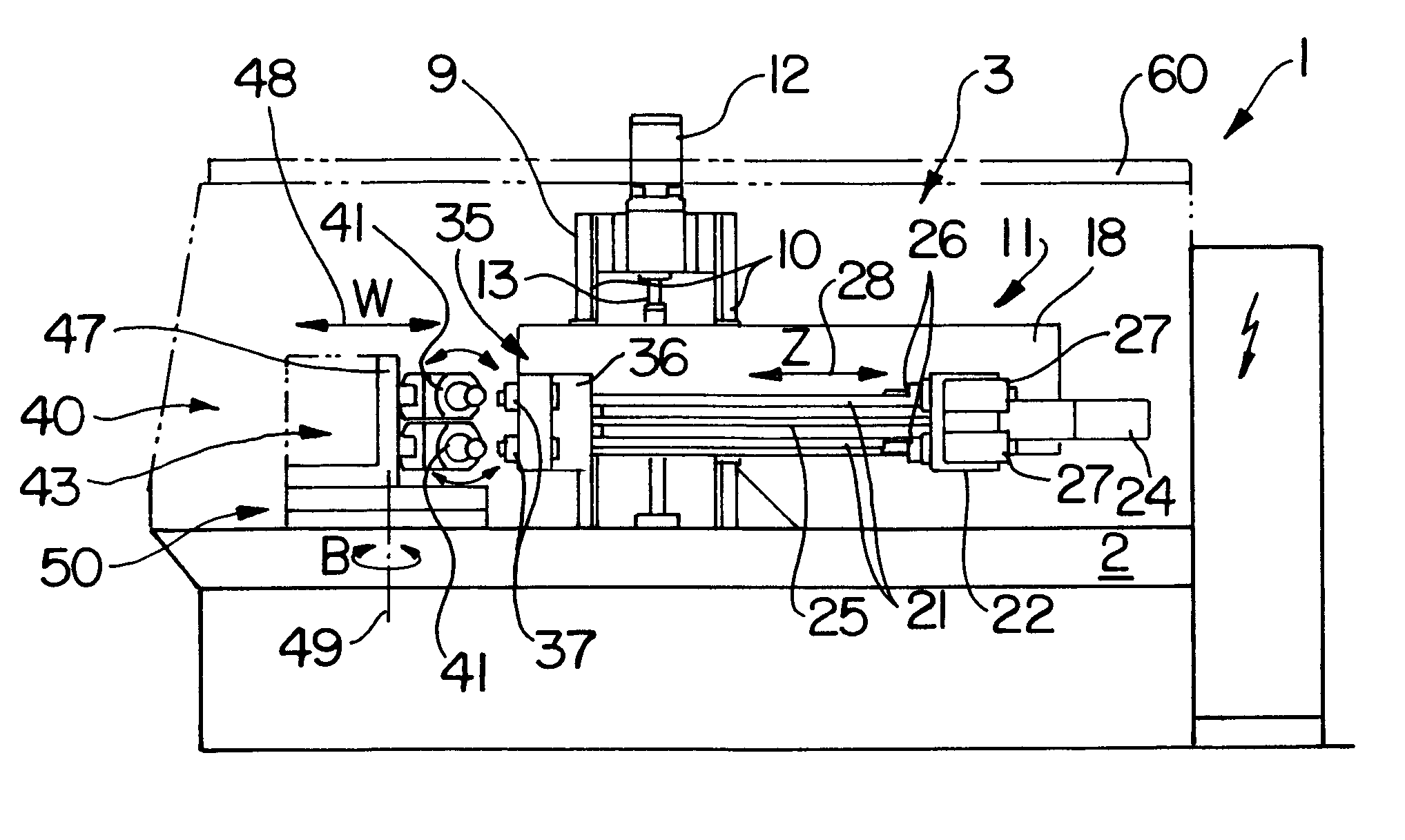

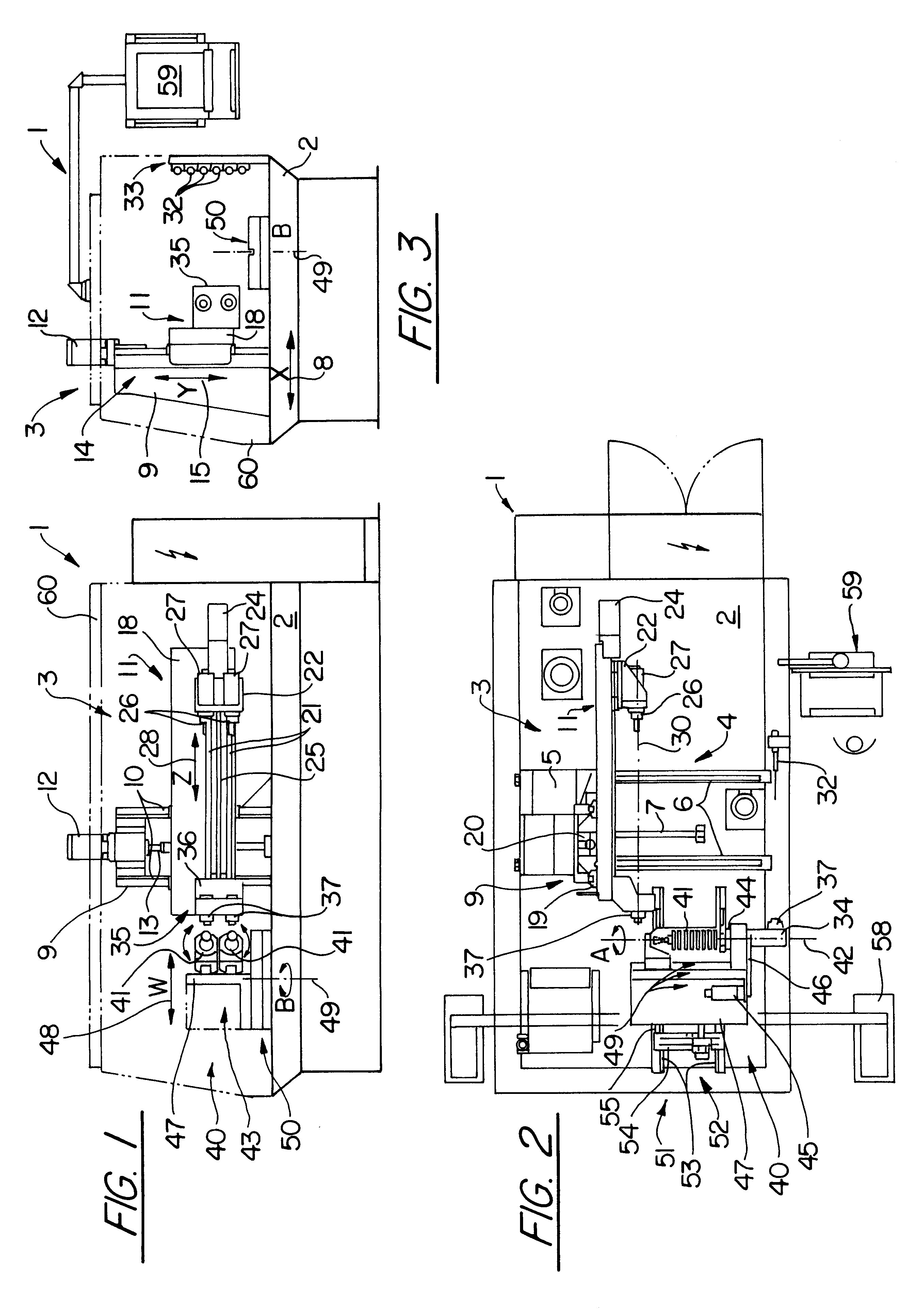

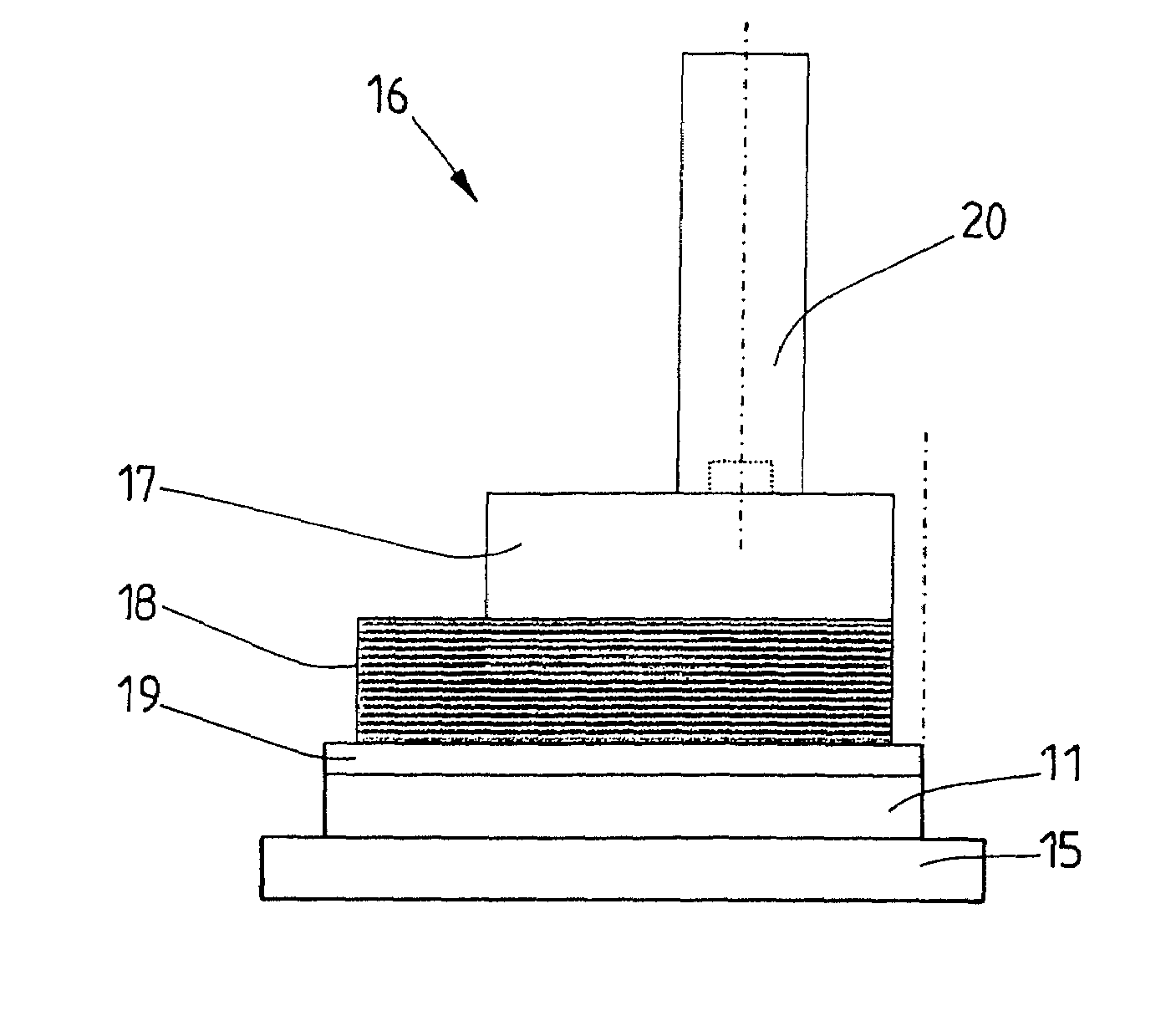

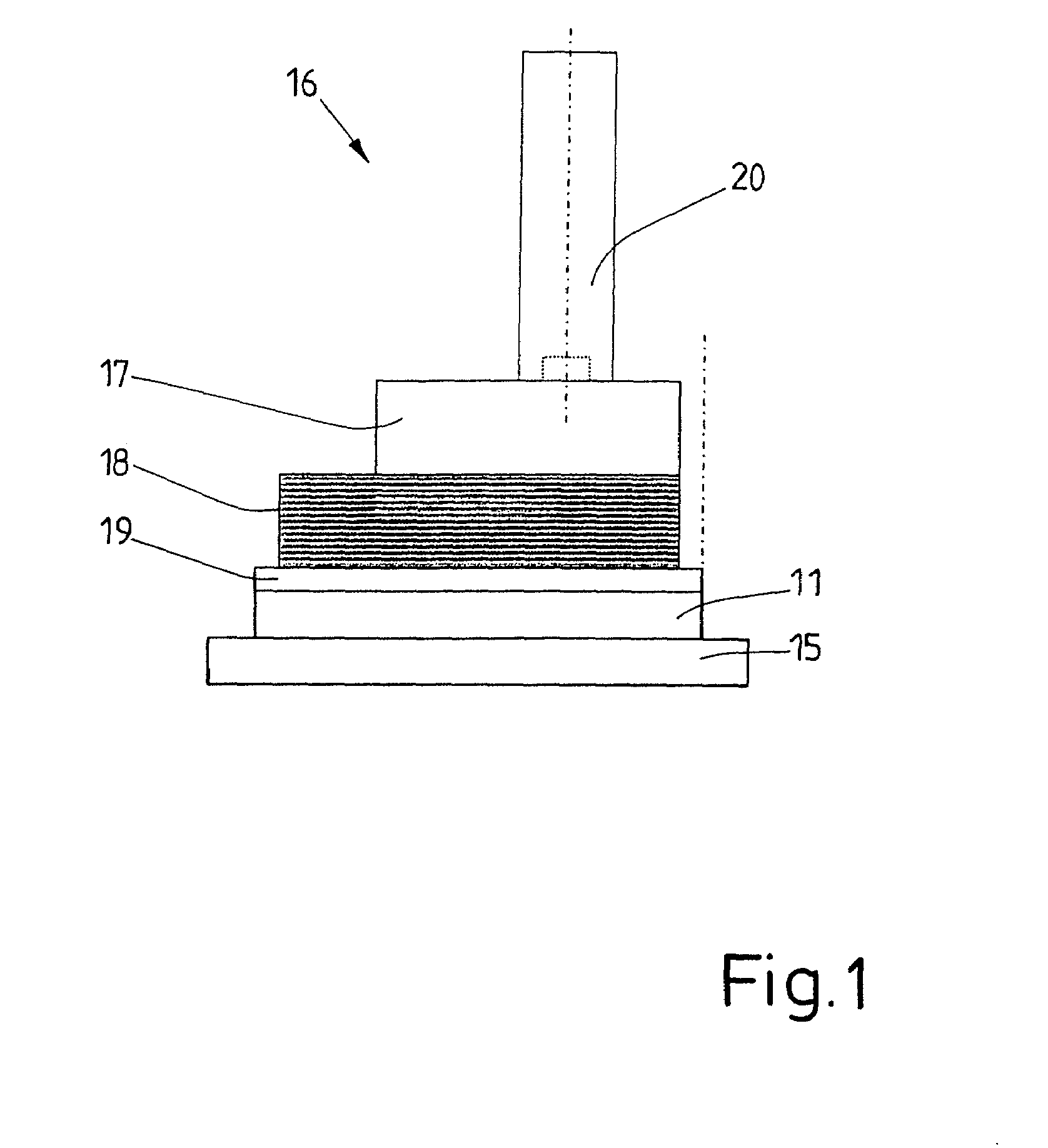

InactiveUS6949056B2Convenient to accommodateReduce configurationLathesAutomatic control devicesEngineeringMachine tool

An improved machine tool having a support structure (16), a spindle (18) rotatably supported by the structure, the spindle adapted for engagement with a workpiece (56), the spindle operatively arranged to selectively rotate in an annular A-axis (19) and about a linear Z-axis (20), a tool frame (25) supported by the structure, the tool frame having an array of individual tool-holding stations adapted for engagement with a tool (49), an actuating mechanism (24), the actuating mechanism operatively arranged to selectively provide movement of the workpiece in the spindle relative to the tool in the tool frame in the Z-axis, in a linear Y-axis (21) that is perpendicular to the Z-axis, and in a linear X-axis (22) that is perpendicular to both the Z-axis and the Y-axis, the position of the stations in the array defined by at least an X-axis coordinate and a Y-axis coordinate, at least two of the stations in the array positioned such that the two stations have neither the same X-axis coordinate nor the same Y-axis coordinate. The tool frame may comprise a tool frame actuating portion operatively arranged to selectively rotate in an annular axis that is about a linear axis that is not the Z-axis, and the annular axis may be a B-axis that is about the Y-axis.

Owner:MFR & TRADERS TRUST COMPANY AS AGENT

Tool changer of machine tool

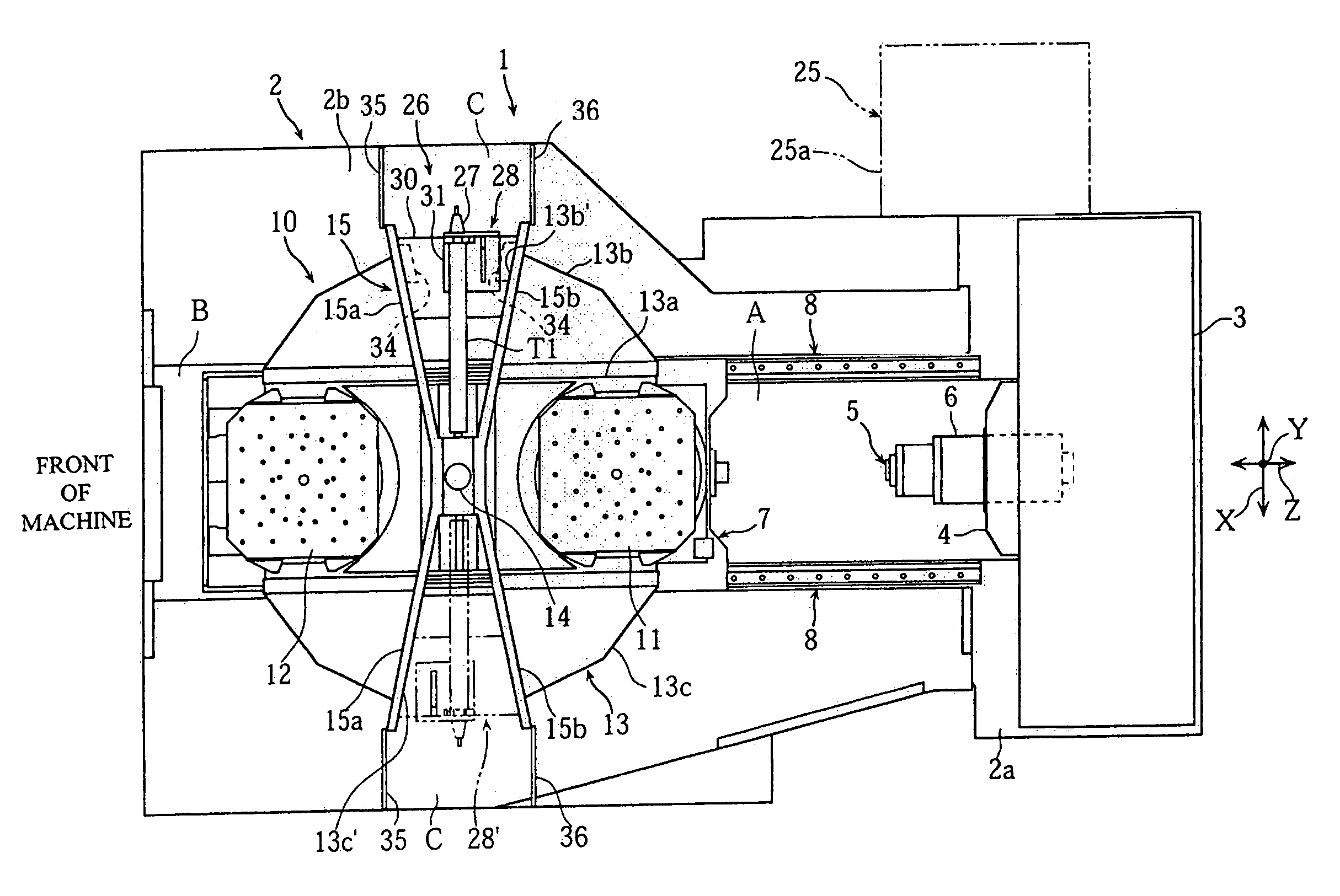

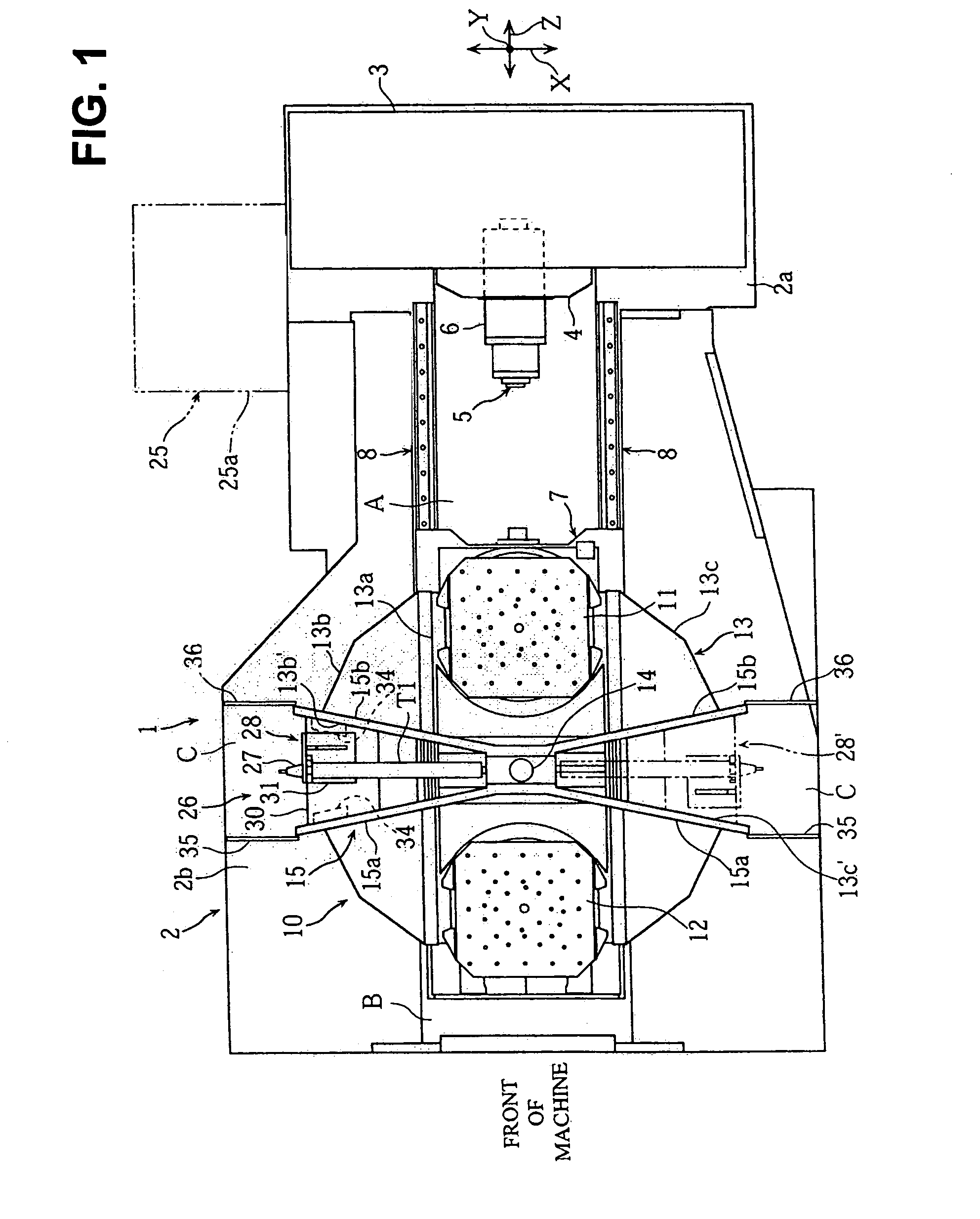

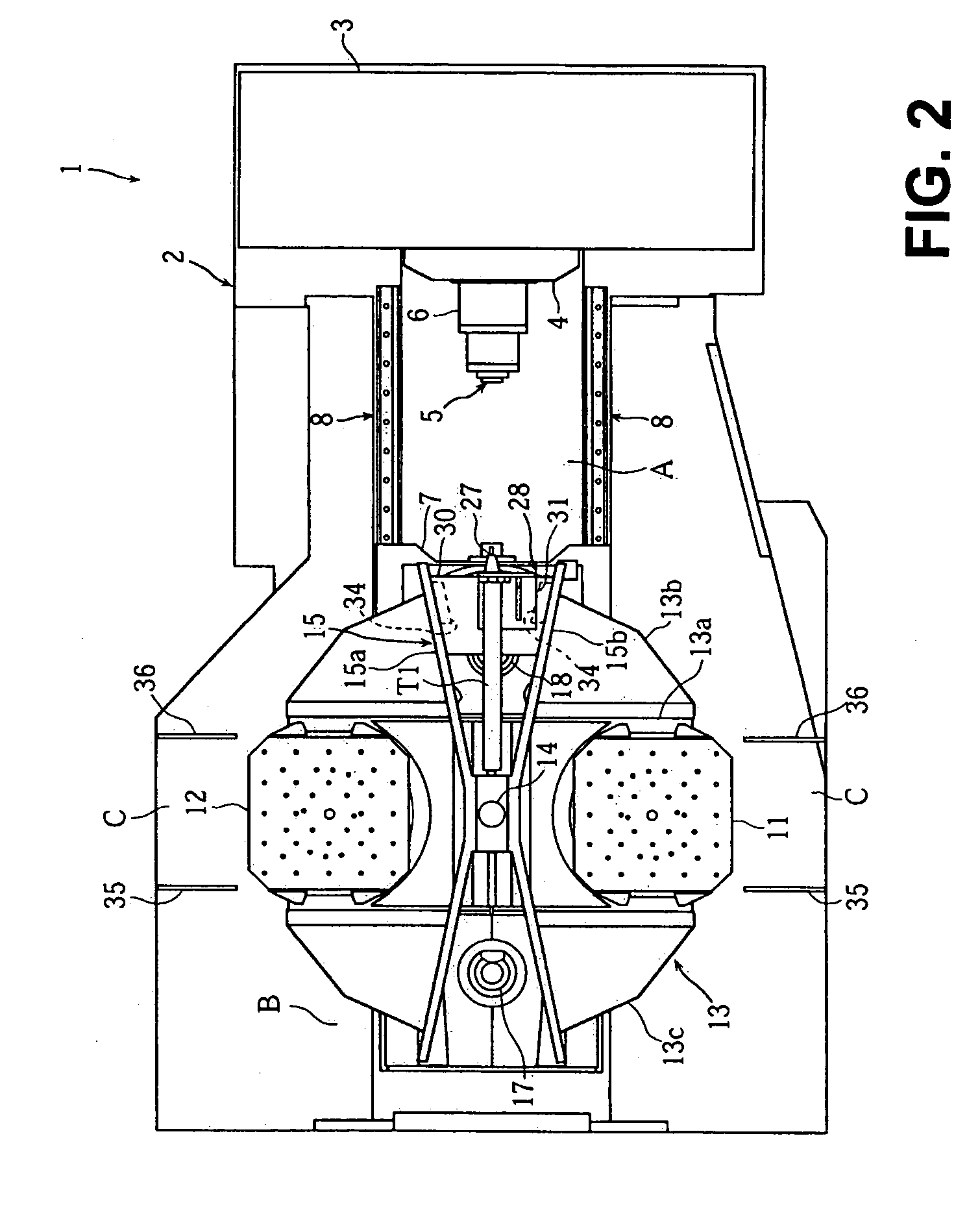

InactiveUS7108647B2Small sizeCost containmentAutomatic control devicesProtection and storage accessoriesSize increaseEngineering

The present invention provides a tool changer of a machine tool capable of suppressing cost increase and preventing size increase of the machine when a tool magazine is mounted. In a tool changer of a machine tool provided with a pallet change mechanism 10 in which a machining-side pallet 11 disposed on a machining area A side and a standby-side pallet 12 disposed on a standby area B side are turned around a turn shaft 14 by a turning member 13 to be automatically changed, a tool magazine 28 holding a plurality of tools T1 to T4 is disposed between the machining-side pallet 11 and the standby-side pallet 12 in the turning member 13 and the tool magazine 28 is turned by the turning member 13 so that the tools T1 to T4 face a spindle 5 disposed on the machining area A side.

