Twist-beam rear axle for a vehicle

A guide rod, rear axle technology, applied in the direction of vehicle components, cantilevers mounted on pivots, interconnection systems, etc., to achieve the effect of suppressing oversteer movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

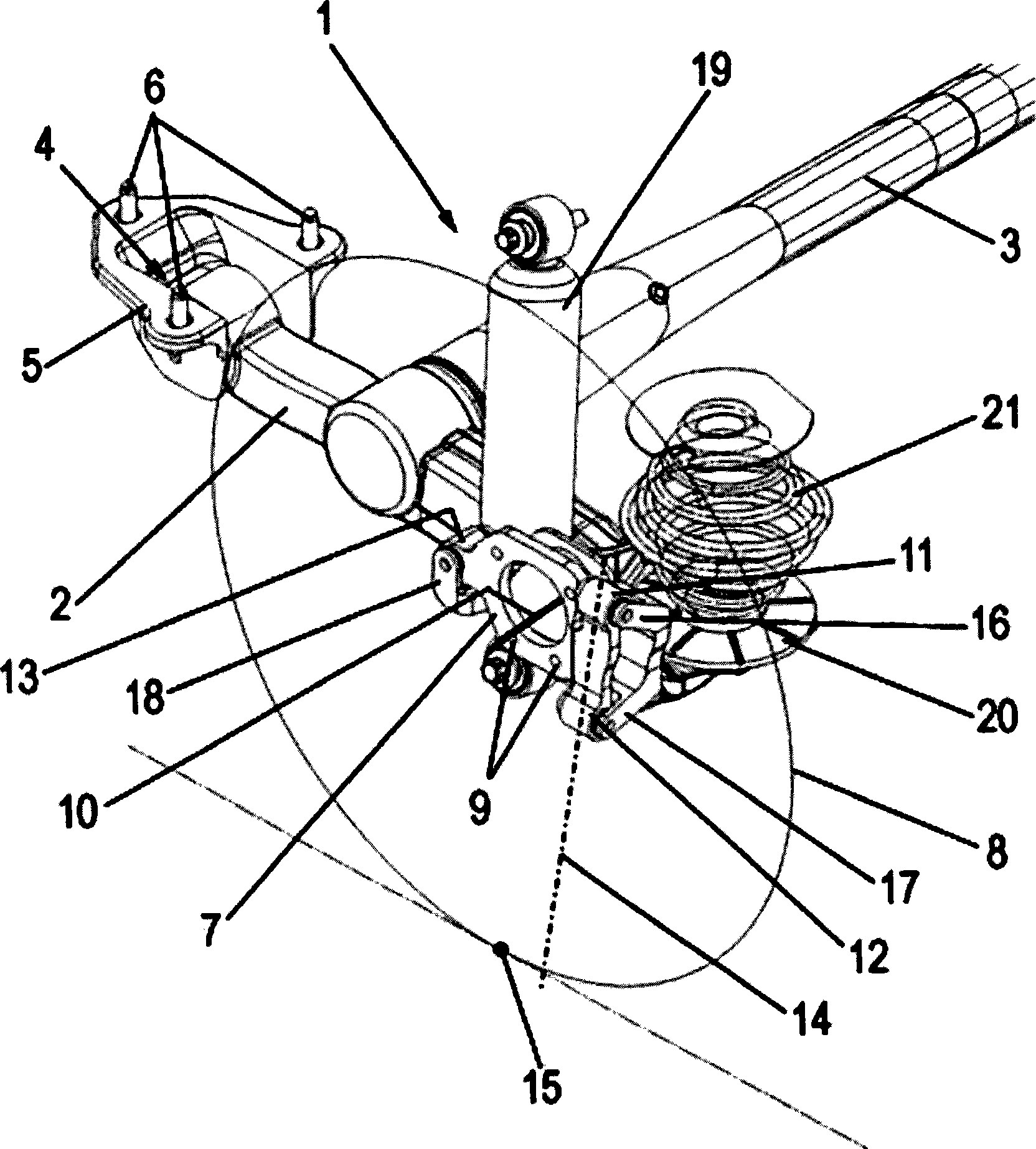

[0024] exist figure 1 An embodiment of a composite control-bar rear axle of a motor vehicle according to the invention is shown schematically with the reference number 1 . For simplicity, in figure 1 Only the shaft section of the composite guide rod rear axle 1 supporting the left rear wheel is shown in the figure. In the same way, the composite link rear axle is equipped with an axle section supporting the right rear wheel, which is designed symmetrically to the axle section supporting the left rear wheel.

[0025] The composite link rear axle 1 thus comprises two rigid longitudinal tie rods 2 extending substantially in the longitudinal direction of the vehicle, which are passed through a bending-resistant, but not torsion-resistant, cross-member extending substantially in the transverse direction of the vehicle 3 interconnected. The crossbar 3 , which is connected to the trailing rod 2 , for example by welding, serves as a stabilizer when the two wheels supported by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com