Six-dimension loading material mechanical test machine

A technology of material mechanics and testing machine, applied in the field of mechanical experiments, can solve the problems of material waste, bulky structure, strength design error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below in conjunction with the accompanying drawings. The overall technical solution here is aimed at a small-load, high-precision loading mechanism.

[0076] 1. Parallel loading mechanism

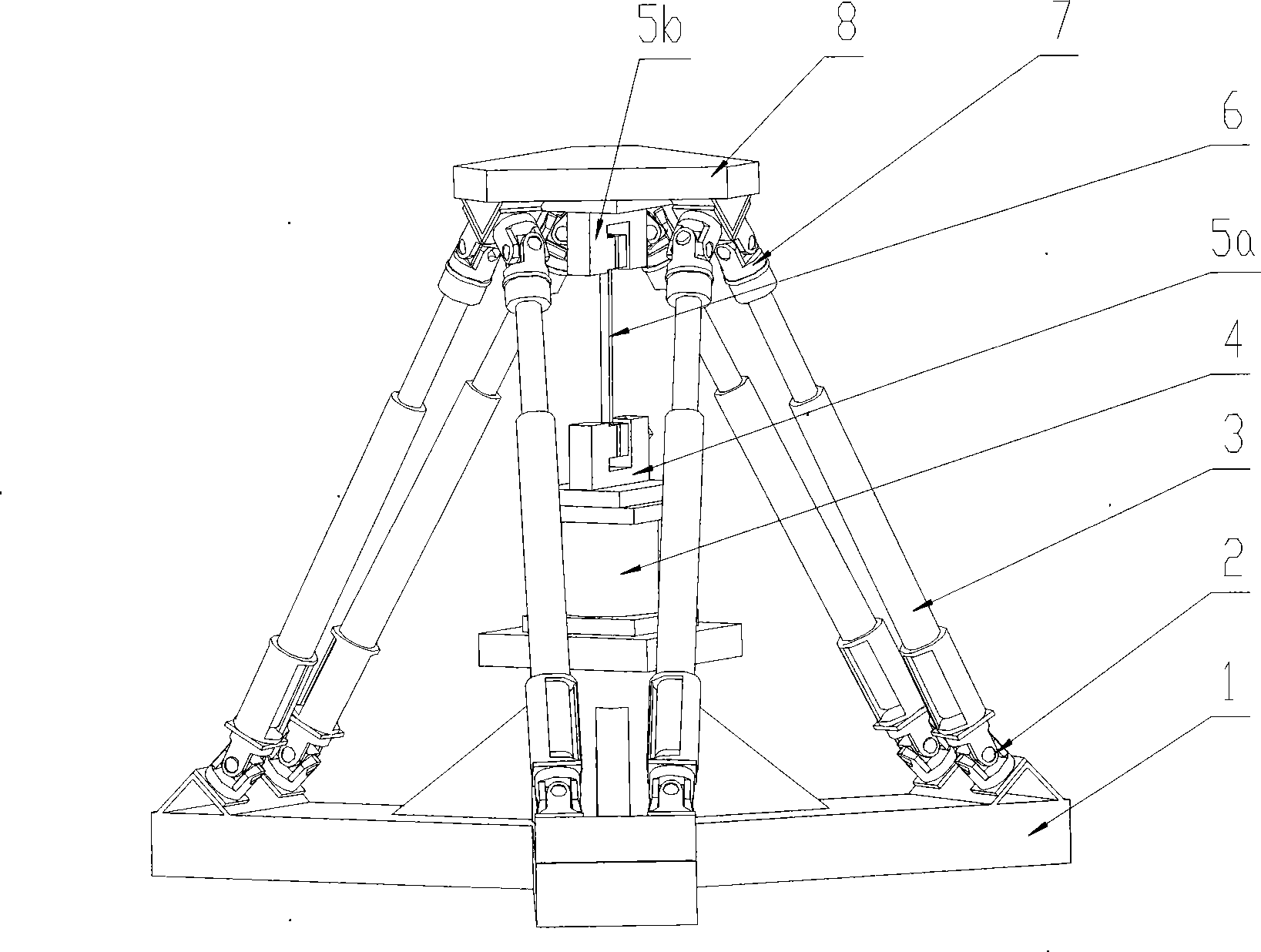

[0077] like figure 1 As shown, the loading mechanism of the six-dimensional loading material mechanics testing machine is composed of the following parts: basic platform 1, Hooke hinge 2 (6 pieces in total), telescopic rod 3 (6 pieces in total), six-dimensional force sensor 4, and fixture 5 (2 pieces in total), 6 test pieces, 7 spherical hinges (6 pieces in total), and 8 movable platforms.

