Six-dimensional mechanical performance testing device and testing method of physical structural parts

A technology for testing devices and structural parts, which is applied in the field of mechanical experiments and can solve problems such as failure, excessive strength margin, and inaccurate strength design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

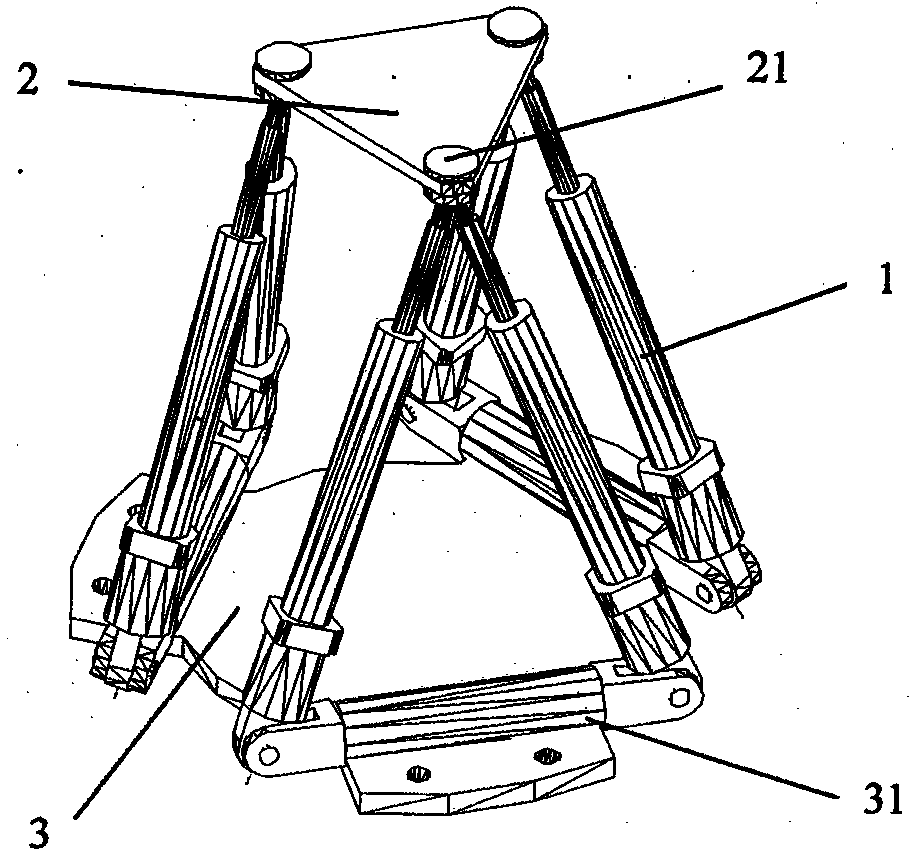

[0072] The following provides an embodiment of a six-dimensional mechanical performance testing device for a physical structure that meets the requirements of a small load and high-precision loading mechanism, which includes the following components:

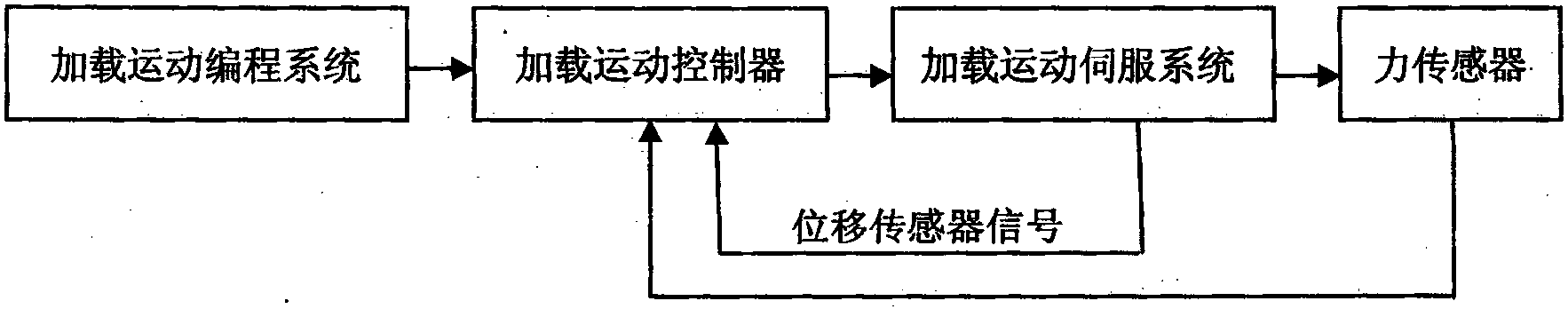

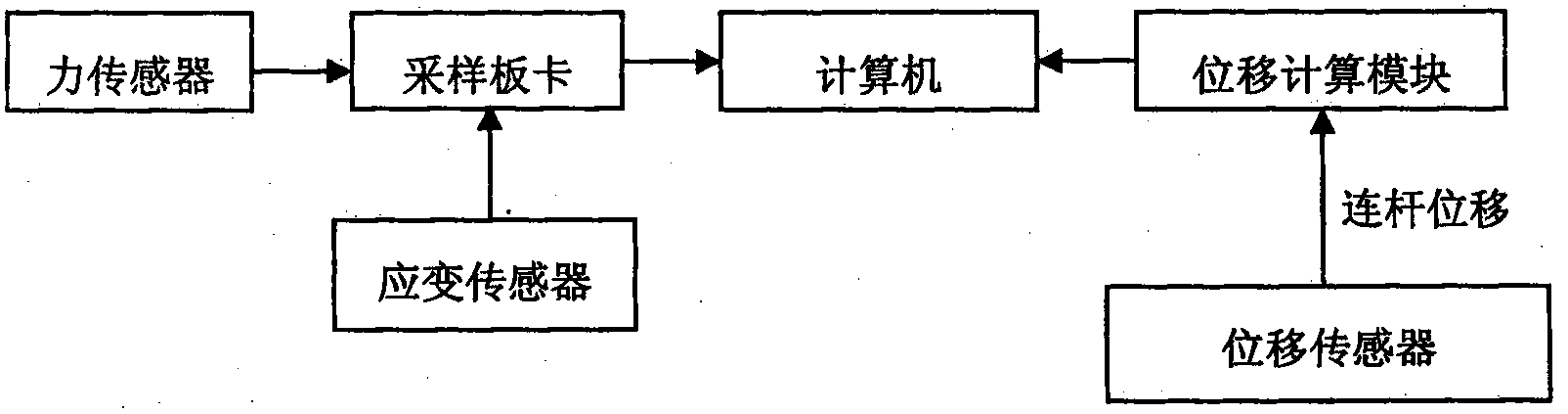

[0073] 1. Control system (such as figure 1 shown), including:

[0074] 1) load motion controller: comprise control computer and multi-axis motion control card, multi-axis motion control card is inserted in the I / O expansion slot of control computer, under the control of control computer to each motion axis (in the technical scheme of the present invention The axis of motion is called a parallel link) to issue a motion control command;

[0075] Among them, the control computer selects Advantech ADVANTECHIPC-610H computer. .

[0076] Among them, the multi-axis motion control control card uses P-MACCompax3M multi-axis motion control card.

[0077] 2) Loading motion programming control system: the software system installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com