Hairspring-collet assembly for a timepiece movement

A clock mechanism and hairspring technology, applied in the field of hairsprings, can solve the problems of interference work, the abutting part cannot be used as an internal spinning thread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

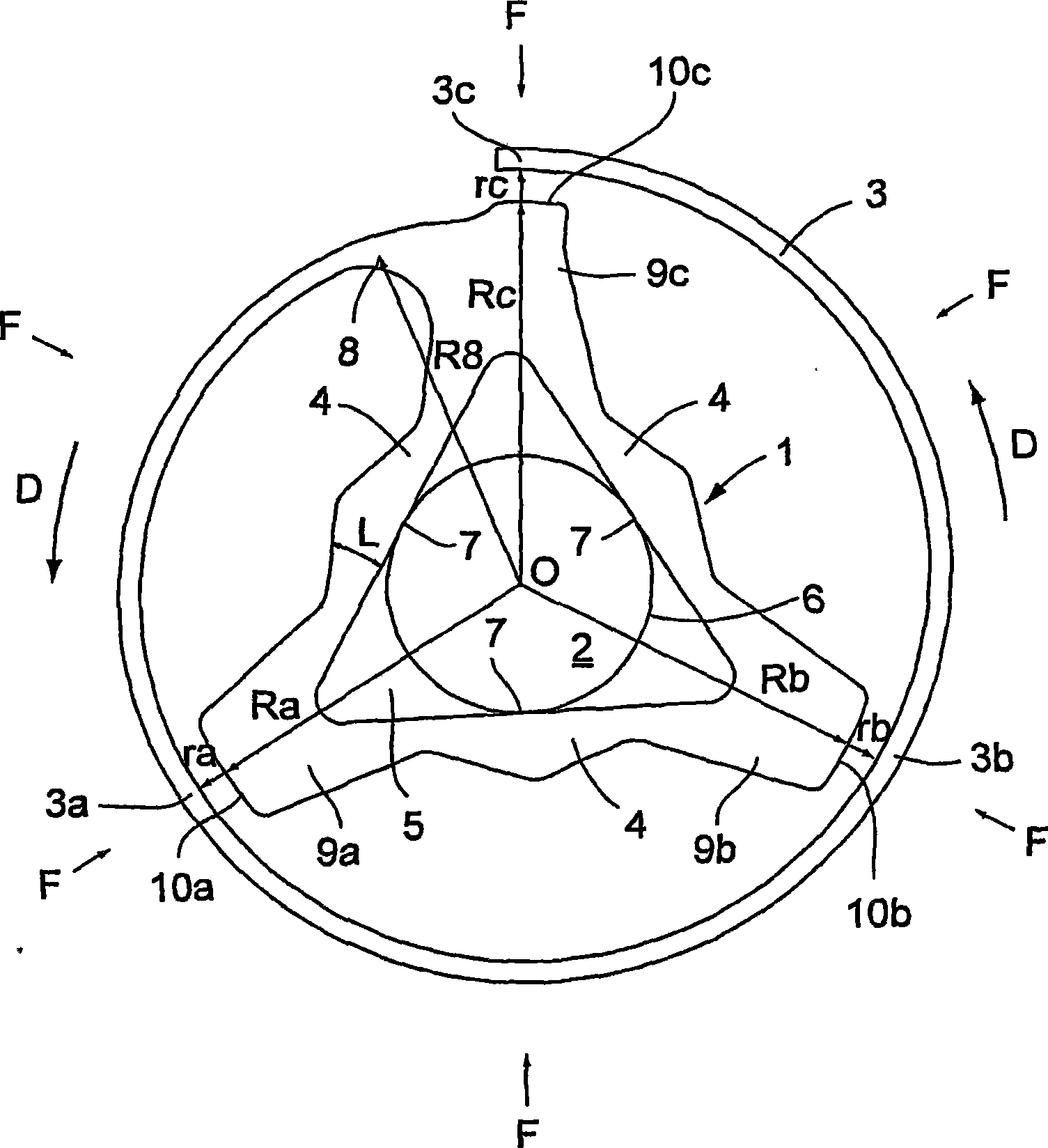

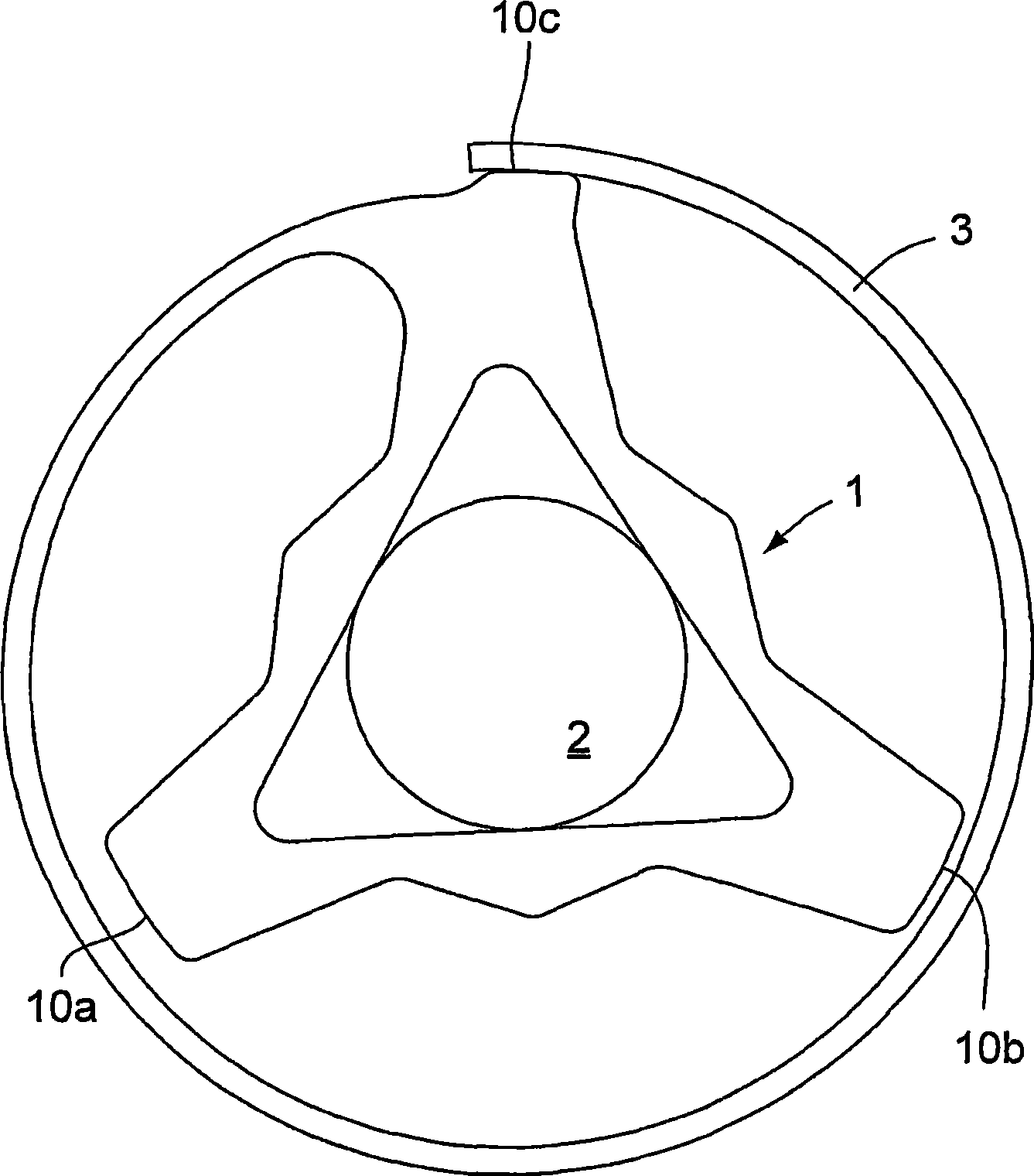

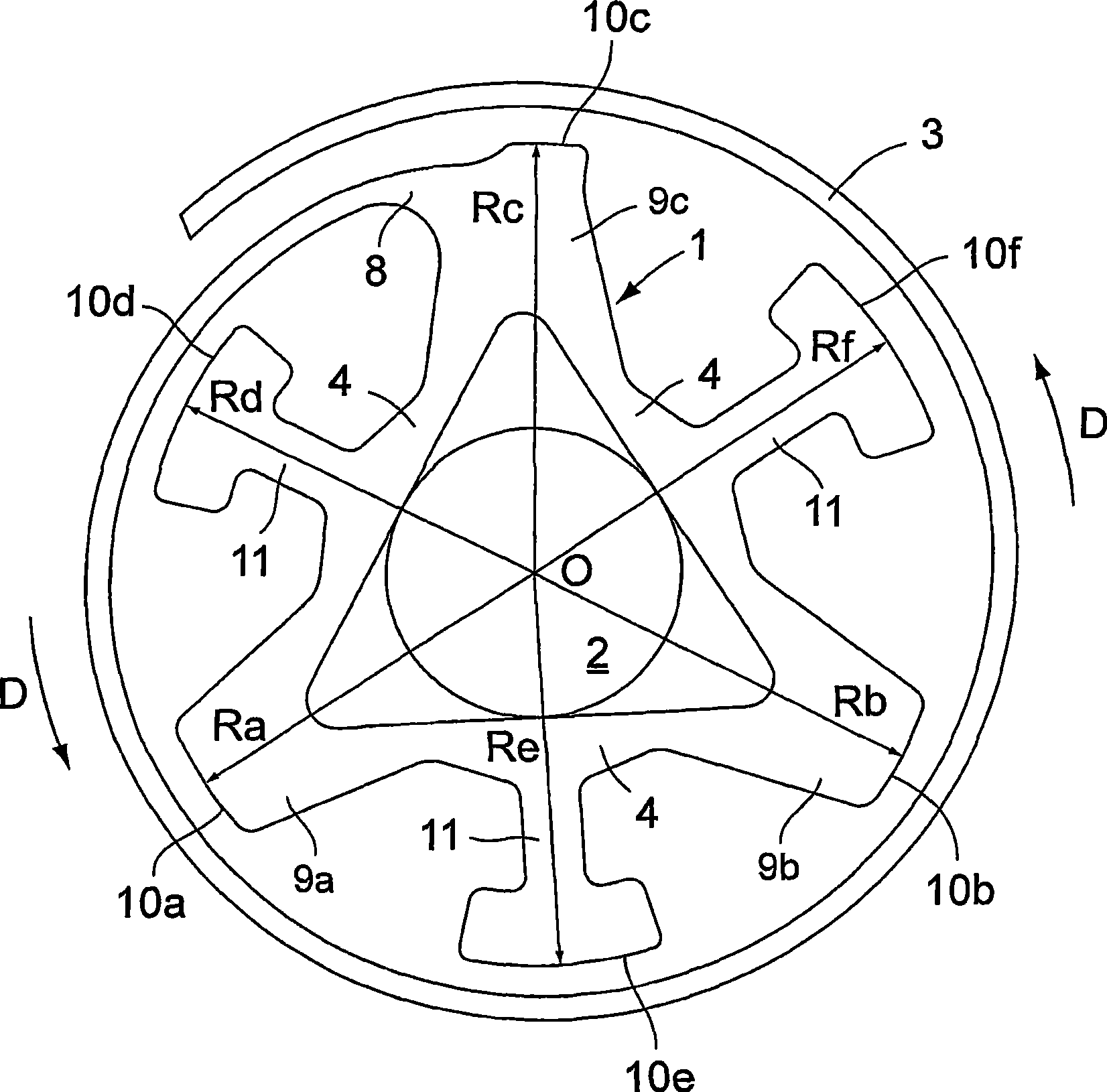

[0011] Such as figure 1 and figure 2 , according to the first embodiment of the present invention, a balance spring for a clock mechanism-collet assembly includes a collet 1 designed to fit on a balance shaft 2, and a collet 1 with an inner end connected to the collet 1 Hairspring 3. In the figure, balance spring 3 is partially shown, only its inner winding visible.

[0012] The inner pile 1 includes three elastic arms 4 arranged in a triangle. The elastic arm 4 forms a central equilateral triangular opening 5 whose inscribed circle has a diameter slightly smaller than the contact surface 6 of the cylindrical or generally conical shaft 2, enabling the shaft 2 to drive the collet 1, which drives the elastic arm 4 outwards. Elastic deformation occurs. By virtue of its triangular shape, the periphery of the opening 5 forms three discrete points 7 of contact with the shaft 2 . The width L of each elastic arm 4 varies in the manner of the elastic arms of the collet in documen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com