Post etch wafer surface cleaning with liquid meniscus

A wafer and solution technology, applied in the field of wafer surface cleaning after etching using meniscus, can solve the problems of high amount of pollutants, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The device, system and method of the present invention for cleaning the surface of a semiconductor substrate will be described below. It will be apparent to one skilled in the art that the present invention may be practiced without some or all of these specific details. In other instances, well known processes have not been described in detail, in order not to highlight essential characteristics of the invention.

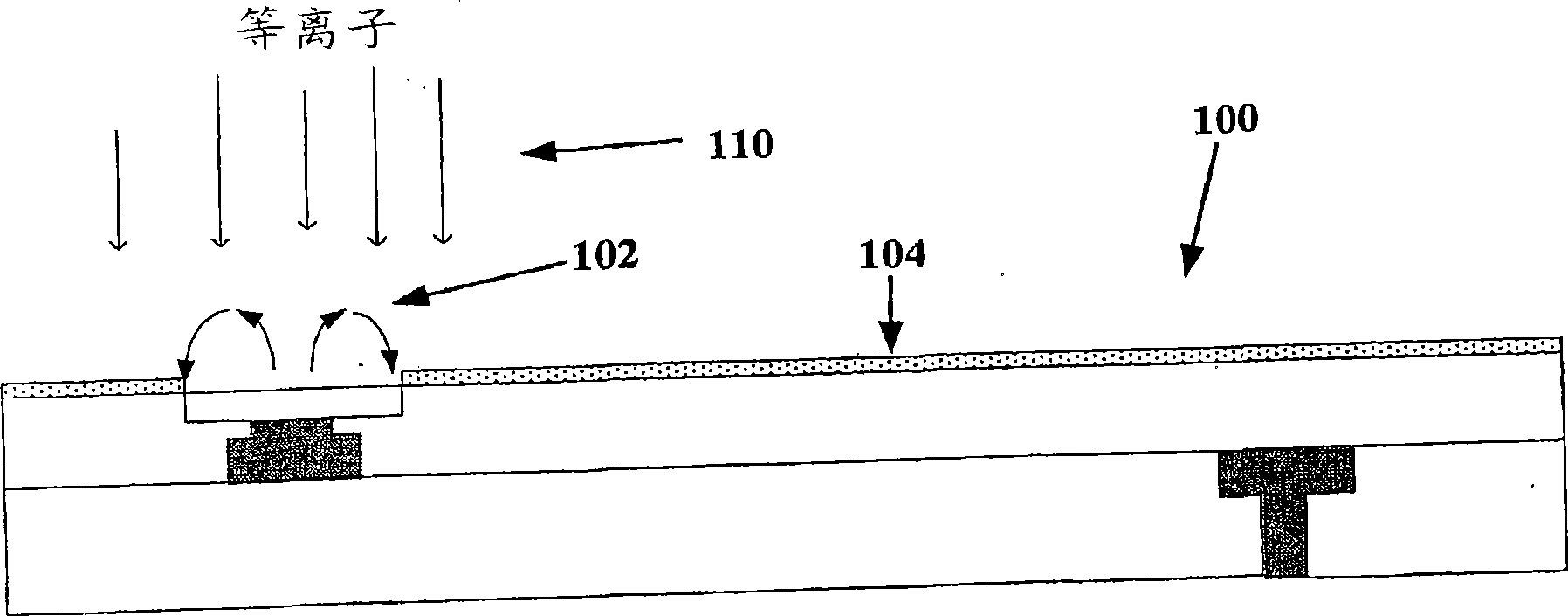

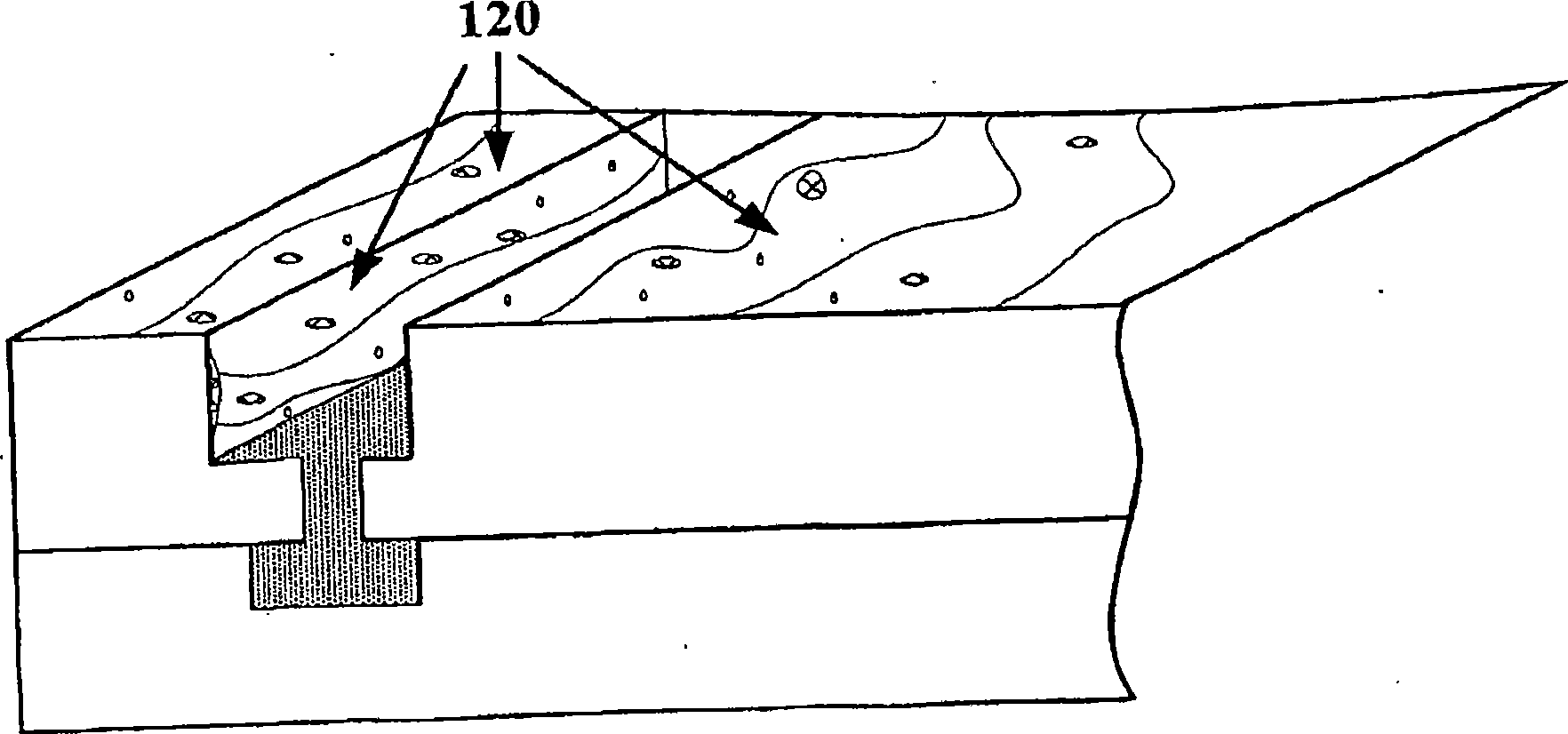

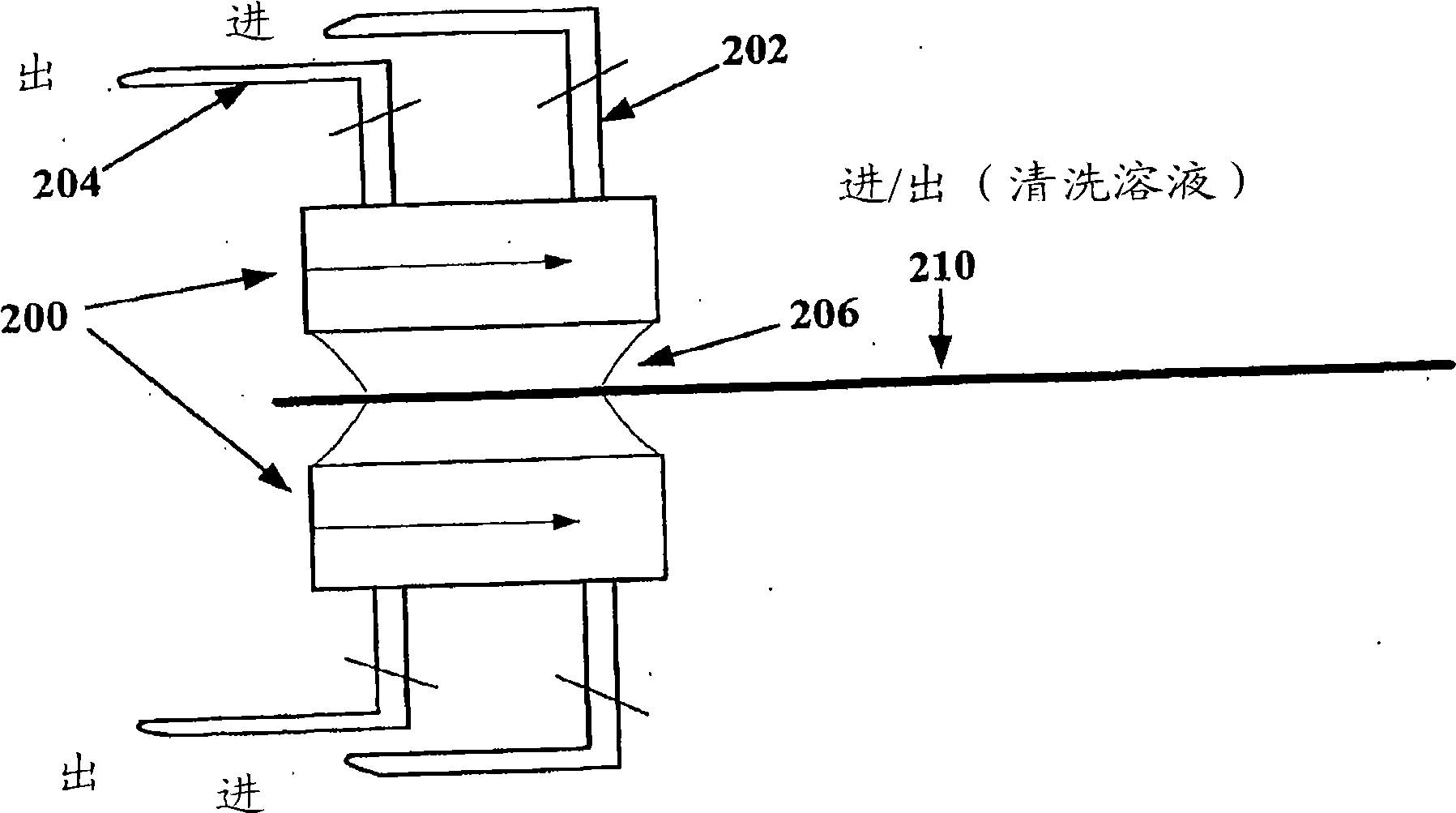

[0022] Any silicon-based material can be used to make the semiconductor substrate. In one example, the substrate is a semiconductor wafer, that is, a thin sheet of semiconductor material, such as a silicon crystal, on which the microcircuits are constructed by diffusing and depositing various materials. Herein, the terms semiconductor substrate and semiconductor wafer are used interchangeably. The embodiments herein disclosed are essentially semiconductor substrate cleaning methods that are used with a dedicated configuration of proximity heads or other equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com