Owner:DMG MORI CO LTD

Machine tool

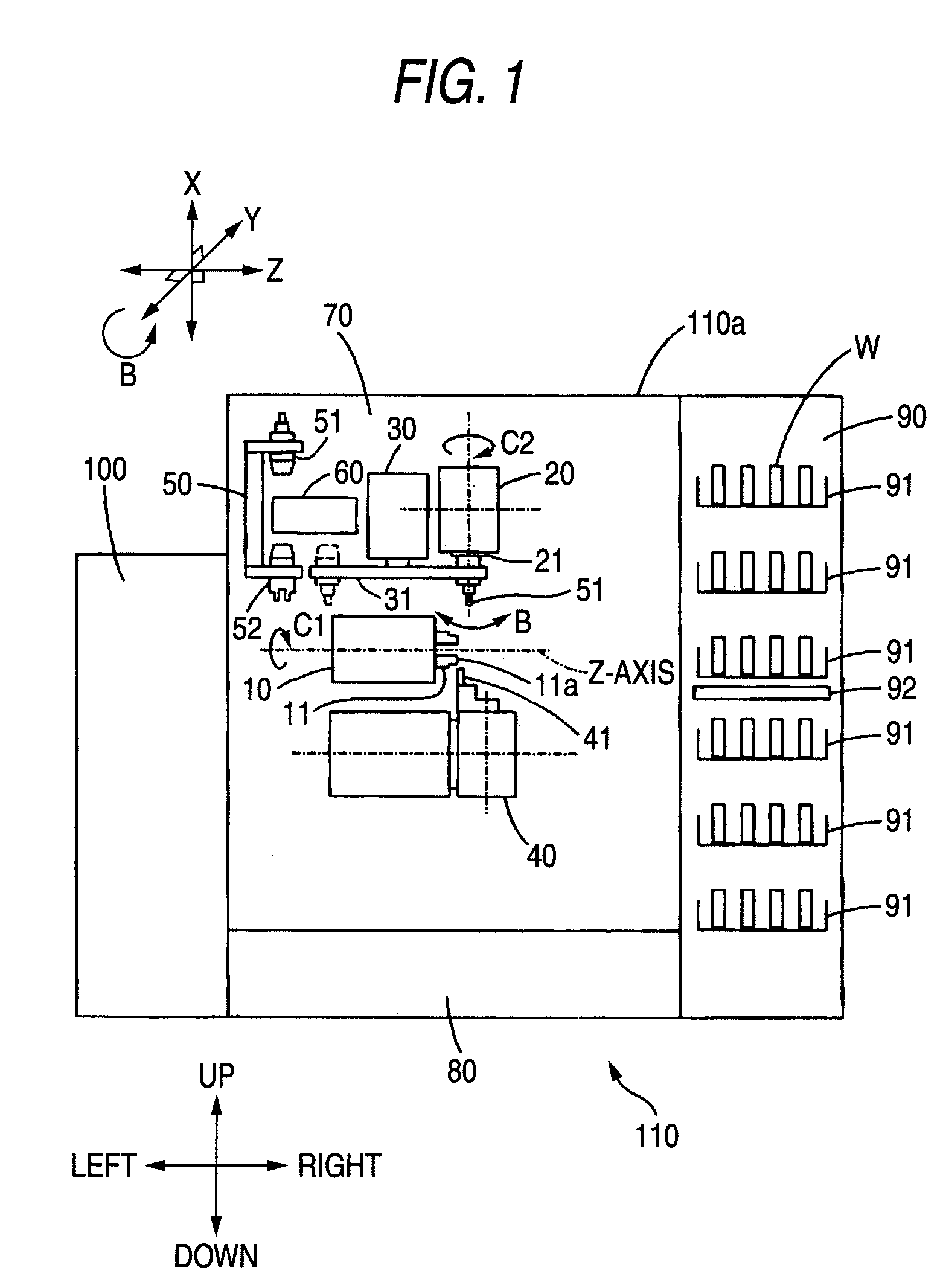

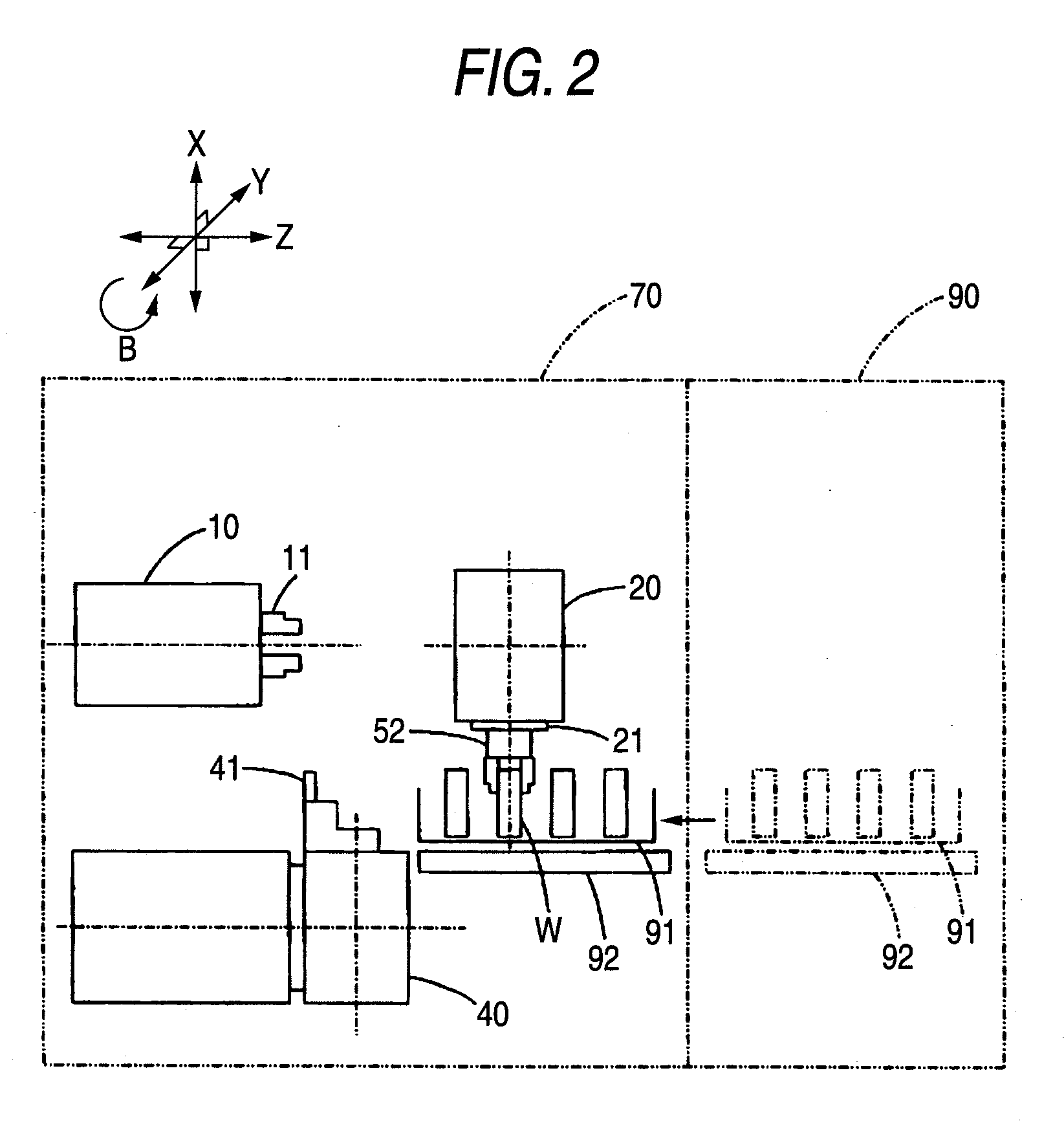

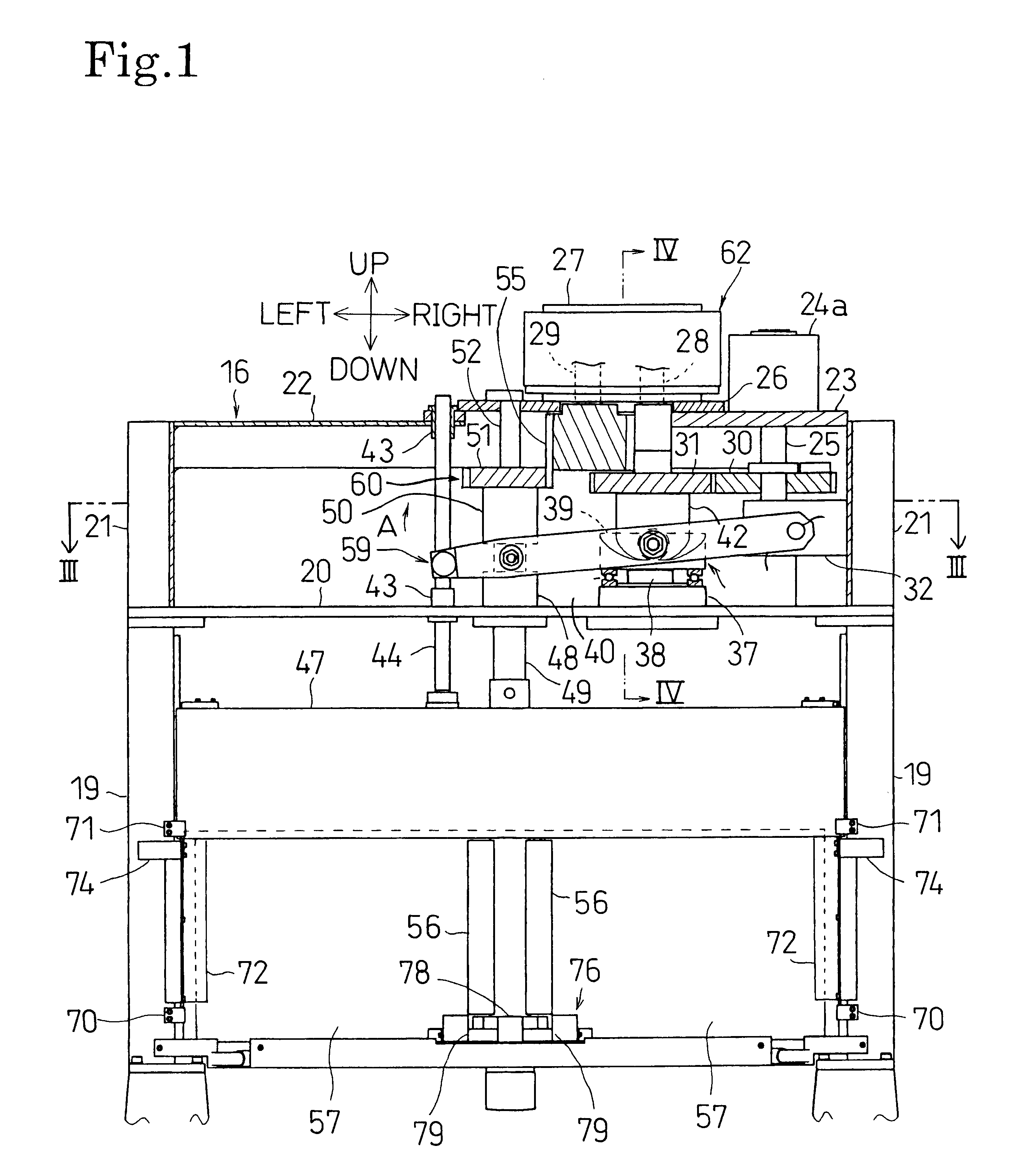

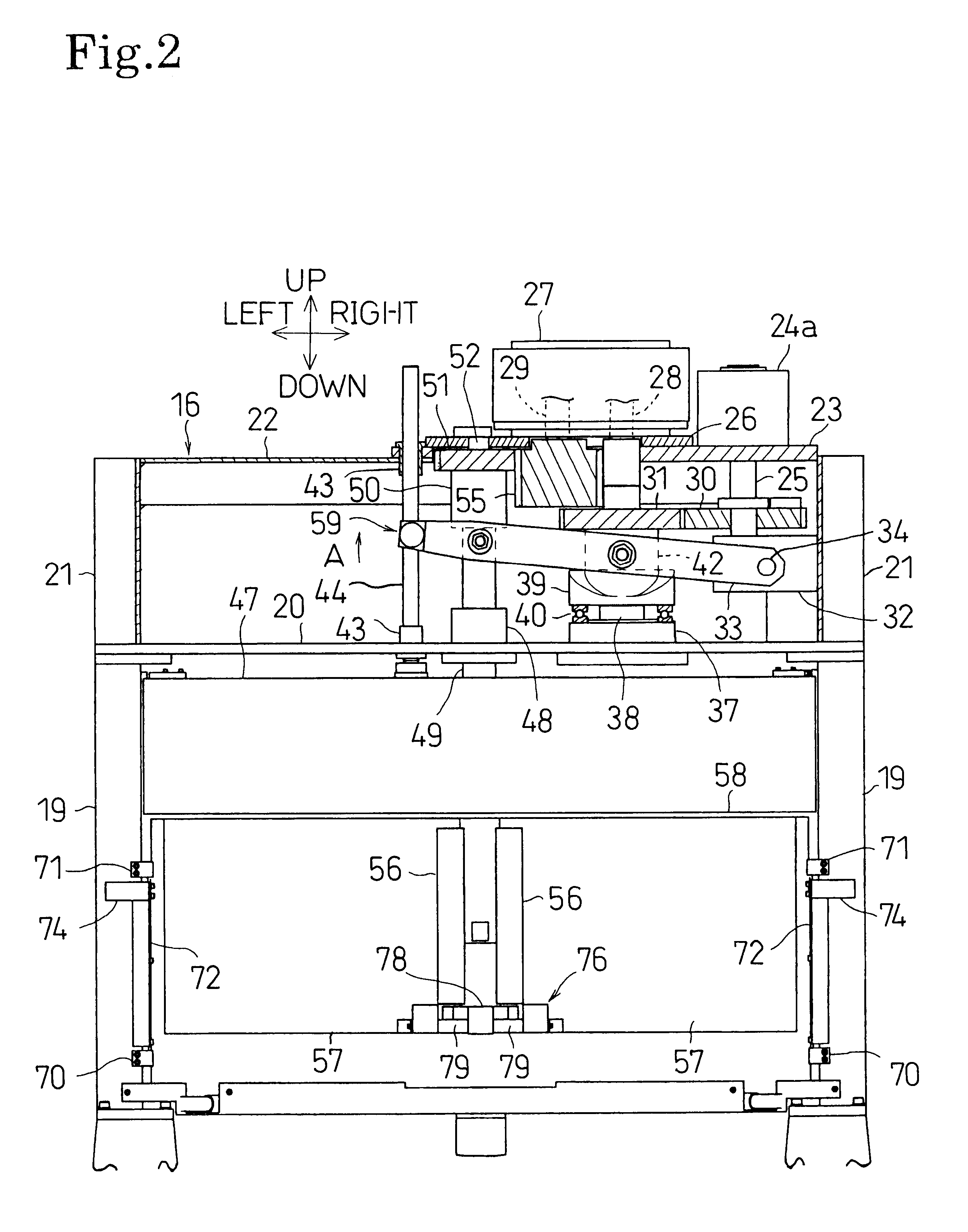

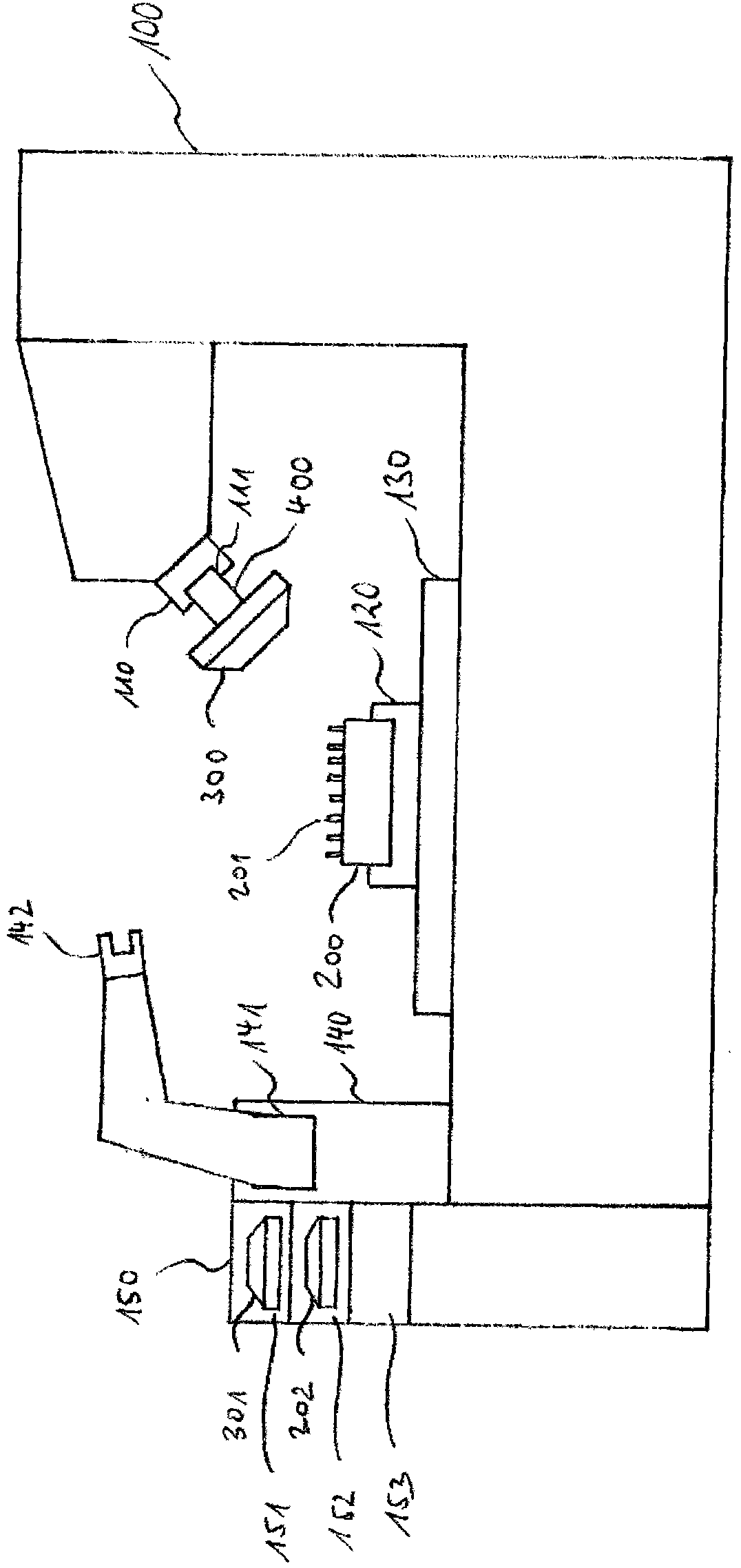

InactiveUS20150298272A1Easy to checkConvenient inspectionLarge fixed membersWork trasfer apparatusEngineeringMachine tool

A machine tool includes a pallet exchanger that is placed adjacent to one side of a body cover covering a workpiece machining space, and that exchanges a first pallet on which a machined workpiece is mounted and that is fixed to an upper surface of a table and a second pallet on which a workpiece to be machined is mounted. The pallet exchanger includes a turning member that has a first holding portion and a second holding portion formed in a pair and turns in a horizontal direction. The first holding portion is located at a first end of the turning member and holds the first pallet, and the second holding portion is located at a second end on the opposite side of the turning member from the first end and holds the second pallet.

Owner:OKUMA CORP

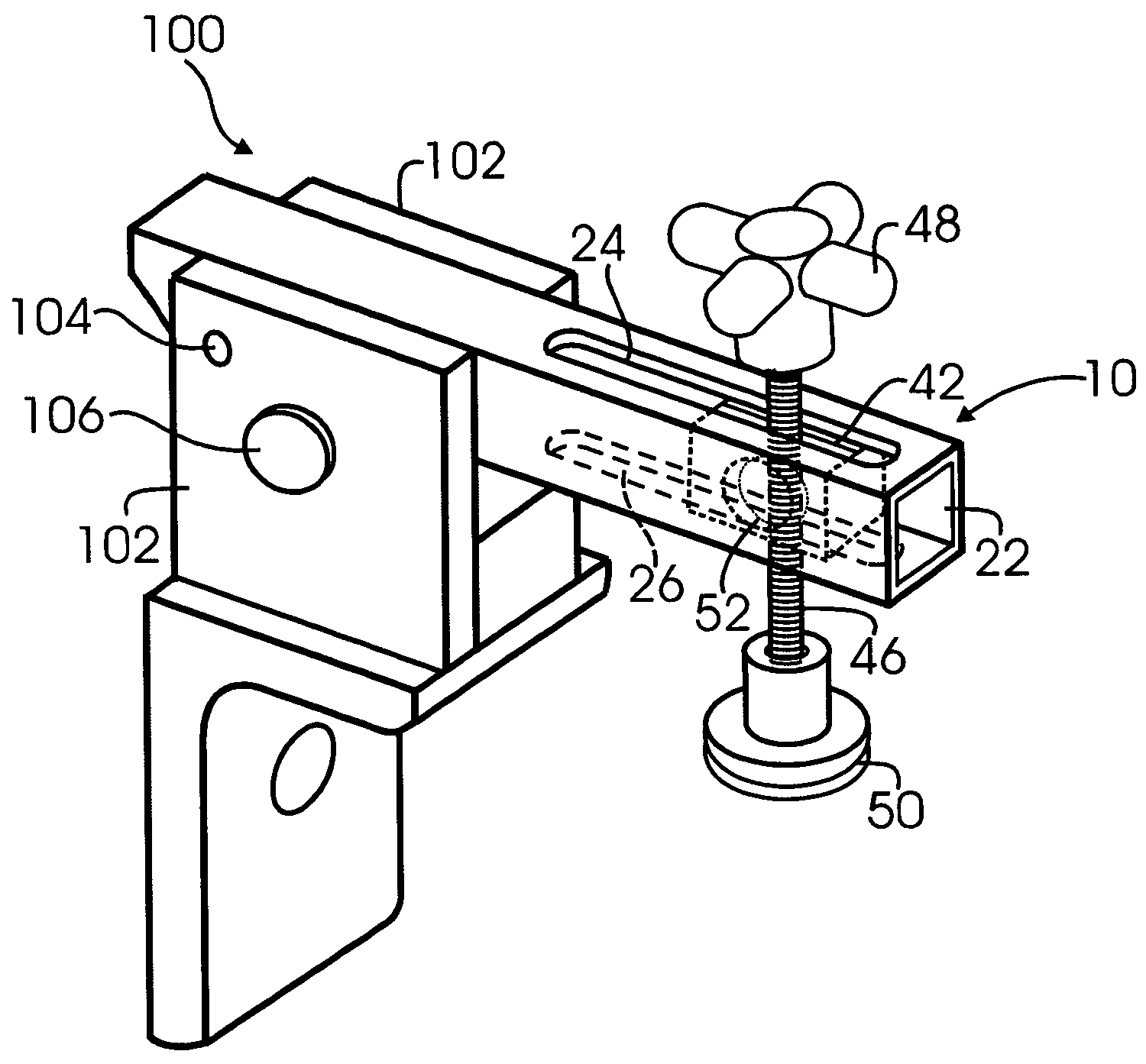

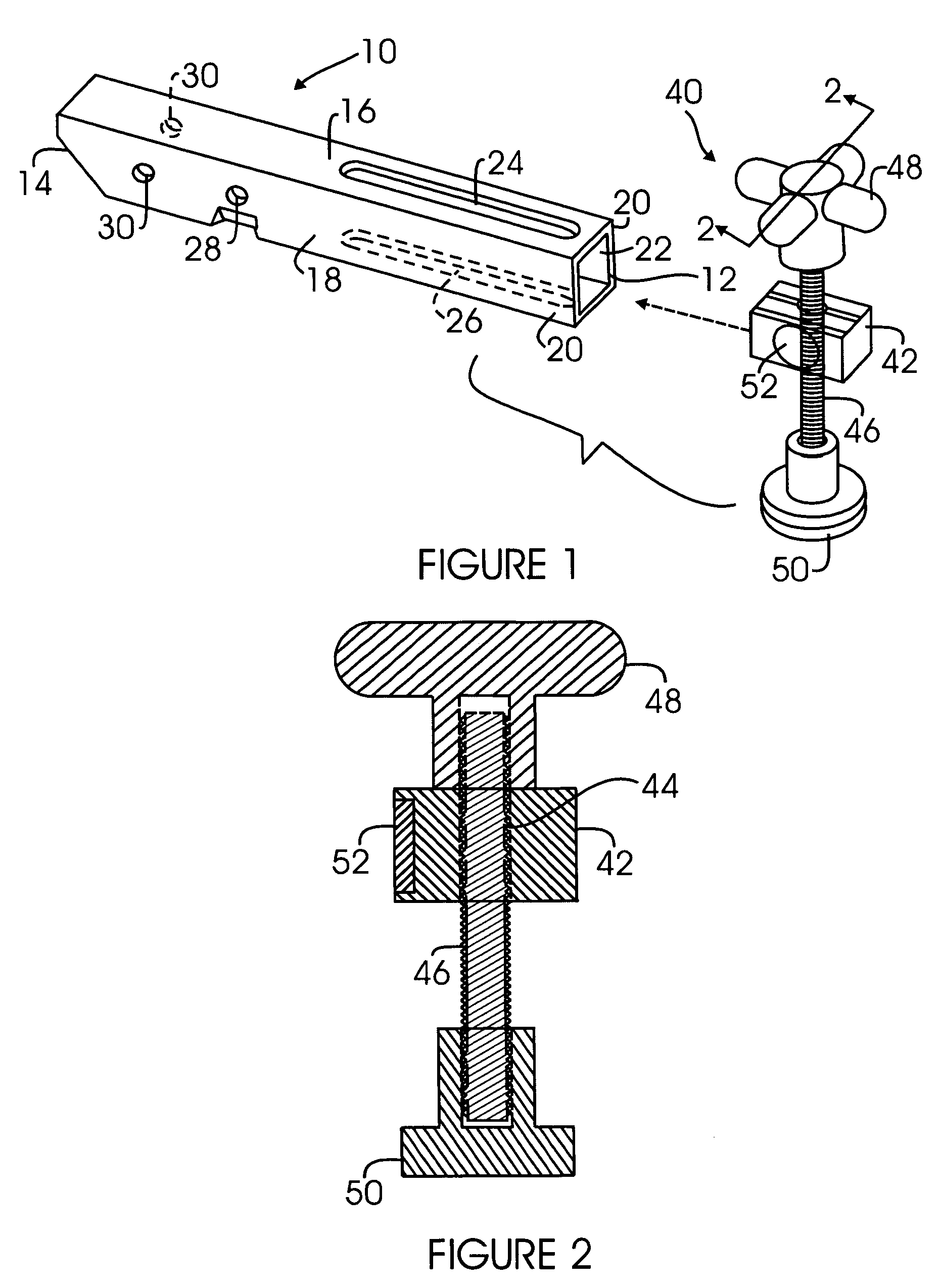

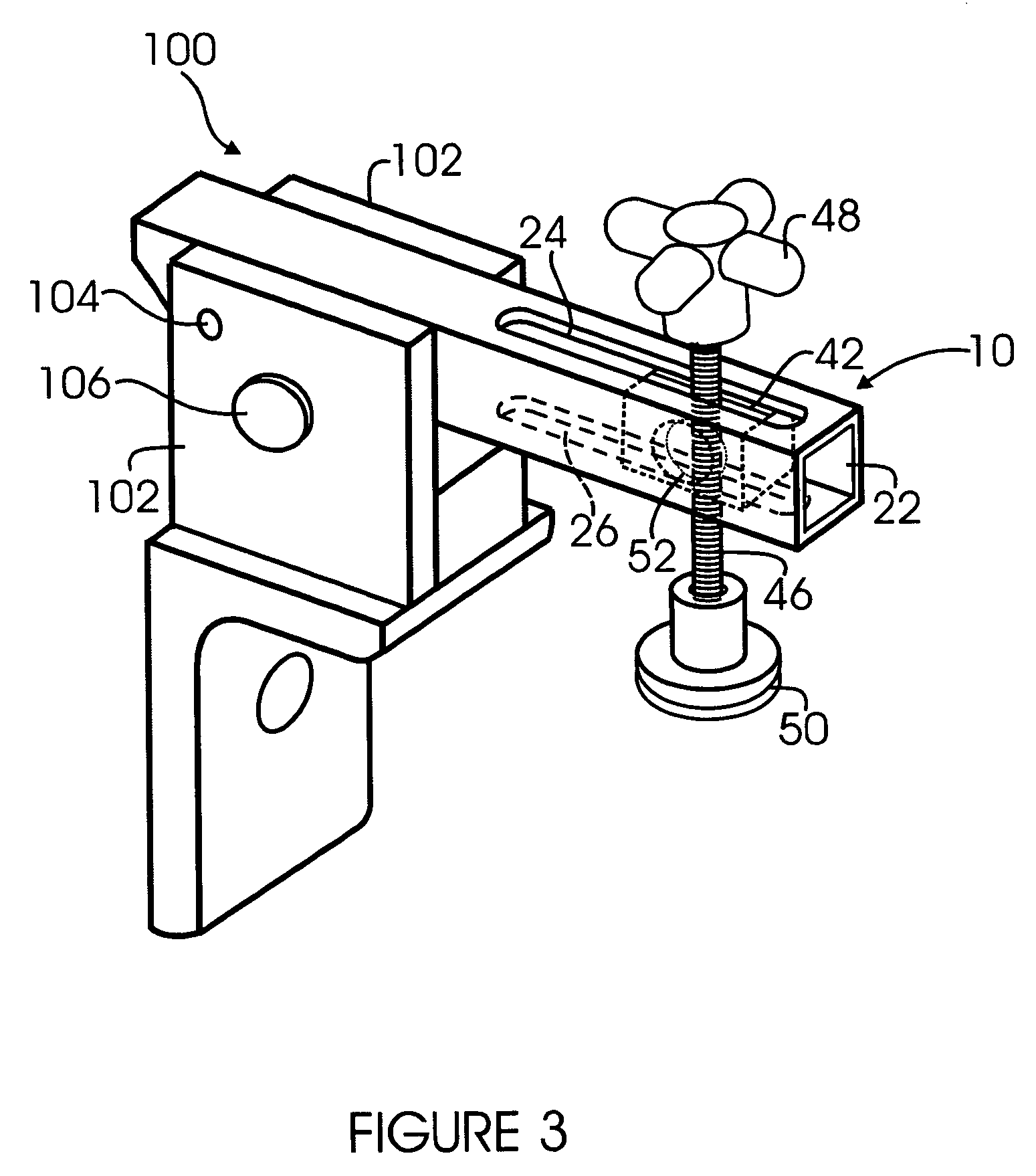

Clamp with magnetic spindle positioner

ActiveUS7108461B1Reduce chanceReduce movementPlaning/slotting machinesFeeding apparatusDetentEngineering

A clamping apparatus includes a clamp arm that is pivotable between a raised position and a lowered position, and a clamp spindle assembly that is adjustably positionable along the length of the arm. A magnet in the clamp spindle assembly magnetically engages the clamp arm with sufficient magnetic force to maintain the spindle assembly in a selected position as the clamp arm is moved between its raised and lowered positions, while allowing the position of the clamp spindle assembly to be manually adjusted.

Owner:THE BOEING CO

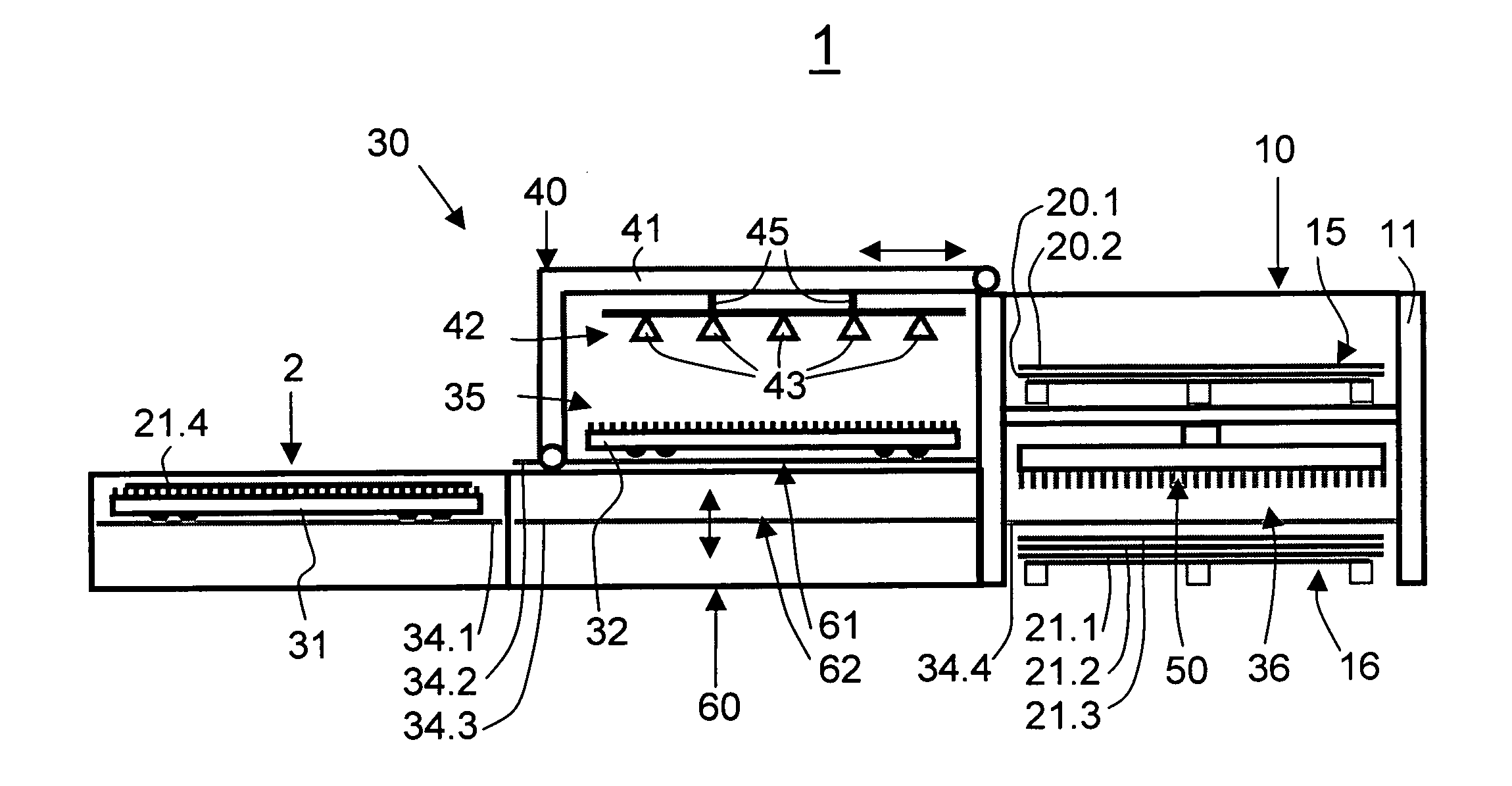

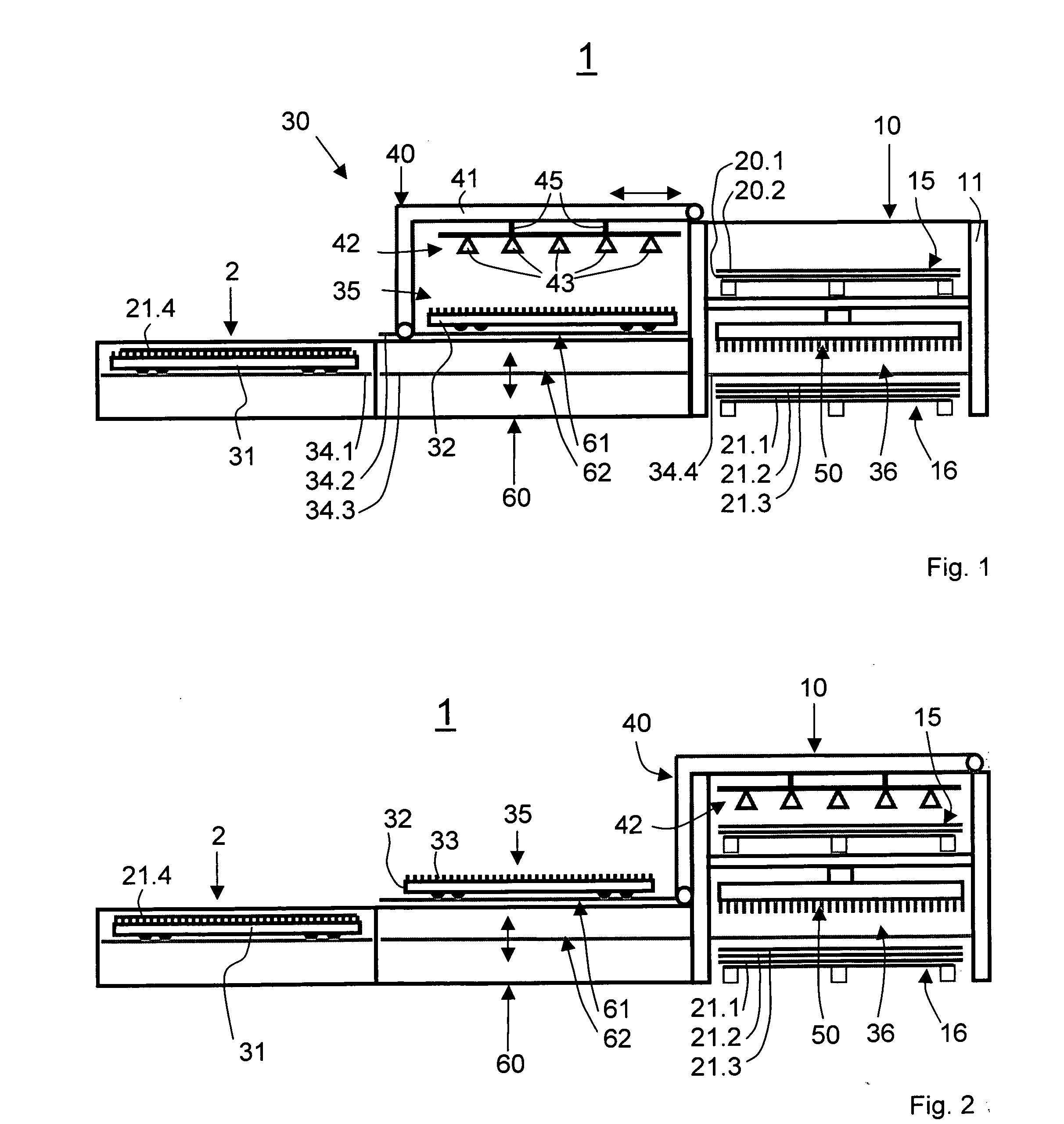

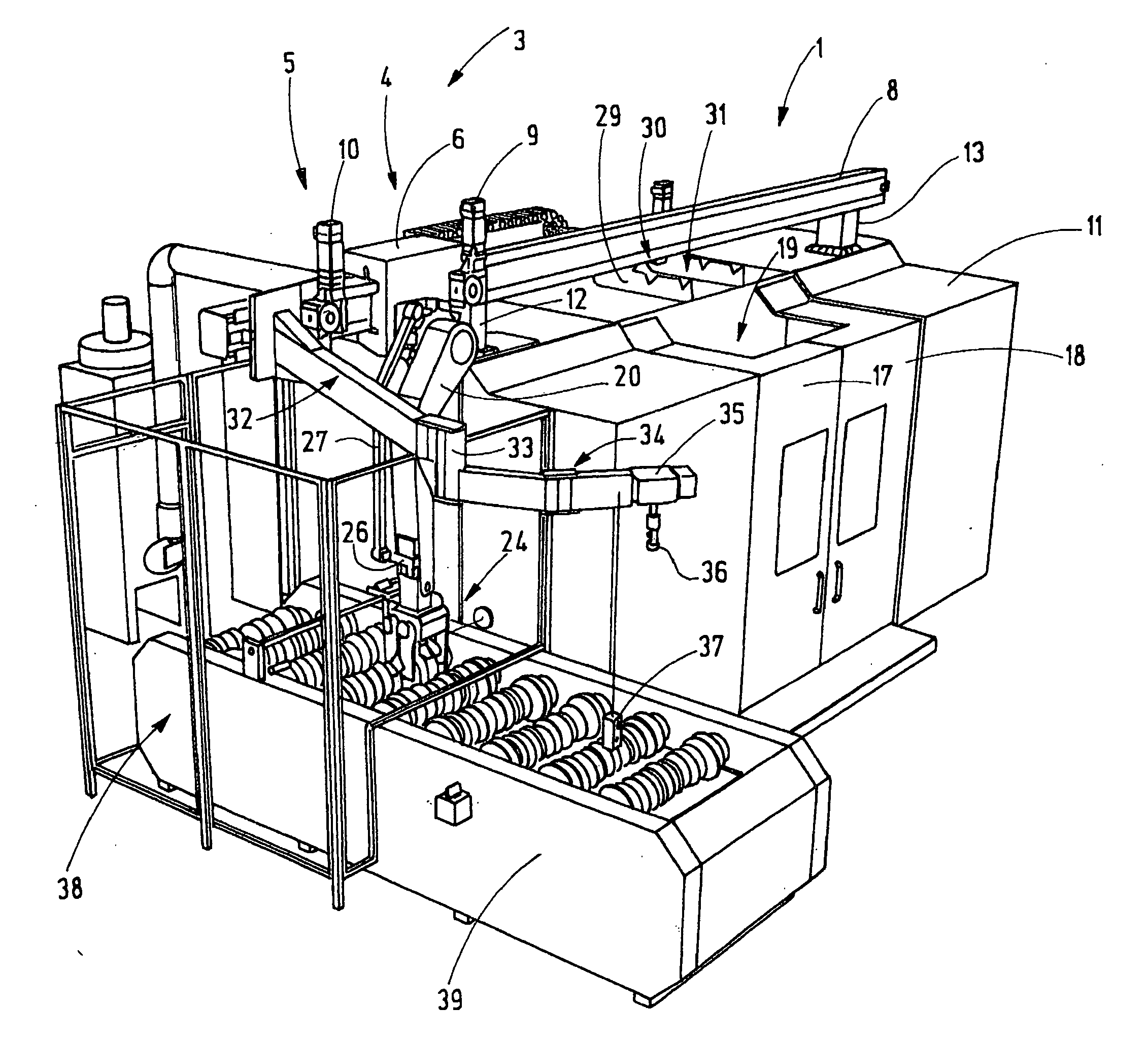

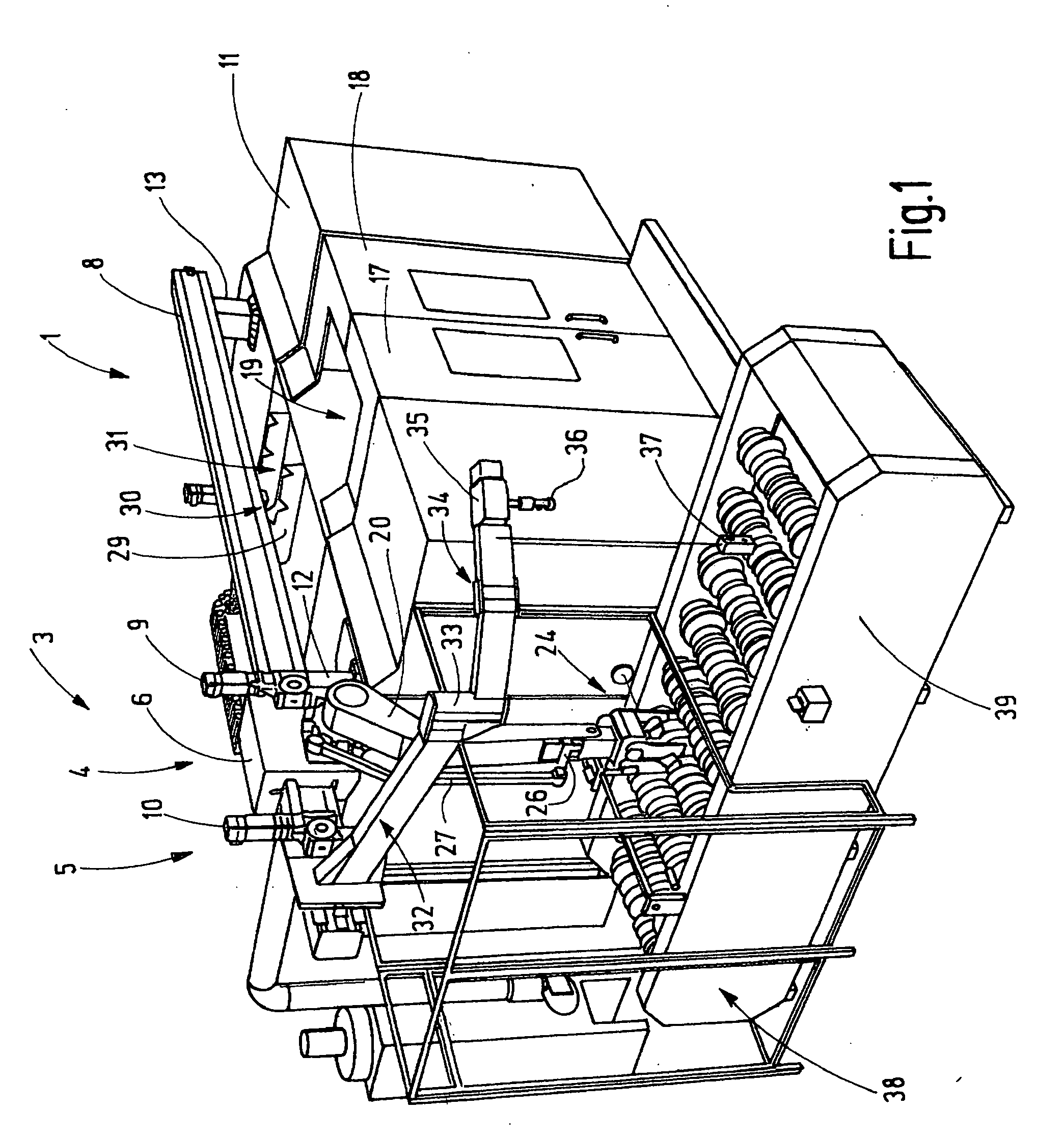

Device and method for loading and unloading a machining machine for machining boards

ActiveUS20080182737A1Easy loading and unloadingShorten the timeMetal-working feeding devicesFeeding apparatusEngineeringMachining

A method for loading and unloading a machining machine for machining boards that includes for loading the machining machine, the changing table is loaded with a board to be machined, whereby the board is separated from the first storage place and is deposited on a changing table. The changing table is conveyed together with the board to the machining machine. For unloading the machining machine, the changing table is conveyed together with a machined board to the second storage place and is then unloaded, wherein the machined board is separated from the changing table and deposited on the second storage place, wherein the unloading of the changing table includes conveying the changing table and the machined board to an unloading place in an area above the second storage place and the machined board is separated from the changing table at the unloading place.

Owner:BYSTRONIC LASER

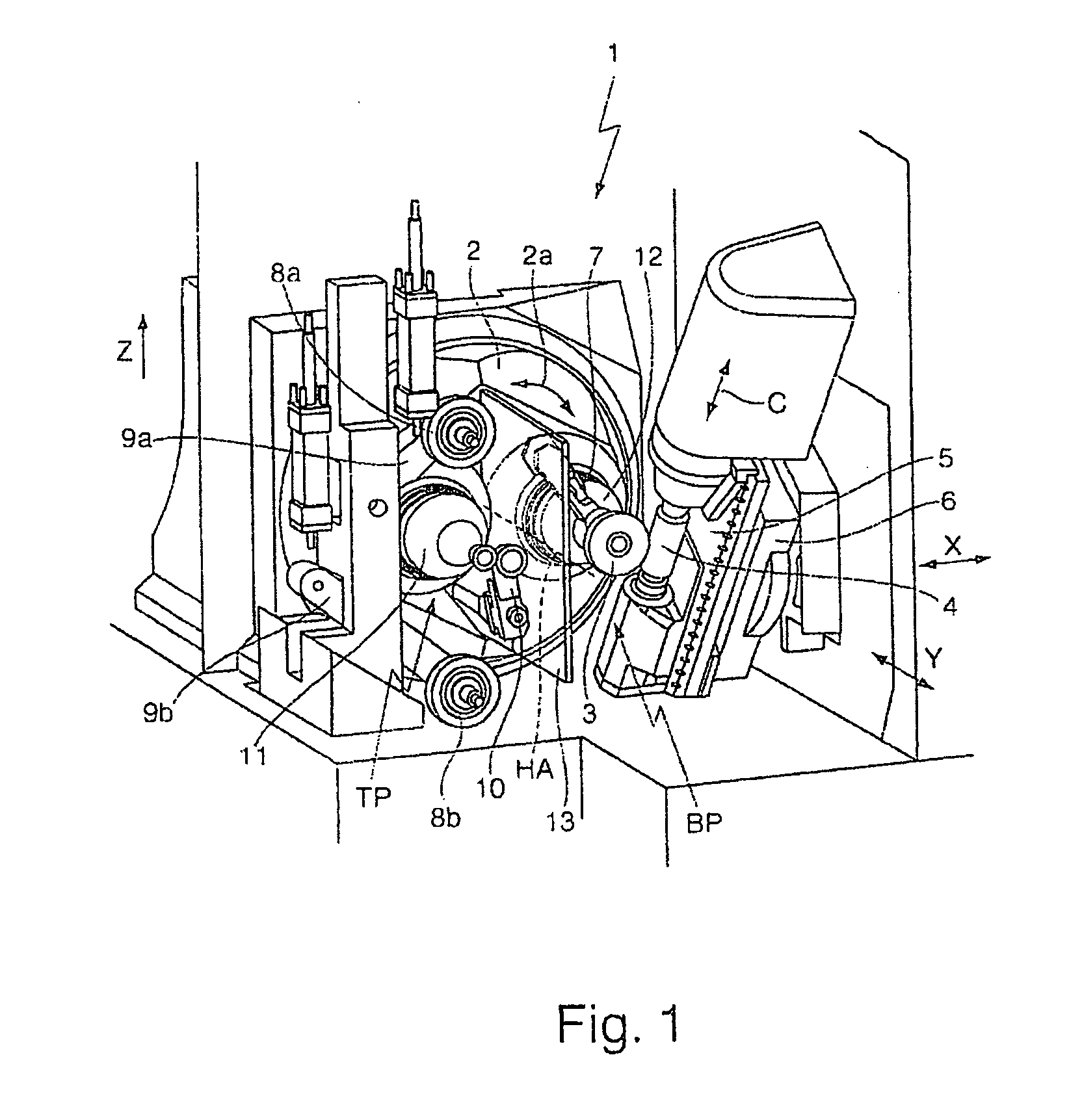

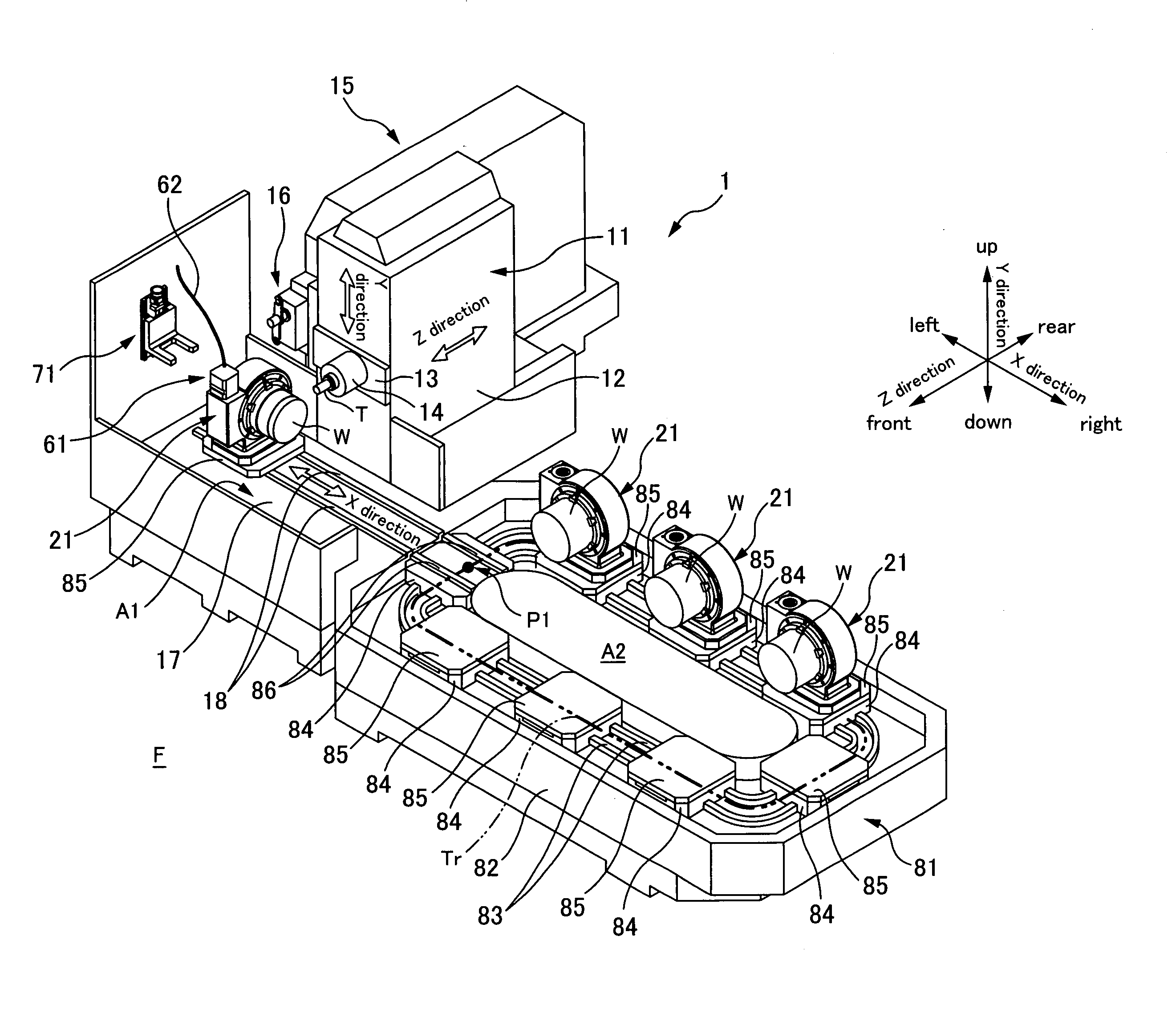

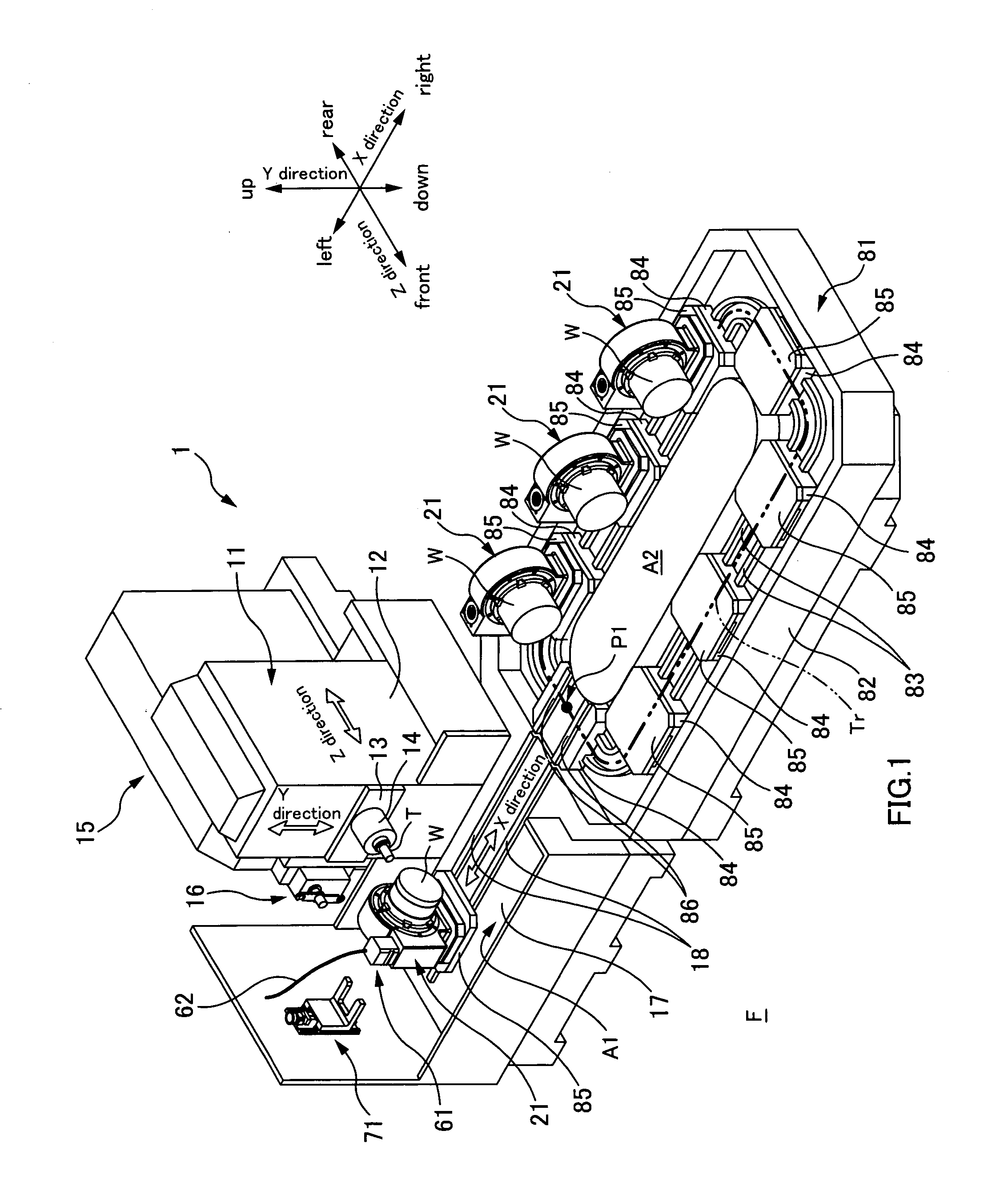

Rotation processing machine and rotation processing method

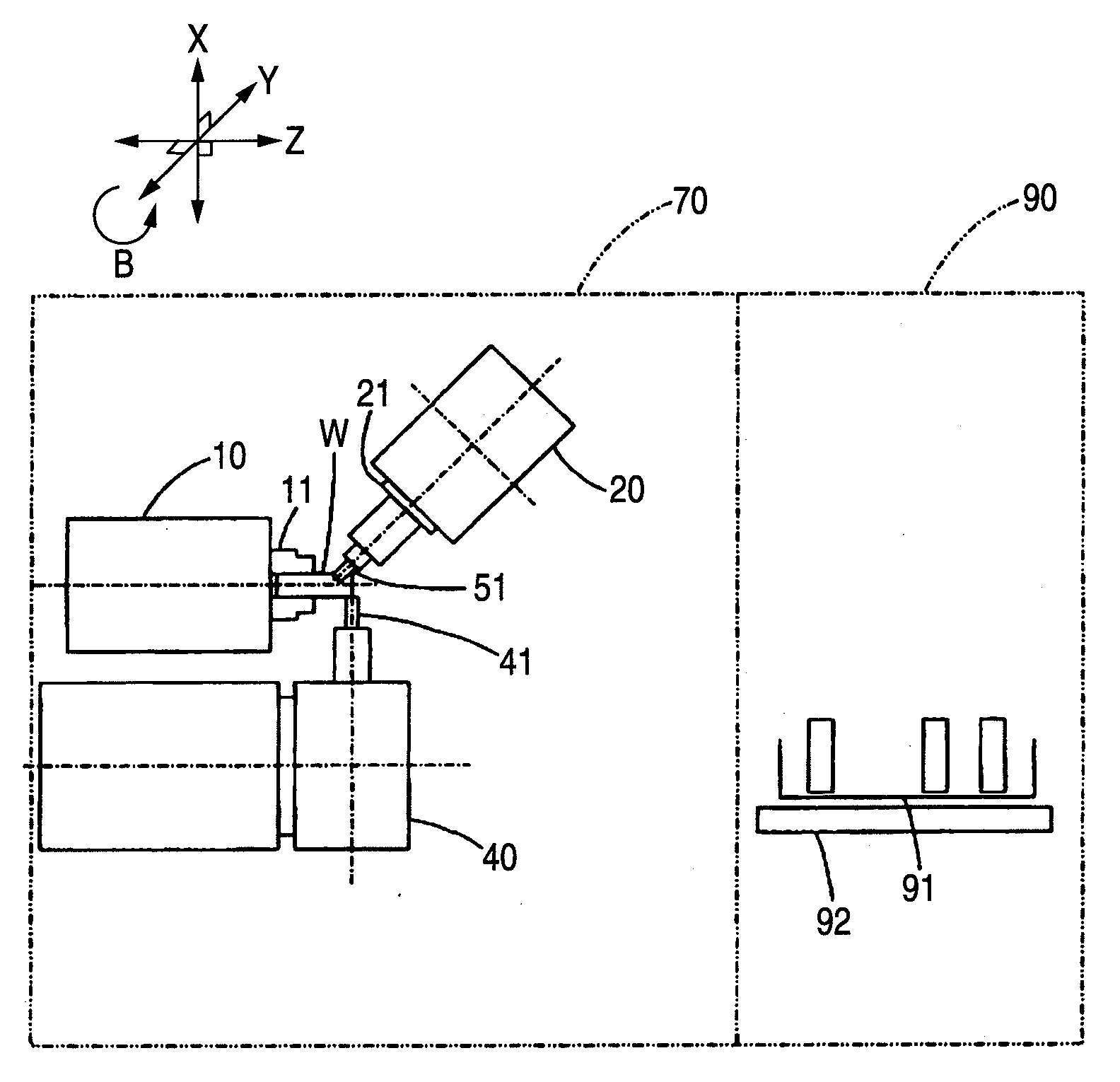

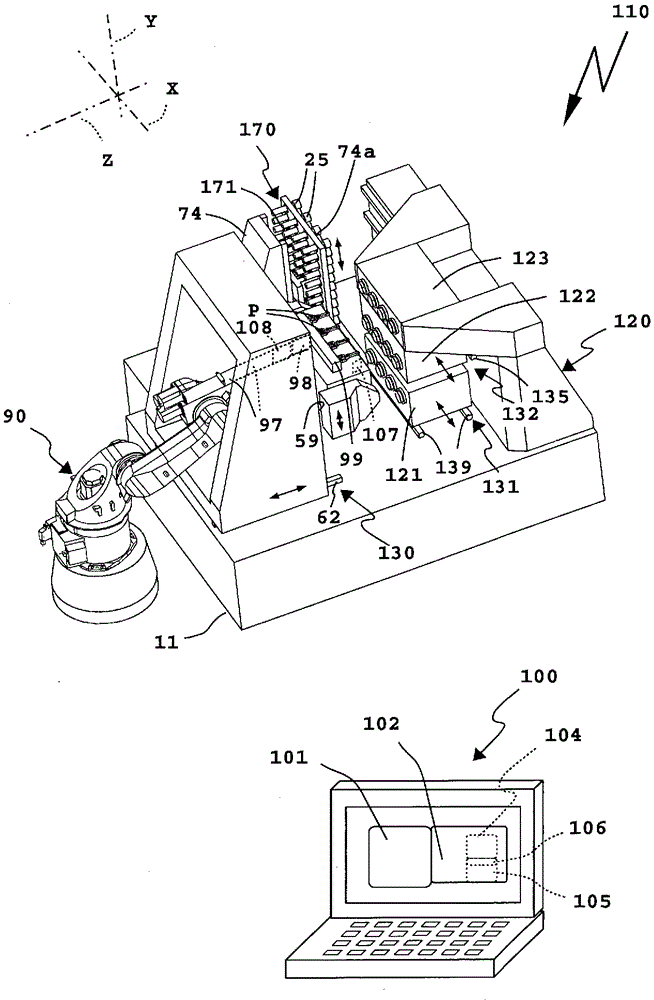

ActiveUS20130225379A1Shorten the timeIncrease overall initial investmentAutomatic control devicesFeeding apparatusPinch gripEngineering

A rotation processing machine, including a rotating device that holds and rotates a workpiece; a processing device on which a cutting tool is mounted to process the workpiece; and a turning loader that has grippers arranged about a turning central axis, and that turns so that the grippers sequentially face the rotating device. The turning loader is configured to deliver and receive the workpiece to and from the rotating device by turning with the workpiece being directly or indirectly held by the gripper, and to deliver and receive the cutting tool to and from the processing device by turning with the cutting tool being directly or indirectly held by the gripper.

