Preparation apparatus of graphite metal wrap for thermal isostatic pressing

A metal sheathing and preparation device technology, applied in the field of preparation of high-performance graphite sealing materials, can solve the problems of sheathing cracking, waste products, etc., and achieve the effects of reducing cracking, reducing manufacturing costs, and good radial positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention uniformly coats metal on the graphite surface by casting method before hot isostatic pressing to form a closed graphite metal sheath, and the coating metal can be silver, copper, aluminum or babbitt alloy and the like.

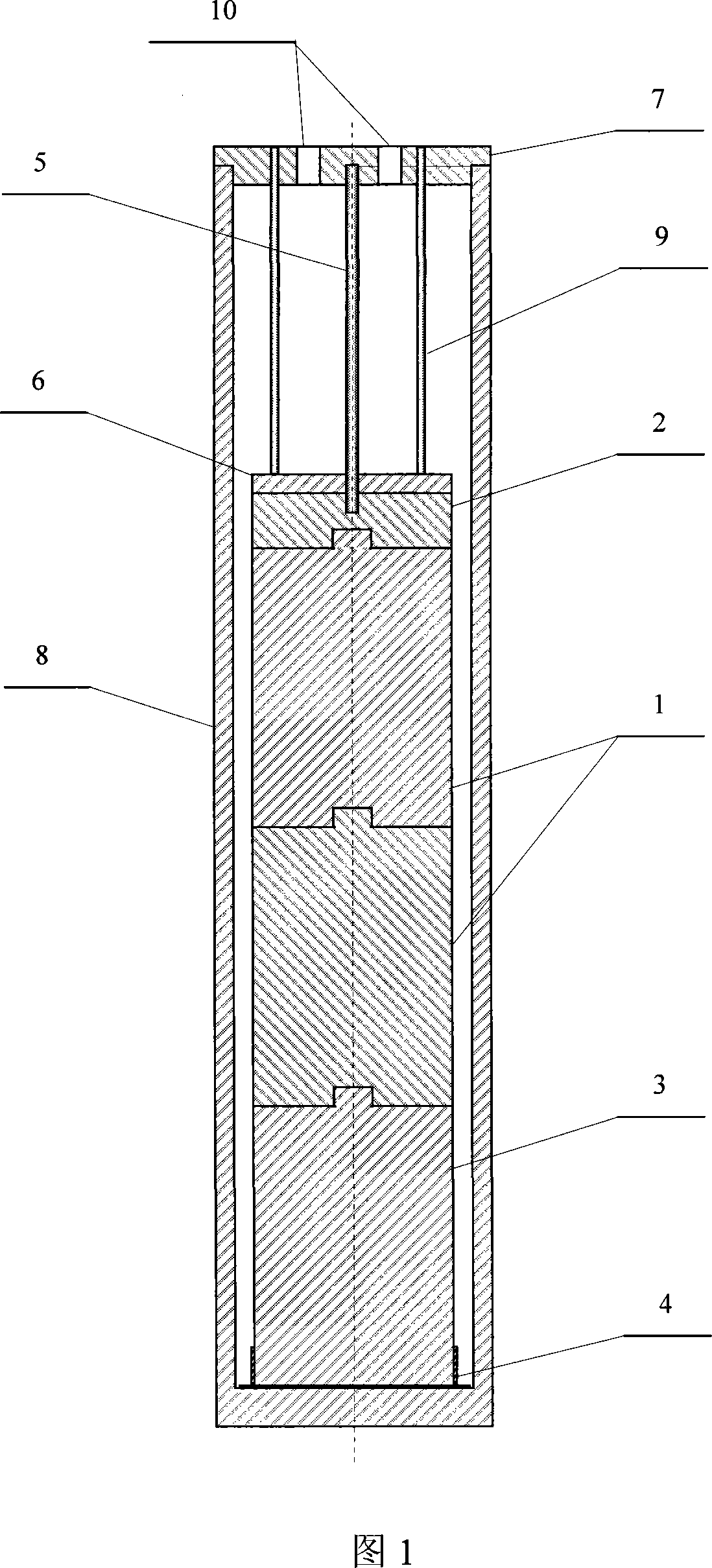

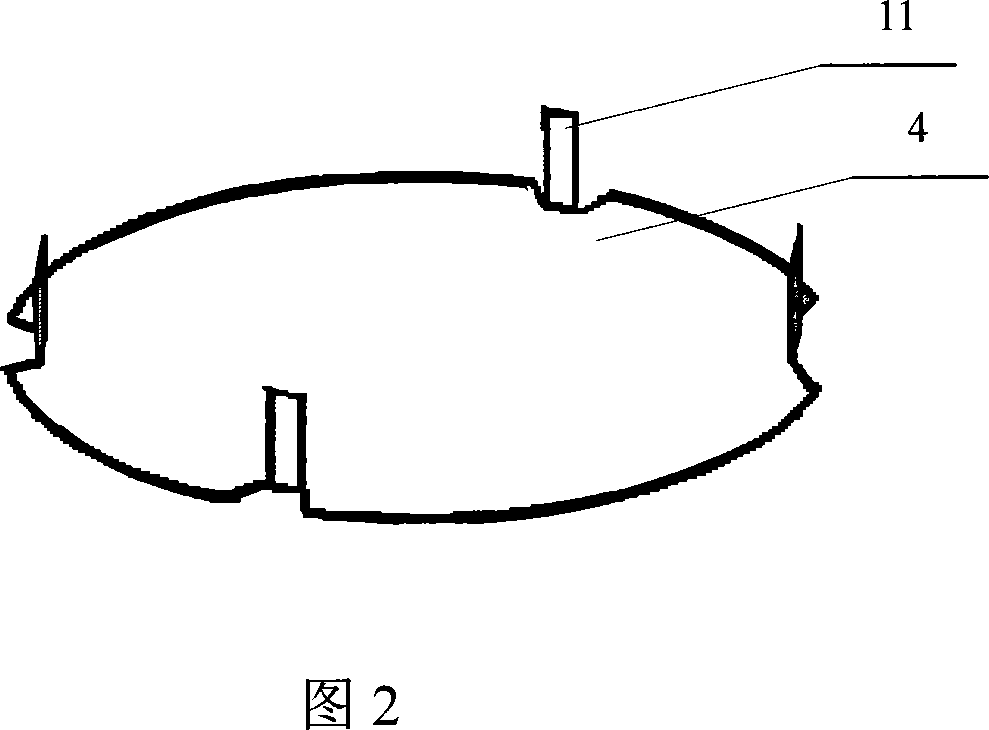

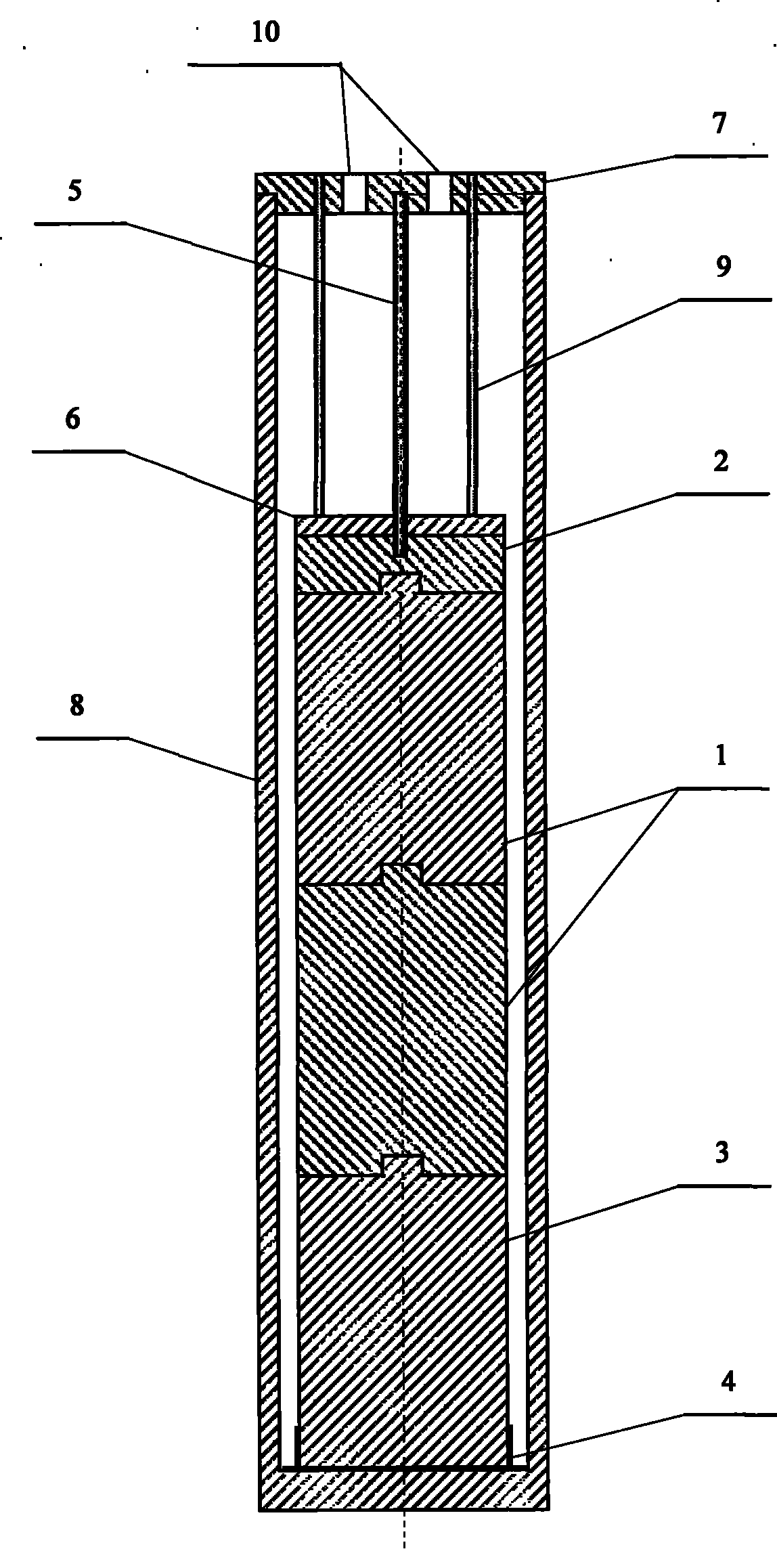

[0019] Taking the outer surface of a graphite column coated with metallic silver as an example, before the hot isostatic pressing treatment, the cylindrical graphite to be impregnated with silver (hereinafter referred to as the graphite column) is placed in the center of the bottom of the graphite crucible by axial fixing and radial fixing methods, and cast Metal silver, coating the outer surface of the graphite column with metal silver to prepare a closed silver sheath. Such as figure 1 As shown, the graphite to be impregnated with silver is processed into a cylinder, a graphite column I1 has a cylindrical boss on one side, and a cylindrical concave hole of the same size on the other side; another graphite column II2 has cylindric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com