Automatic audit submitting system for materiel warehouse-in

A material, automatic technology, applied in logistics, instruments, data processing applications, etc., to avoid missed audits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

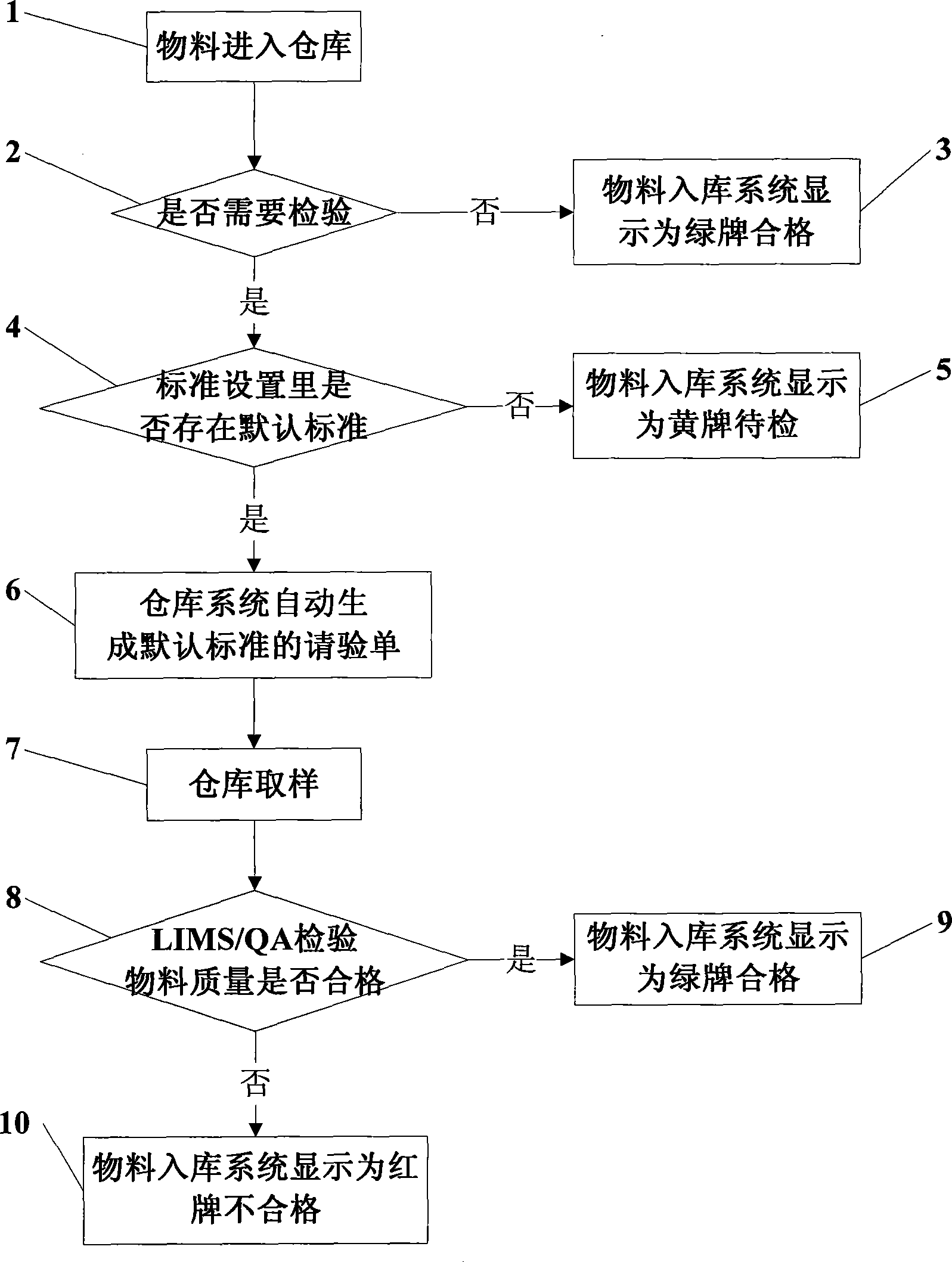

[0020] Such as figure 1 As shown, in the material warehousing automatic review system of the present invention, step 1 is that the material enters the warehouse; step 2 is whether inspection is required; if not, the material warehousing system in step 3 shows that the green card is qualified; if so, then in the In step 4, check whether there is a default standard in the standard setting, if not, then in step 5, the material storage system displays a yellow card pending inspection; if so, in step 6, the system automatically generates a request for inspection of the default standard; step 7 Sampling for the warehouse; step 8 is to check whether the quality of the material is qualified by LIMS / QA; if so, the material storage system will display a green card in step 9; if not, in step 10, the material storage system will display a red card failed.