Owner:AISIN AW CO LTD

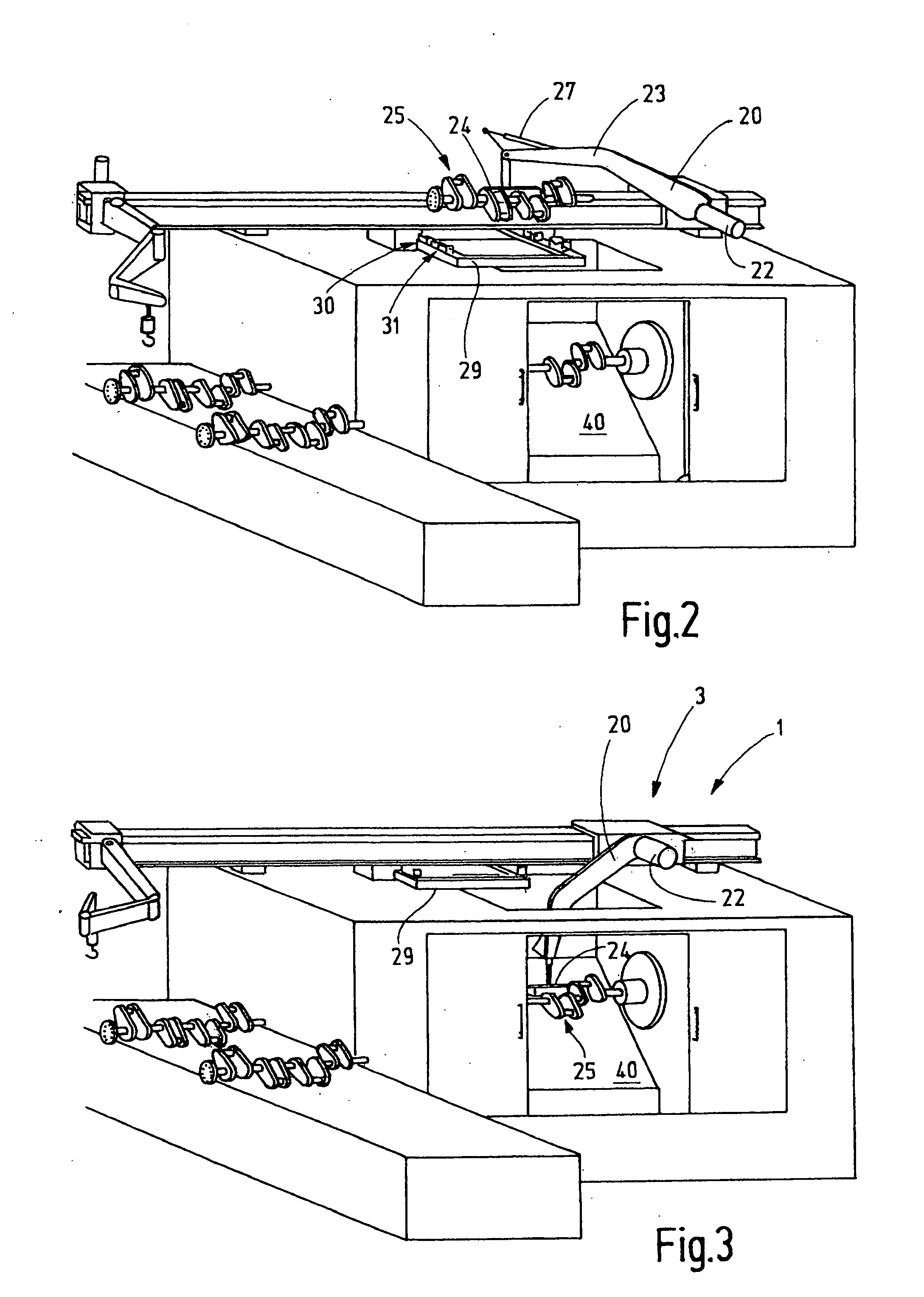

Machine tool with work piece handling arrangement

InactiveUS20070179033A1Shorten the timeMinimize the numberMilling machinesFeeding apparatusEngineeringMachine tool

In a machine tool arrangement comprising a machine tool component including a mounting structure for a work piece to be machined by a suitable metal cutting tool, a housing enclosing the machine tool component, a horizontal support beam is disposed above the housing and carries handling equipment for supplying work pieces from an adjacent loading area to the machine component for machining and returning the finished work pieces to the storage structure and an intermediate storage structure is disposed near the machine tool component for temporarily storing unfinished work pieces to be machined and finished work pieces after being machined.

Owner:GEBR HELLER MASCHFAB GMBH

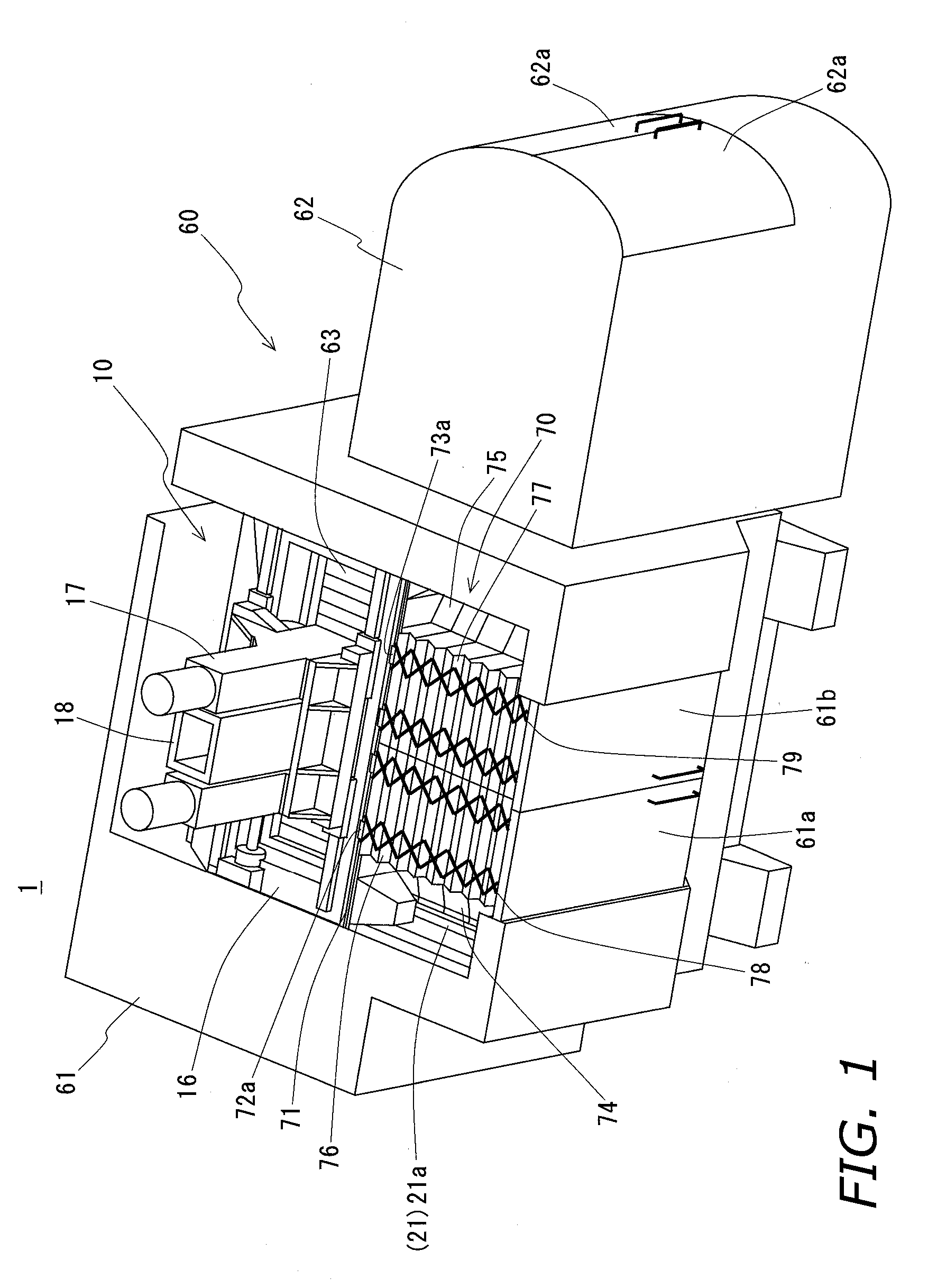

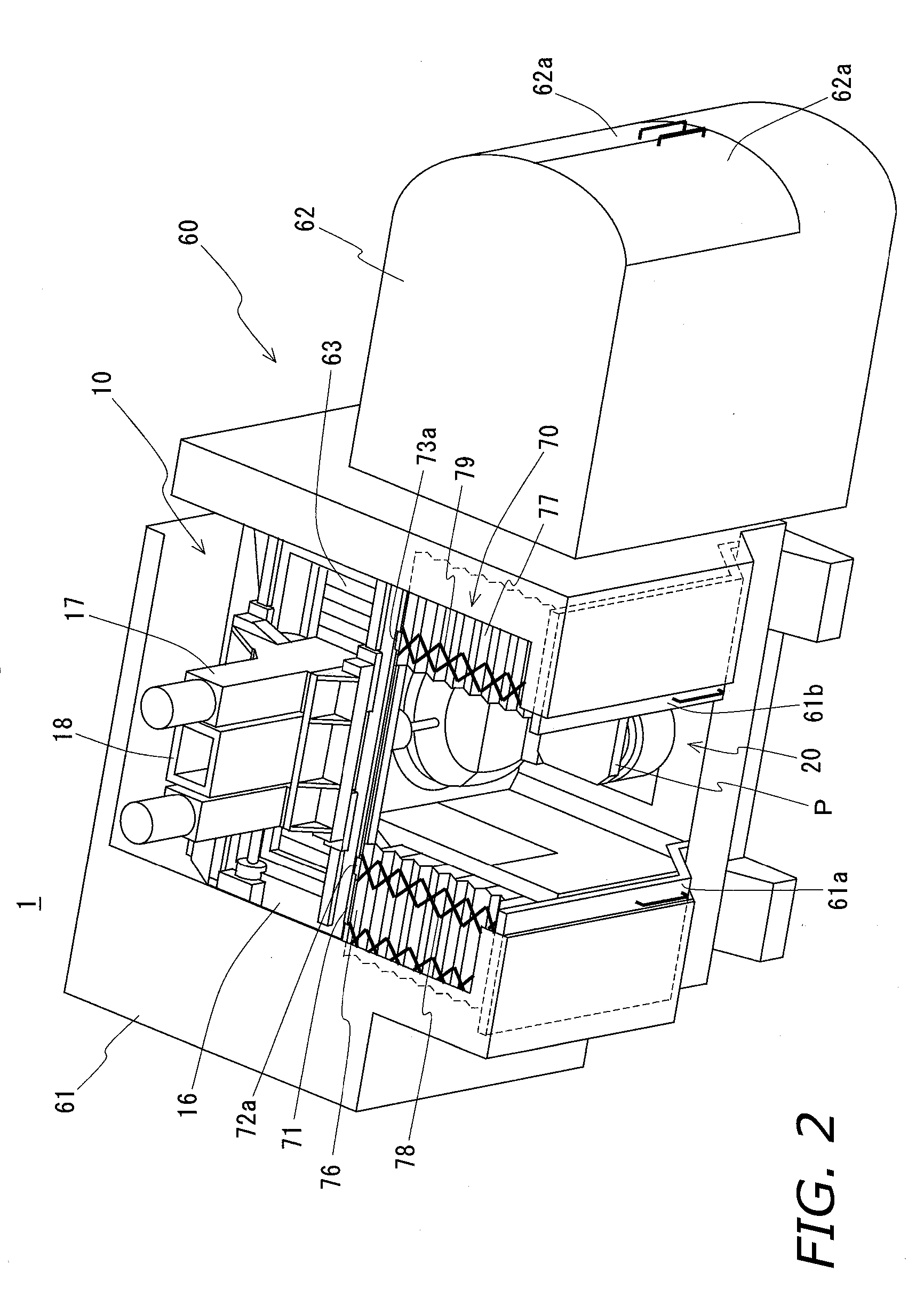

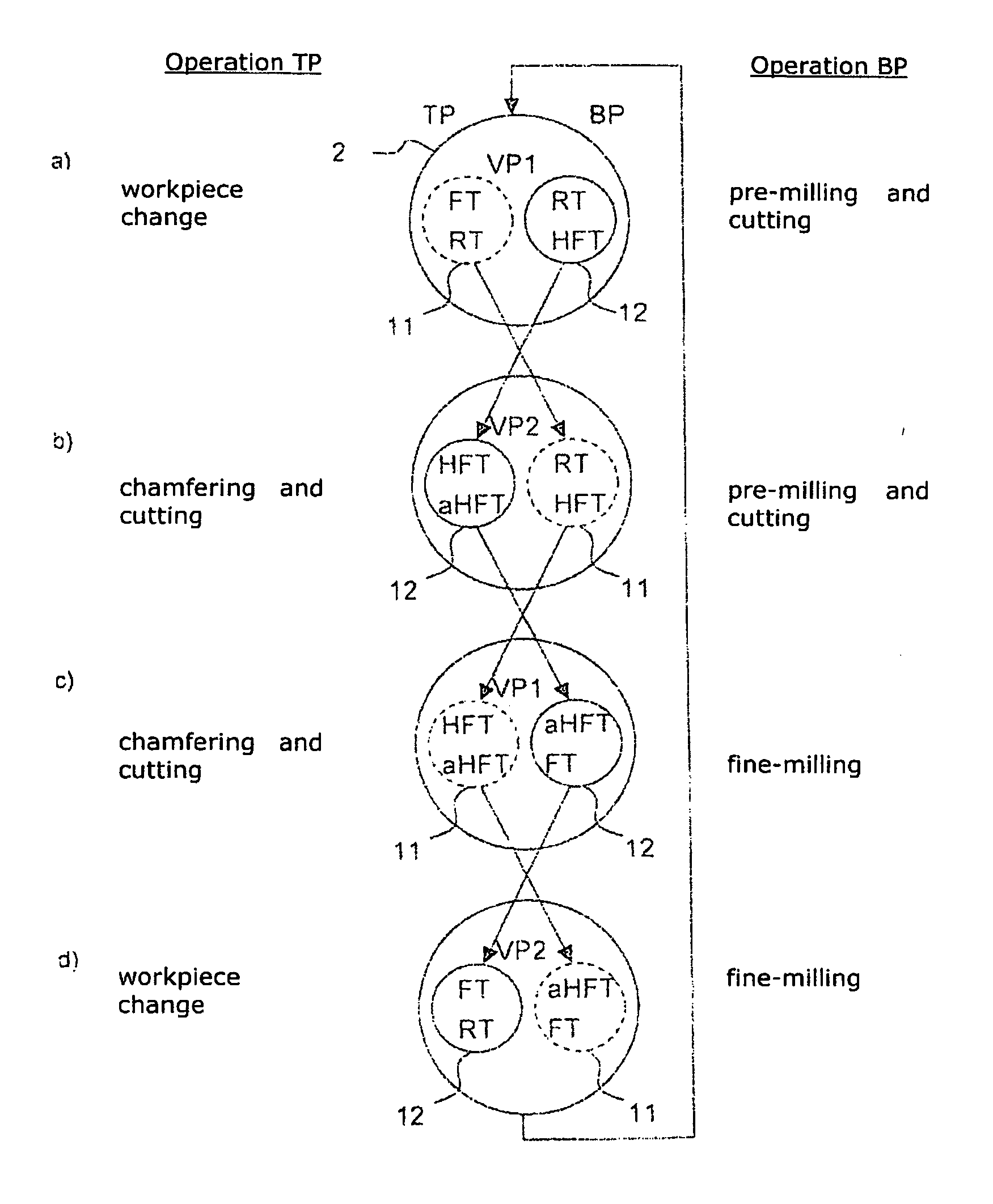

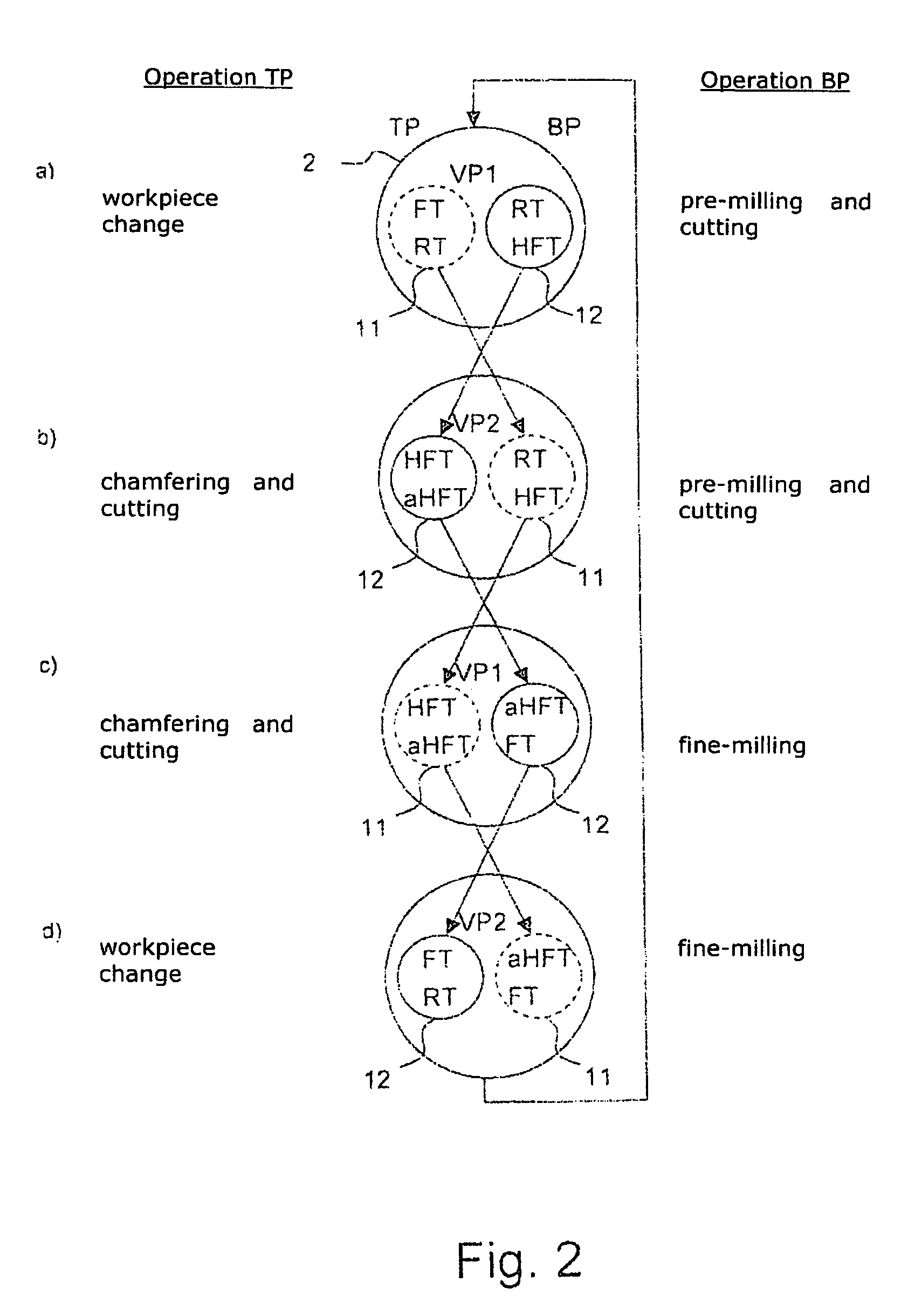

Deburring by hobbing with integrated secondary deburring without a smoothing tool

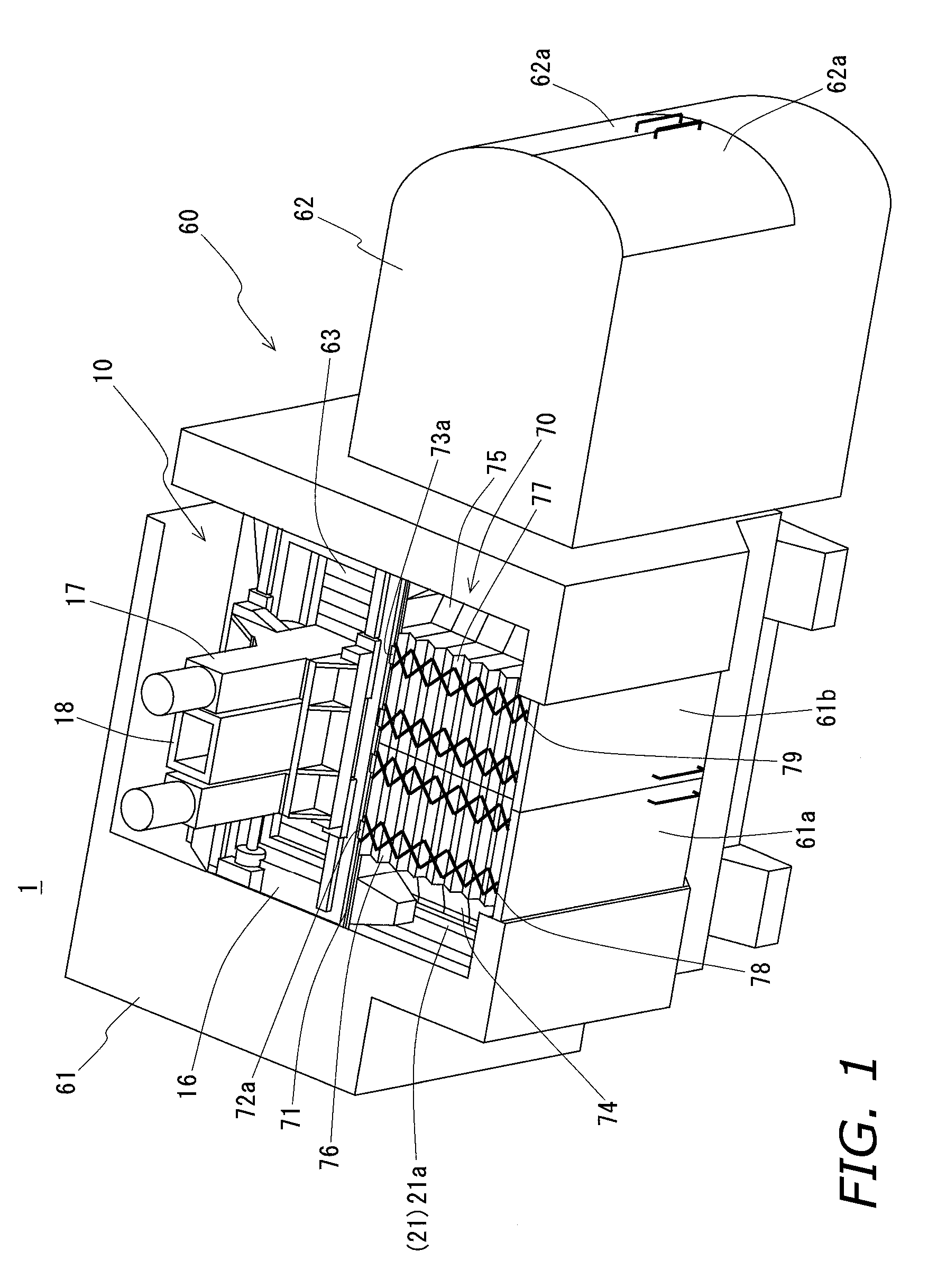

ActiveUS20090238654A1Simple structureEasy maintenanceGear wheelsFeeding apparatusGear wheelEngineering

