Negative-pressure drainage tube

A technology of negative pressure drainage and drainage section, which is applied in the field of drainage tube and can solve problems such as tissue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

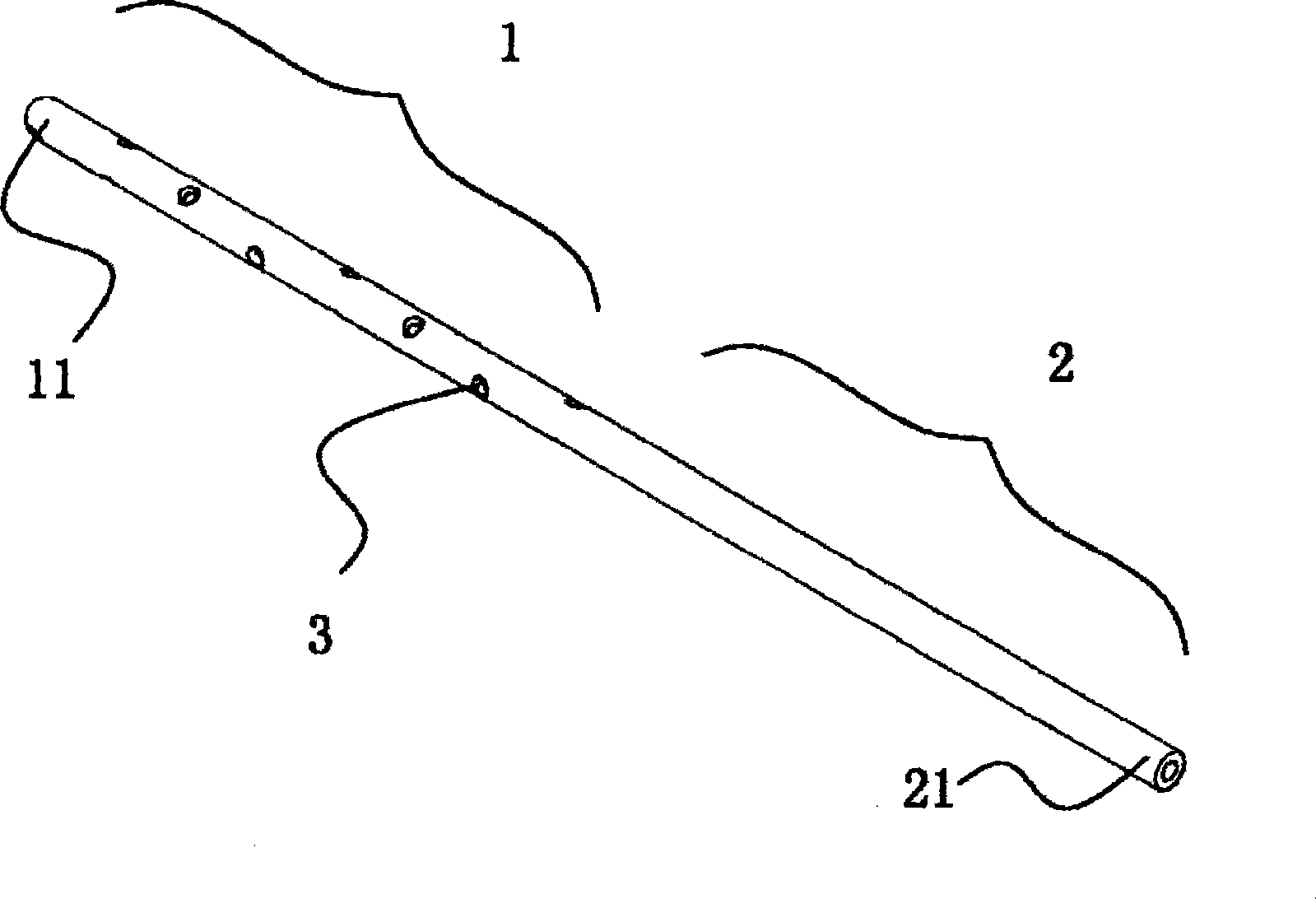

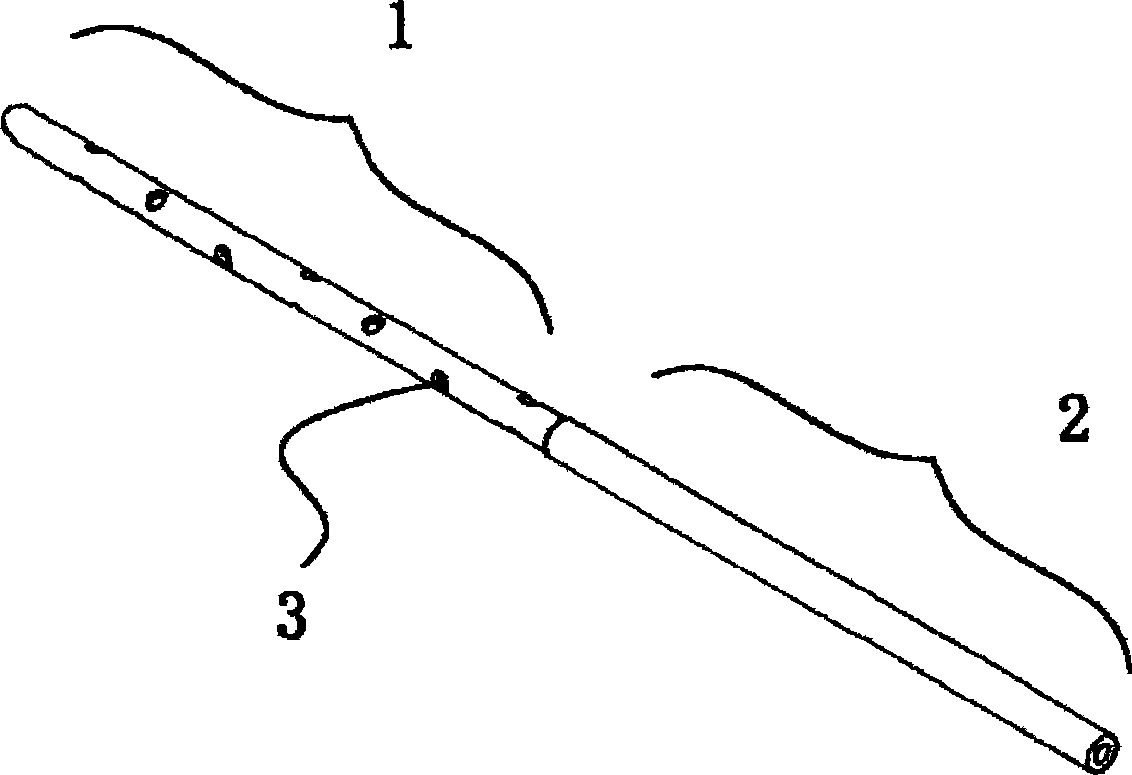

[0017] See attached Figure 2-3 , on the basis of the existing silicone rubber or soft plastic negative pressure drainage tube with multiple drainage holes, the outer diameter of the drainage section is slightly reduced, and the reduction is about 2 times the thickness of the non-woven fabric to be covered times. The non-woven fabric is made into a bag 4 suitable for the thickness of the above-mentioned drainage section, so that it can be tightly covered outside the drainage section, covering all the drainage holes, and the opening of the bag is fixedly combined with the drainage tube, and connected with the drainage tube Smooth transition. In order to make the drainage effect better, the outer surface of the drainage section where the drainage tube is covered in the non-woven bag can be provided with a large number of longitudinal or oblique fine grooves communicating with the drainage holes.

Embodiment 2

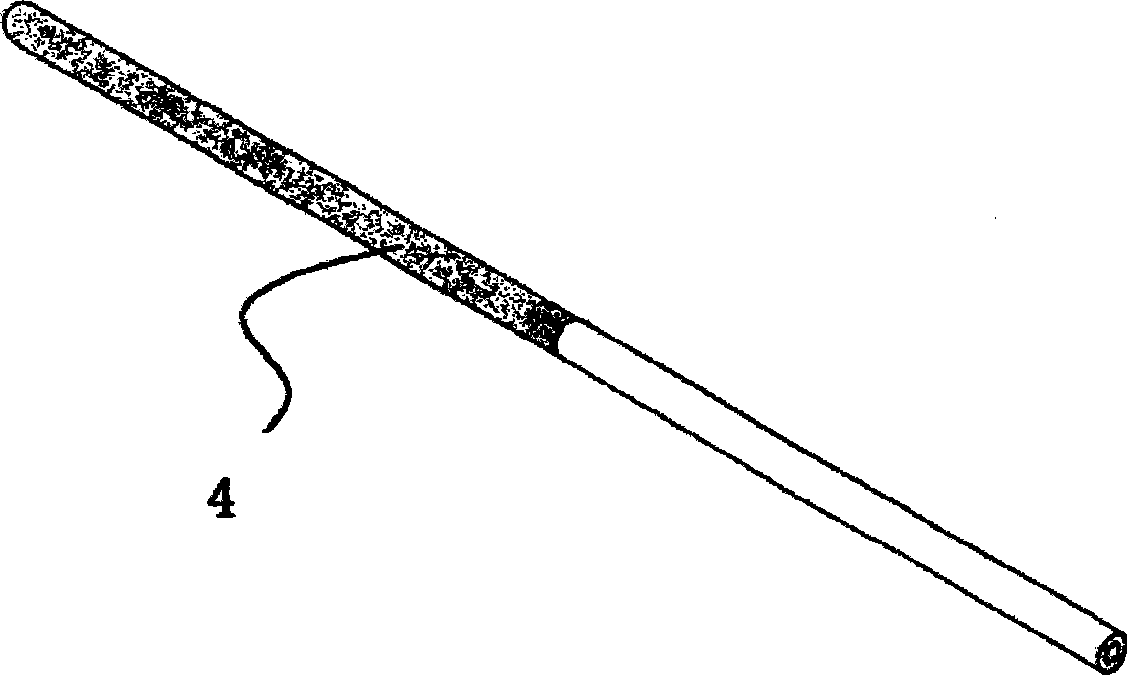

[0019] See Figure 3-4 , on the basis of the existing negative pressure drainage tube with multiple drainage side holes made of silicone rubber or soft plastic, three longitudinal grooves 5 are arranged on the outer surface of the drainage section of the drainage tube, and the drainage holes are distributed In the groove, there are several drainage holes in each groove. Paste the fine-bubble open-pore silicone rubber sponge 6 in the groove, the diameter of the foam is 0.1-1mm, and the outside of the glued sponge should be roughly equal to the outer contour of the drainage tube or slightly protruding. The number of longitudinal grooves is not limited to three, and there can be an appropriate number of one or more, and each groove has at least one drainage hole. It is also possible to replace the silicone rubber sponge with other tough porous materials such as non-woven fabrics.

Embodiment 3

[0021] See attached Figure 5-6 , On the basis of Example 2, change 3 longitudinal grooves to 1 oblique groove 7, from a spatial point of view, the grooves are spiral, and non-woven fabric strips 8 are pasted in the grooves. Changing the width and inclination of the oblique grooves can change the ratio of the surface of the drainage section covered by the non-woven strip to the entire surface of the drainage section. The purpose of this improvement is to facilitate sticking during manufacture, reduce labor costs, and make the non-woven fabric strip not easy to be peeled off.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap