Machine tool and method for machining a workpiece

A technology for workpieces and machine tools, applied in the field of processing workpieces and machine tools, to achieve high time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In the following, the invention will be described and explained in detail with preferred embodiments of a machine tool and a method according to the invention for machining workpieces by using exemplary schematic diagrams.

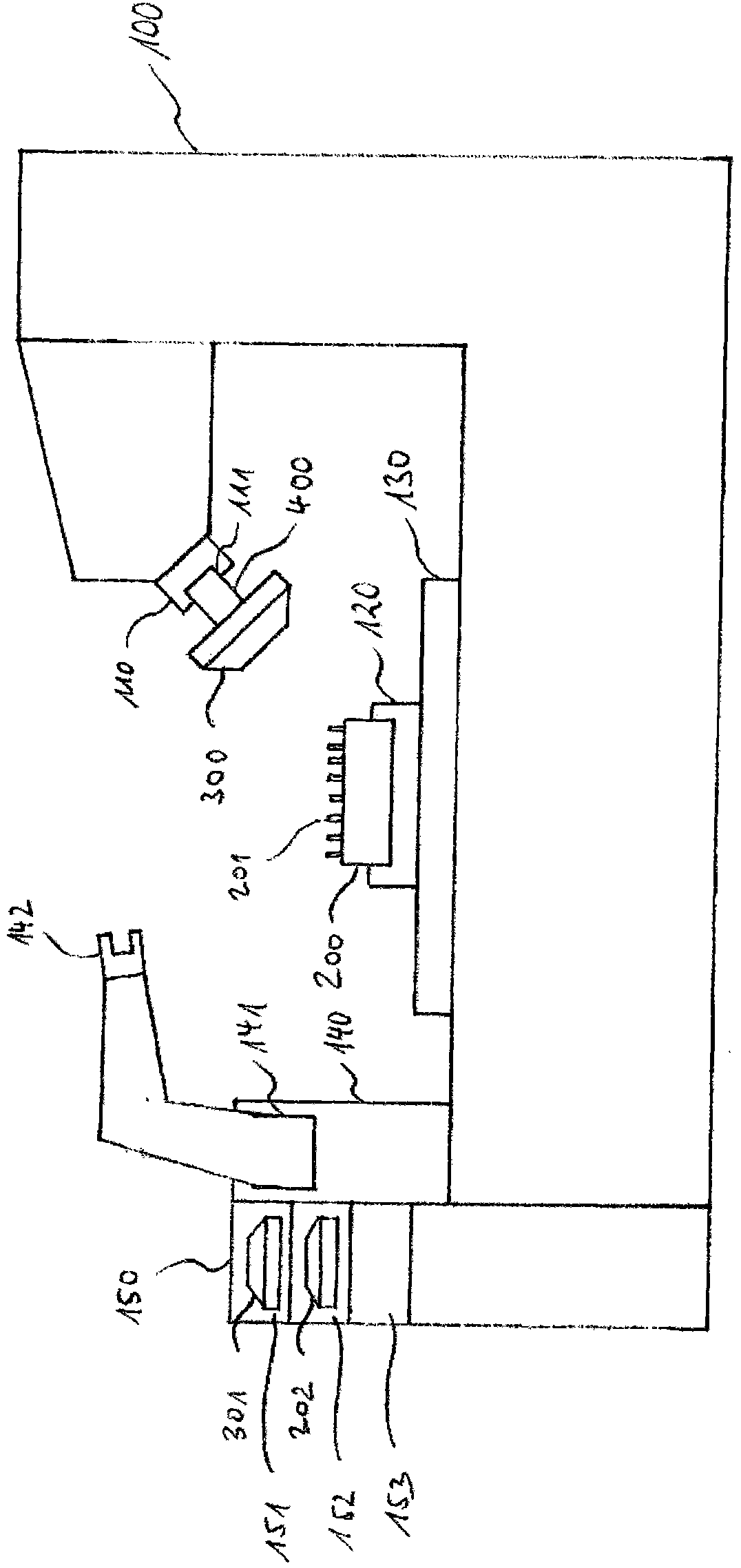

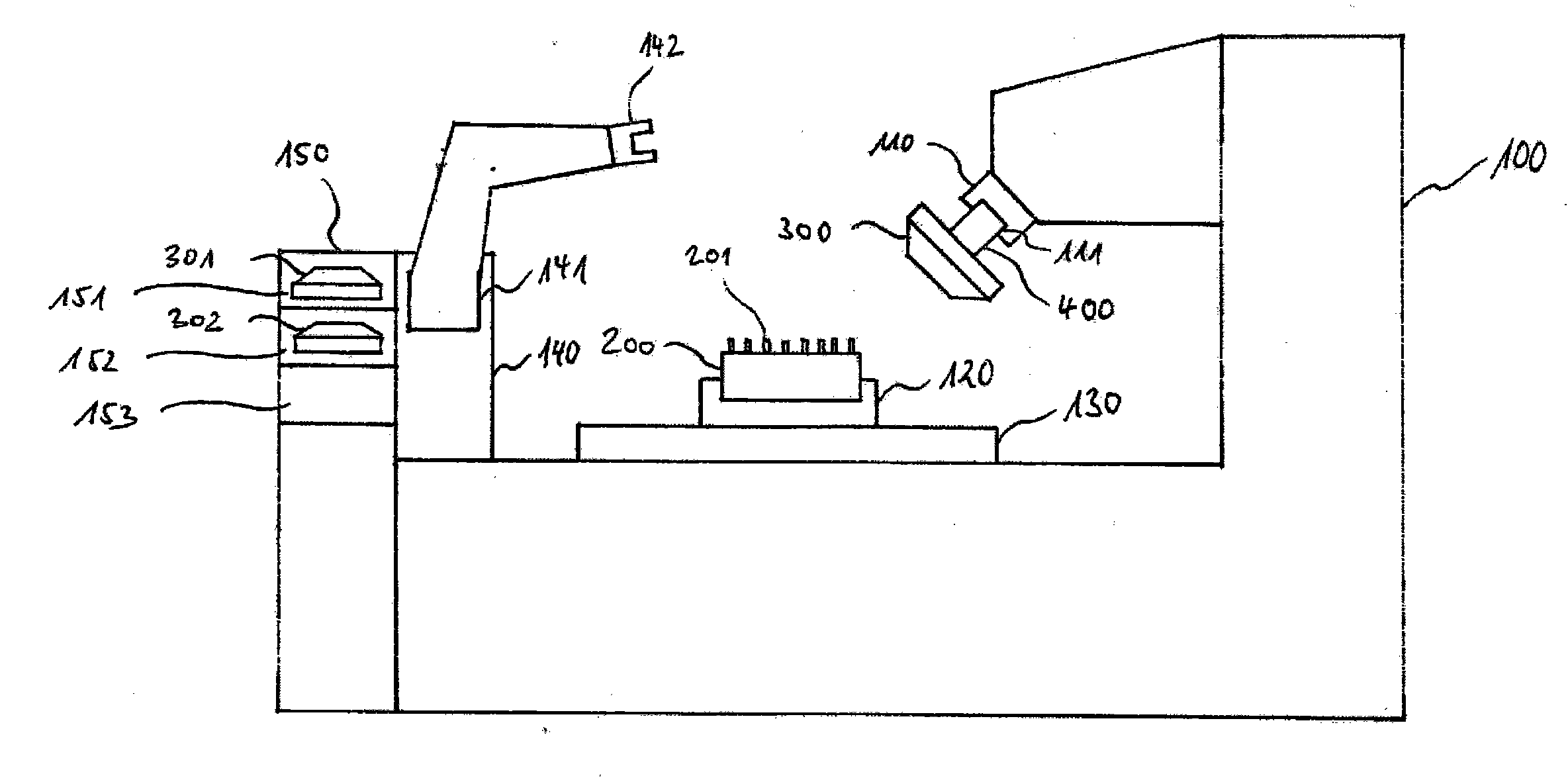

[0074] figure 1 An exemplary schematic view of a preferred embodiment of a machine tool 100 according to the invention for machining a workpiece 300 suitable for carrying out the method according to a preferred embodiment of the invention is shown. In particular, a preferred embodiment of the inventive method will be described below, in which gears such as, for example, ring gears, pinion gears or bevel gears are produced on a machine tool comprising 5 axes by using a tool head in the form of teeth. However, the invention is not limited to the production of gears with toothed heads but is particularly suitable for the sequential machining of several workpieces on machine tools where only one tool or at least only few tools are necessary for machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com