Six-dimensional force high-frequency fatigue testing machine and its use

A fatigue testing machine and six-dimensional force technology, applied in the field of testing machines, can solve problems such as inability to apply high-frequency multi-dimensional force, and achieve the effect of stable and accurate driving force output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] The present invention proposes a six-dimensional force high-frequency fatigue testing machine and a method of using the fatigue sample of a dynamic load mechanical part as the test object, which can be used to simulate the actual force situation of the dynamic load mechanical part, and measure its performance under static load and dynamic load. Load and deformation in the alternating fatigue test to solve the problem that the existing fatigue testing machine cannot apply high-frequency multi-dimensional force, so as to be close to the force condition under the actual working state, and accurately measure the fatigue bearing capacity of the specimen.

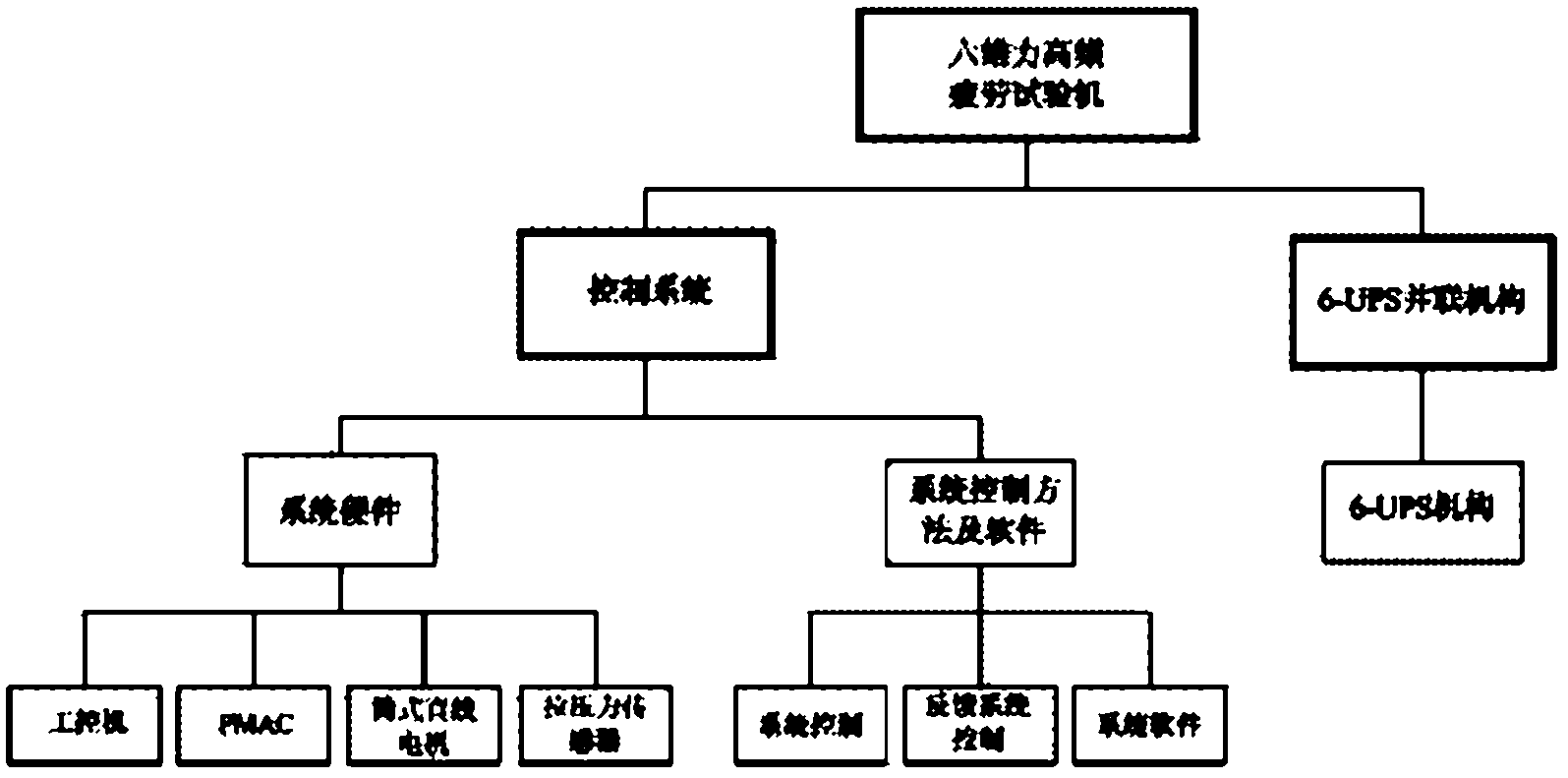

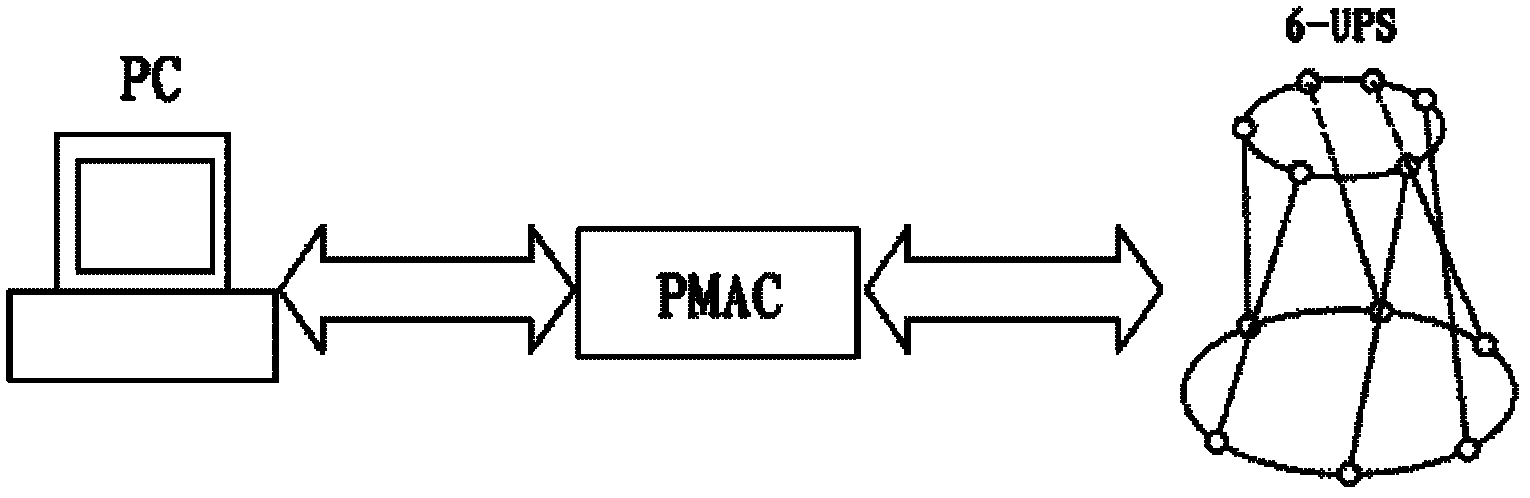

[0128] A kind of six-dimensional force high-frequency fatigue testing machine of the present invention, it comprises two parts of 6-UPS parallel mechanism and control system (as figure 1 ), characterized by:

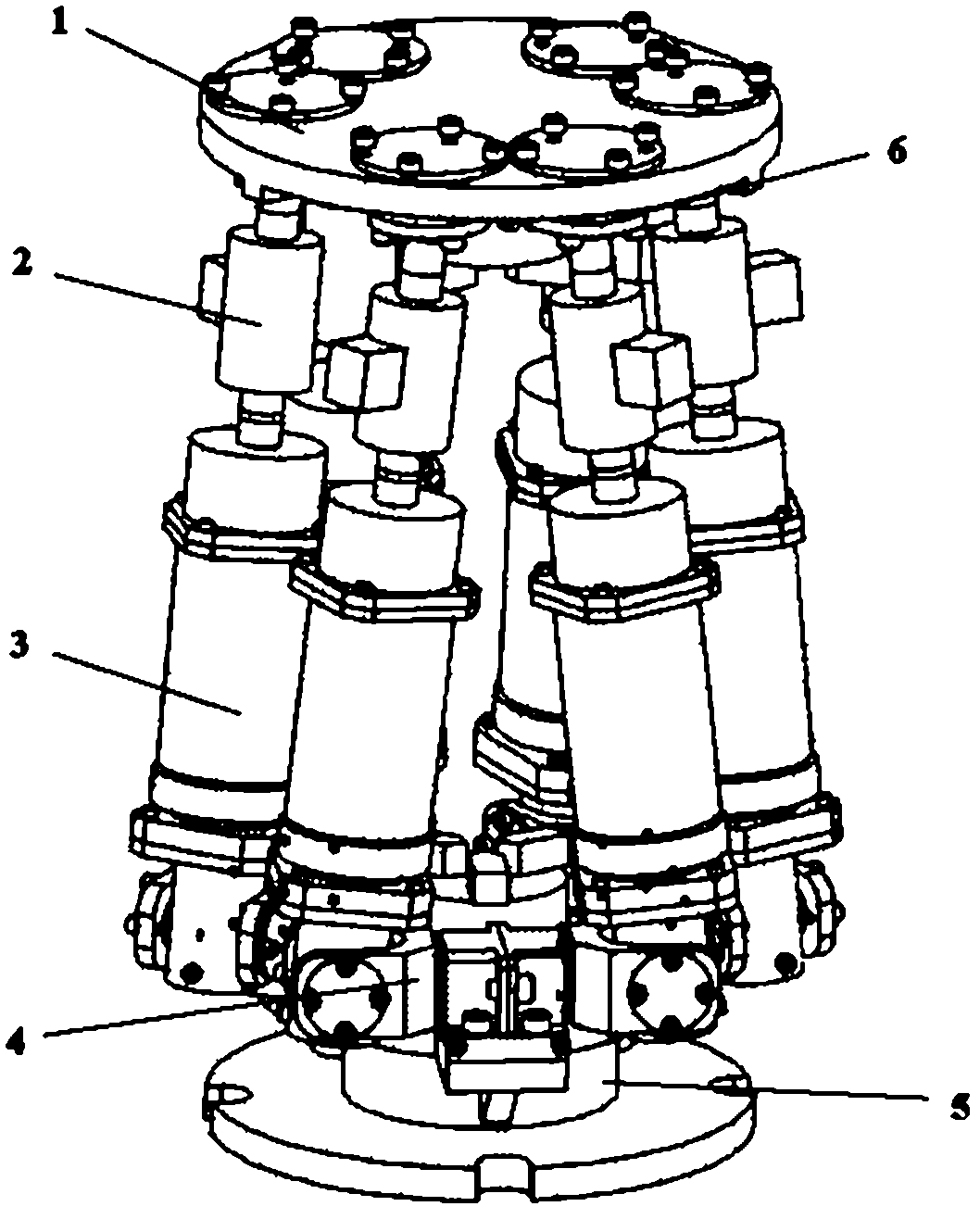

[0129] 1.6-UPS parallel mechanism

[0130] The six-dimensional force high-frequency fatigue testing machine uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com