Machine tool having a number of multispindle spindle assemblies

A spindle and assembly technology, which is applied in the field of machine tools for machining workpieces, can solve problems such as ineffective and fast workpiece machining, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

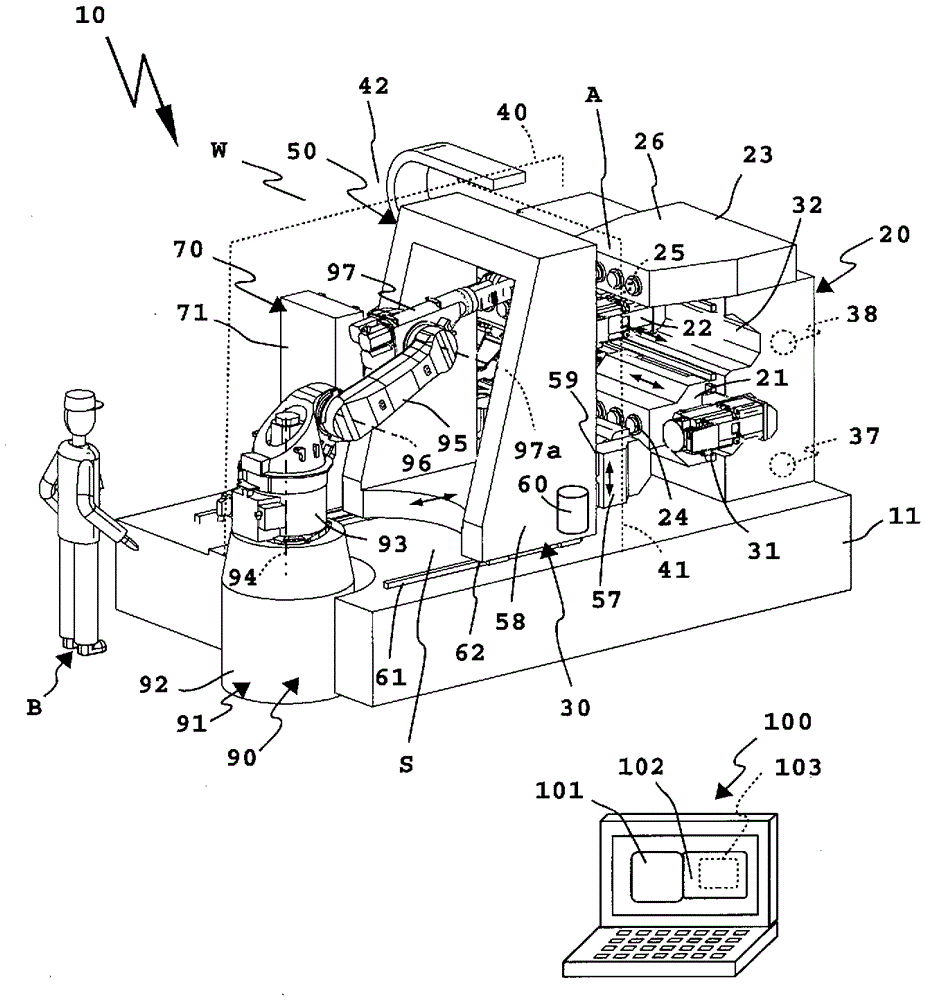

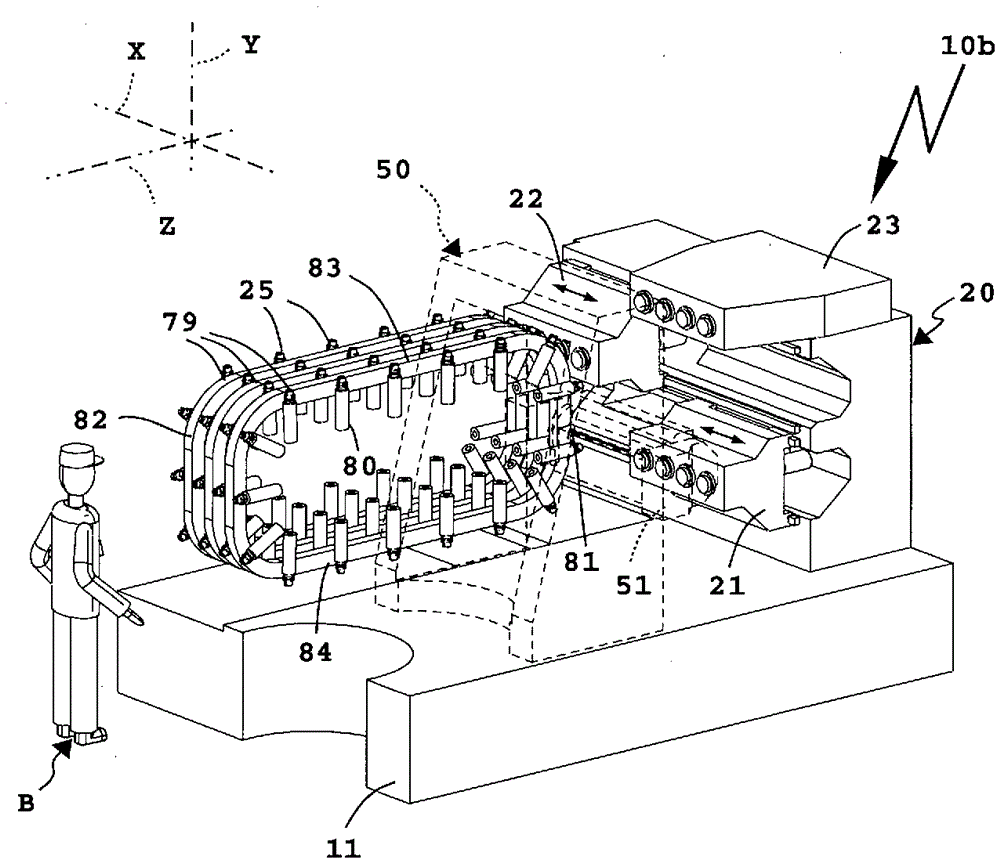

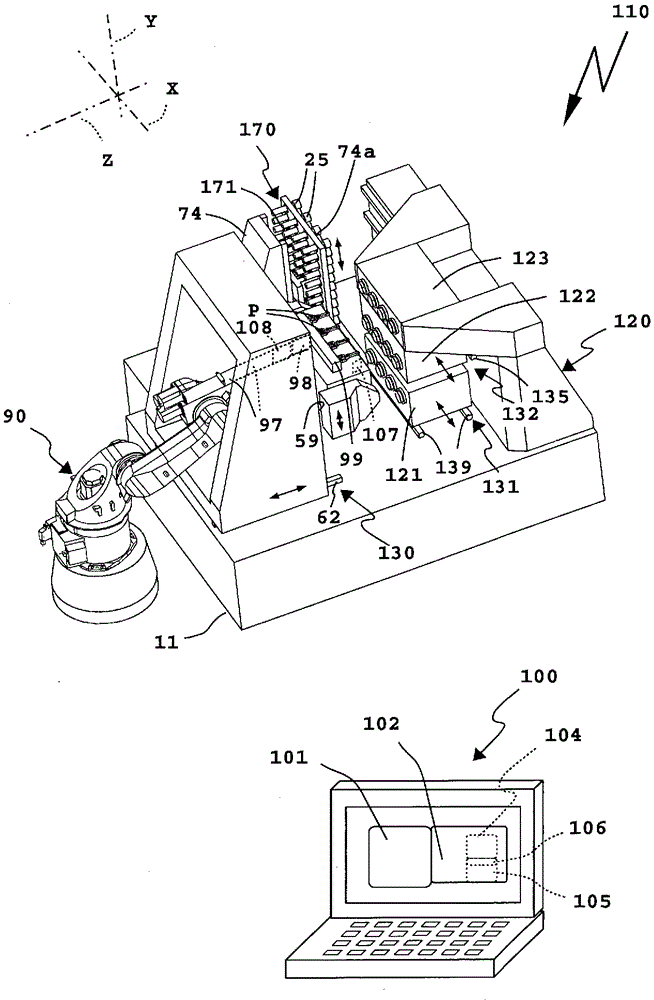

[0057] In the following description, the same or the same type of components are partially provided with the same reference numerals. Pressing figure 1 Two of the machine tools Figure 4 with 5 In the variant shown in the part, reference signs with additional letters "a" or "b" are used partially, while in the embodiment according to FIG. 7, the reference signs are compared to Figure 1-6 The embodiment is large by 100. Of course, the different variants mentioned in combination with different embodiments can also be combined without difficulty.

[0058] Arranged on the machine frame 11 of the machine tool 10 is a support 20 with a first spindle assembly 21, a second spindle assembly 22 and a third spindle assembly 23, which accordingly have a total of 4 work spindles 24.

[0059] A machining tool 25 (for example, a drill, a milling cutter or the like, in particular a machining tool for cutting machining or a machining tool provided for grinding machining) can be detachably arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com