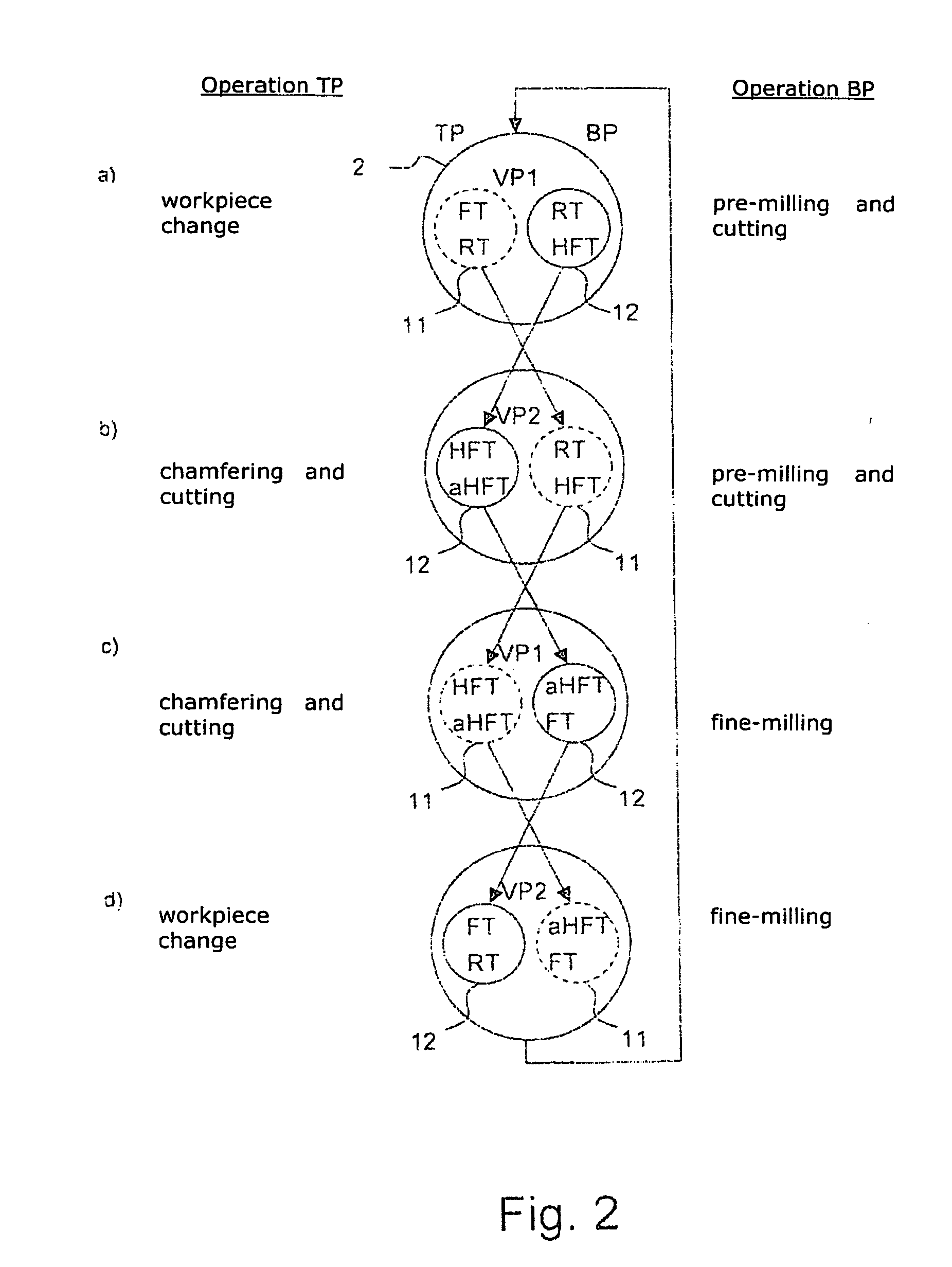

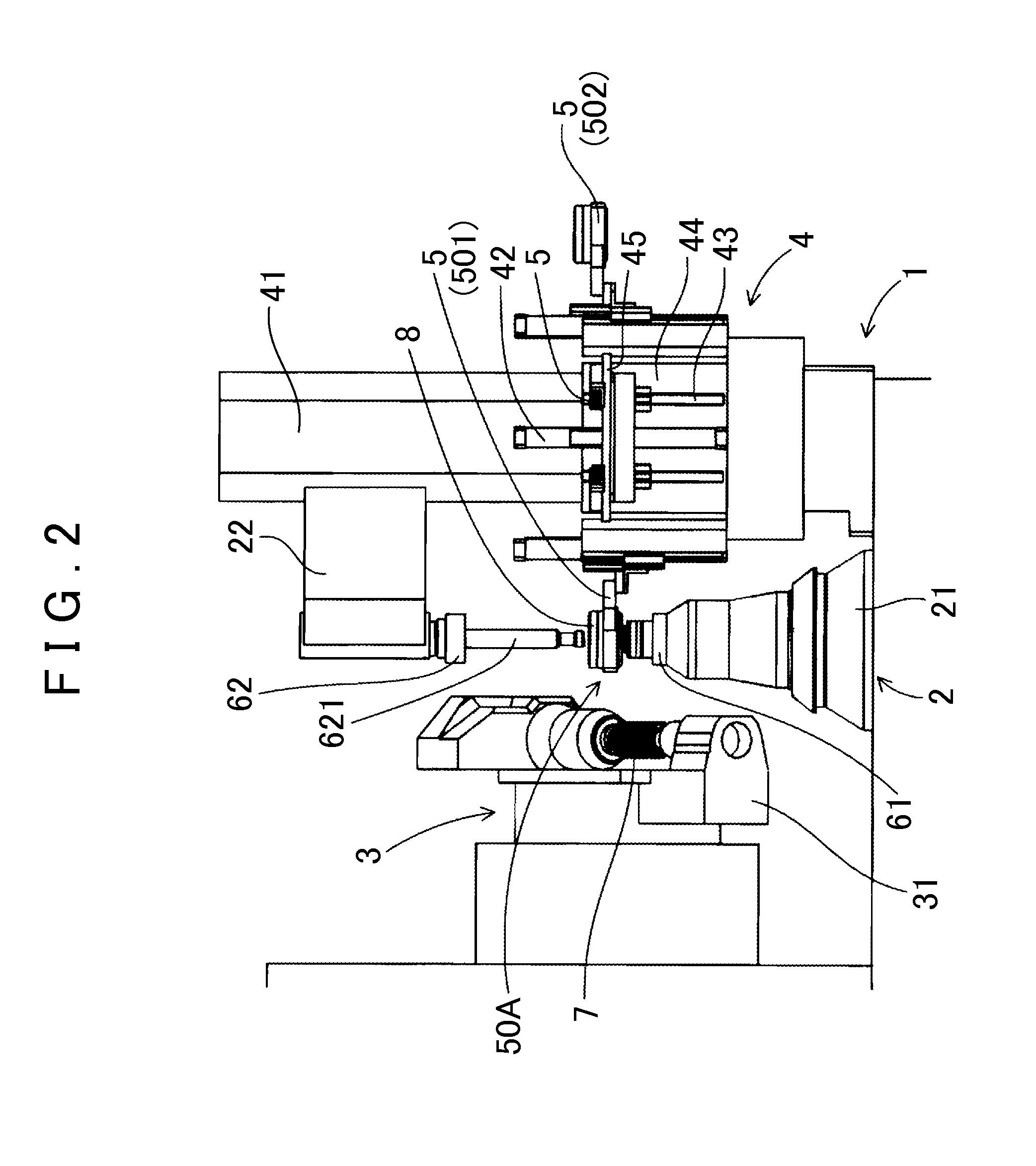

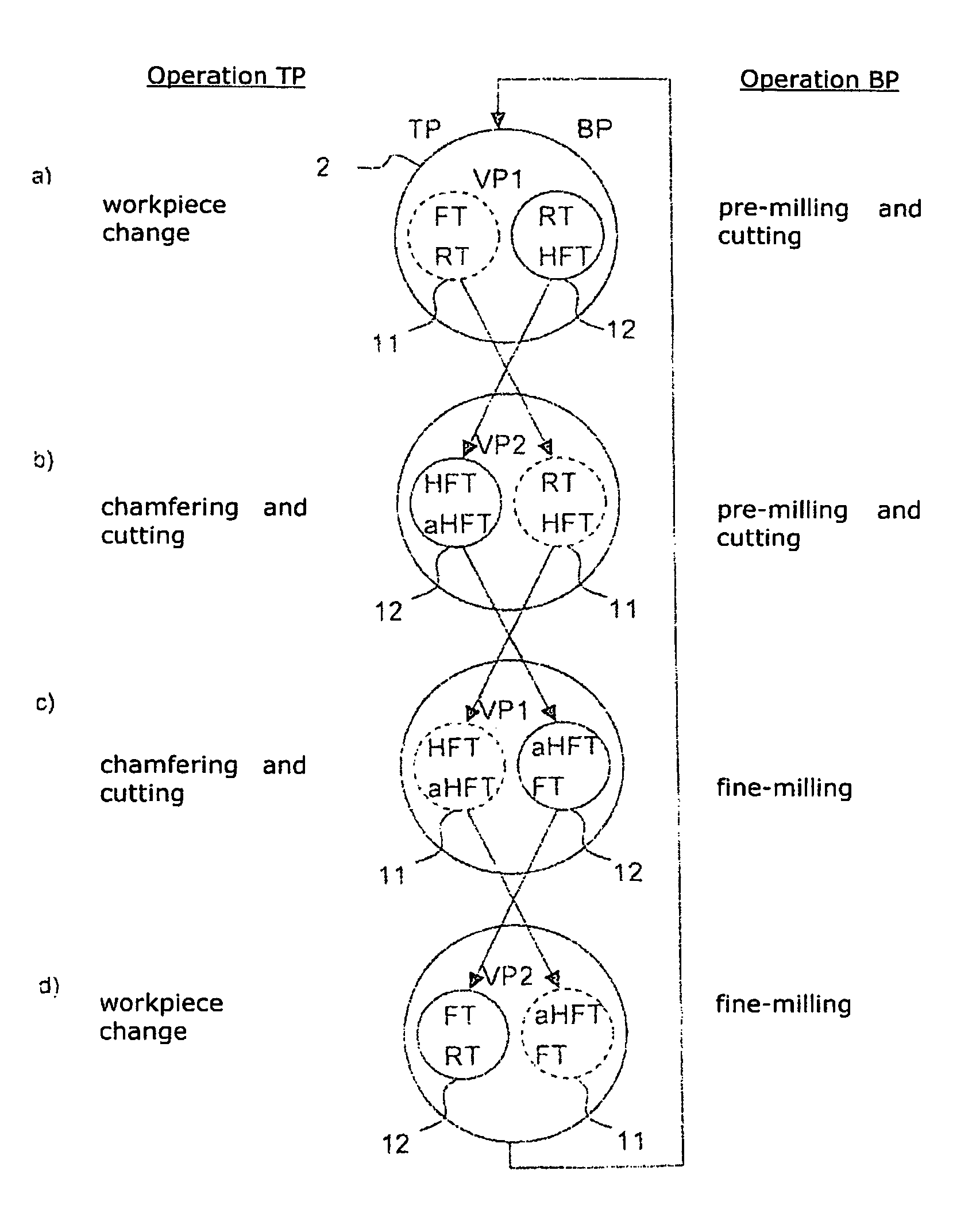

The invention relates to a method for tooth-machining of workpieces (3), especially gear wheels, comprising milling, deburring by hobbing and integrated secondary deburring. The method proceeds on a machine tool (1) having two workpiece spindles (11, 12) which may exchange places. A workpiece (3) is mounted on a first workpiece spindle (11), followed by the workpiece spindles (11, 12) exchanging places, followed by pre-milling and, where applicable, cutting (=deburring by shaving) of the workpiece (3), followed by a further exchange of places, followed by chamfering and cutting of the workpiece (3), followed by a further exchange of places, followed by a finish-milling of the workpiece (3), followed by a further exchange of places, followed by a workpiece change. At the same time, the same procedure takes place on the second workpiece spindle (12), staggered in time by an exchange of places of the workpiece spindles (11, 12). With the method according to the invention, well-deburred toothed workpieces (3) may be produced quickly and at low cost.

Owner:FELSOMAT

Spindle gripping device and method

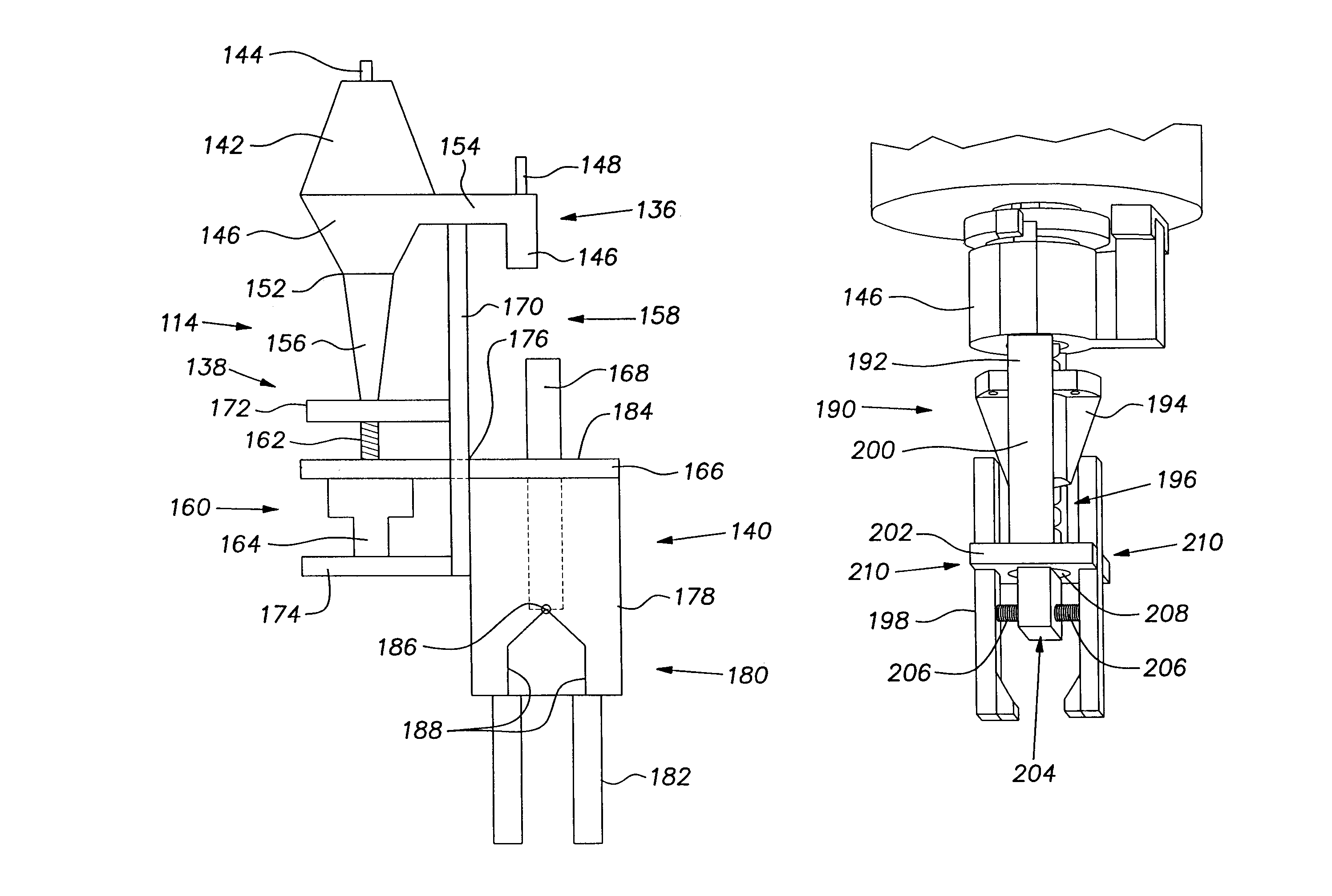

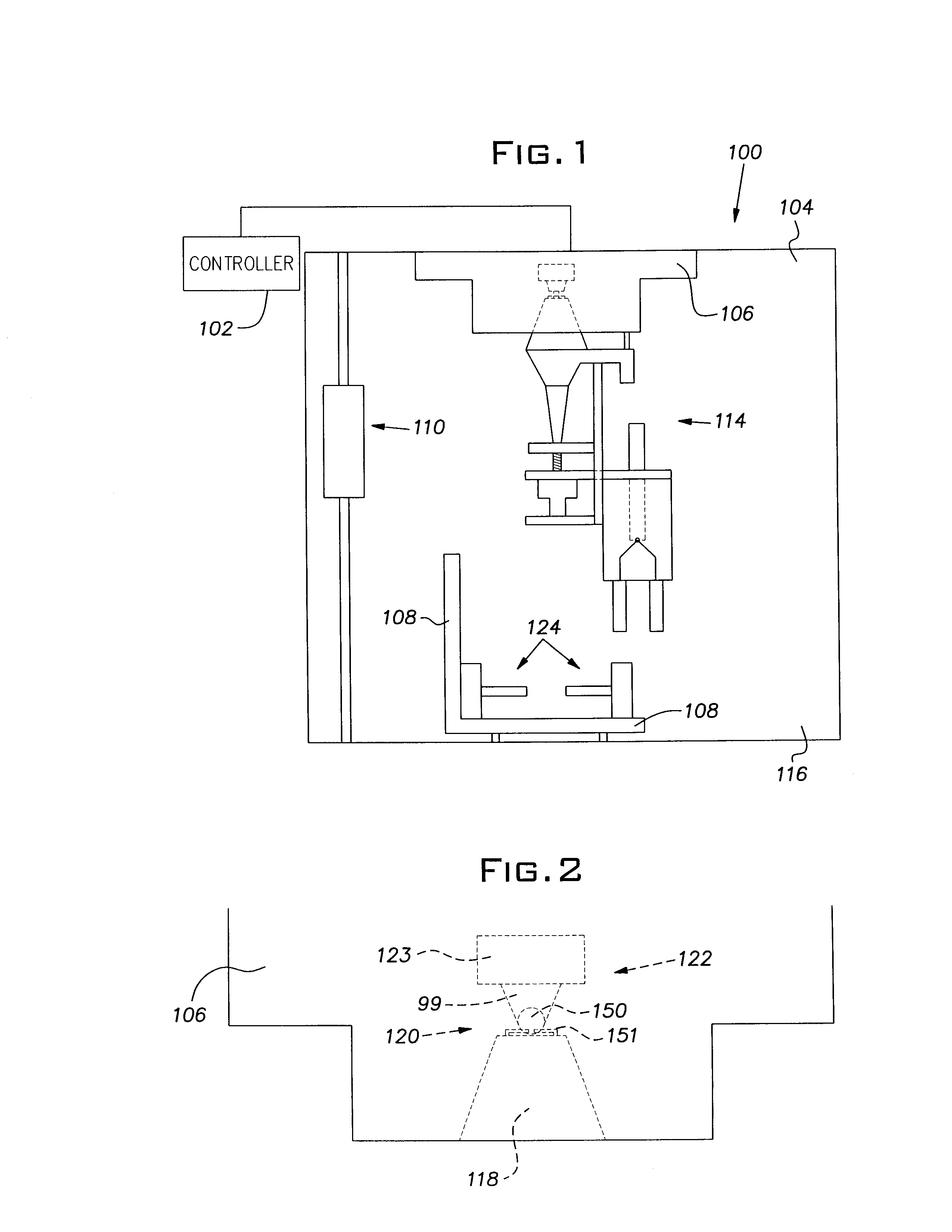

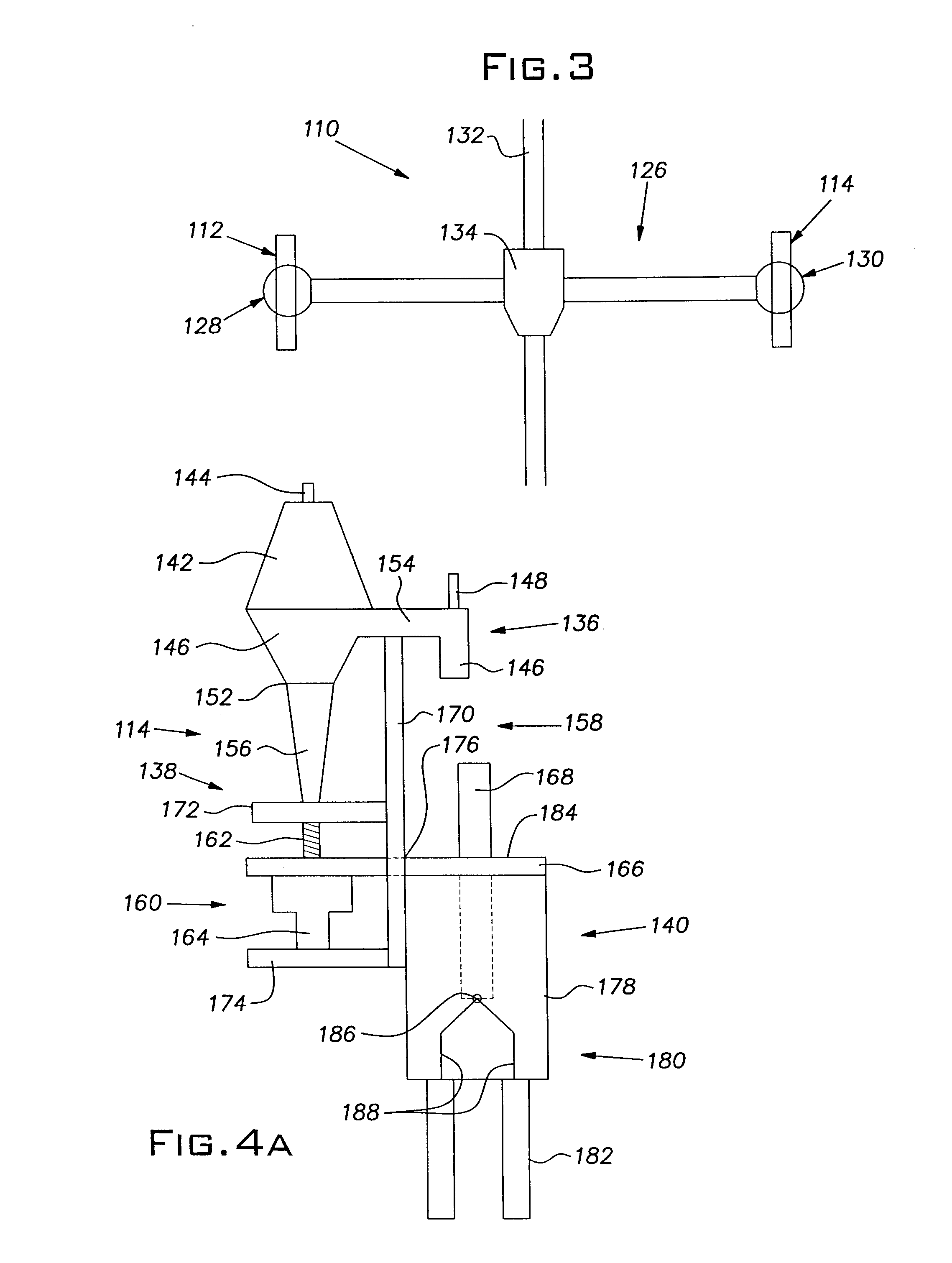

InactiveUS8092357B1Easy to assembleReduce disadvantagesFeeding apparatusMetal-working hand toolsLinear motionEngineering

A spindle gripping device and method for use in a CNC machine for re-orienting a workpiece. The gripping device includes an attachment portion, a translational driver, and a gripping portion. The attachment portion mechanically attaches the gripping device to a spindle of the CNC machine, and allows a transfer of the rotation of the spindle to the gripping device. The translational driver translates the input rotational force into a linear movement. The gripping portion uses the linear movement to open and close claws of the gripping device. A controller monitors and controls the operation of the CNC machine, so as to control an exchange of the working tool with the gripping device, and to control actuation and subsequent movement of the gripping device to reposition the workpiece into a desired orientation.

Owner:HONDA MOTOR CO LTD

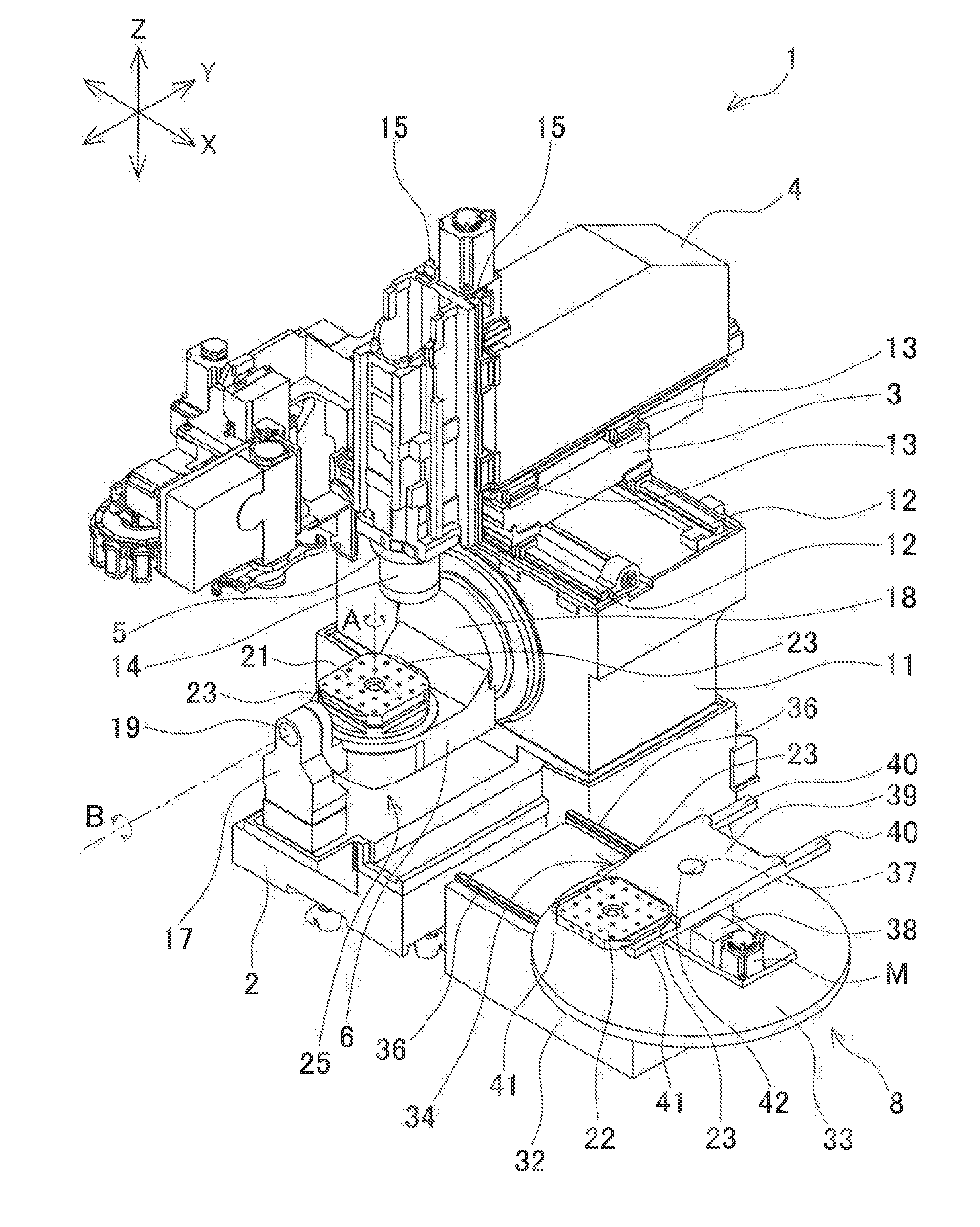

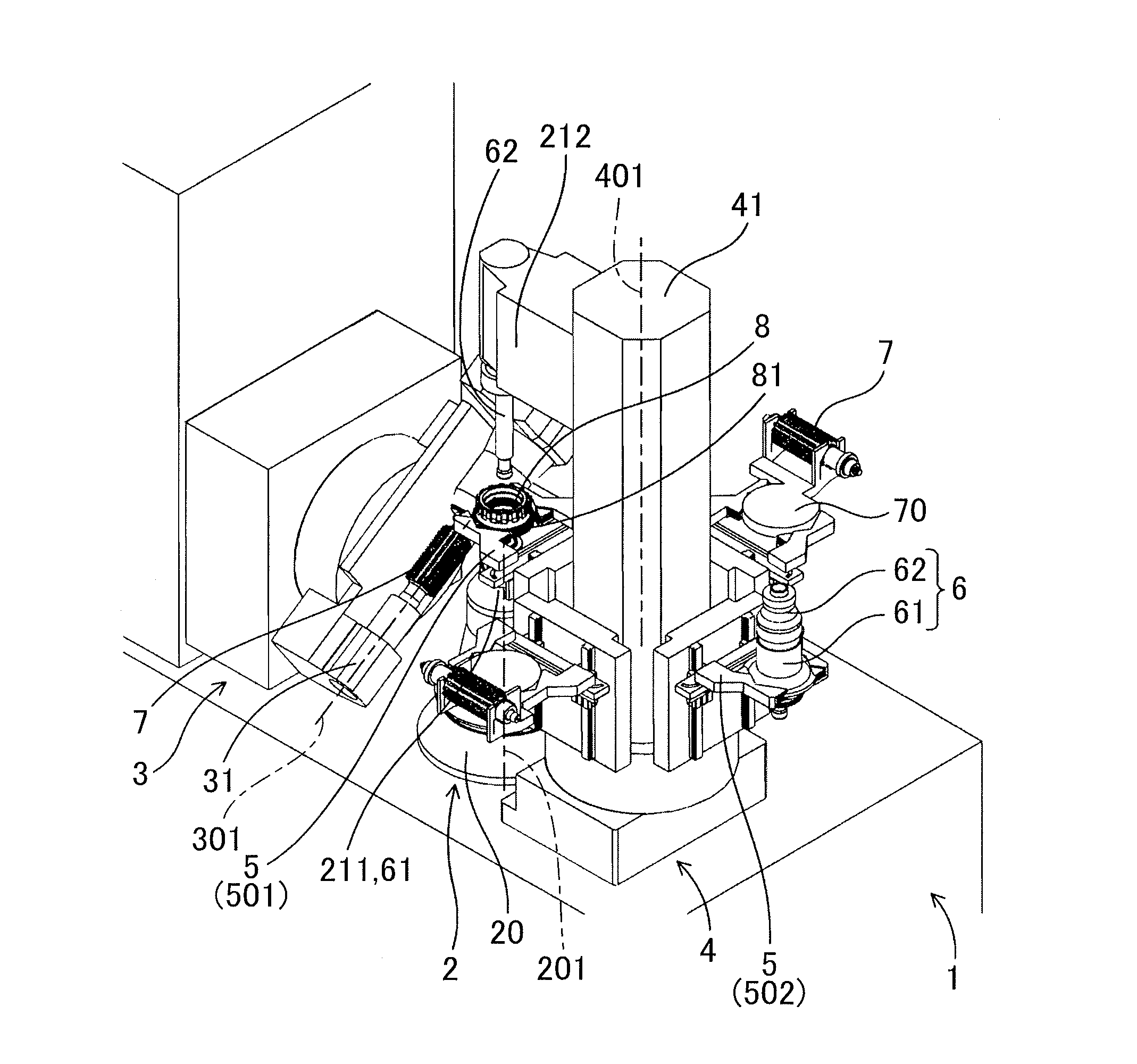

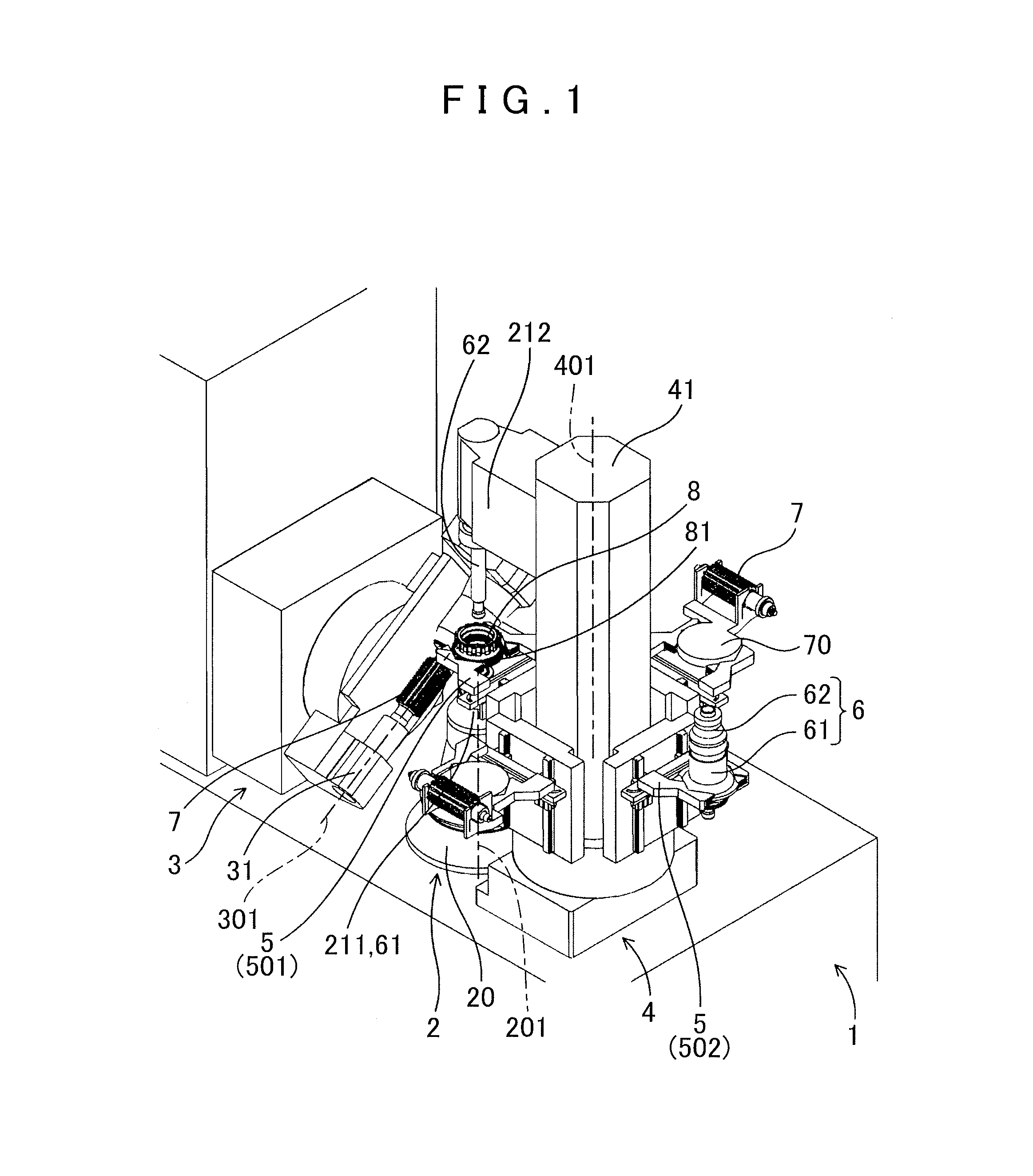

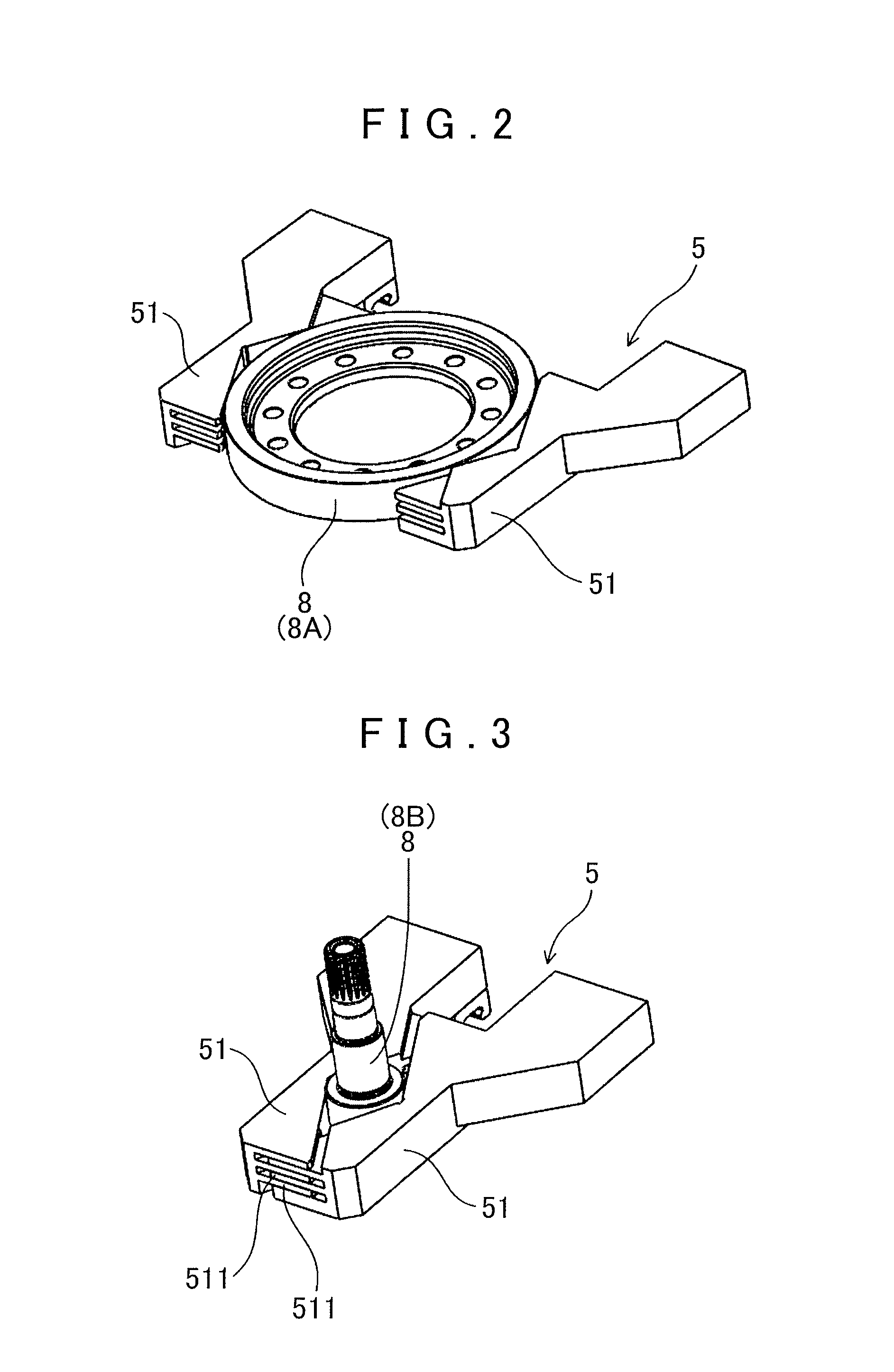

Rotation processing machine

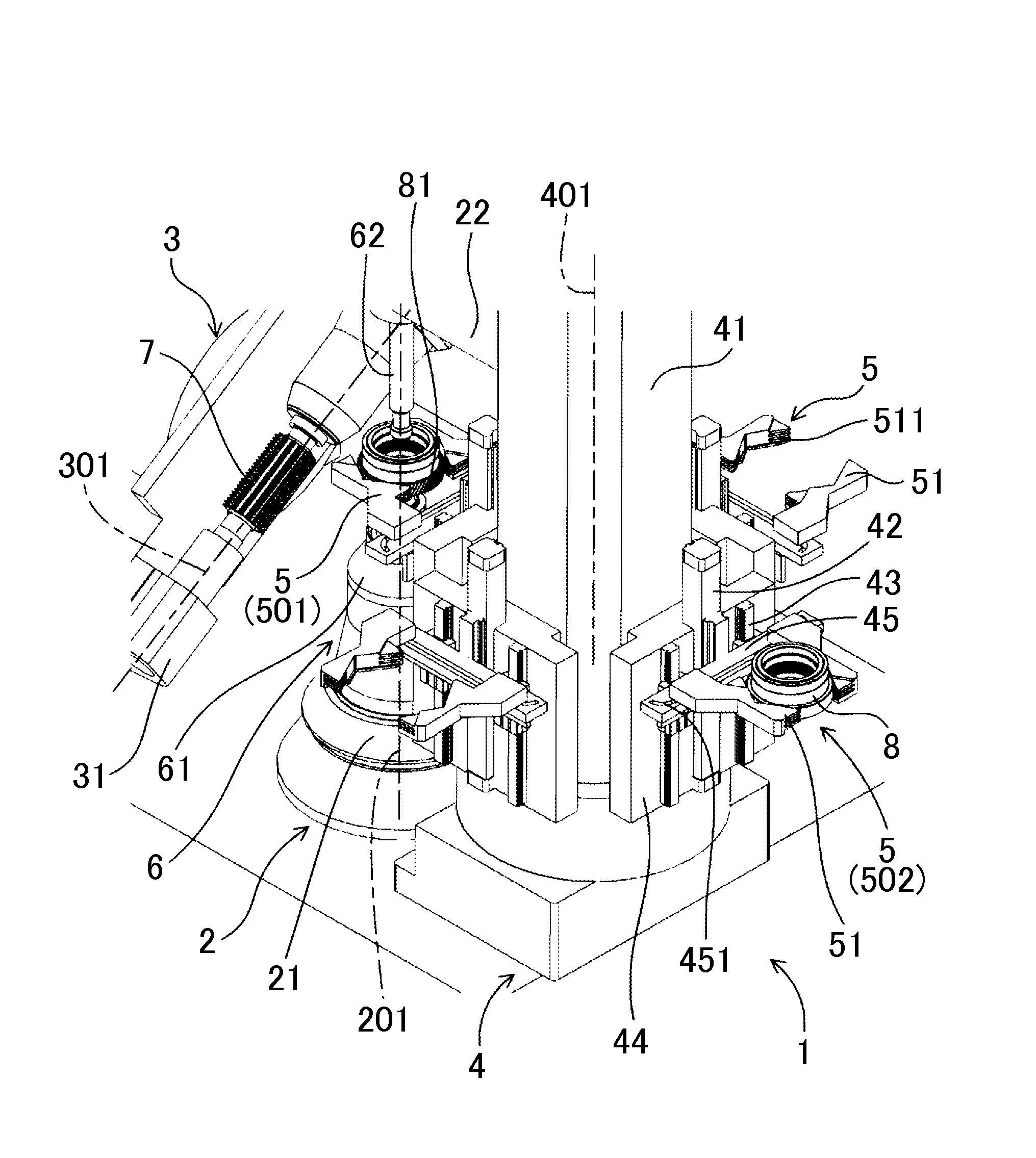

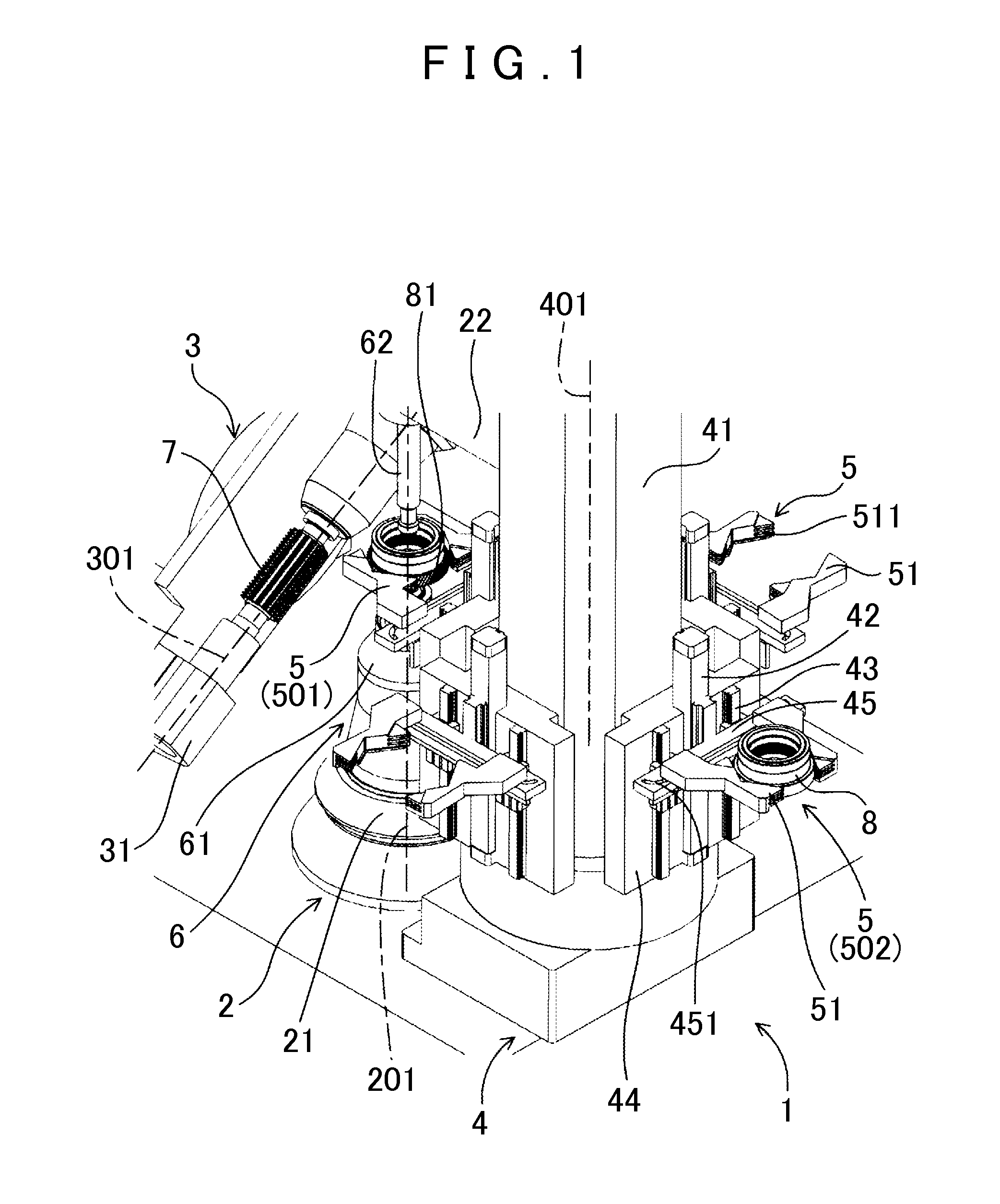

ActiveUS20130223945A1Shorten the timeIncrease overall initial investmentWork trasfer apparatusPositioning apparatusEngineeringMechanical engineering

A rotation processing machine includes a rotating device supporting a cylindrical workpiece via a rotation support jig; a processing device on which a cutting tool is mounted; and a turning loader that has grippers arranged about a turning central axis and that turns so that the grippers sequentially face the rotating device. The grippers are configured to individually move up and down, and a height position of each gripper is settable to a first height position where the gripper delivers and receives the cylindrical workpiece to and from the rotating device, and a second height position where the gripper delivers and receives the rotation support jig to and from the rotating device. The turning loader turns each of the grippers between an external delivery / reception position where the gripper faces an external transfer stand and an internal delivery / reception position where the gripper faces the rotating device, and is configured to set the gripper to the first or second height position at one of the external delivery / reception position and the internal delivery / reception position, and to turn the gripper to the other delivery / reception position while holding the gripper at the set height position.

Owner:AISIN AW CO LTD

Deburring by hobbing with integrated secondary deburring without a smoothing tool

ActiveUS7624505B2Well-deburred toothedRapid productionGear wheelsOther manufacturing equipments/toolsGear wheelEngineering

The invention relates to a method for tooth-machining of workpieces (3), especially gear wheels, comprising milling, deburring by hobbing and integrated secondary deburring. The method proceeds on a machine tool (1) having two workpiece spindles (11, 12) which may exchange places. A workpiece (3) is mounted on a first workpiece spindle (11), followed by the workpiece spindles (11, 12) exchanging places, followed by pre-milling and, where applicable, cutting (=deburring by shaving) of the workpiece (3), followed by a further exchange of places, followed by chamfering and cutting of the workpiece (3), followed by a further exchange of places, followed by a finish-milling of the workpiece (3), followed by a further exchange of places, followed by a workpiece change. At the same time, the same procedure takes place on the second workpiece spindle (12), staggered in time by an exchange of places of the workpiece spindles (11, 12). With the method according to the invention, well-deburred toothed workpieces (3) may be produced quickly and at low cost.

Owner:FELSOMAT

Machine tool and detachable/attachable motor

ActiveUS7213316B2Machining rate dropCompact processElectric lighting sourcesCharge manipulationRotary stageProcess region

A machine tool is provided with: a rotating table apparatus that has a table for holding a workpiece, and that rotates the table based on a drive force that has been input; a processing area for processing the workpiece, the rotating table apparatus being carried into and out from the processing area; and a drive source for inputting the drive force when connected to the rotating table apparatus, the drive source being provided in the processing area such that the drive source can be disconnected from the rotating table apparatus.

Owner:SANKYO SEISAKUSHO

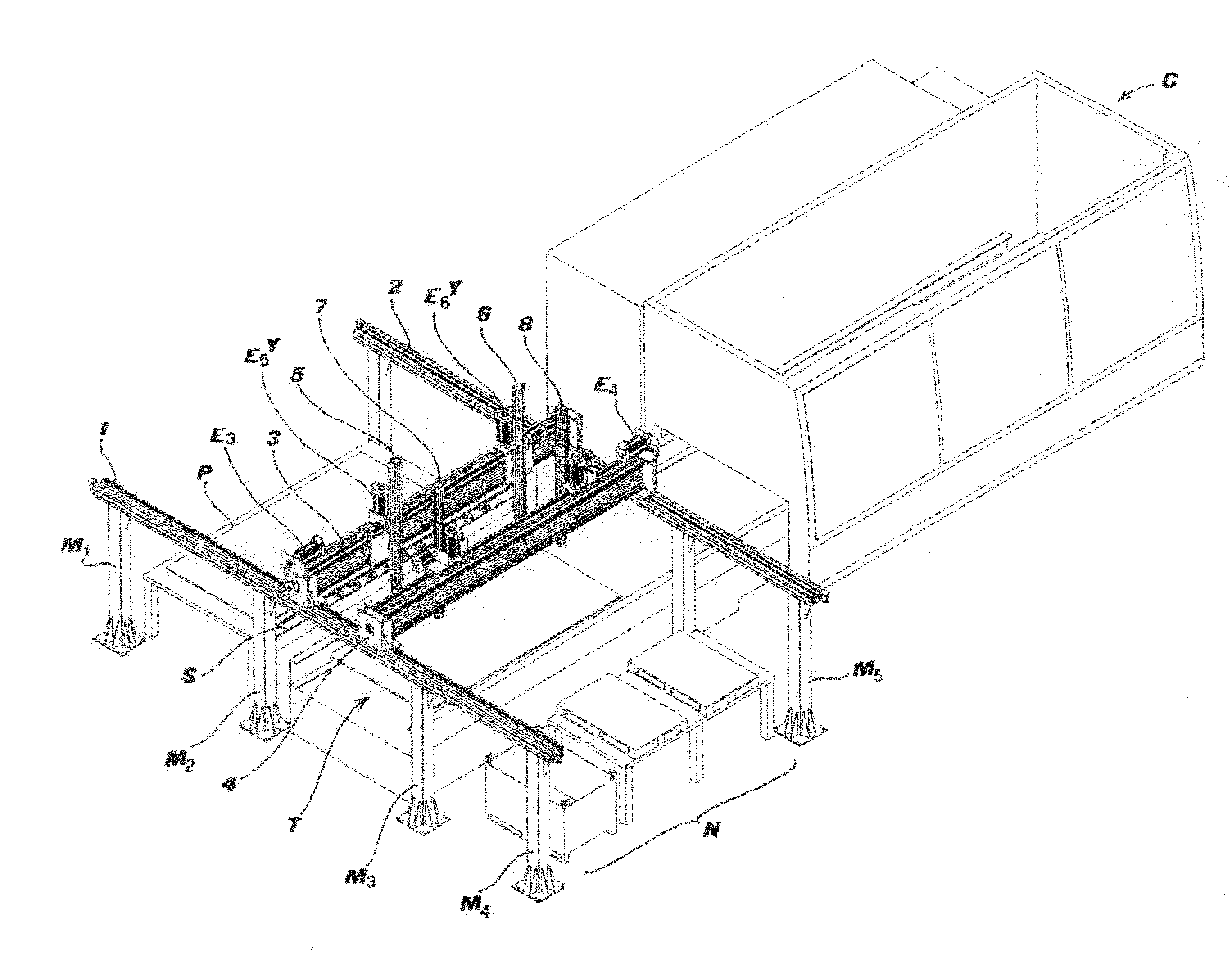

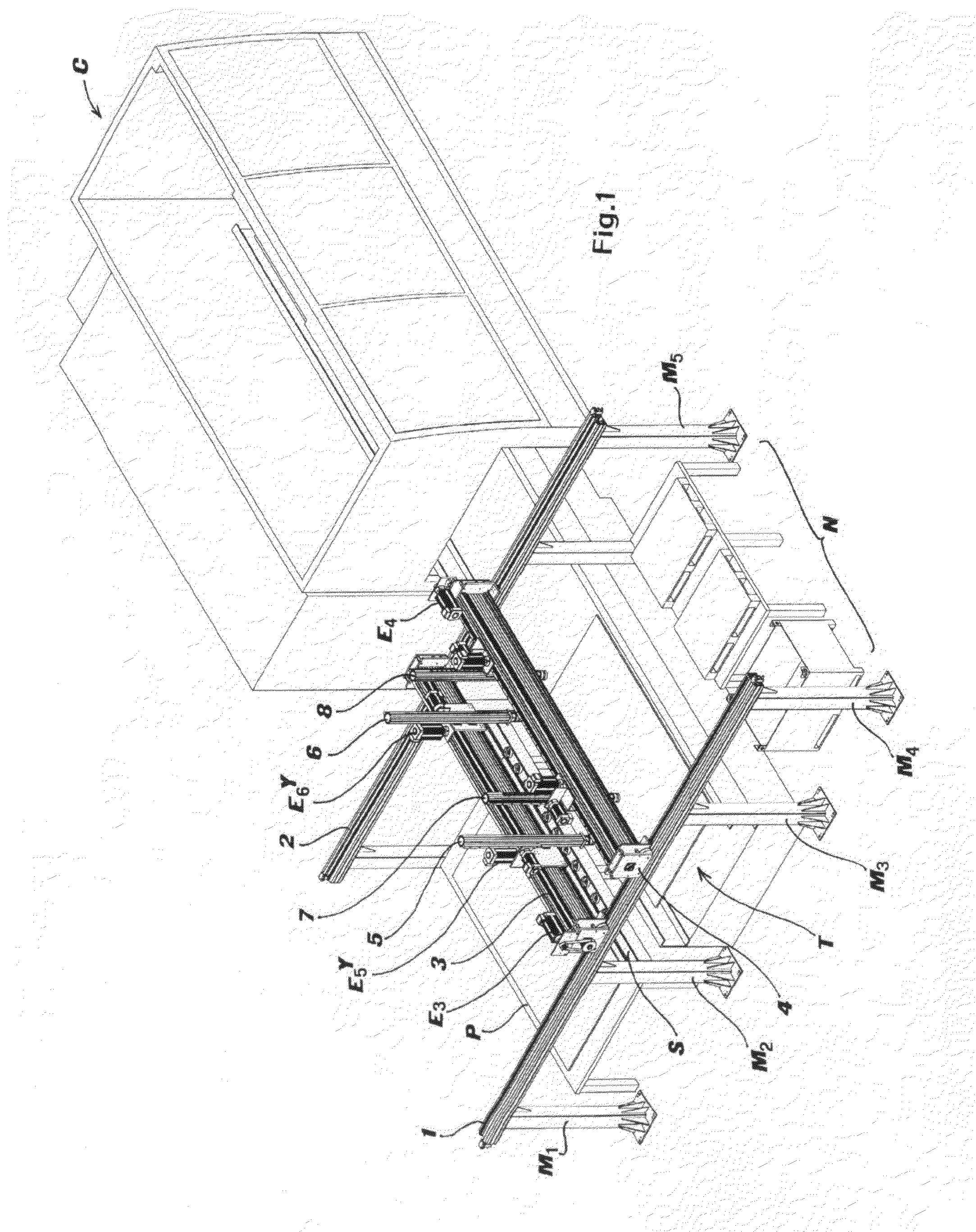

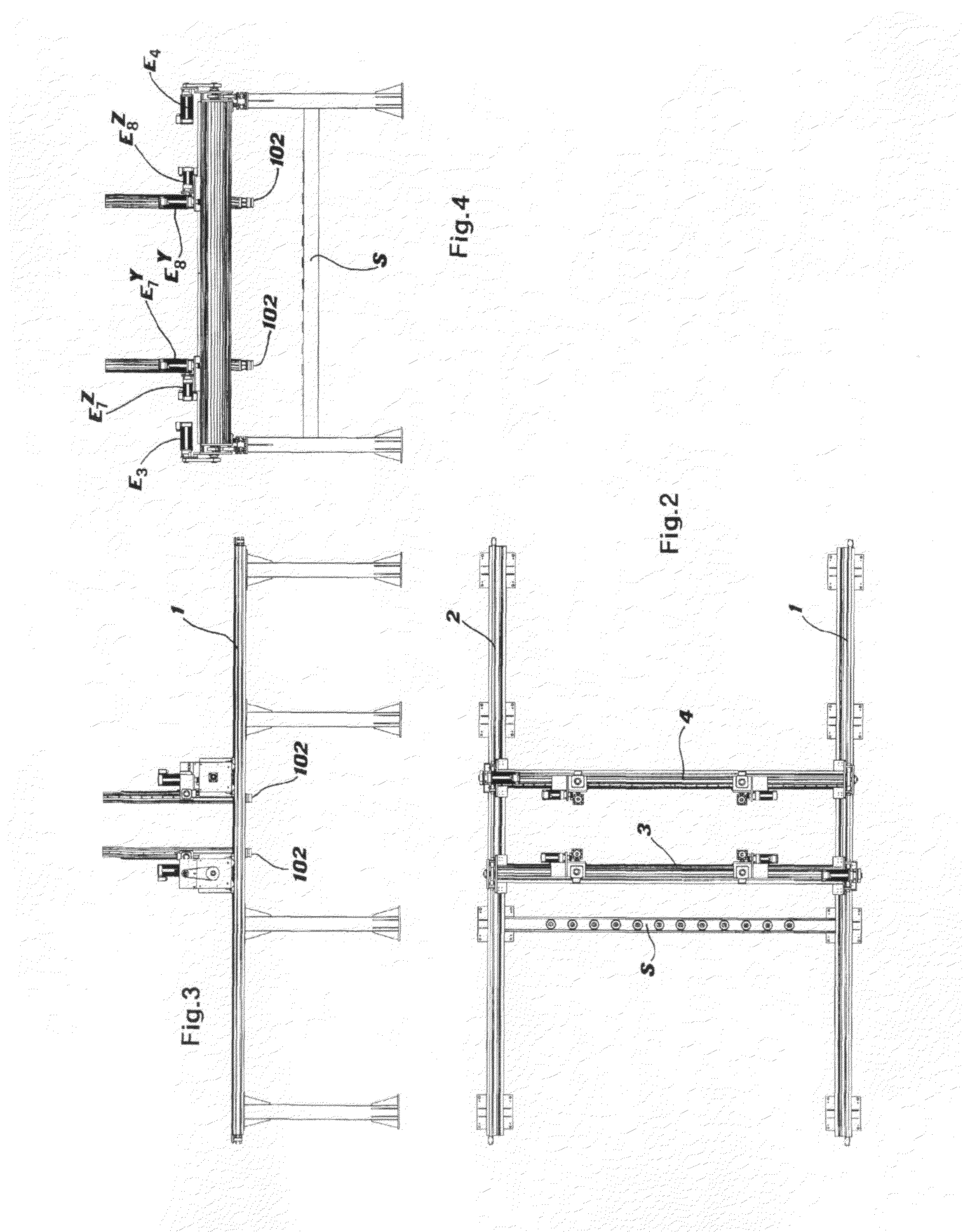

Loading/unloading system serving a sheet cutting centre, feeding tray therefor and relative handling method

ActiveUS20100296905A1Metal-working feeding devicesWelding/cutting auxillary devicesHorizontal axisEngineering

A system for loading / unloading sheets is disclosed, some of which also being of metal, and handling method thereof, serving a laser cutting centre. The system includes a pair of rails (1, 2), supported at a preset height above a feeding tray (T) of the cutting centre, whereon at least one Cartesian robotized hand is movably mounted, capable of moving along horizontal axes X and Y as well as along a vertical axis Z, mutually orthogonal, and including at least two bridge cranes (3, 4) sliding along the rails (1, 2) each of which supports at least one pair of robotized hands (5-8), and the robotized hands (5-8) have an electromagnetic pick-up head which may be coupled with a suction-cup device (103). Feeding tray (T) consists of bars whereon small tesserae (204) of ceramic material are fitted.

Owner:ASTES4 SA

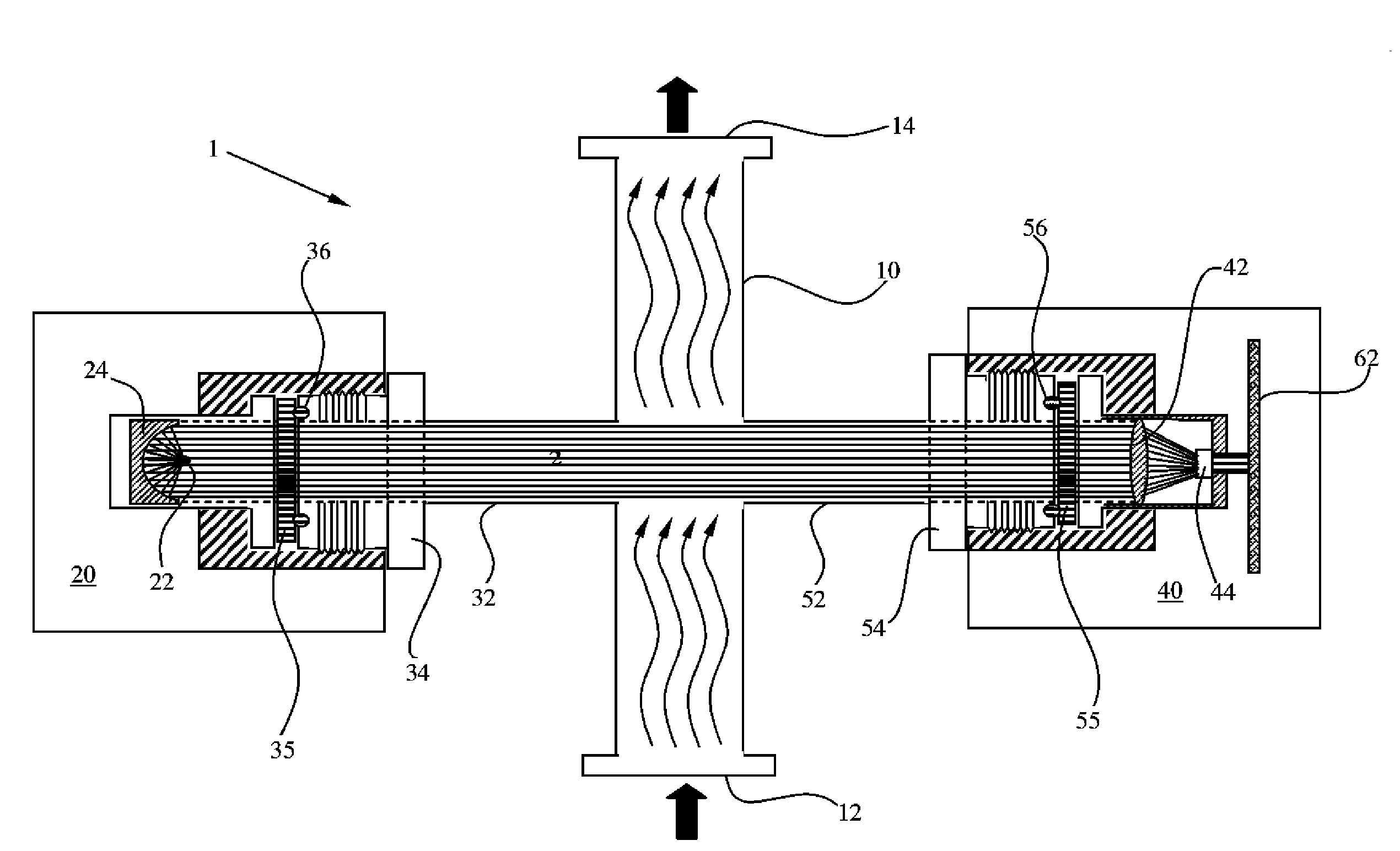

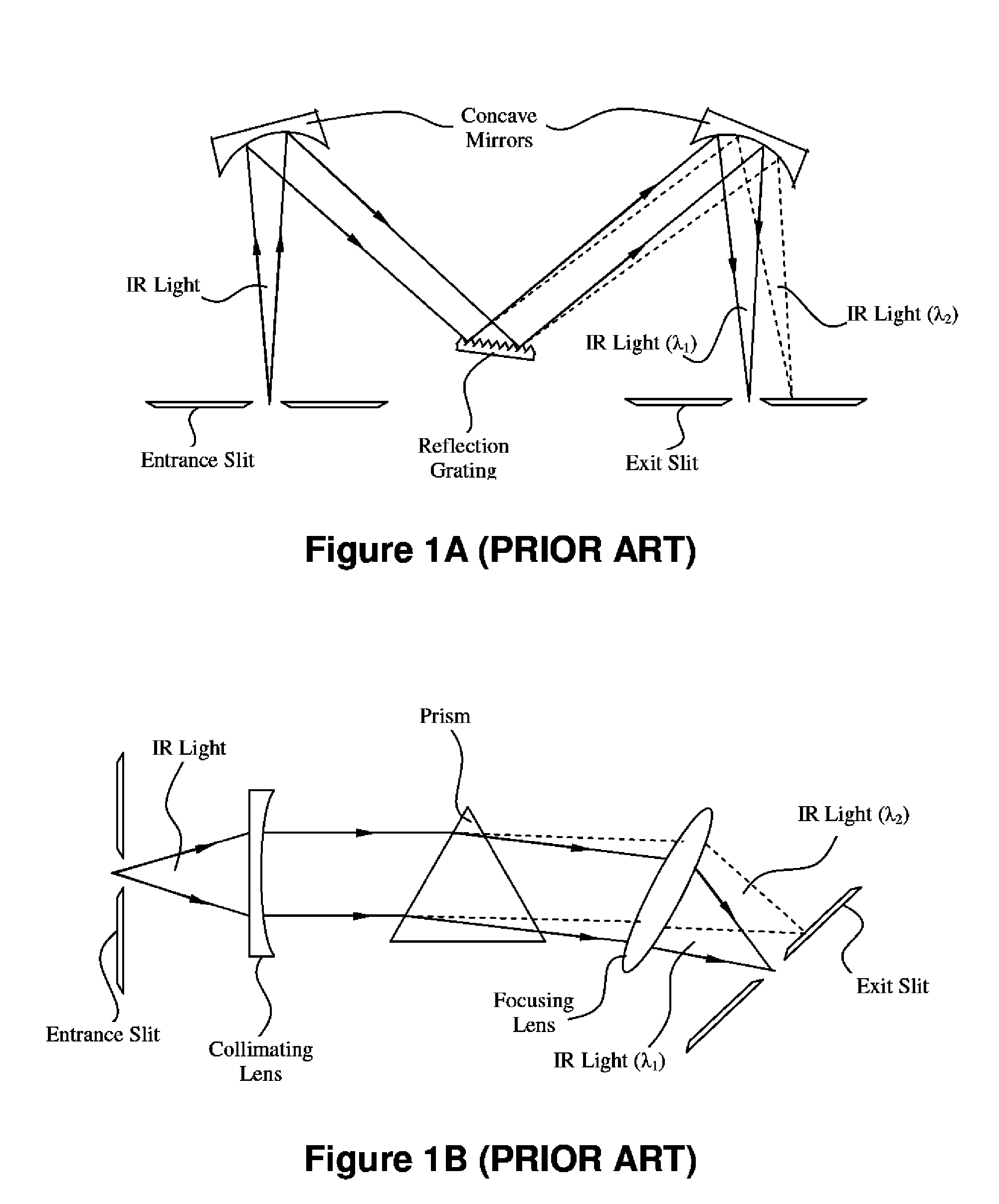

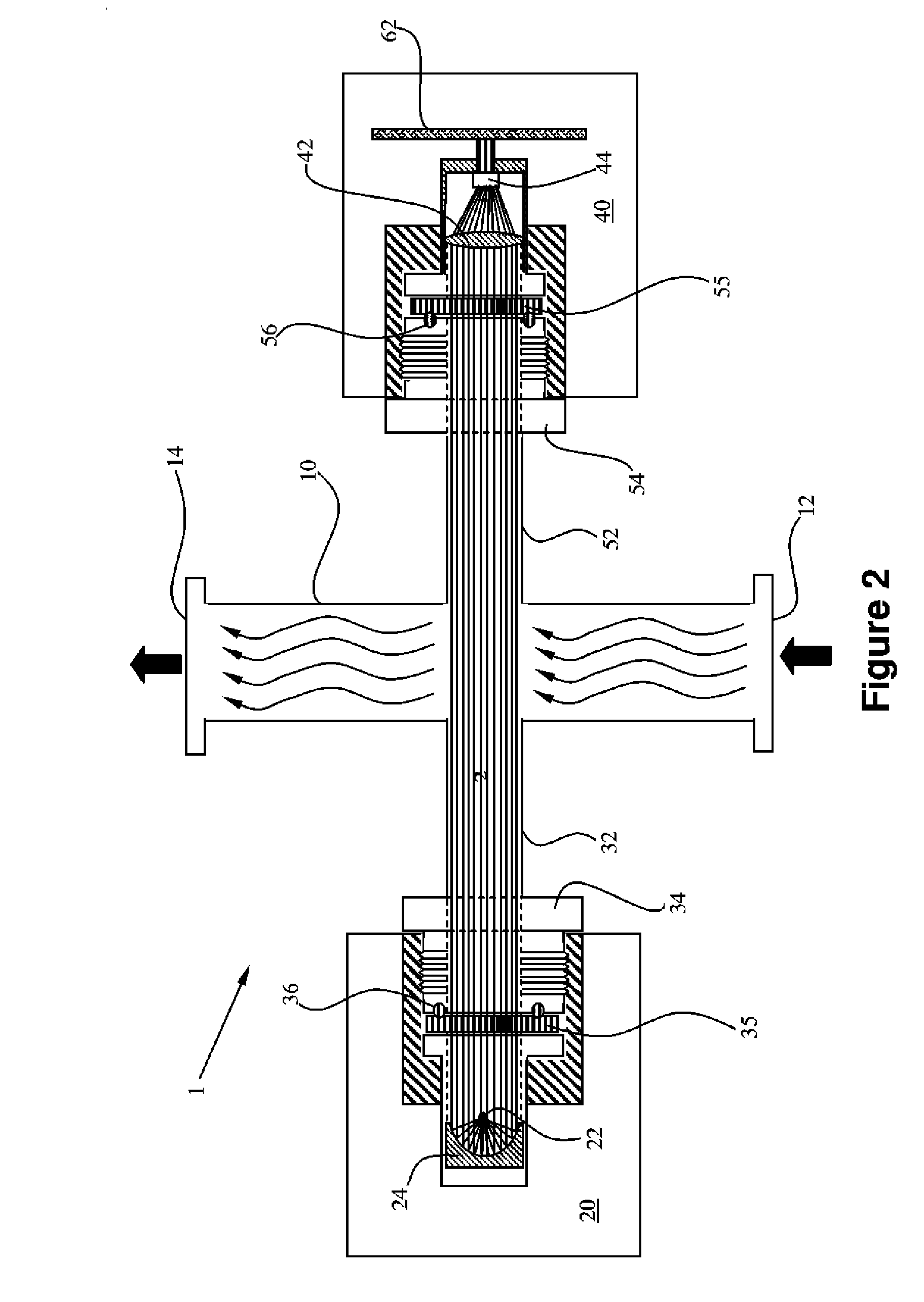

Monitoring system comprising infrared thermopile detector

InactiveUS20090039266A1Minimizes reflection and refractionReduce lossesSemiconductor/solid-state device testing/measurementSensing radiation from gases/flamesThermopileMonitoring system

The present invention relates to a semiconductor processing system that employs infrared-based thermopile detector for process control, by analyzing a material of interest, based on absorption of infrared light at a characteristic wavelength by such material. In one embodiment, an infrared light beam is transmitted through a linear transmission path from an infrared light source through a sampling region containing material of interest into the thermopile detector. The linear transmission path reduces the risk of signal loss during transmission of the infrared light. The transmission path of the infrared light may comprise a highly smooth and reflective inner surface for minimizing such signal loss during transmission.

