Wall and column underpinning method

A column underpinning and wall technology, applied in building maintenance, construction, building construction, etc., can solve problems such as the height of columns and beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

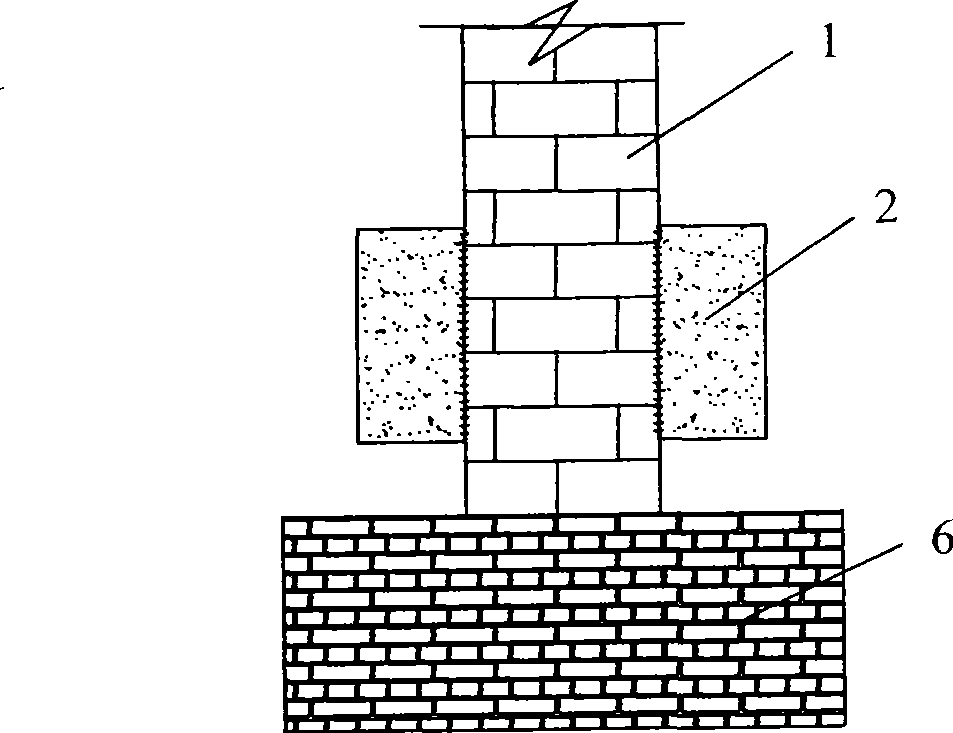

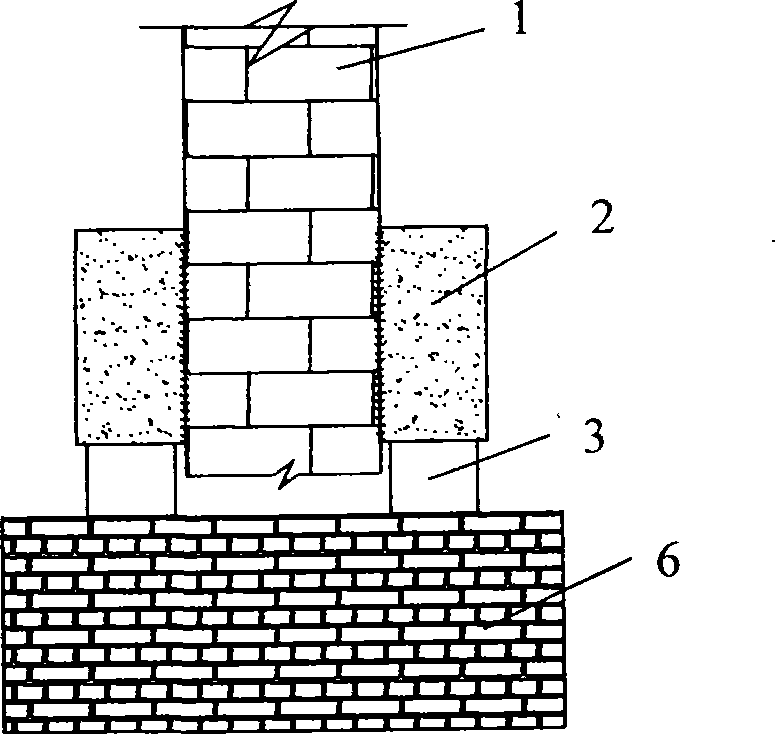

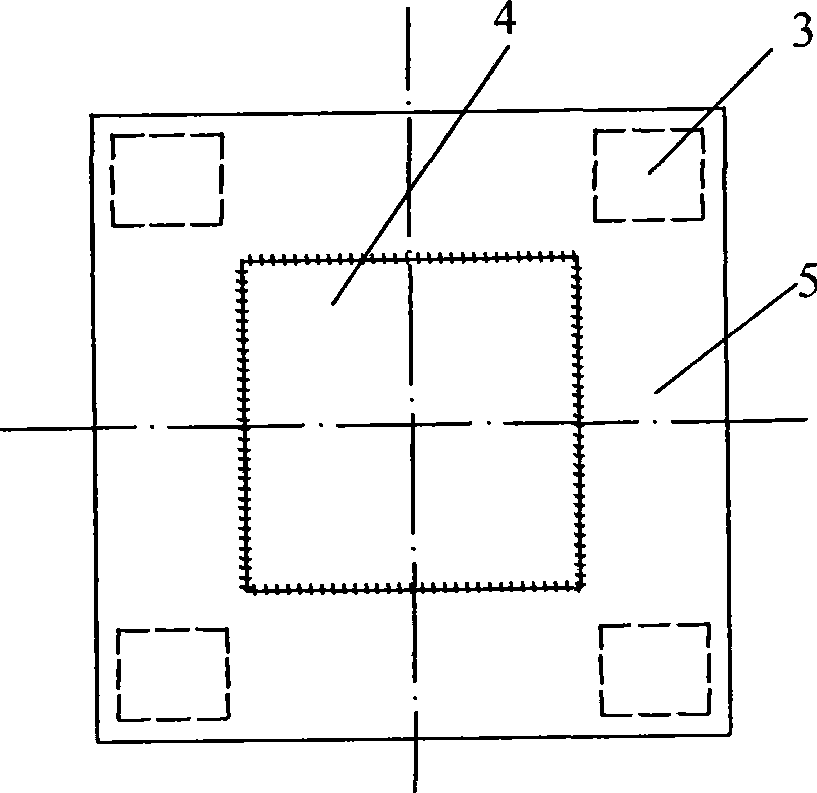

Embodiment 1

[0034] Such as Figure 7 , Figure 8 As shown, a reinforced concrete column-holding beam 5 is poured around the column 4, and the column and the reinforced concrete column-holding beam 5 are connected by an interface agent (the surface of the column can also be chiseled or not). The prestressed tendons 7 are worn to apply normal stress to the reinforced concrete column-hugging beam 5 . When the underpinning of the column 1 is cut off, the force of the column 4 is transmitted to the underpinning foundation 6 through the reinforced concrete column-holding beam 5 and the displacement device 3 . In the process of transferring the load from the column 4 to the reinforced concrete column-wrapped beam 5, the force is transmitted between the column 4 and the reinforced concrete column-wrapped beam 5 through the friction force between them and the normal stress friction force exerted by the prestressed tendon 7 on the column.

[0035] The advantages of the method described in this em...

Embodiment 2

[0037] Such as Figure 9 and Figure 10 As shown, a reinforced concrete column-holding beam 5 is poured around the bottom of the column 4, and the connection between the column 1 and the cast reinforced concrete column-holding beam 5 is connected by chiseling and interface agent; , and then jack unloading devices 8 are set on both sides of the upper column-holding beam 5 . The jack unloading device 8 is composed of an unloading jack 81 and an unloading column 82 .

[0038] When the underpinning of the column 1 is cut off, the force of the column 1 is transmitted to the underpinning foundation 6 through the column-holding beam 5 and the displacement device 3 . During the process of the column load being transferred to the column-holding beam, the column and the column-holding beam transmit force through the friction force between them and the normal stress friction force exerted by the jack unloading device on the column.

[0039] Similarly, this embodiment also has the adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com