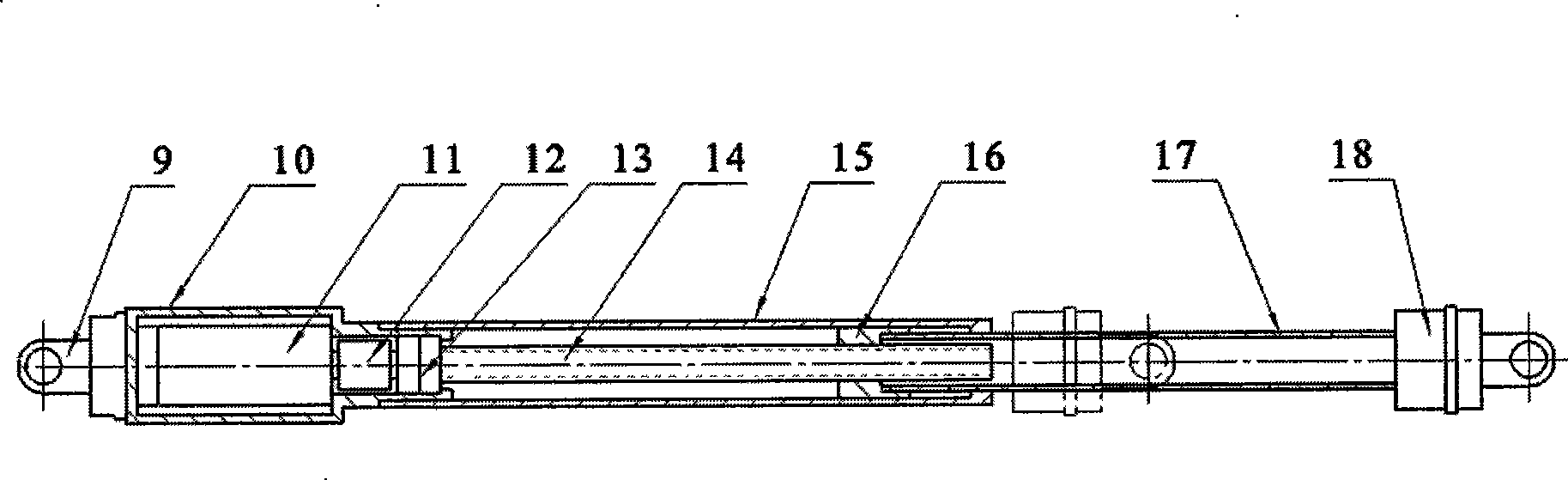

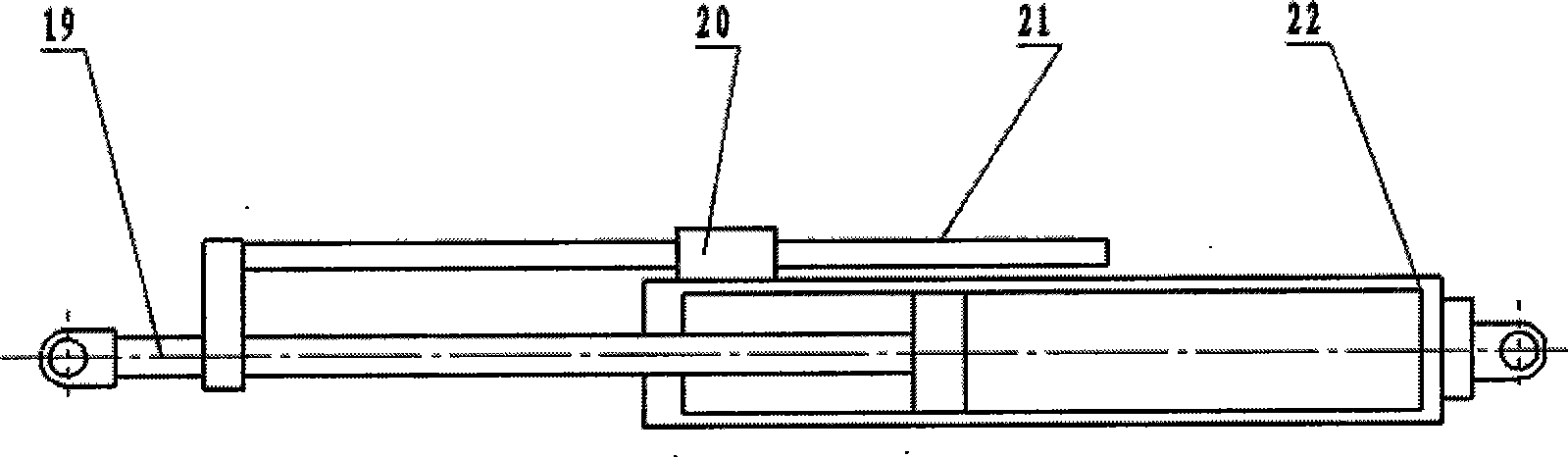

[0078] Hooke hinge 2, telescopic rod 3, clamp 5, and ball hinge 7 are all assemblies, which are composed of multiple parts or sub-assemblies respectively. The Hooke hinge 2 and the ball hinge 7 adopt common structural standard components, and the telescopic rod 3 is a motor-driven form. The fixture 5 is divided into an upper fixture 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com