Owner:ADVANCED TECH MATERIALS INC

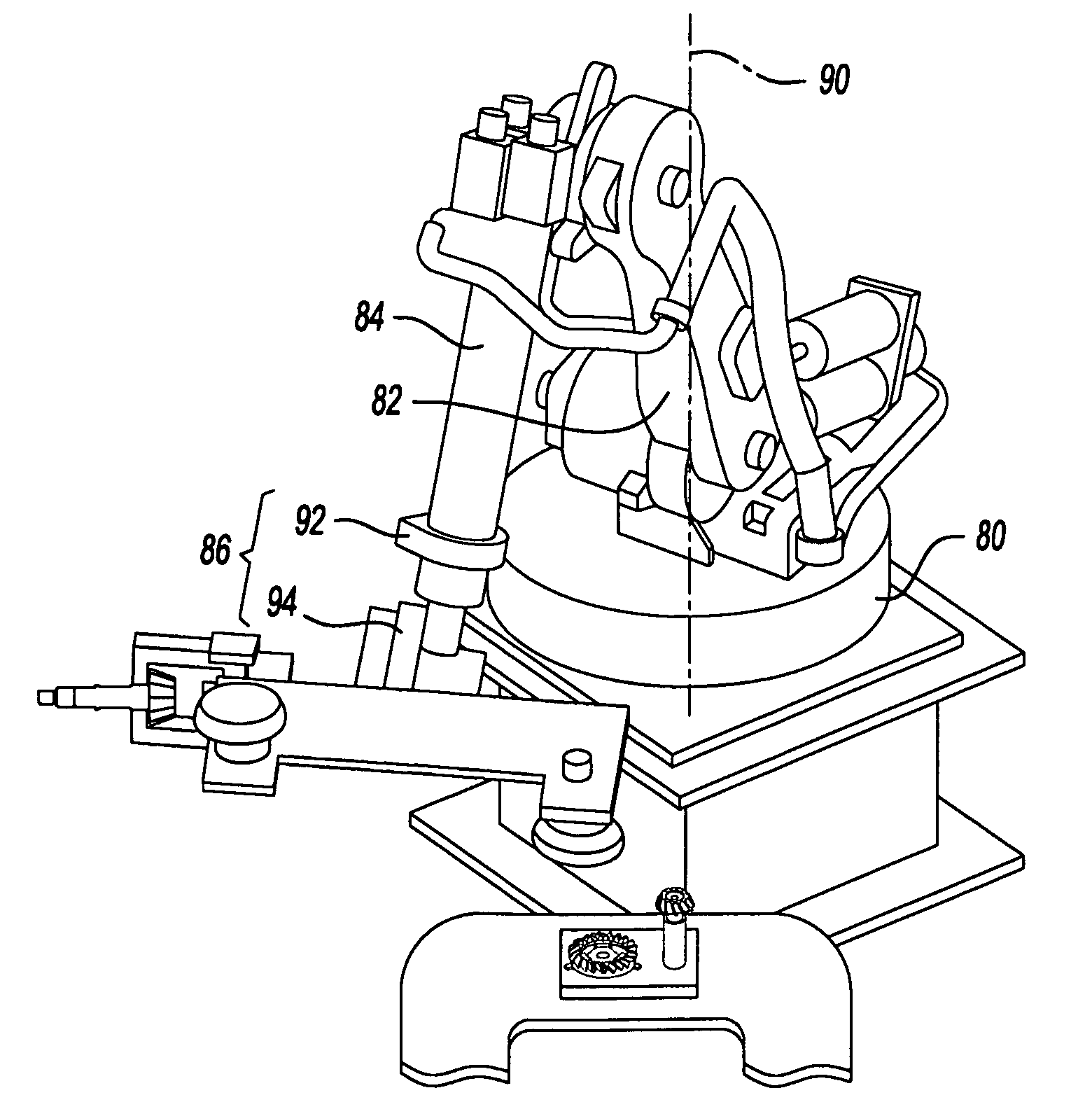

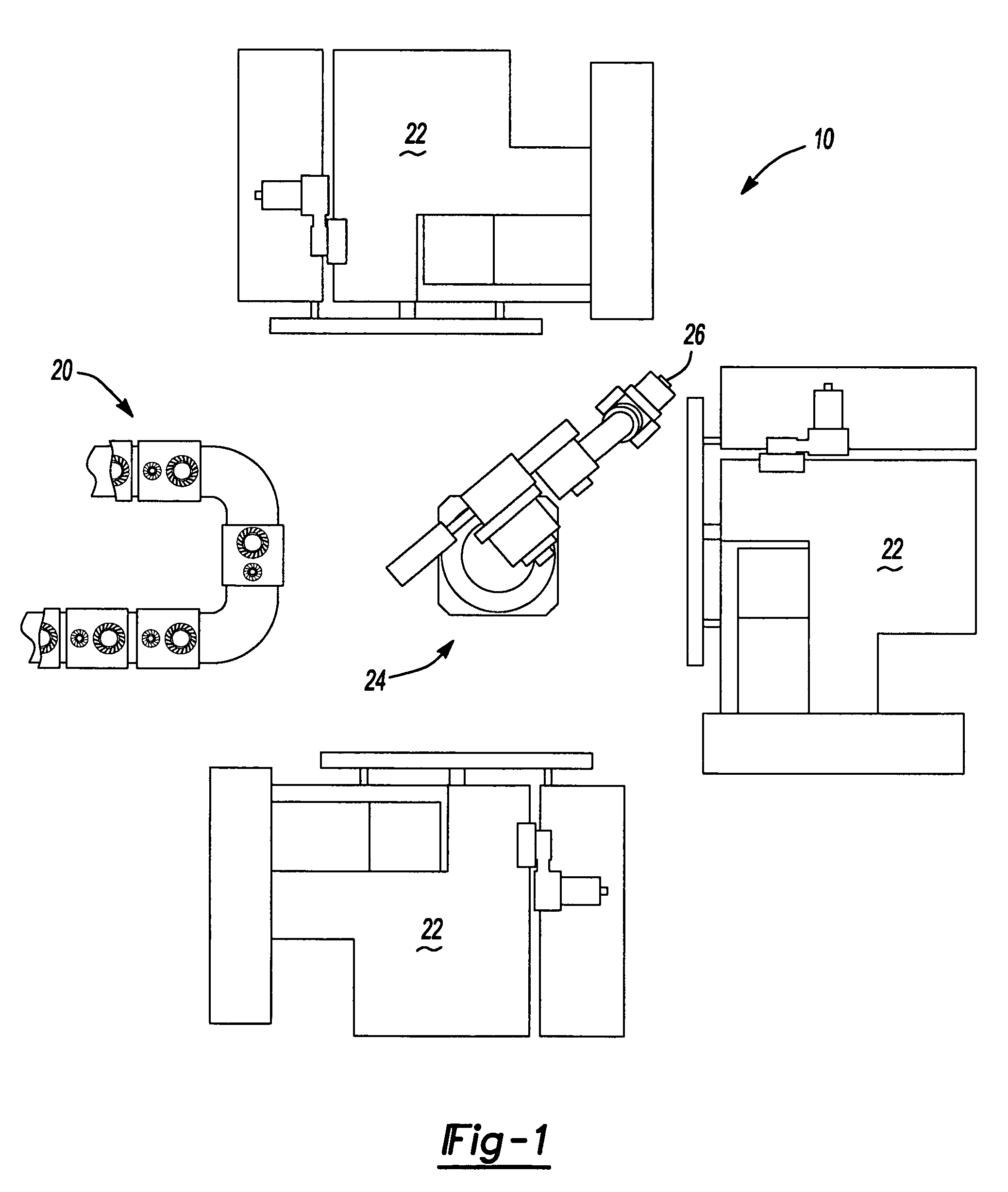

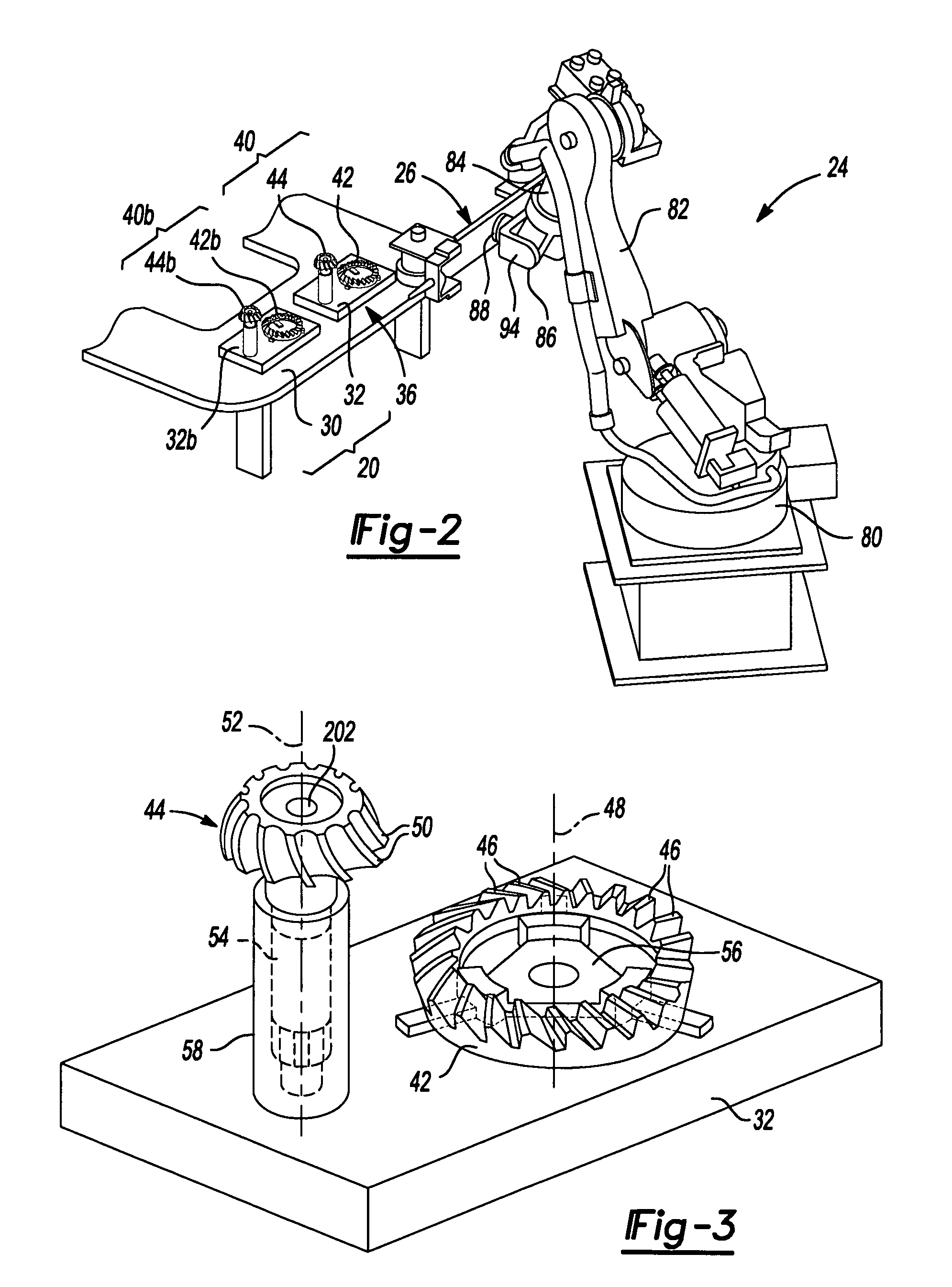

Process for lapping ring and pinion gears

ActiveUS7299533B1Minimized footprintEdge grinding machinesMeasurement/indication equipmentsRotational axisGear wheel

A method for processing a gear set through a lapping operation that includes: providing a lapping machine tool having a first spindle and a second spindle, the second spindle being rotatable about an axis that is generally perpendicular to a rotational axis of the first spindle, the lapping machine tool having a loading zone for loading the first and second spindles; providing a robot with an end effector; loading a first gear set to a first end of the end effector, the first gear set having a ring gear and a pinion gear; moving the first end of the end effector into the loading zone; and loading the first gear set to the lapping machine tool without removing the end effector from the loading zone such that the ring gear is loaded onto the first spindle and the pinion gear is loaded onto the second spindle. An end effector is also provided.

Owner:AMERICAN AXLE & MFG

Machining centers

The machining center has a base, a frame and at least a machine tool mounted onto the frame, at least a tool magazine associated with the machine tool for changing the tool and a workpiece gripping and supporting member. The machining center comprises a movable vertical member adapted to support from the top the workpiece gripping and supporting member. The movable vertical member is adapted to position the workpiece gripping and supporting member in a first operative position in which the workpiece is automatically loaded onto or unloaded from the workpiece gripping and supporting member of the machining center and in a second operative position in which the workpiece is machined by the machine tool of the machining center. The gripping and supporting member is adapted to hold firmly the workpiece during the machining operation and support it from the top so that the chips formed by the machine tool during the machining operation fall downwards by force of gravity thereby clearing the machining area from the chips.

Owner:MACHINING CENTS MFG

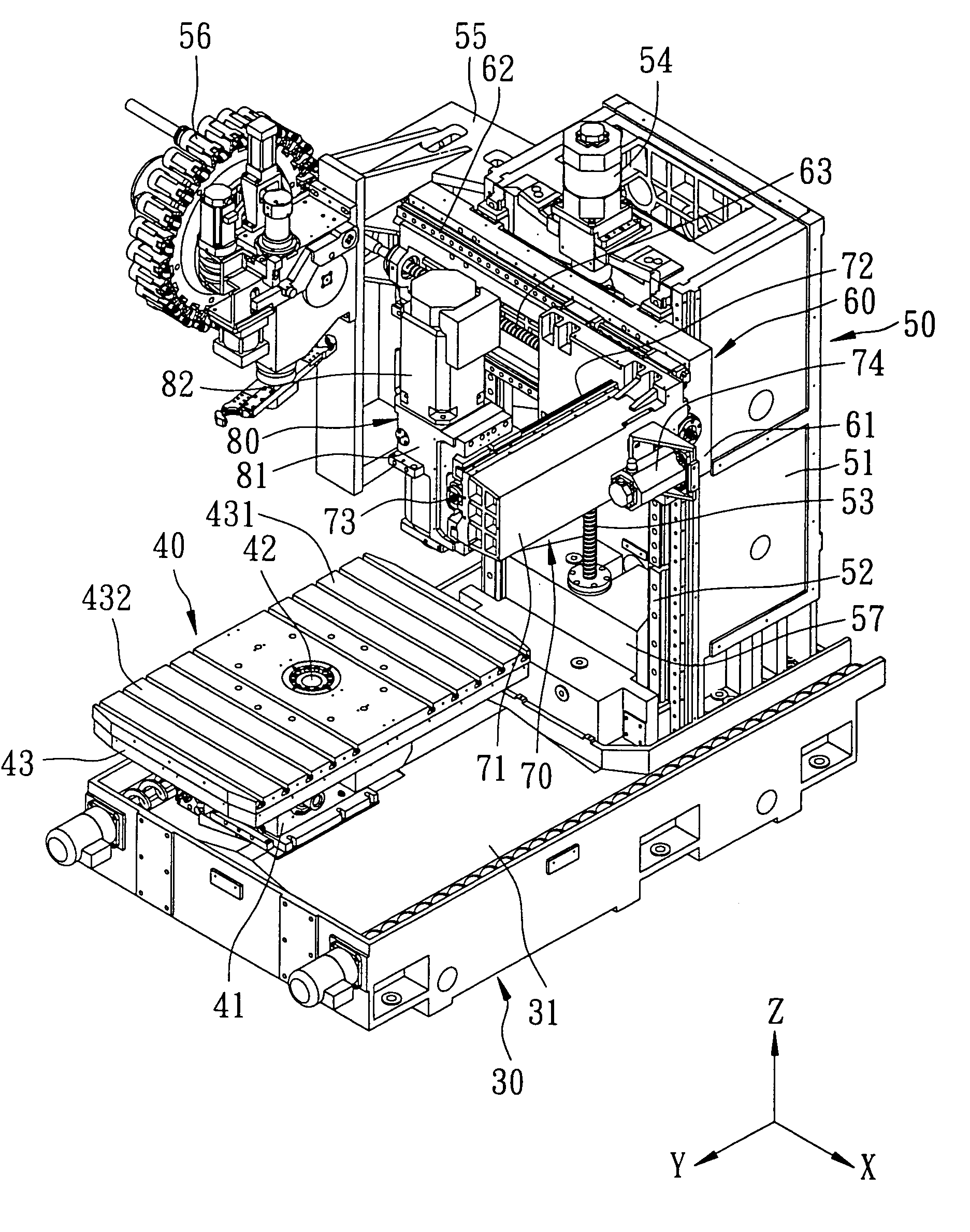

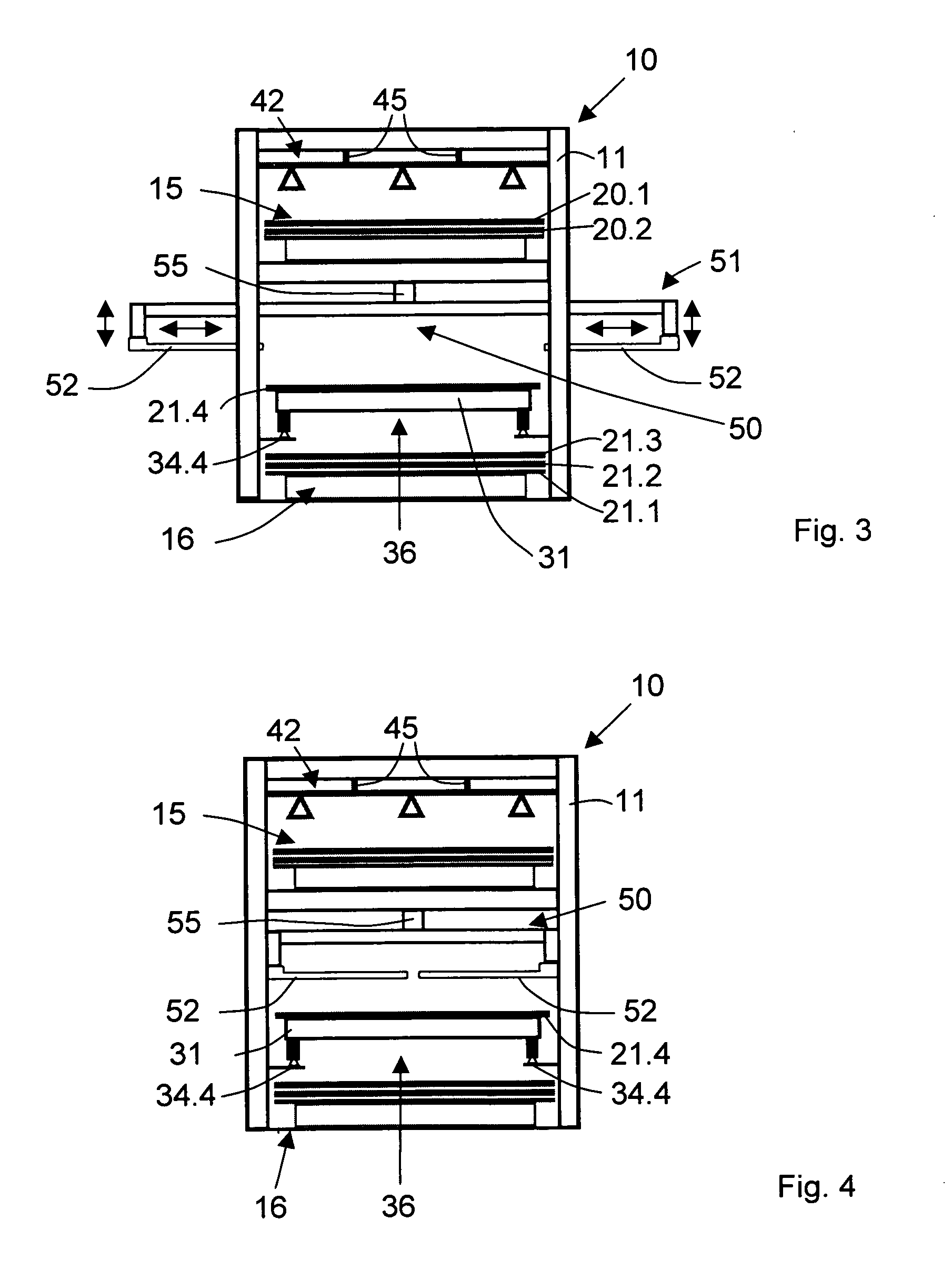

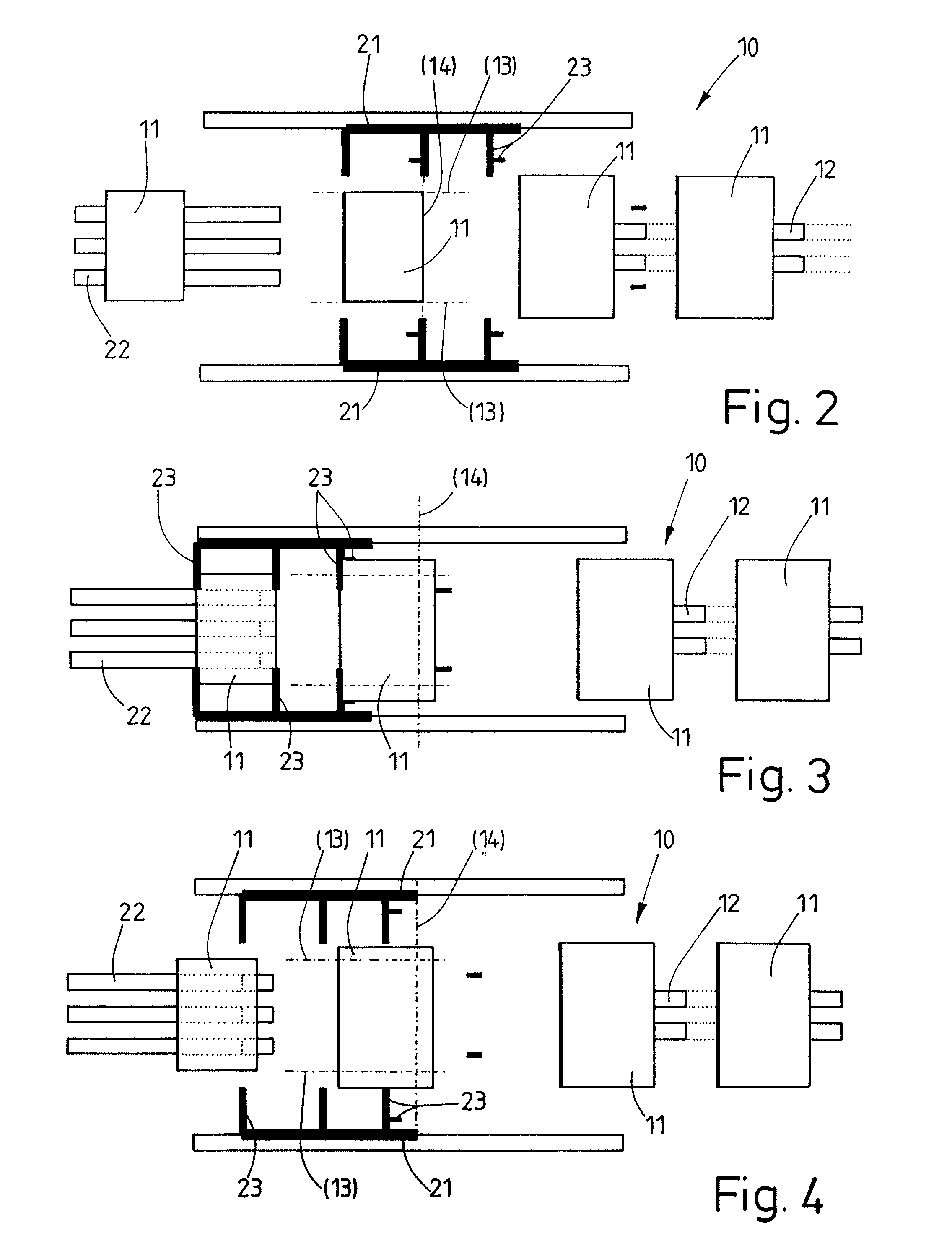

Machine tool having a number of multispindle spindle assemblies

InactiveCN105579192AProcess stabilityHigh precisionWorkpiecesMilling machinesEngineeringMachine tool

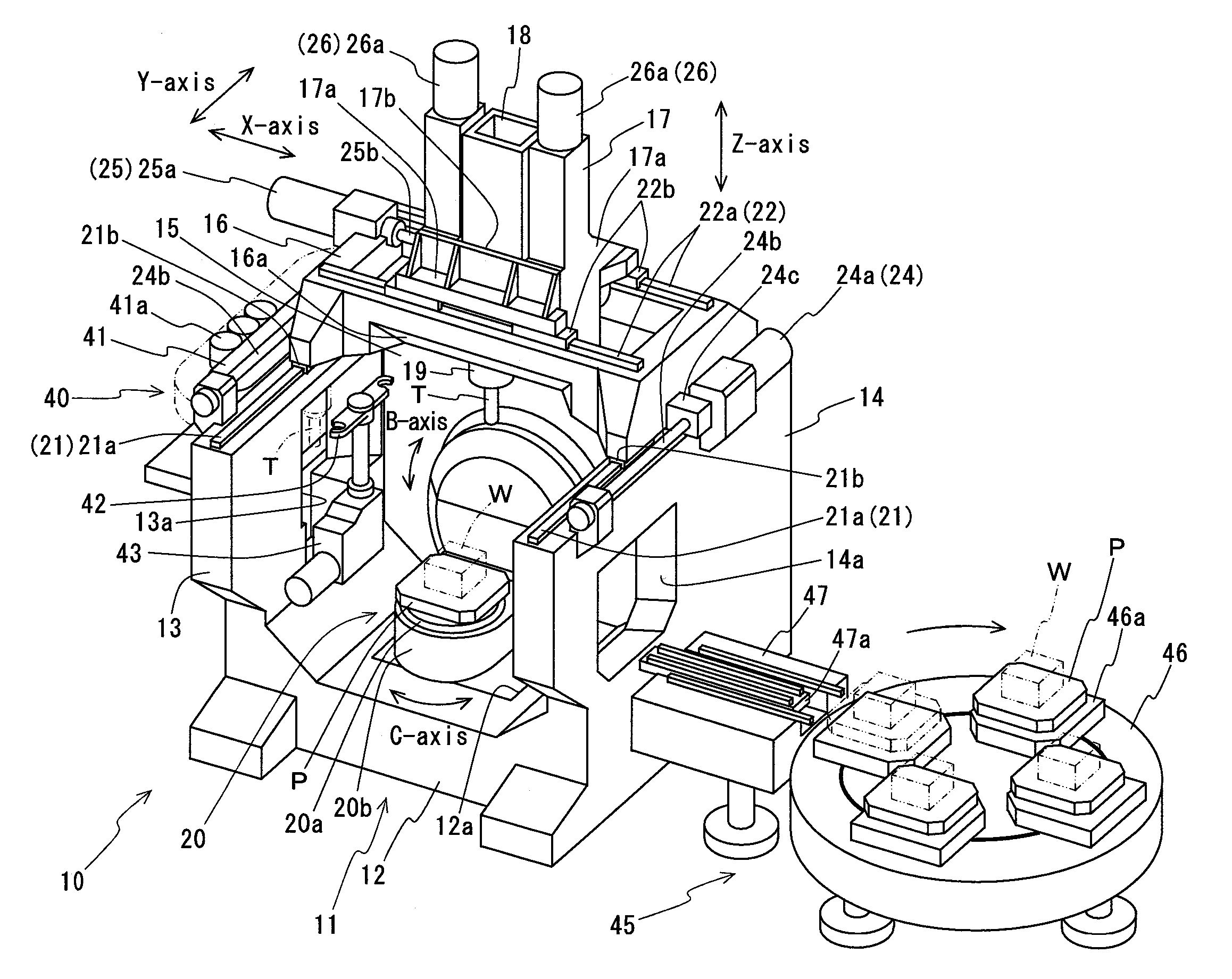

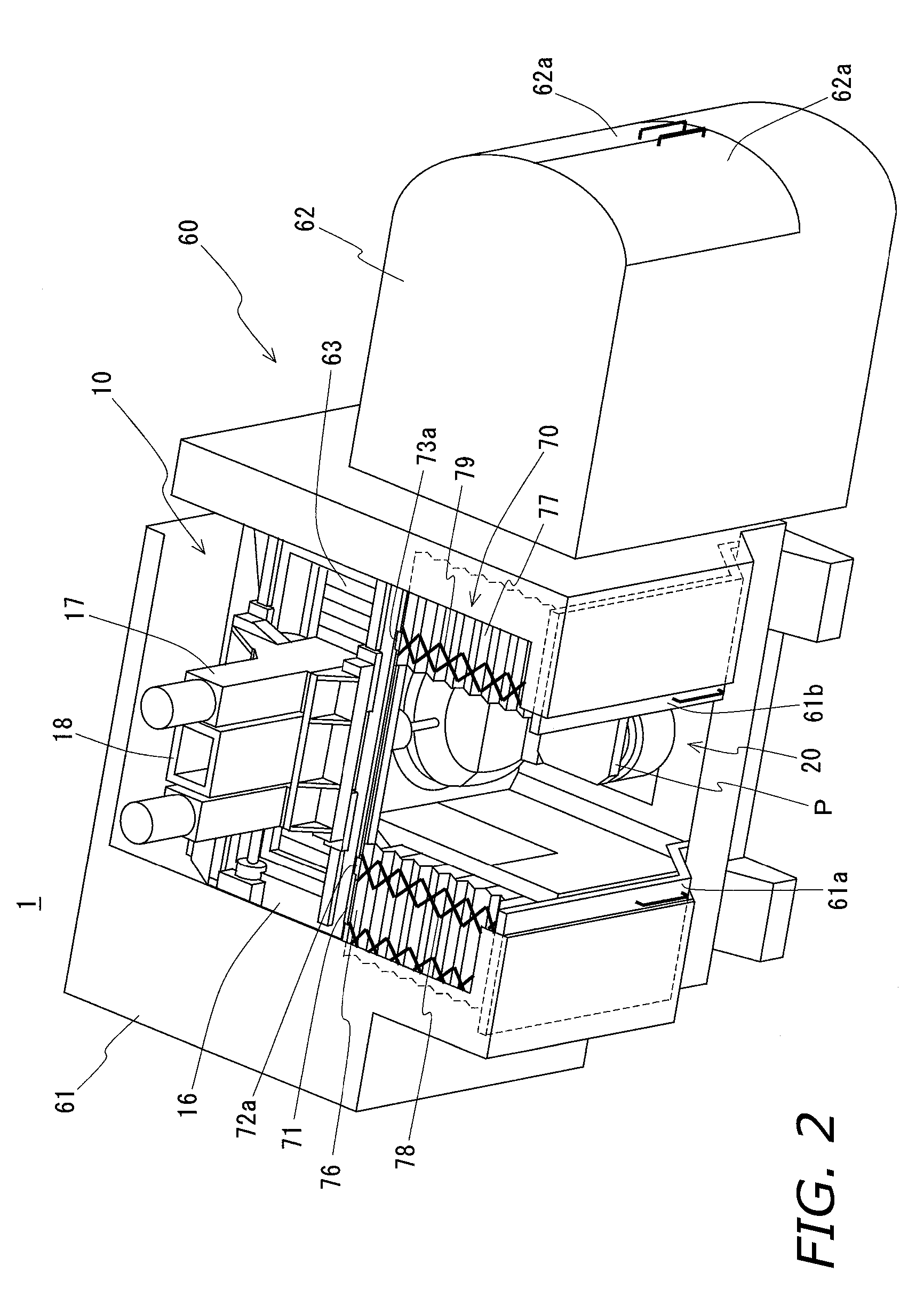

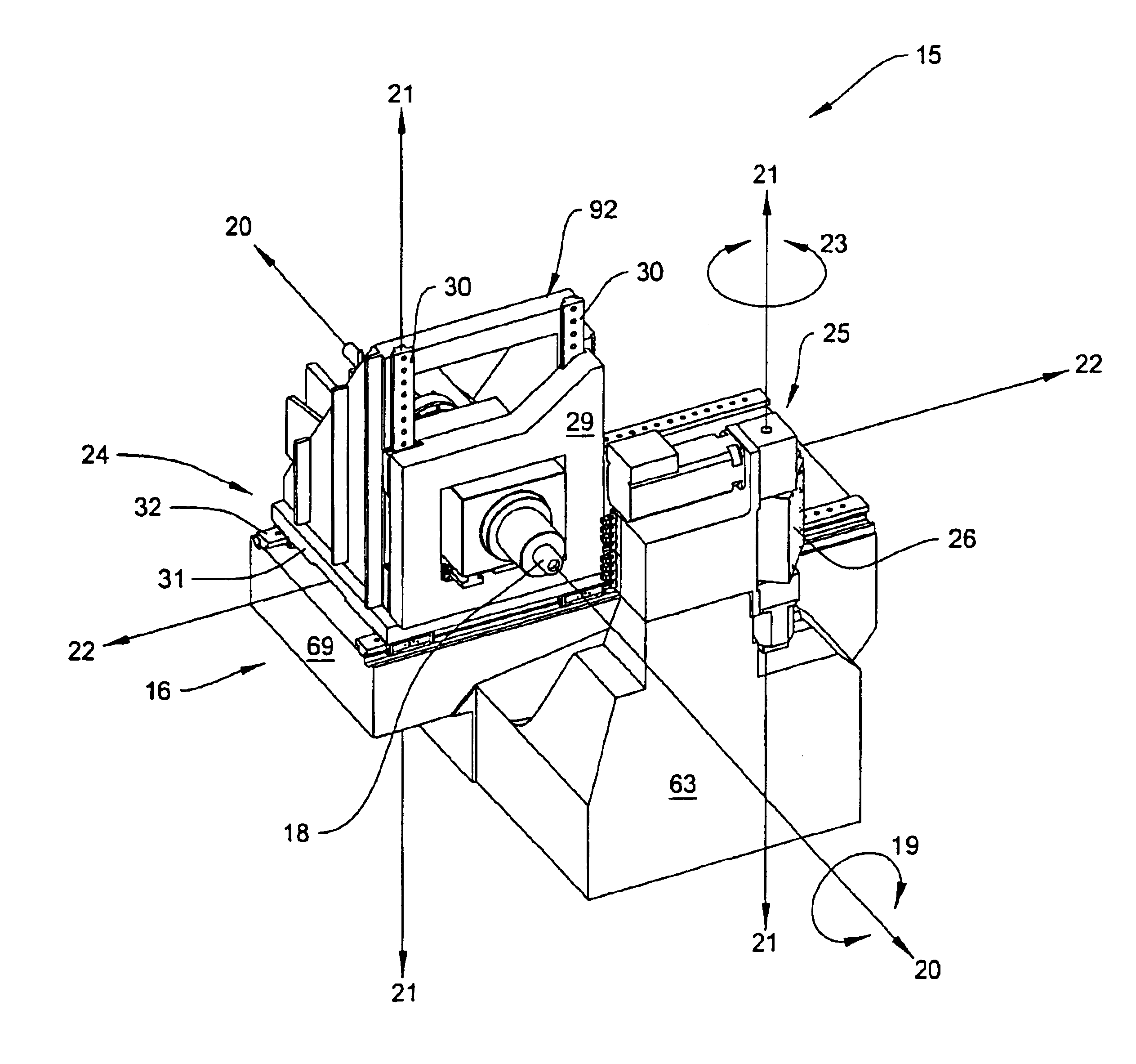

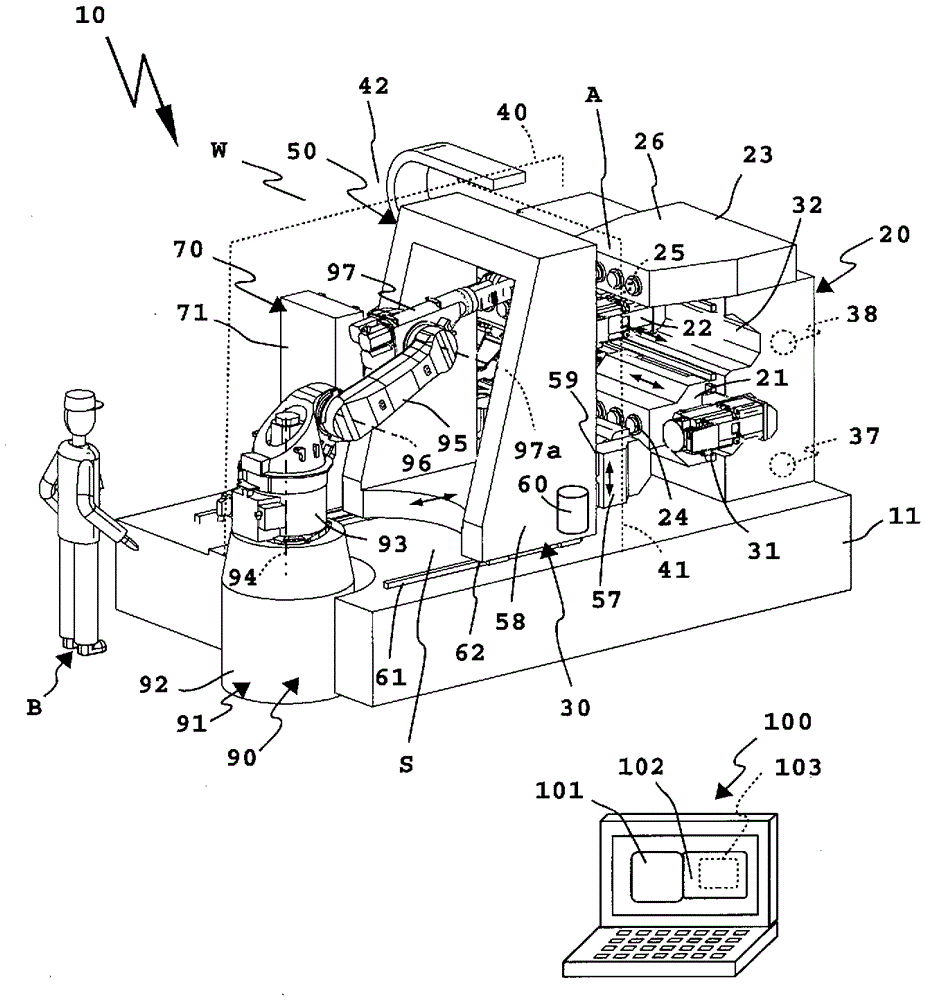

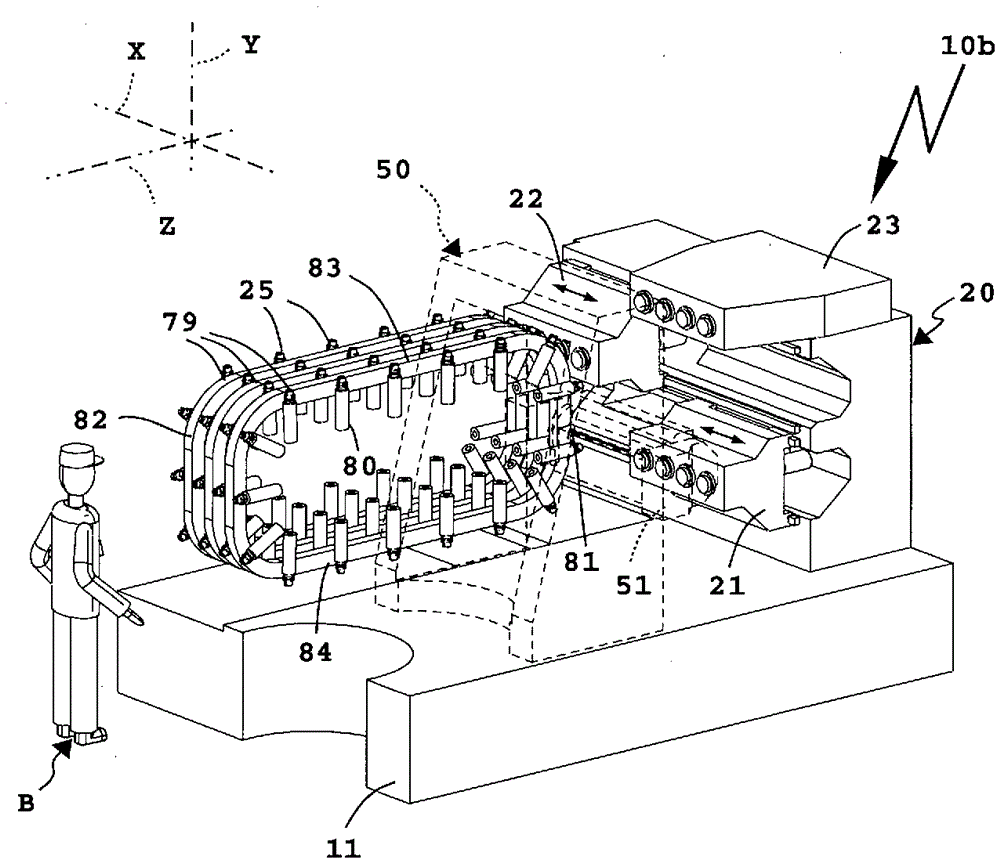

The invention relates to a machine tool for machining workpieces (P), wherein the machine tool (10) has a first spindle assembly (21) and at least one second spindle assembly (22) each having at least two working spindles (24) which are arranged in a common spindle housing (26, 126) and on which in each case a machining tool (25) for workpiece machining is arrangeable, wherein the machine tool (10) has a workpiece holding device (50) for holding workpieces (P) for the purpose of workpiece machining by way of the machining tools (25), wherein the machine tool (10) has a guide arrangement (30) for the relative positioning of the workpiece holding device (50) holding the workpieces (P) and the first and the at least one second spindle assembly (22) for workpiece machining. In the machine tool (10), provision is made for the first spindle assembly (21) to be guided on a first spindle-assembly guide (31) of the guide arrangement (30) and for the at least one second spindle assembly (22) to be guided on a second spindle-assembly guide (32), separate from the first spindle-assembly guide (31), of the guide arrangement (30), such that the spindle assemblies are movable independently of one another into a working region (A), in which the workpieces (P) are provided for workpiece machining by the workpiece holding device (50), and a tool changing region (W) provided for changing machining tools (25) on the working spindles (24).

Owner:ALFING KESSLER SONDERMASCH

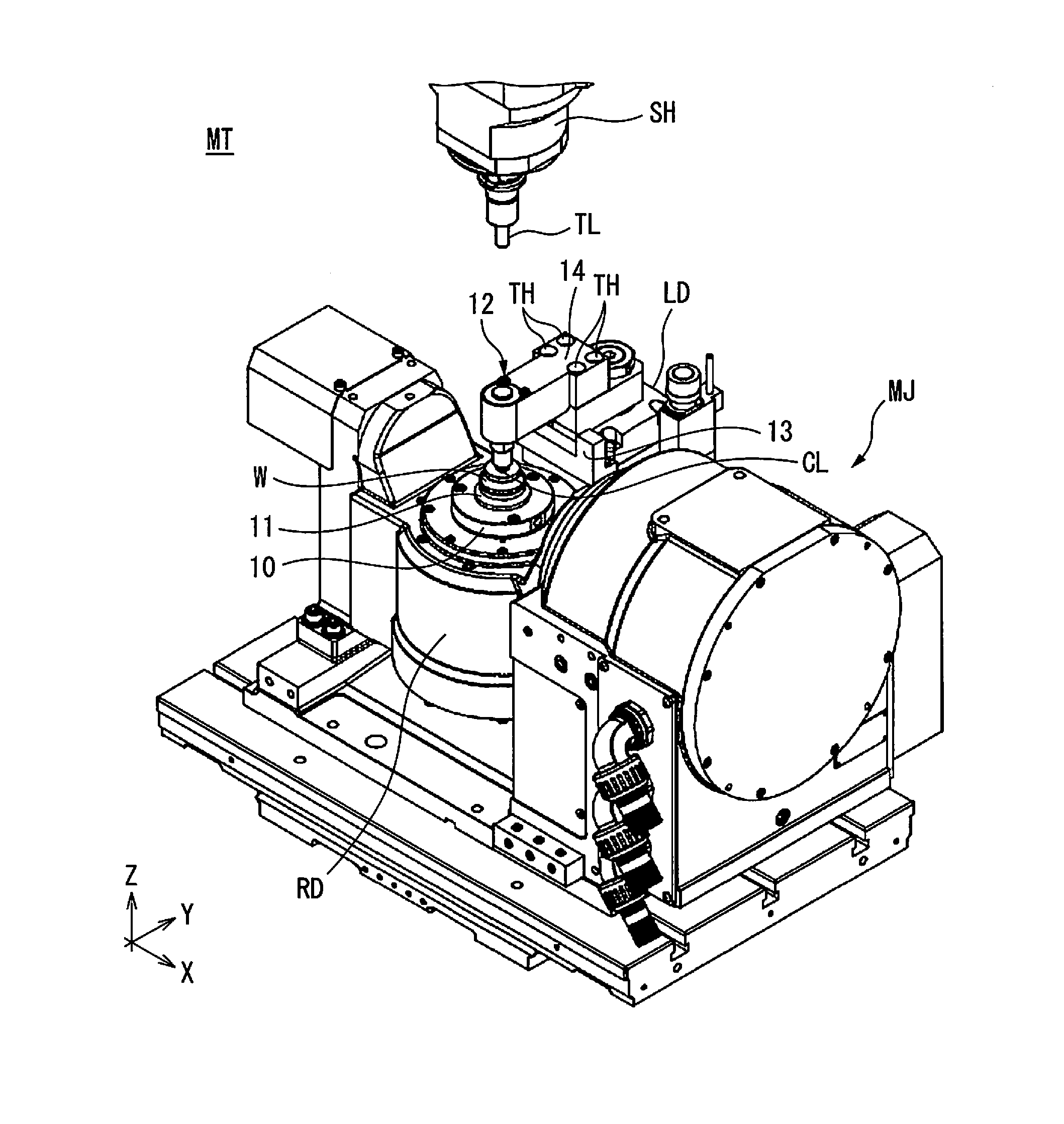

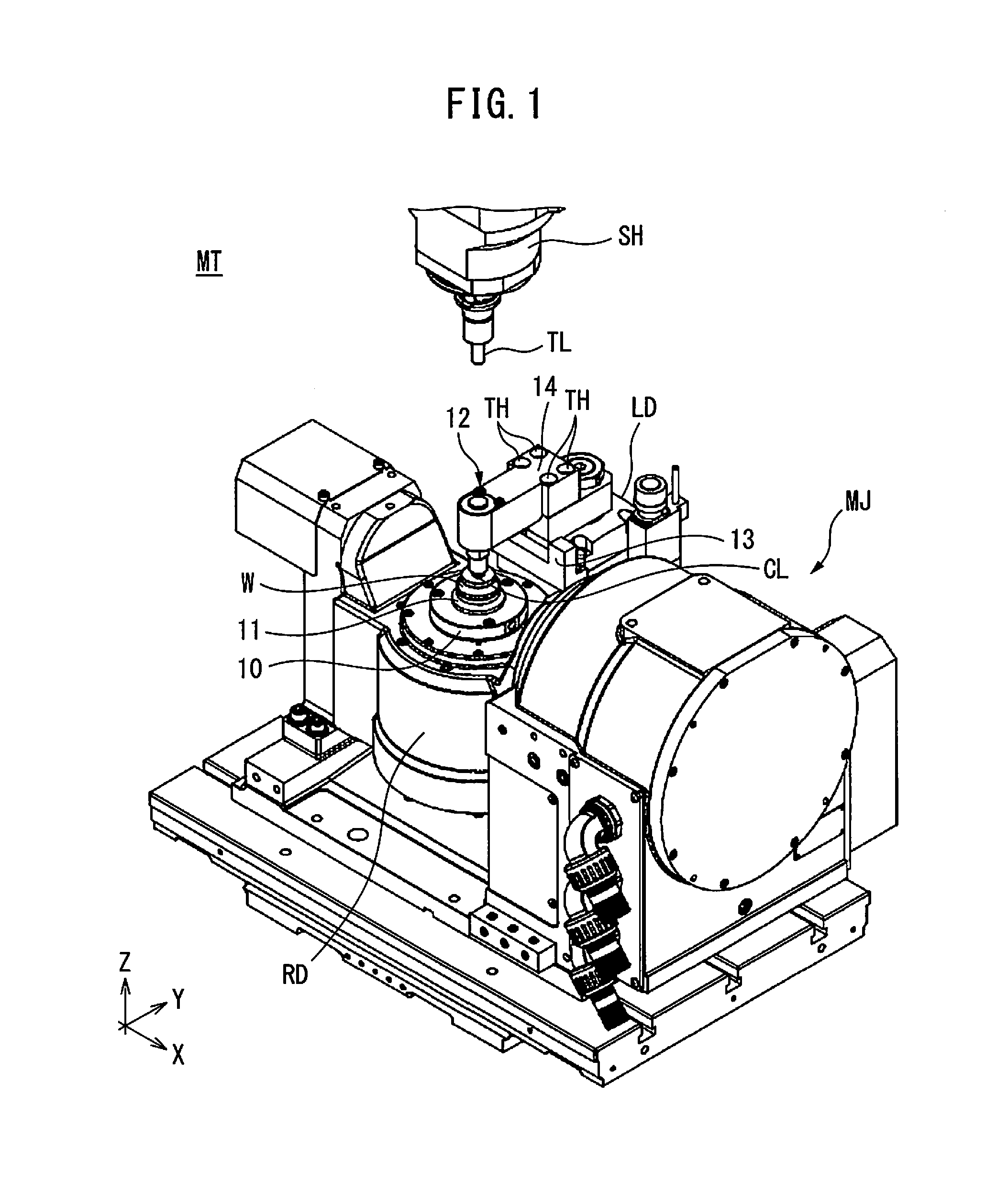

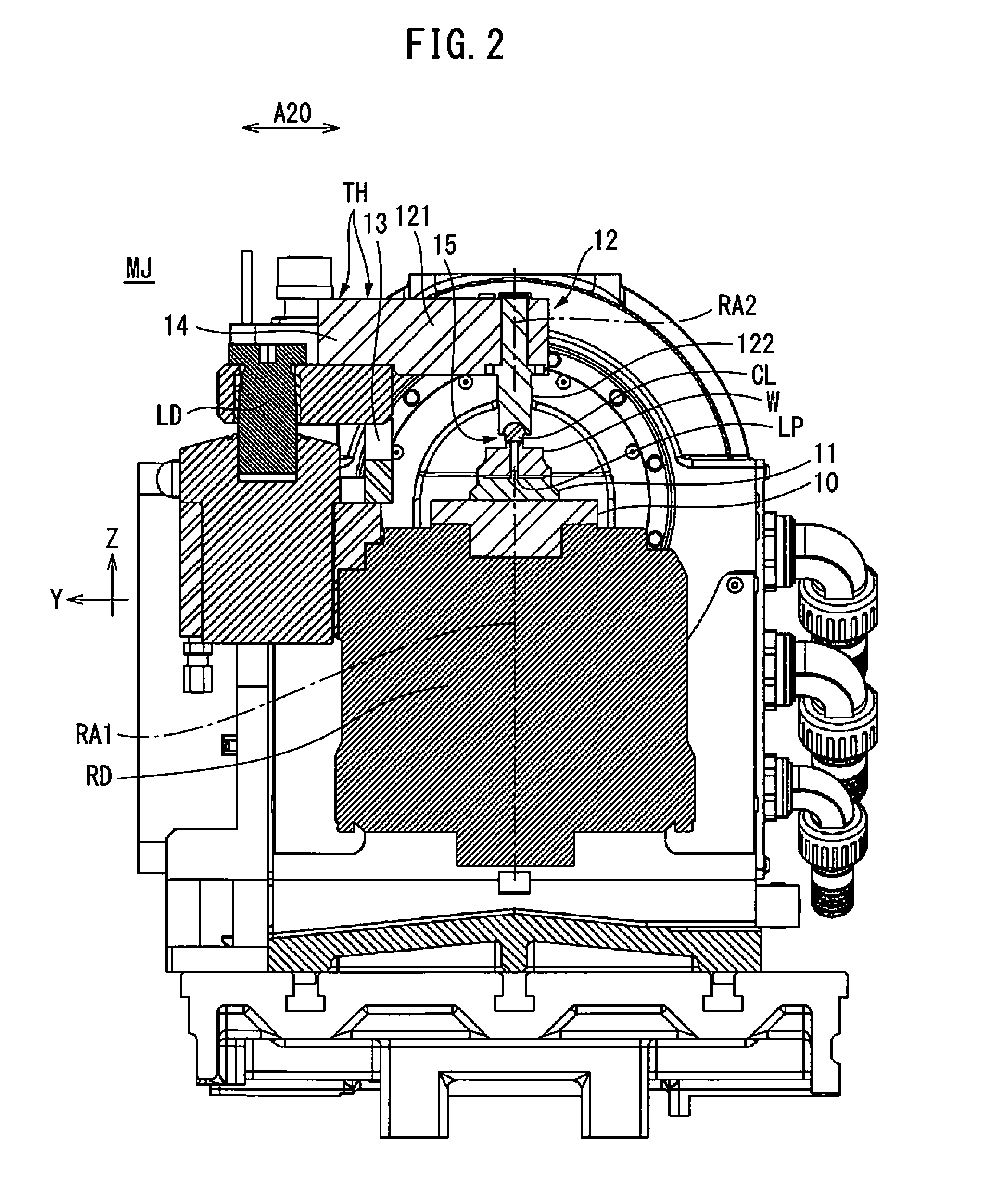

Machining jig for rotatably supporting workpiece with respect to tool of machine tool and machining system

A machining jig for rotatably supporting a workpiece comprising: a rotary drive part which rotates a seating part about a rotation axis, a clamp arm which has a rotary type clamp member which cooperates with the seating part to fasten a workpiece at a position separated from the seating part in a direction along the rotation axis of the seating part, a linear drive part which moves the clamp arm in a direction along a rotation axis, a position adjusting part which adjusts a position of the clamp arm in a plane intersecting the rotation axis, and a tilt adjusting part which adjusts a tilt of the clamp member so that a rotation axis of the clamp member becomes parallel with the rotation axis of the seating part.

Owner:FANUC LTD

Pallet changer apparatus

InactiveUS6341928B1Easy accessReduce the possibilityCharge manipulationFeeding apparatusEngineeringCam

In a pallet changer apparatus, a pallet changing arm is connected to a motor via a raising / lowering mechanism and an intermittent drive unit. During operation of the motor, the pallet changing arm is raised from a lowermost position to an uppermost position, and is held at the uppermost position, and then is lowered from the uppermost position to the lowermost position. The pallet changing arm is also connected to the motor via a turning mechanism and a second cam drive portion. During operation of the motor, the pallet changing arm is turned while being held at the uppermost position. The pallet changing arm is moved up and down and turned by using the single motor provided above a table. The table below the pallet changing arm is reduced in size so as to allow an operator to perform operations without being impeded by the table. The structure also eliminates the need to determine the drive time of a plurality of drive force sources based on output signals of sensors, thereby decreasing the possibility of a malfunction and improving reliability.

Owner:BROTHER KOGYO KK

Machine tool with work piece handling arrangement

In a machine tool arrangement comprising a machine tool component including a mounting structure for a work piece to be machined by a suitable metal cutting tool, a housing enclosing the machine tool component, a horizontal support beam is disposed above the housing and carries handling equipment for supplying work pieces from an adjacent loading area to the machine component for machining and returning the finished work pieces to the storage structure and an intermediate storage structure is disposed near the machine tool component for temporarily storing unfinished work pieces to be machined and finished work pieces after being machined.

Owner:GEBR HELLER MASCHFAB GMBH

Machining center in which tool holders have a multiple coupling with a cover

InactiveUS6205631B1Quickly displacedImpair accuracy of machineLathesPlaning/slotting machinesCouplingEngineering

A machining center has machine tools which each have a working space for machining workpieces 21, a clamping station 18 in which workpieces 21 to be machined are clamped into workpiece holders 19, and a loading device which transports the workpiece holders 19 between the clamping station 18 and the working space of at least one machine tool. A multiple coupling 70 for transferring fluidic energy, which is selectably docked in the clamping station 18, is provided on the workpiece holder 19 (FIG. 5).

Owner:CHIRON WERKE

Machine tool and method for machining a workpiece

ActiveCN101941163AShorten the timeImprove efficiencyAutomatic control devicesPrecision positioning equipmentEngineeringMachine tool

A method and machine tool for machining a workpiece on the machine tool comprising at least 5 axes with a tool by using an NC program, the machine tool comprising a clamping means for clamping a workpiece and a work spindle including a tool holding means for holding a workpiece, where the workpiece is clamped on the tool holding means of the work spindle of the machine tool, the tool is clamped in the clamping means of the machine tool, and the workpiece clamped in the tool holding means of the work spindle is controlled in a program-controlled manner in relation to the tool clamped in the clamping means for removing material from the workpiece.

Owner:DECKEL MAHO PFRONTEN GMBH

Method for converting a trimming machine for the preferably three-sided trimming of a stack of sheets

InactiveUS20080216623A1Precise positioningFor automatic positioningAutomatic control devicesFeeding apparatusControl systemEngineering

The invention provides for the replacement of the cutting plate (15) and the press die (16) to be carried out automatically, specifically with the aid of a positioning device for positioning the stack of printed sheets (11) to be trimmed under the press die (16). In this way, the automatic conversion of the automatic three-knife trimmer for a format change is possible without a significant change to the automatic three-knife trimmer. Only the control system of the positioning device has to be changed and expanded. The positioning device (21) automatically ensures that the new press die (16) and the new cutting plate (15) are positioned exactly. In particular, the positioning of the die plate (19) under the format plate (18) can be carried out automatically by means of the positioning device with the required high accuracy, to be specific with higher accuracy than would be possible manually.

Owner:WOHLENBERG BUCHBINDESYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com