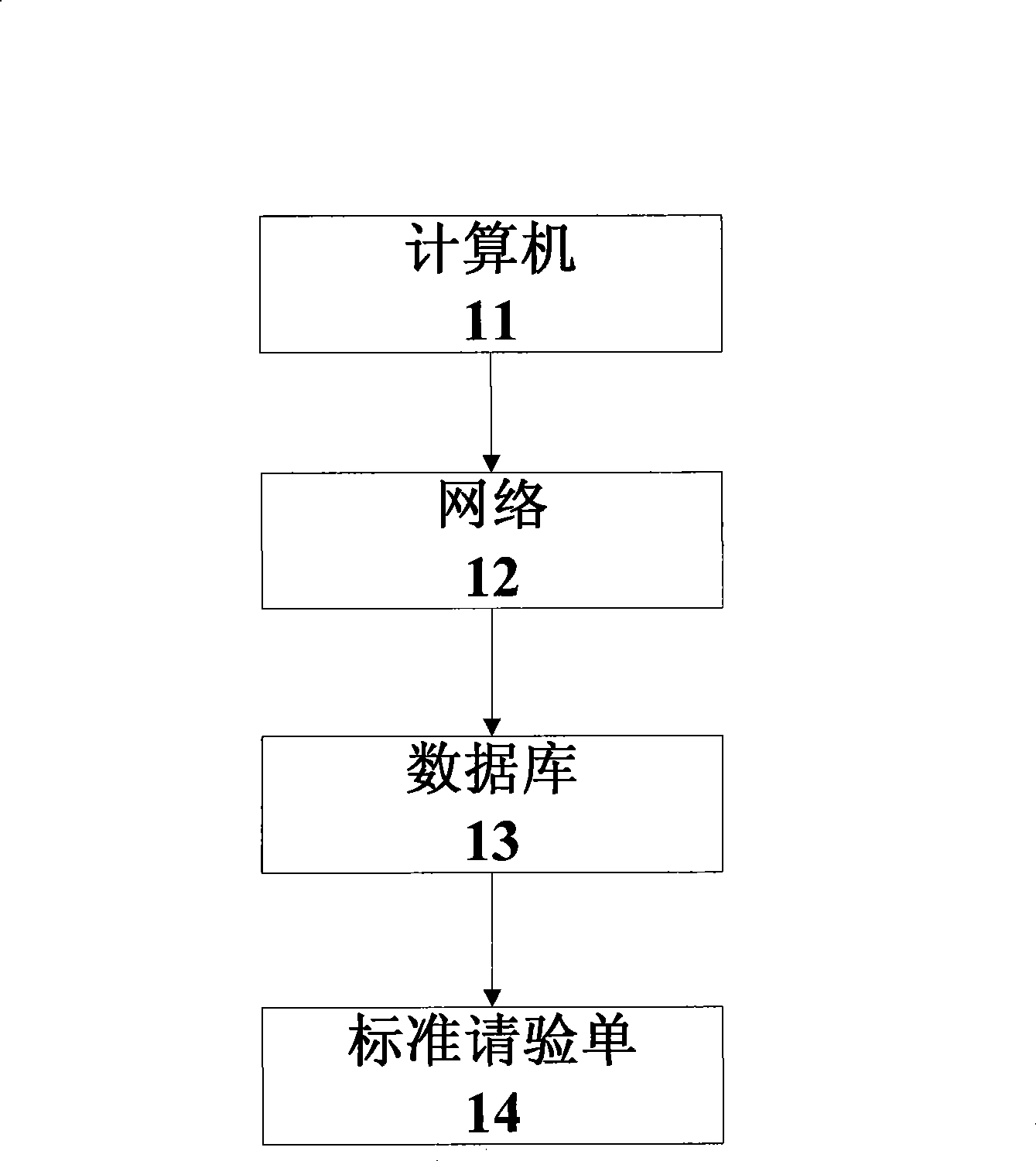

[0021] Such as figure 2 As shown, when the material enters the warehouse, it is connected to the database 13 through the network 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com